Features

/customfabricator

/laser

/sawing

From the

Senior Editor

SKILL SETS WANTED

t’s no revelation that the talent pool for the fabrication industry is waning. As fabricators retire, there are not enough bodies to fill those job openings. Automation and other technologies have evolved the type of responsibilities fabricators now have on the shop floor, but the need for actual people remains.

Educational institutions are working with industry to help teach students who will leave the class and laboratory as a wellrounded prospect, capable of operating a press brake or welding or inspecting a secure seam while also understanding the importance of being a reliable employee by showing up on time and performing as part of a team.

ll materials present unique cutting challenges. Matching the right tools with the application is part of the battle. Band saws are the best option for job shops that need speed, quality and consistency. The equipment is also the most cost-effective method when it comes to cutting exotic materials. Blade choices are based on the type and size of the material being cut. Understanding material characteristics before you cut can deliver longer band saw blade life and the best production results. Some basic guidelines can help.

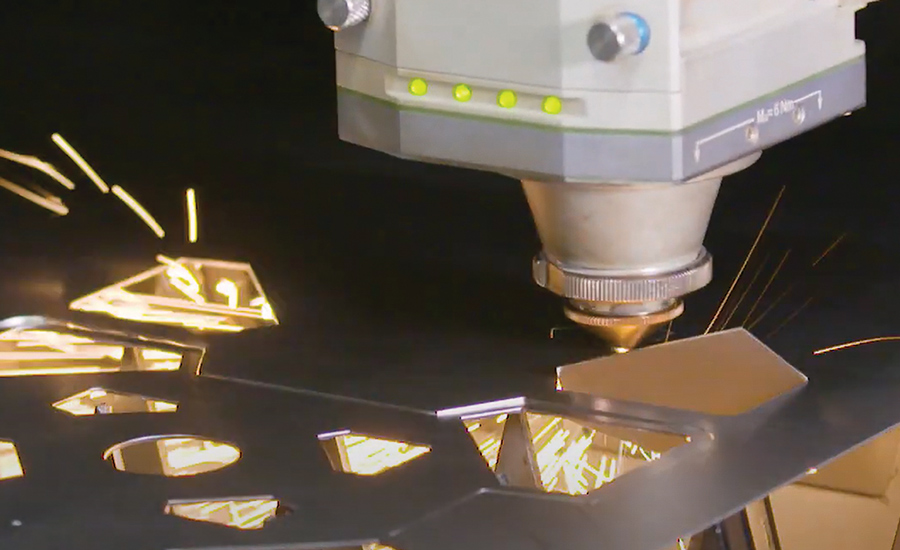

