feel the need—the need for speed!” Peter “Maverick” Mitchell, played by Tom Cruise, uttered the iconic line in the 1986 film Top Gun. The sentiment behind the famous quote can be heard among fiber laser users.

“Over the last five years, there has been a demand for higher and higher fiber laser speeds,” says Brett Thompson, TruLaser sales engineer for Trumpf Inc. “Manufacturers want to cut faster and cut thick metal reliably.”

Fiber lasers have established a strong track record for industry and defense. Flexible, versatile and cost efficient, fiber lasers can cut, weld, mark and process metal. Changes in beam mode, fiber optics, geometries and other component advances have made 8kW to 10kW machines common over the past few years. The drawback to fast cutting speeds is, says Thompson, “how do you keep up?”

Bottlenecks in downstream operations have driven the development of automation for these racehorses, but a high-speed fiber with a material handling system still requires operators to sort and de-nest parts on the back end.

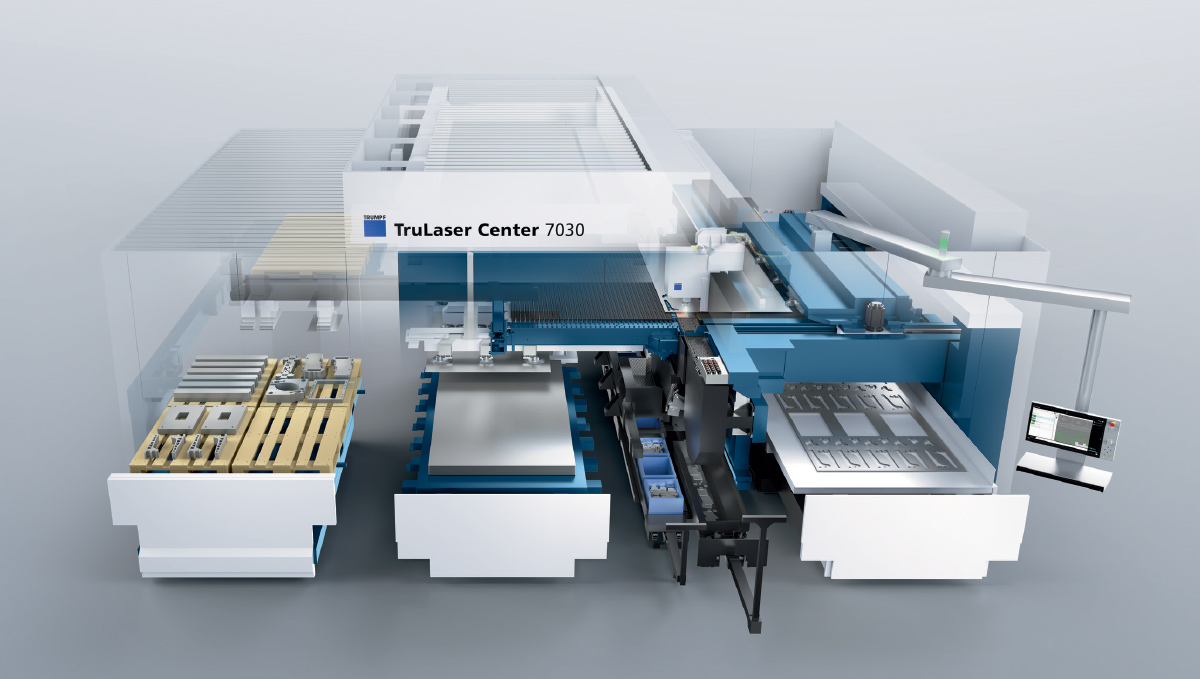

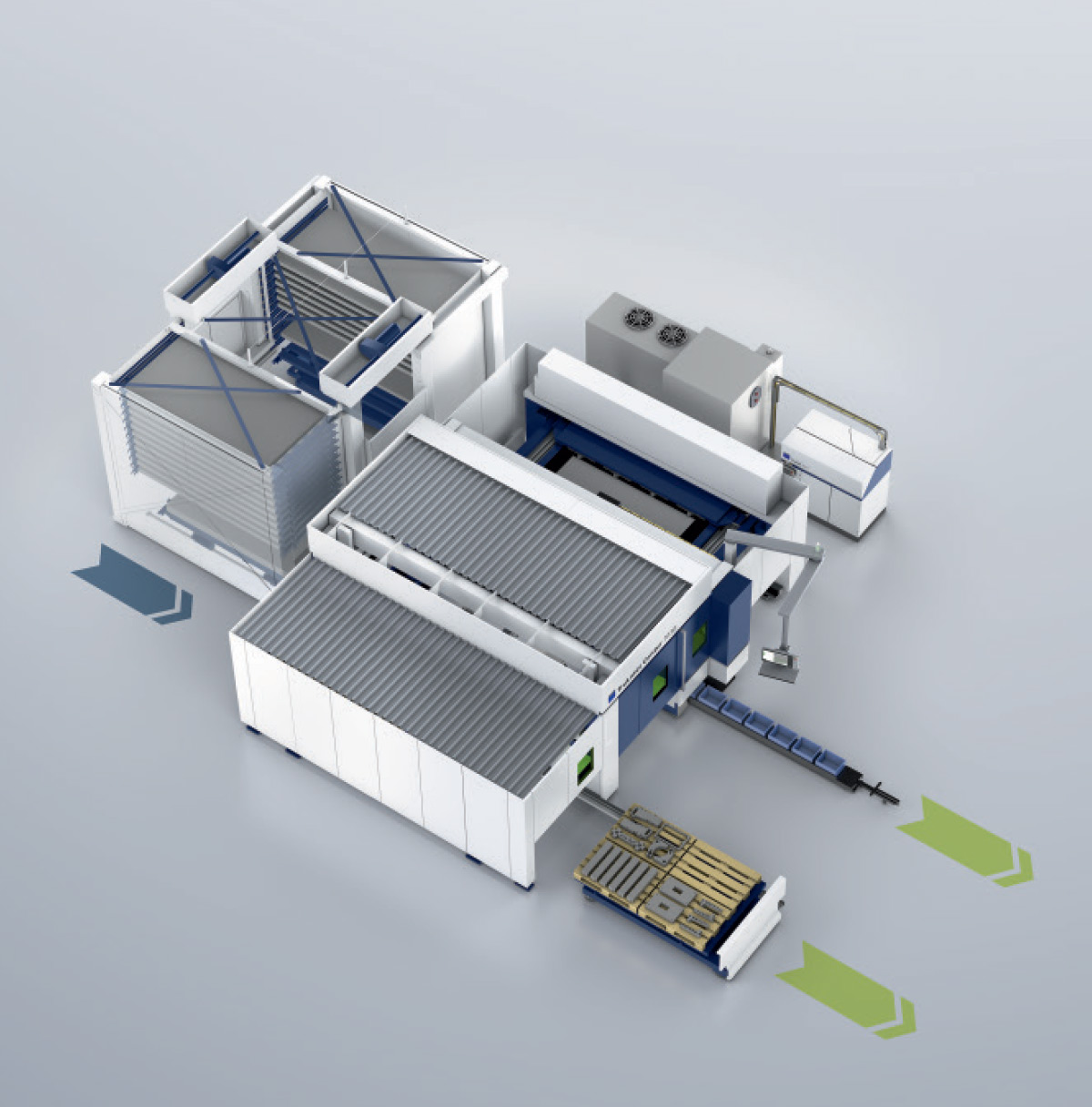

The machinery builder evaluated its components, redesigned them and integrated them into the first full-service laser machine. Unlike a traditional 2D laser, the TruLaser Center 7030, introduced in 2017, separates parts while the laser is cutting. It can place components onto pallets, into storage shelves or into bins on a conveyor under the cutting head and eliminates downstream processes. Brush tables and intelligent automation combine to ensure reliable parts handling.

Because the laser integrates all production steps into one process, it eliminates workpiece tipping, parts getting caught in the skeleton and the need for microjoints. Process reliability and production costs improve dramatically.

