Aerospace

Aerospace

Features

/fabricating

/pressbrakes

/software

Senior Editor

everal years ago I realized a lifelong dream—to own a horse. I took on a rescue that was little more than skin and bones when I first saw him. Large doses of TLC got him back on his feet and we were soon taking to the trails. In 2018 he was diagnosed with an endocrine disorder that affects the pituitary gland.

Diagnosis, drugs, diet and frequent hoof trims has become our ritual in the long journey to manage his illness. Regular blood tests to monitor a particular hormone produced by the pituitary gland and insulin, hay testing and balancing, a low sugar/low starch diet, medication and an array of supplements are now all part of a day’s work at the barn.

Careful rehabilitation has him looking and feeling like his old self again and we are living the dream and able to ride. When a recent blood test showed elevated hormone levels, I expressed concern. But our specialist reminded me of the following: “Managing these horses is part science, part art and you need to pay attention to the whole picture, not just the snapshots in time that the blood work highlights.”

n the December 2019 edition of FFJournal, this column covered the surface effect and basic characteristics of percussion laser drilled, small-diameter holes. Two metal removal technologies were discussed: photo ablative drilling (PAD) and thermal laser drilling (TLD). The distinction between the two methods is the significant difference in power density of the focused laser beam as it is focused on the material.

In everyday practice, we need to calibrate the performance of the laser drilling system before we perform actual drilling. The following steps are applicable to both PAD and TLD:

Equipment qualification record (EQR). In published technical standards, calibration of the laser beam characteristics is a requirement. The spatial and temporal characteristics are measured and recorded to make sure the laser and the beam delivery optics are within the limits specified by the manufacturer and meet the settings developed for the specific drilling process.

compatibility equals productivity

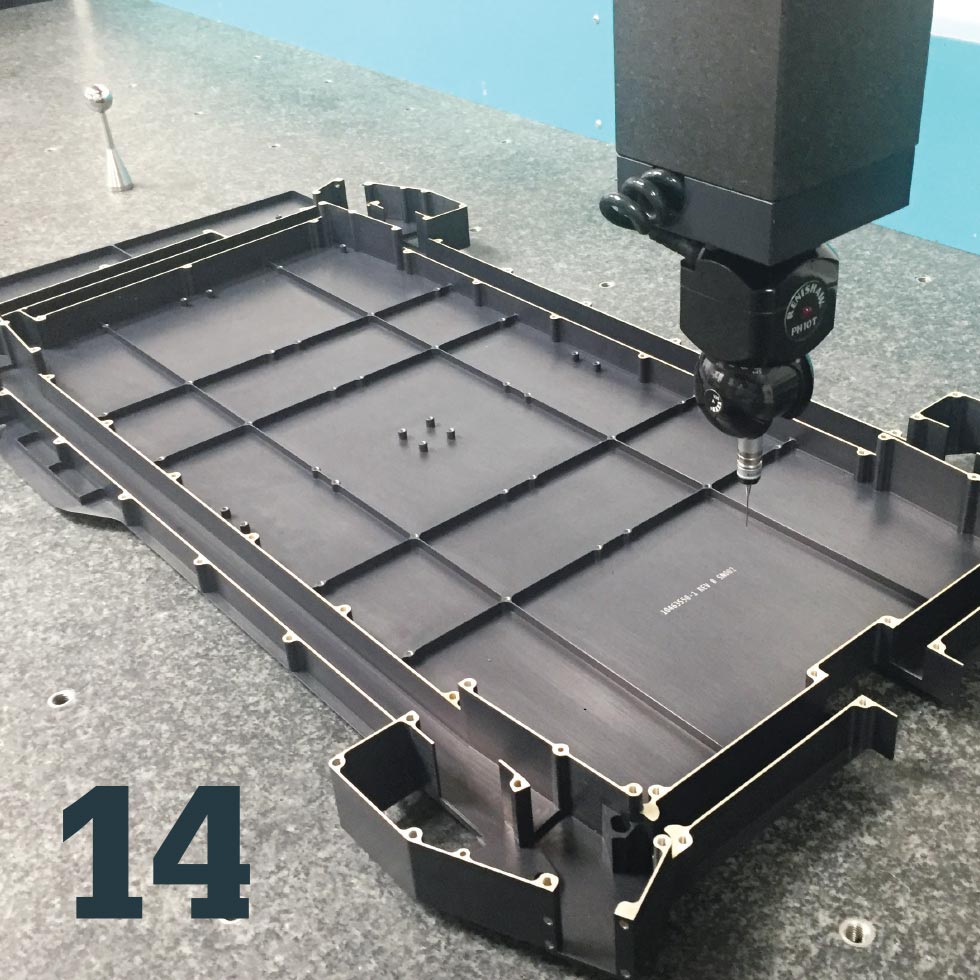

utomated measurement and inspection have become pervasive across manufacturing segments. Driven by Industry 4.0, concepts like maintaining digital continuity throughout the manufacturing process (and beyond) and cyber-physical interoperability, customers want more data and better traceability. As a result, tolerances for fabricated parts are tightening and 100-percent inspection requirements are not uncommon.