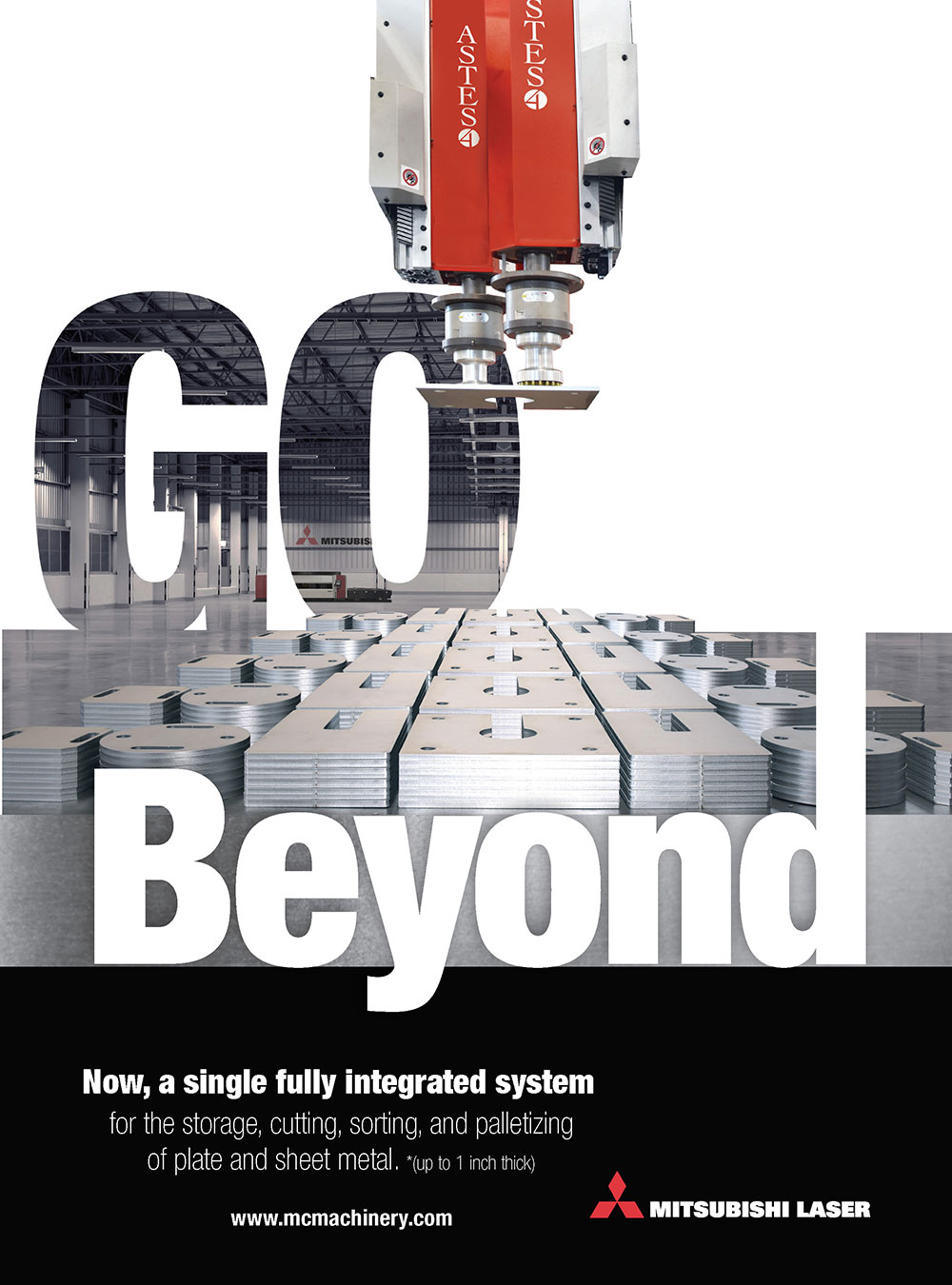

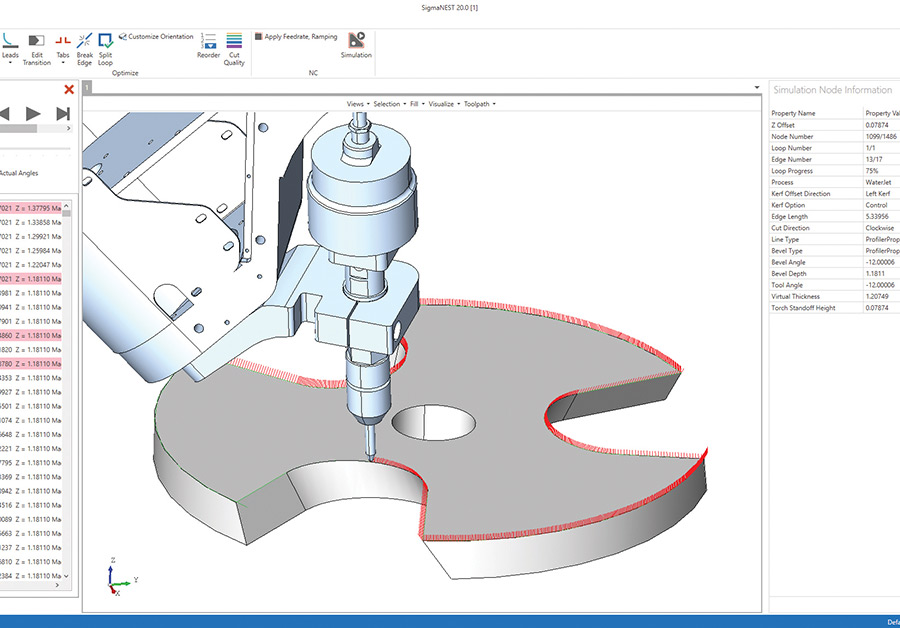

Robot payload capacity of 12 kg to 25 kg is needed to support the cutting end effector and its umbilical. The key is to have a robot with good accuracy and trepanning capability along with a cutting end-effector designed for robotic applications. An end-effector with non-contact height sensing will ensure that focus is maintained as the robot moves about its pre-programmed path with the cutting-end effector moving above the surface with a tip to part stand-off of about 1 mm to 2 mm.

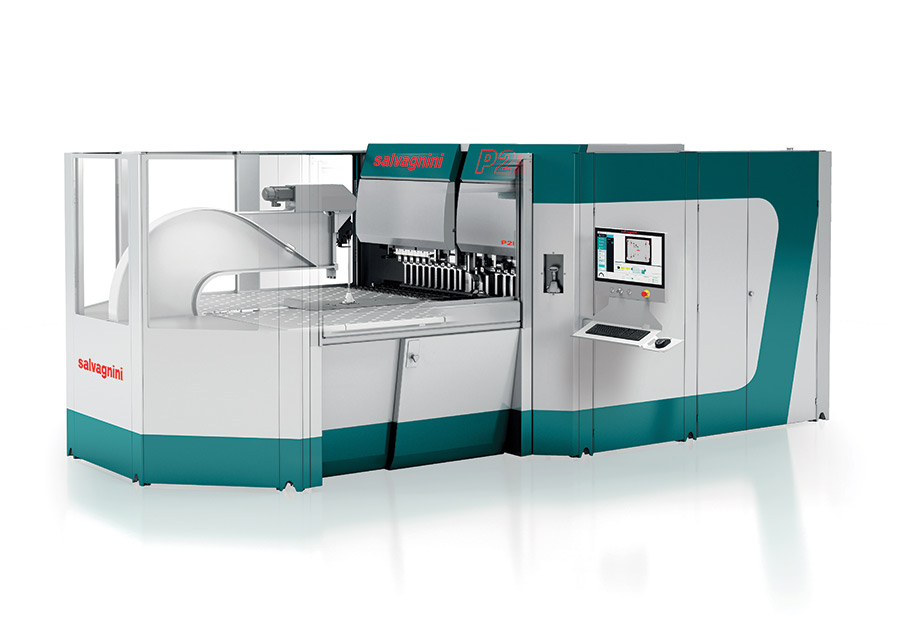

Light was also a critical design element for Salvagnini America Inc. when the manufacturer broke ground in April 2019 on a new $7 million, 30,000 sq. ft. multi-purpose educational campus.

s students gathered at campuses around the country, some schools were forced to close down in-person instruction just days into the fall term. The COVID-19 pandemic continues to force educators to rethink syllabi, including how to use remote teaching tools and software to provide students with a fulfilling experience. Educators are adjusting, postponing or attempting to combine remote methods and in-person instruction for skills that cannot be learned over a screen and a WiFi connection.