In addition to identifying factors that contribute to cut loss, Trumpf engineers studied ways the equipment could move beyond automating material and parts handling. “Our goal is hands-off production,” Thompson says. “For customers who are trying to embrace and incorporate the Internet of Things (IoT), the connectivity of their production floor and data retrieval, the next steps need to be automation of the work process from software to material, parts and downstream operations like bending.”

A specialized vision system inside the cutting head peers through the nozzle during operation to monitor the cutting process and maintain optimum parameters despite material variations. Inconsistencies in material thickness, poor surface condition, varying material quality and heat input into the part are variables that can contribute to poor cut quality and, ultimately, a loss of cut.

We ultimately want the machine to pick the best way to cut the material regardless of what it is or where it came from.

We ultimately want the machine to pick the best way to cut the material regardless of what it is or where it came from.

Trumpf is working on its next technology breakthrough. “When throughput goes up, part costs go down and fabricators gain more cutting time on their machines,” says Thompson. “That’s why we want to move beyond the need to program parameters.”

Power, speed, beam quality, beam diameter, focus and gas pressure are just some of the defining characteristics required to run material.

“For example, Chinese hot-rolled steel is typically poor quality versus what we source in the U.S.,” explains Thompson. “We have a parameter to account for that. But even an experienced operator can struggle with material variations. We want to get away from having to plug in those parameters. We ultimately want the machine to pick the best way to cut the material regardless of what it is or where it came from.”

www.us.trumpf.com.