Automated measurement, inspection and reporting allows shops to respond effectively. Measurement technology also provides a double-edged benefit for shops. Using software, those same measurement tools originally designed to inspect parts are providing efficiency and productivity multipliers in the quality lab, on the shop floor and in the field.

e live in a jaded world when it comes to leadership. We have all heard the person who gives incredible advice on team leadership, recites maxims on how to enable employees, but then, when such leadership is most critical, the same person fails horribly to lead even by the most fundamental measures. Too many have talked a great leadership “game” only to have their own leadership fall woefully short of the most basic expectations.

Being a leader means more than flowery words and motivating speeches with classic quotes from Patton. The best leaders are humble, compassionate, focus on results. They possess the mind of a teacher, the ethics of a child, fearlessness in the face of difficult decisions and a dedication to promote the team’s results over their own career aspirations.

True leaders treat others with respect, achieve goals, innovate, improve, serve customers, teach and develop people to be ready for greater challenges. A true leader focuses on action, open discussion, frontline presence and proof of results. Let us break those ideas down.

The Quick Change Gooseneck welding fixture allows for easy out-of-position welding applications. No tools are needed to change positions (rotate the gooseneck) or change goosenecks; just push down, turn and lock into eight different positions. The Gooseneck is available as an option on new Lightning straight-handle 250 amp to 450 amp guns. Pre-installed jump liners will be included with this product.

American Torch Tip Co., Bradenton, Florida, 800/342-8477, www.americantorchtip.com.

Camfil APC, Jonesboro, Arkansas, 800/479-6801,

www.camfilapc.com.

Miller Fabrication Solutions, Brookville, Pennsylvania, named Paul Sorek as director of business processes. He succeeds Rich Steel, who was named director of lean manufacturing. Sorek oversees automation, engineering, process development and quality control. He spent the previous 15 years at a lumber company, including the last eight as its president.

raditionalists, Boomers, Gen-Xers, Millennials and Gen Z—catchy labels coined to describe five generations of Americans working shoulder to shoulder. Pew Research reports that millennials represent the largest labor pool but the number of employees age 55 and over is climbing at a projected annual rate of 24.3 percent. The U.S. Department of Labor estimates that Gen-X and Baby Boom workers will number 13 million by 2024 with millennials making up the majority by 2026.

A skills gap study published in 2018, the fourth such report prepared by Deloitte and the Manufacturing Institute, reveals troubling statistics. It states that the industry may have up to 2.4 million jobs to fill between now and 2028. This deficit puts U.S. $2.5 trillion in economic output at risk over the next decade.