When the virus first struck, many workplaces and schools shifted to remote work/instruction. Some faculty at Ferris State University in Big Rapids, Michigan, used Zoom or Google Hangouts applications to conduct classes and communicate but that option did not always prove accommodating to all students.

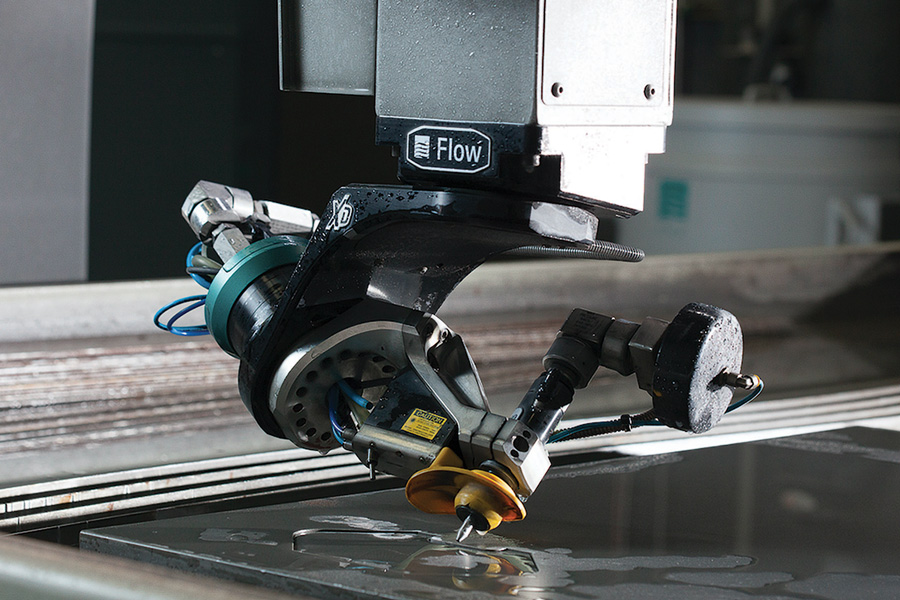

HPA also provides value added services such as tight tolerance waterjet cutting, shearing, grinding, marking, and many other services.

HPA’s friendly and knowledgeable staff is always waiting to help you with your alloy needs.

HPA’s friendly and knowledgeable staff is always waiting to help you with your alloy needs.

HPA is ISO 9001:2015 Registered and DFARS compliant.

HPA’s friendly and knowledgeable staff is always waiting to help you with your alloy needs.

HPA’s friendly and knowledgeable staff is always waiting to help you with your alloy needs.

HPA is ISO 9001:2015 Registered and DFARS compliant.

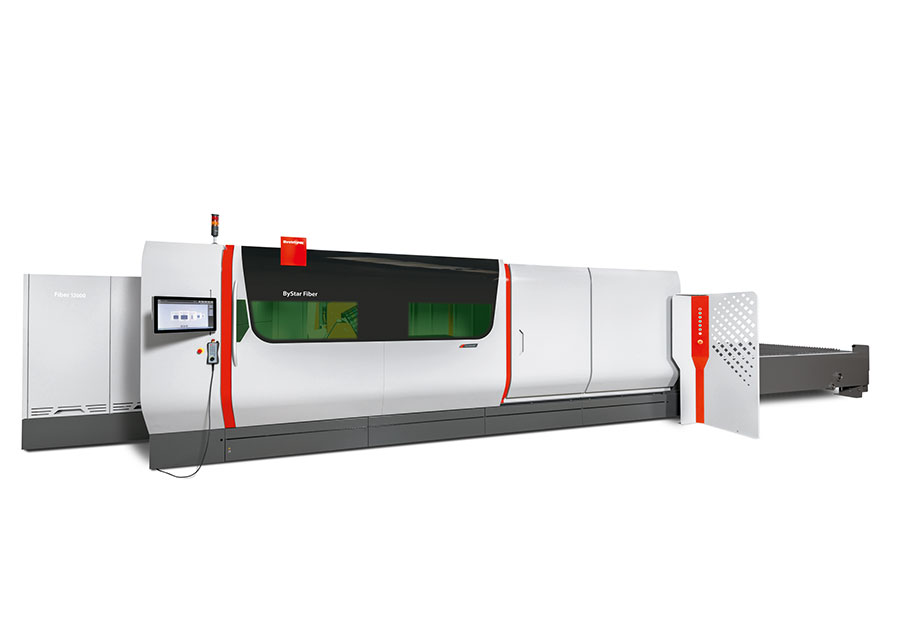

uring the space race in the 1960s, Robert Gilruth, the head of the Space Task Group at Langley Research Center, asked mathematicians to look beyond the numbers. When it comes to choosing a new fiber laser, Dustin Diehl, laser division product manager for AMADA AMERICA INC., is asking manufacturers to do likewise. The metalforming equipment builder introduced the 4 kW VENTIS 3015 AJ series fiber laser to the U.S. market in January 2020. Steady sales have followed that launch.

“It’s easy to get hung up on wattages,” notes Diehl. “Customers will tell us they need a faster fiber laser to cut thicker material. We’re able to show them a machine that with just 4 kW of power can perform at a level usually reserved for 6 kW or 8 kW systems.”

here are talkers enough among us; I’ll be one of the doers.” Charles Dickens penned these words in 1841 in his novel “Barnaby Rudge.” The storyteller wrote during London’s Industrial Revolution and used his quill to document Victorian Britain’s class divide, poverty and greed in such classics as “Oliver Twist,” “A Christmas Carol” and “Great Expectations.”

