or some homeowners, a staircase is a work of art as well as a practical necessity. Achieving the desired effect and design is as important as the safety parameters. “Our customers want what they want, and they’ll scrap an entire staircase if it doesn’t fit their vision,” says Michael Estrada, owner at Estrada Engineering in Whittier, California. His finished staircases have graced the pages of Architectural Digest, “so finish definitely matters for us.”

Nick Wohler, owner of Inland Tool Solutions Inc. in Orange, California, takes into consideration each customer’s needs when making suggestions and often keeps customers like Estrada informed of the latest products available in the marketplace. At Wohler’s recommendation, Estrada began using Continental Abrasives’ zirconia standard density flap discs and has continued to do so over the last year. “I normally don’t care for thinner flappers, but Continental’s thinner flappers work for us—we almost use them as grinding discs,” Estrada says.

The floating effect of many of Estrada’s staircases is achieved without groove marks that otherwise cover the welds. “It’s smooth so you don’t see the welds or the grinding marks left behind,” he says. “It’s so smooth you don’t see it. Feathering is almost eliminated.”

I have pretty much standardized my

I have pretty much standardized my offering with Continental because of the finish

and life.

I have pretty much standardized my offering with Continental because of the finish and life.

I have pretty much standardized my offering with Continental because of the finish and life.

The results: longer cutting life and speed with a cleaner finish compared to what the customer used before. The results were increased cutting life “while reducing quantity usage by 10 to 15 percent on both sizes,” Wohler adds. “The new cost to the customer was a lateral move.”

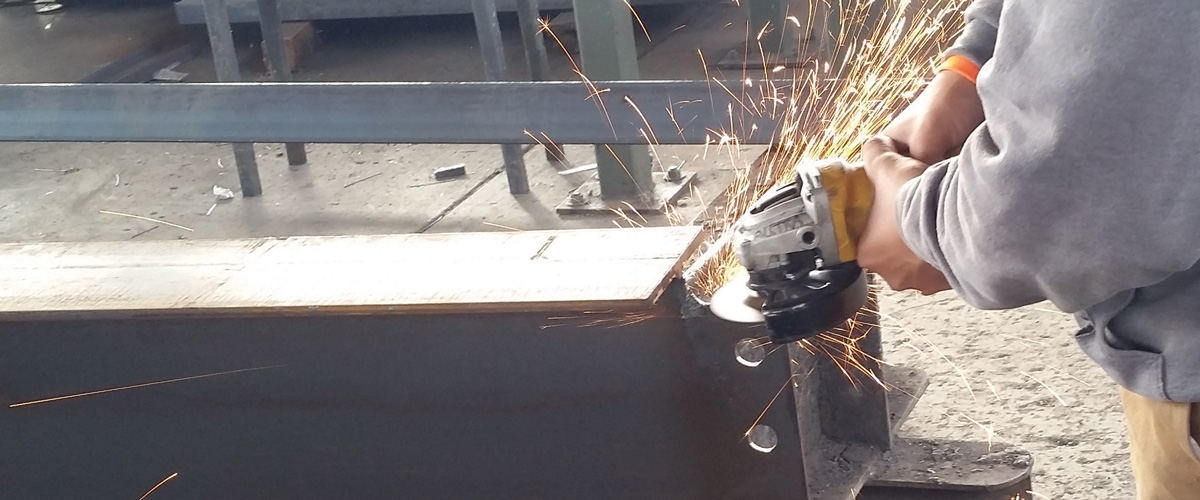

Ernie Vasquez, foreman at Able Iron Works in Pomona, California, uses Continental’s Ulticut on I-beams and steel tubing. “We use the 4-1/2-in. and 7-in. Type 27 grinding wheels, Macrodisc zirconia flap discs and double-cut carbide burrs from Continental,” Vasquez says. “They last long and cut fast. We started using them four years ago and have stuck with them. We use them on everything, from hand rails to heavy I-beams and steel tubing.”

www.ableironwork.com.