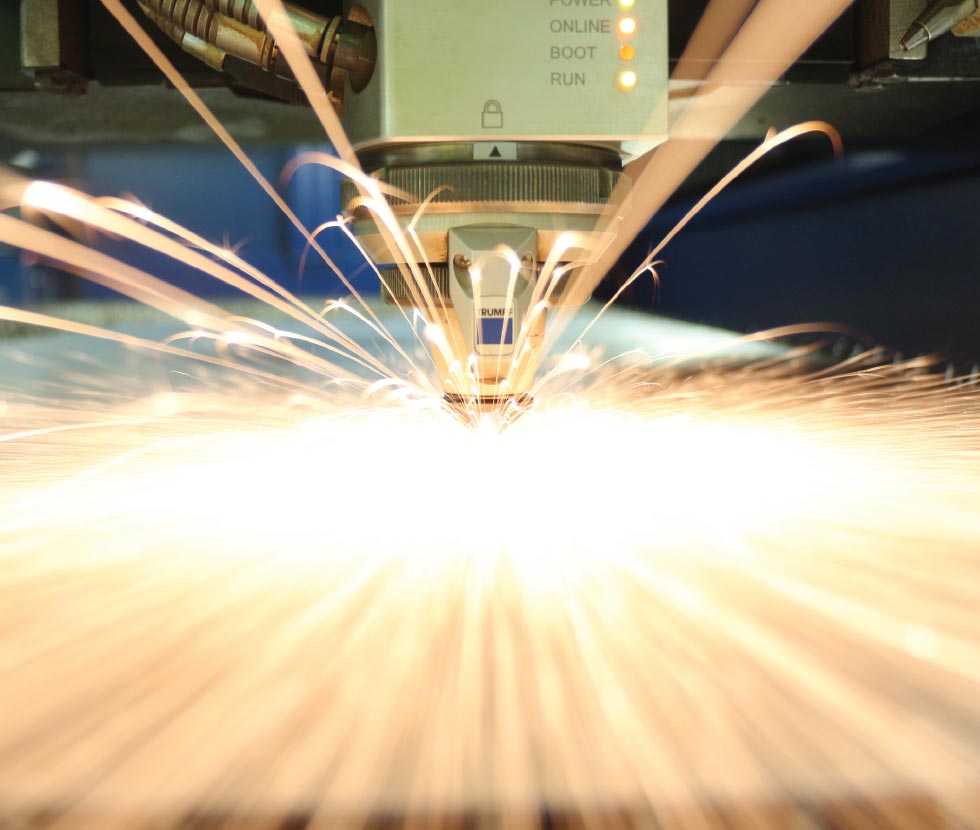

feel the need—the need for speed!” Peter “Maverick” Mitchell, played by Tom Cruise, uttered the iconic line in the 1986 film Top Gun. The sentiment behind the famous quote can be heard among fiber laser users.