George and Arthur Trachte were also “doers.” The two started a sheet metal shop in 1901 and before long had revolutionized the corrugated water tank industry with their patented roll-forming process, which replaced solder with rivets. Feed troughs, mortar boxes, oil storage tanks and feed cookers grew to include buildings made of angled steel, iron framework and corrugated sheeting.

est Central Steel Inc.’s customers lamented having to send parts away to be processed. WCS saw an opportunity to fulfill a growing need for its customers, enabling it to produce parts and supplement supply chains, offering a local solution.

“We create parts our customers need and it helps them grow their businesses faster as well as reduce costs,” says Bill Pattison, WCS director of business development. “Rather than selling the stock steel, we realized there was an opportunity to help our customers and [help] our business grow by producing the parts they need.”

processing

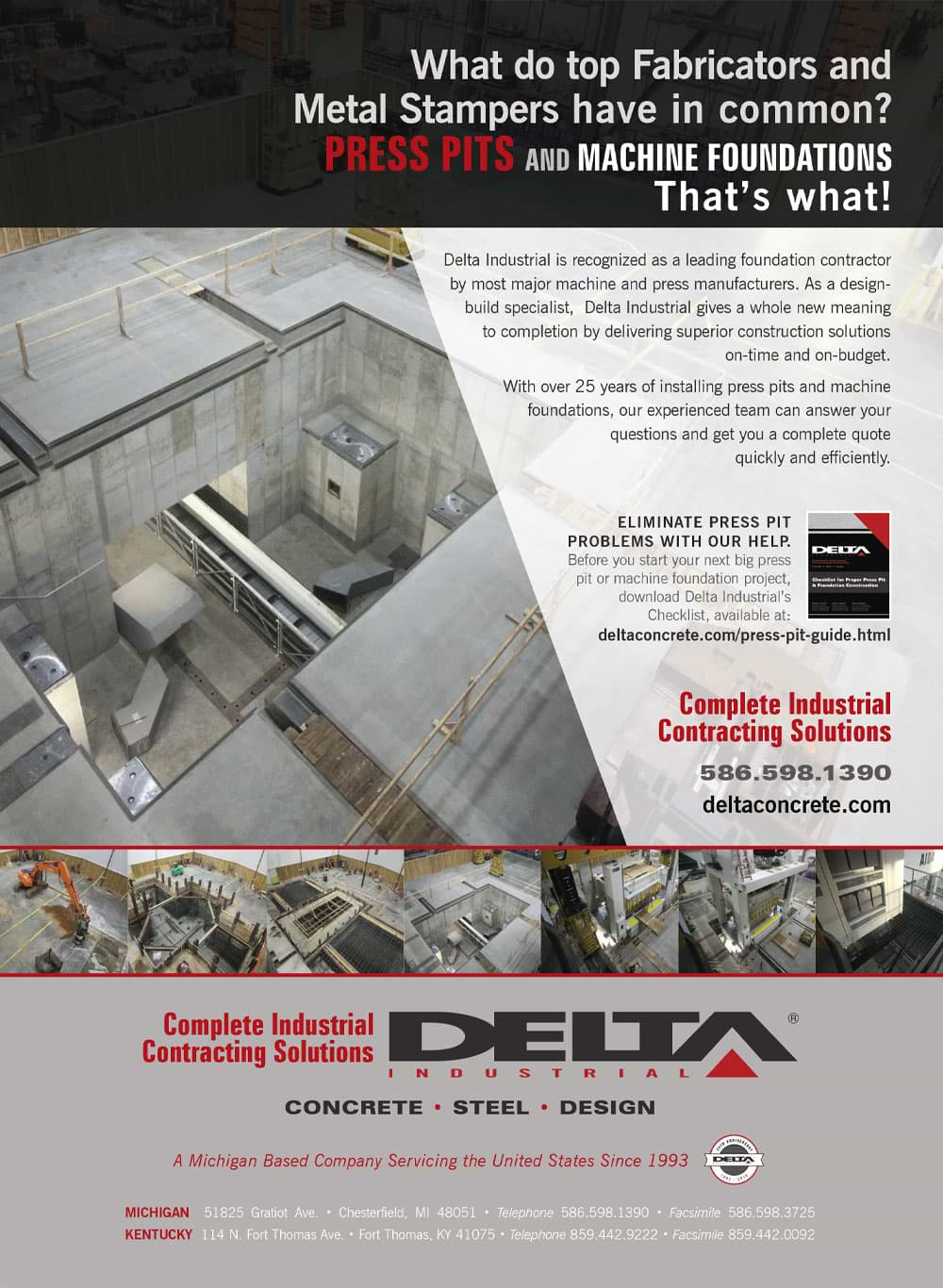

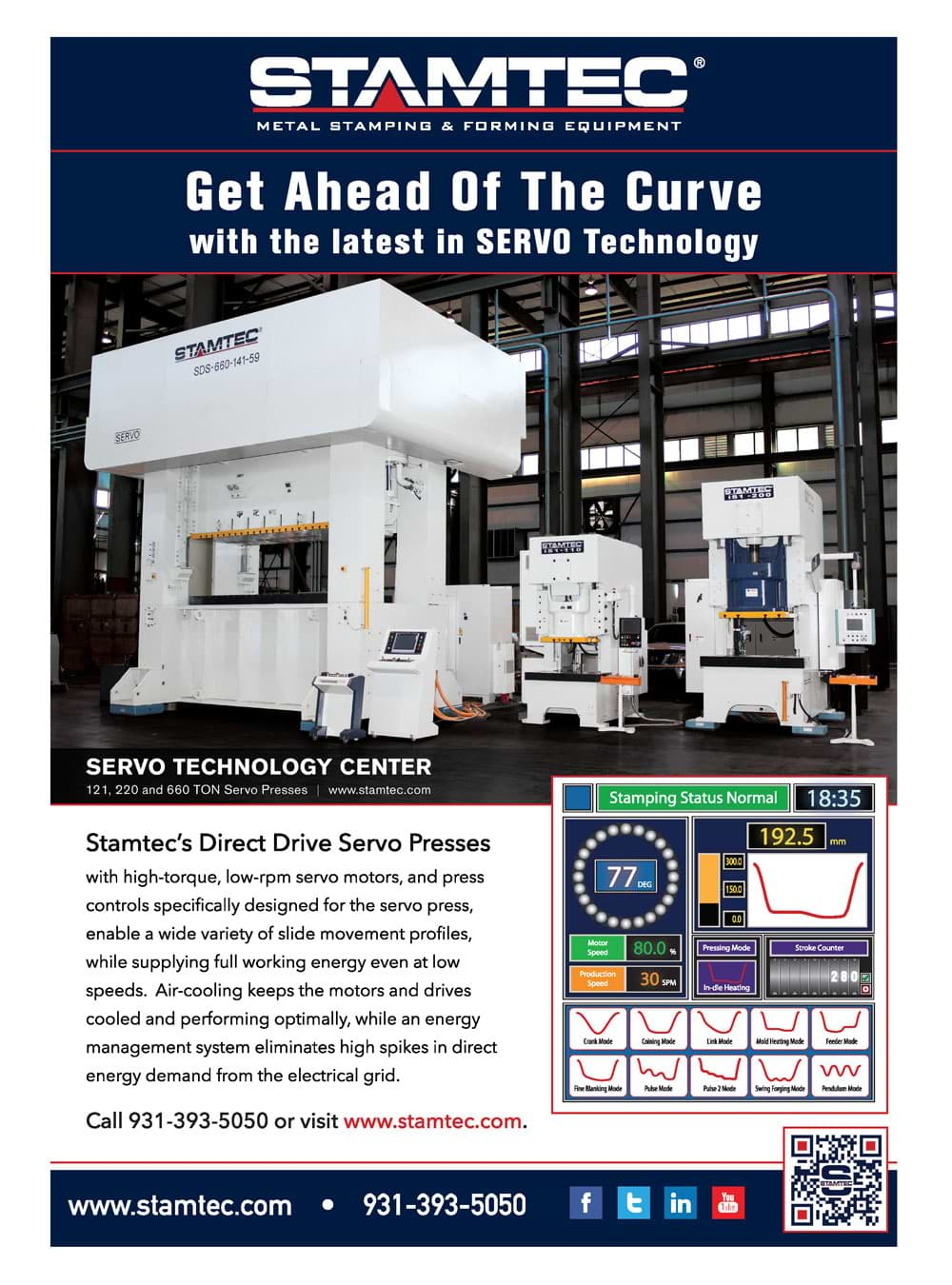