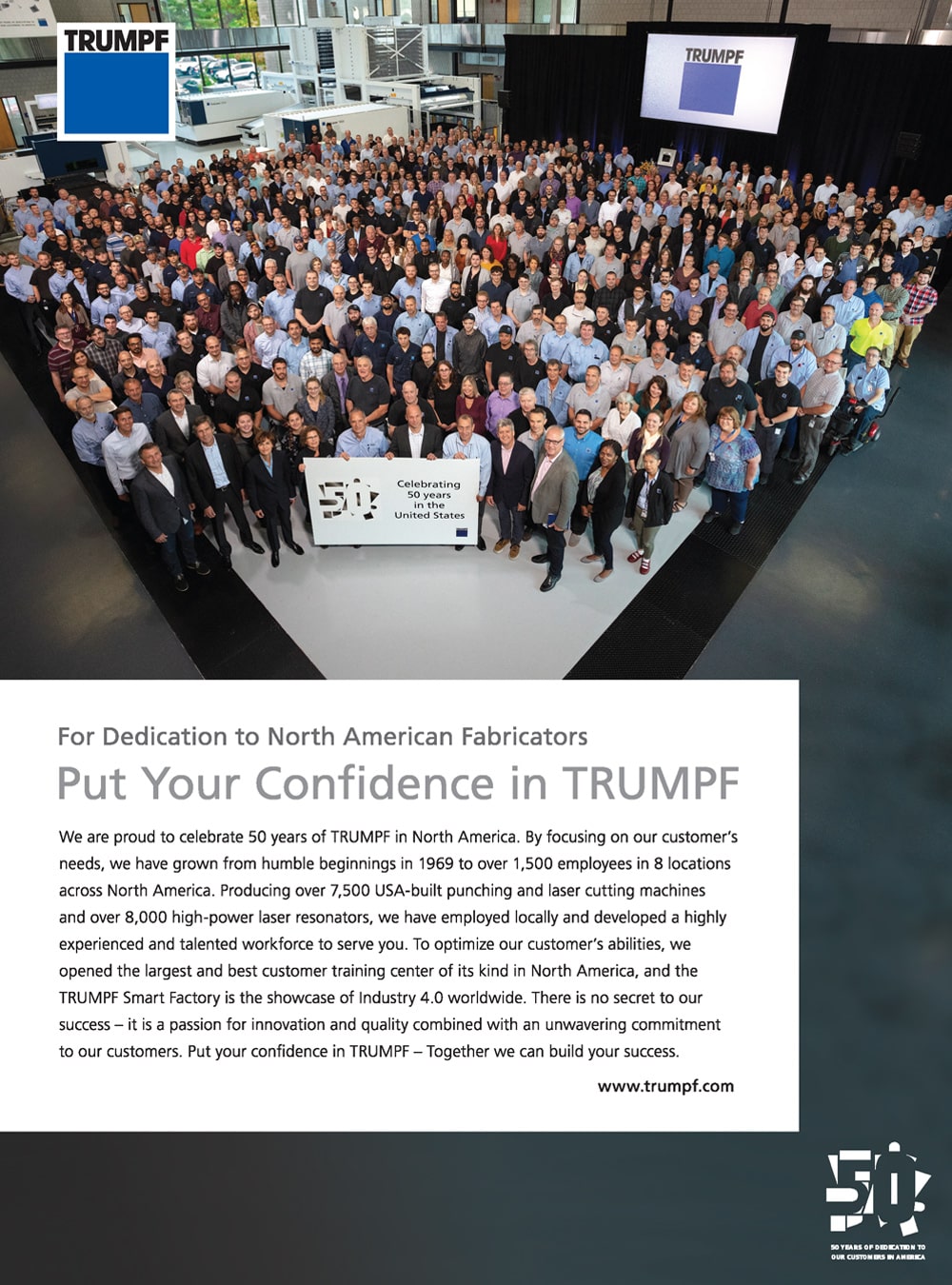

“Over the last five years, there has been a demand for higher and higher fiber laser speeds,” says Brett Thompson, TruLaser sales engineer for Trumpf Inc. “Manufacturers want to cut faster and cut thick metal reliably.”

ubbed the vehicle-friendly state, Alabama is expected to become the nation’s No. 2 automaker by 2022. In 2018 Mercedes-Benz produced its 3 millionth vehicle while Honda and Hyundai closed 2018 with production numbers of more than 320,000 vehicles each. Toyota and Mazda jointly plan to build a $1.6 billion vehicle production plant in Huntsville. The facility is expected to open in 2021. Toyota Boshoku America is building a $50 million factory in Athens, Alabama.

The Economic Development Partnership of Alabama credited investments in infrastructure, workforce development, training, and a network of suppliers with helping Alabama mature into a “true automotive state.”

Chapter

etal asteroids? Most are made from rock or ice but in recent months, NASA approved the next fabrication and testing phase of its spacecraft and subassemblies for its mission to explore Asteroid Psyche, an asteroid scientists believe to be metal. It originates from a planet possibly as large as Mars. It is voyages such as these that innovate technology that then flows down into everyday manufacturing operations.

At Space Metal Fabricators Inc., engineers use the latest technology to work with customers to take concepts and fabricate them into actual products that outfit the manufacturing, automation solutions, control systems, nuclear fuel and food service industries.

without

the bust

he aerospace sector is a not a fast-paced up and down industry. The longer economic cycles within the industry are buoyed by extended product life cycles and high barriers to entry. The current industry upswing may slow but it will continue to climb, a departure from what might typically result in a 30 percent or more bust cycle.

“We’re near the 15-year marker of what typically is a seven-year boom cycle—and I don’t see a bust cycle following it any time soon,” says Richard Aboulafia, vice president, analysis, Teal Group Corp., Fairfax, Virginia.

In 1956, Milon Viel and Ross Clarke opened up a fabrication business. Viel had spent time in the Air Force and then worked for Douglas Aircraft, and Clark was a retired co-pilot and mechanic for Hearst Airlines in San Simeon. Initially, the company designed and built aluminum window frames but soon began to cut a wide variety of materials exactly to customer specifications, focusing on the growing aerospace industry and manufacturers that did not have in-house sawing capabilities.

Today, Metal Cutting Service is a partner and supplier for manufacturers in aerospace and defense, semiconductor makers, aluminum and steel distribution. The company has been based in City of Industry, California, a suburb of Los Angeles, since 1975. Current owner David Viel joined his father in 1977, working part-time while in college and transitioning to a full-time position in 1981. He became company president in 1993.

or some homeowners, a staircase is a work of art as well as a practical necessity. Achieving the desired effect and design is as important as the safety parameters. “Our customers want what they want, and they’ll scrap an entire staircase if it doesn’t fit their vision,” says Michael Estrada, owner at Estrada Engineering in Whittier, California. His finished staircases have graced the pages of Architectural Digest, “so finish definitely matters for us.”

Nick Wohler, owner of Inland Tool Solutions Inc. in Orange, California, takes into consideration each customer’s needs when making suggestions and often keeps customers like Estrada informed of the latest products available in the marketplace. At Wohler’s recommendation, Estrada began using Continental Abrasives’ zirconia standard density flap discs and has continued to do so over the last year. “I normally don’t care for thinner flappers, but Continental’s thinner flappers work for us—we almost use them as grinding discs,” Estrada says.

View Index

Editor-in-Chief

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323, www.ffjournal.net

312/654-2309, Fax: 312/654-2323

mdalexander@ffjournal.net

Alaska, Arizona, Arkansas, California, Hawaii, Idaho, Montana, New Mexico, North Dakota, Oklahoma, Texas, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@ffjournal.net

Alabama, Colorado, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Pennsylvania, South Carolina, South Dakota, Tennessee

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@ffjournal.net

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@ffjournal.net

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@ffjournal.net

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJournal® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJournal® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.