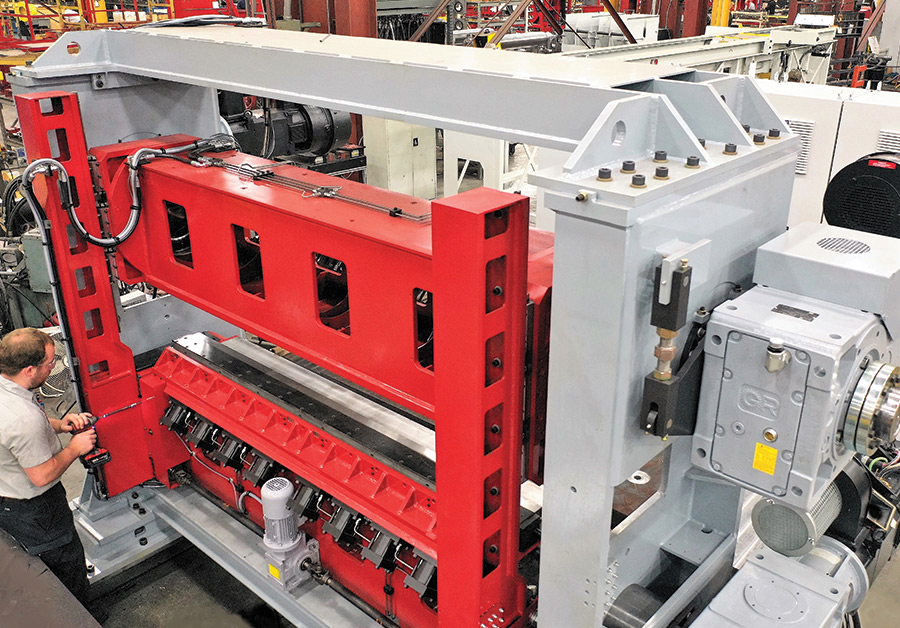

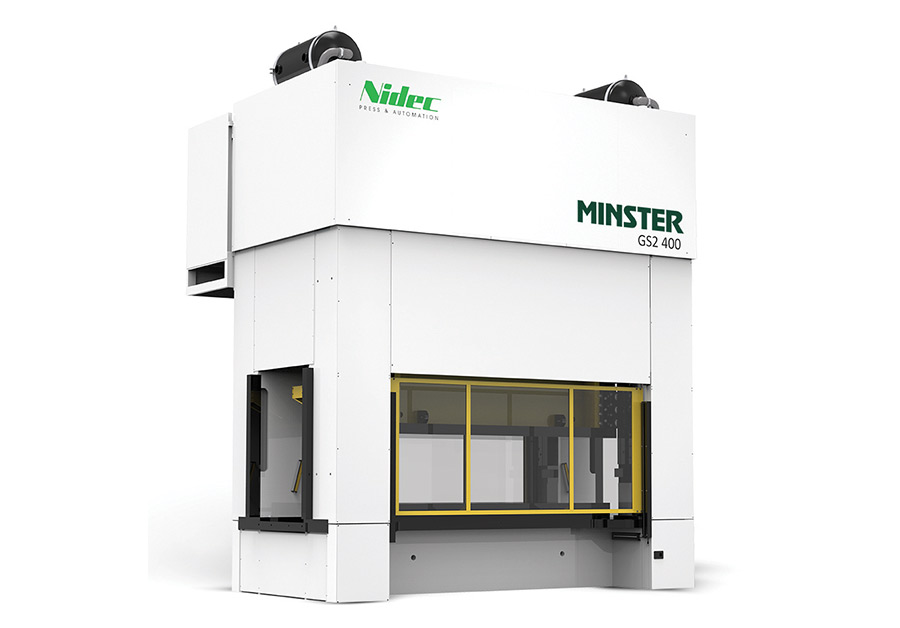

n the 1500s, the term lifeblood referred to “blood necessary for life.” Since then, the word has come to mean “the element most important to the continuing success of something.” Both definitions could apply to Engel Diversified Industries Inc. The Jordan, Minnesota-based Tier 1 and Tier 2 contract manufacturer supplies manufacturing sectors from automotive and fluid handling, to energy data transmission, defense, medical equipment and, most recently, bike racks and bakeware.

Steady growth has taken the company from 5,000 sq. ft. to 55,000 sq. ft. of combined manufacturing and office space. Part development, in-house tooling and design, fabrication and aftermarket support are part of Engel Diversified’s value-added services. But stamping remains the heart of the business.

“Stamping is our lifeblood,” says Stuart Rubin, president of Engel Diversified. “We have a lot of different skill sets but, at the end of the day, we’re metal stampers.”

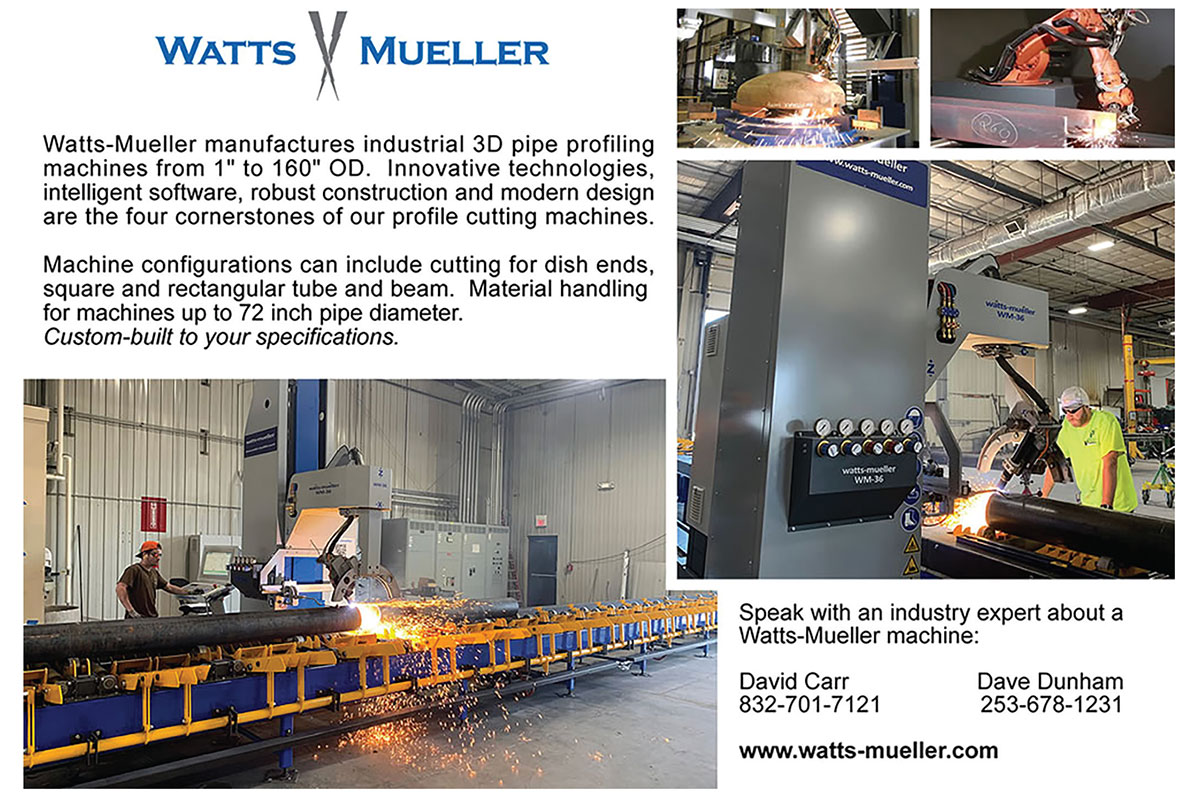

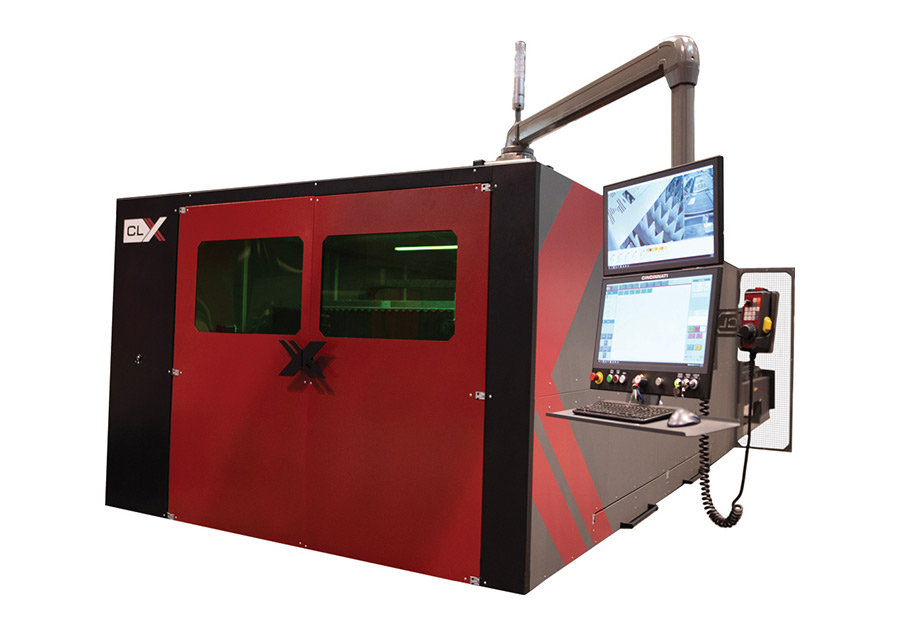

f one step in a process falls out of line with the rest, bottlenecks can build at any point. Top Coat Fabrication’s Jason Hayes likens the production floor to a performance.

“The bottleneck is always moving and, as a result, we have to dance around while maneuvering and changing up processes depending on the job order, so we can be more efficient today than we were yesterday,” he says. “We needed a machine that would free up workers to cut or perform other processes when not cutting.”

As the Jones Creek, Texas-based fabricator saw an increase in work from oil and gas/petrochemical customers, the need to fabricate pipe also increased. Faster turnaround required an investment in new equipment.

he 2009 biopic “Gifted Hands” tells the story of Ben Carson, who rose above poverty and subpar grades to become the youngest physician in the U.S. to be named director of pediatric neurosurgery at John Hopkins Hospital. Over the course of his career, he broke ground for surgical procedures. In 2017 he was appointed the United States Secretary of Housing and Urban Development. When asked about his successes, Carson cited his faith.

For Alan Weible—a man “gifted in his hands”—faith has also proved a plumbline for life and career choices.

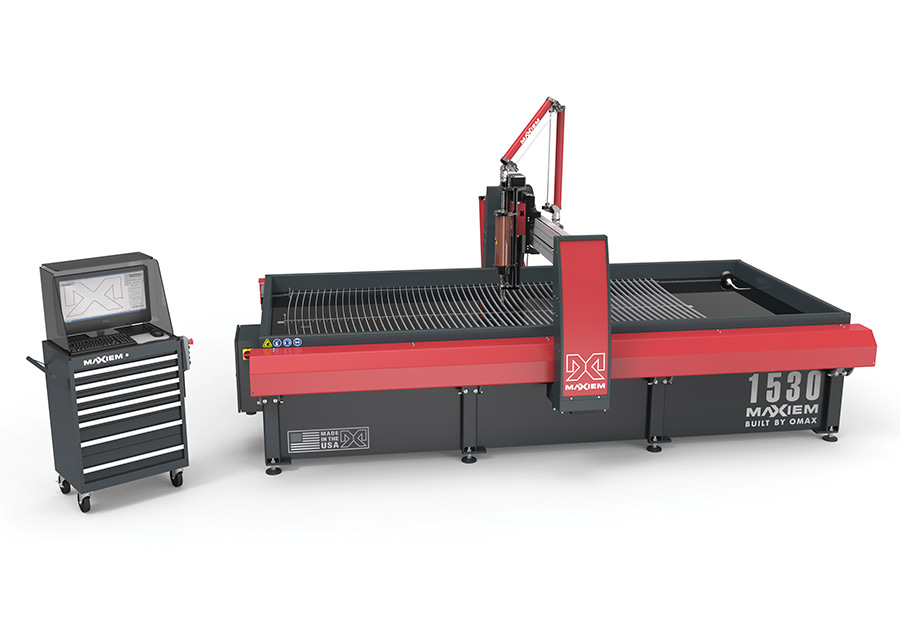

“I tried college and knew right away it wasn’t for me,” says the owner of Weebz Welding & Waterjet in San Antonio, Texas. “Instead I enlisted in the Air Force and joined the aerospace and missile welding program. It took finesse to master the skill sets because we worked with small parts made from really thin materials.”

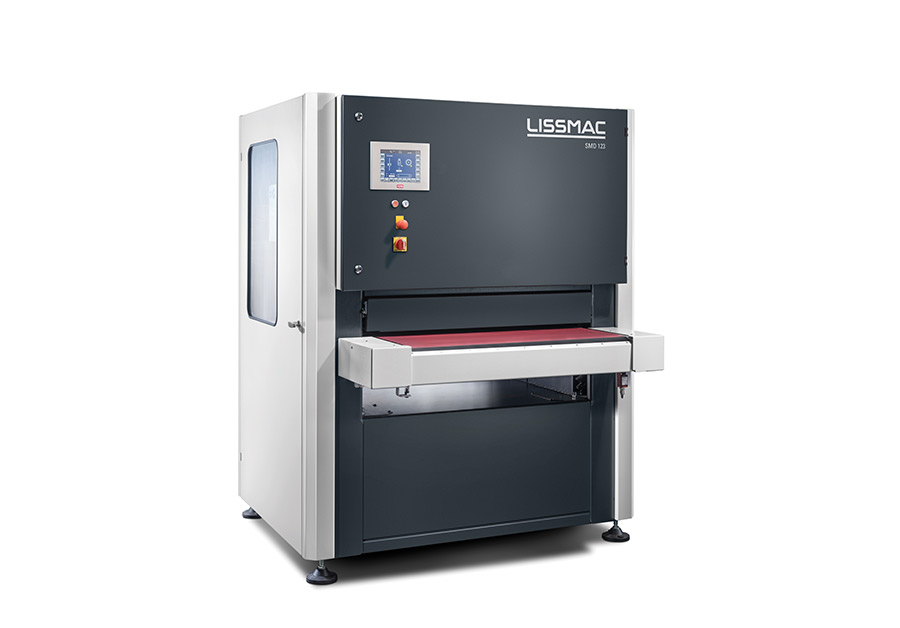

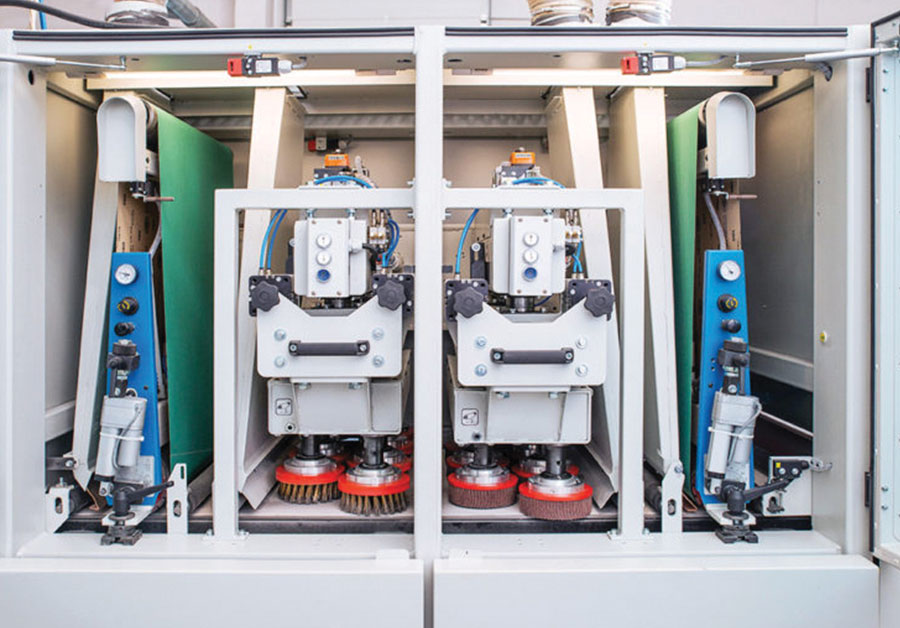

rag racing started out on dry lake beds in the 1930s and moved to commercial drag strips in the 1950s. Today at NHRA Mello Yello Drag Racing Series events, there are more than 200 classes of vehicles in 15 categories—and the Top Fuel dragsters are some of the fastest-accelerating machines in the world. They can roar down the dragstrip from start to finish in less than 3.7 seconds.

These 11,000-horsepower “kings of the sport” are powered by supercharged, fuel-injected adaptations of Chrysler Hemi engines, and, at 330 mph, there’s no room for component error. Chad Head, general manager of Kalitta Motorsports, Ypsilanti, Michigan, says that “as an example, any loose burr in a cylinder head could break away and catastrophically destroy the engine.”

he short version of Ernest Hemingway’s advice to a young writer included, “When people talk, listen completely. Most people never listen.” The team at Sawblade.com takes listening seriously because many new ideas have sprouted from conversations with people who use the blades and related equipment.

The company’s products are all “made for us or by us,” Chris Luke, CEO of Sawblade.com, Houston, says. This direct involvement allows for a give-and-take with customers, providing them a better overall experience and lower cost. Instead of accolades, Luke often prefers to hear what customers think can be improved about the company’s products and services—everything from the blades themselves to the packaging they’re shipped in.

“For years, we put wheels in wooden crates to ship them out. Customers complained because the nailed-shut crates were too hard to open, so we switched to a patented corrugated box,” Luke says.

- HYDRAULIC IRONWORKERS

- CIRCULAR COLD SAWS

- TUBE & PIPE NOTCHERS

- MEASURING DEVICES

View Index

Editor-in-Chief

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323, www.ffjournal.net

312/654-2309, Fax: 312/654-2323

mdalexander@ffjournal.net

Alaska, Arizona, Arkansas, California, Hawaii, Idaho, Montana, New Mexico, North Dakota, Oklahoma, Texas, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@ffjournal.net

Alabama, Colorado, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Pennsylvania, South Carolina, South Dakota, Tennessee

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@ffjournal.net

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@ffjournal.net

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@ffjournal.net

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJournal® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJournal® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.