he 2009 biopic “Gifted Hands” tells the story of Ben Carson, who rose above poverty and subpar grades to become the youngest physician in the U.S. to be named director of pediatric neurosurgery at John Hopkins Hospital. Over the course of his career, he broke ground for surgical procedures. In 2017 he was appointed the United States Secretary of Housing and Urban Development. When asked about his successes, Carson cited his faith.

For Alan Weible—a man “gifted in his hands”—faith has also proved a plumbline for life and career choices.

“I tried college and knew right away it wasn’t for me,” says the owner of Weebz Welding & Waterjet in San Antonio, Texas. “Instead I enlisted in the Air Force and joined the aerospace and missile welding program. It took finesse to master the skill sets because we worked with small parts made from really thin materials.”

Weible’s five-year stint in the Air Force equipped him for a job with NASA when he was 25 years old. “I was in the right place at the right time,” he recalls. “They were looking for a welder in Houston so I relocated and was hired.” According to Tulsa Welding School, NASA welders are “among some of the most prestigious and skilled metalworkers in the world.”

Welding for NASA by day, Weible continued to hone his skills by night, teaching himself different welding techniques in his one-car garage under the name Weebz Welding. “By the time I got the first welding machine wired up, I was already working an eight-hour shift in the evening performing specialty welding for space shuttle and space station parts,” he says.

“The trickledown effect of these events heavily impacted manufacturing in Houston,” recalls Weible. “My wife Jennifer and I reviewed our status and decided to move back to San Antonio and start over. Leaving NASA was the hardest decision of my life, but deep down I knew my journey was just getting started. I just had to have the courage and faith to take the first step.”

“We found one shop where we could get parts cut but service was terrible,” he says. “Jennifer and I saw an opportunity to branch out and become the go-to company for waterjet cutting in the region.” Weible predicted that installing waterjet technology would generate revenue. After researching machine builders, he chose to work with Flow International Corp.

Because Weebz is a small family business, Riggins advised Weible to start with a standard model to keep his initial investment manageable. “At the time, our Flow Mach 2b 4020 equipped with our HyPlex Prime direct drive pump fit the bill. It gave him 2D waterjet cutting capability with 6.5-ft. by 13-ft. cutting travel and up to 60,000 psi cutting pressure. We wanted to make sure Alan took the right approach to capital equipment investment so that he could thrive moving forward.”

Weible installed the Mach 2b in 2013. “We went straight from test cut to production and had customers lining up in the first two weeks. We made a bold statement to the community about our plans. But we knew we couldn’t do that with just one machine.”

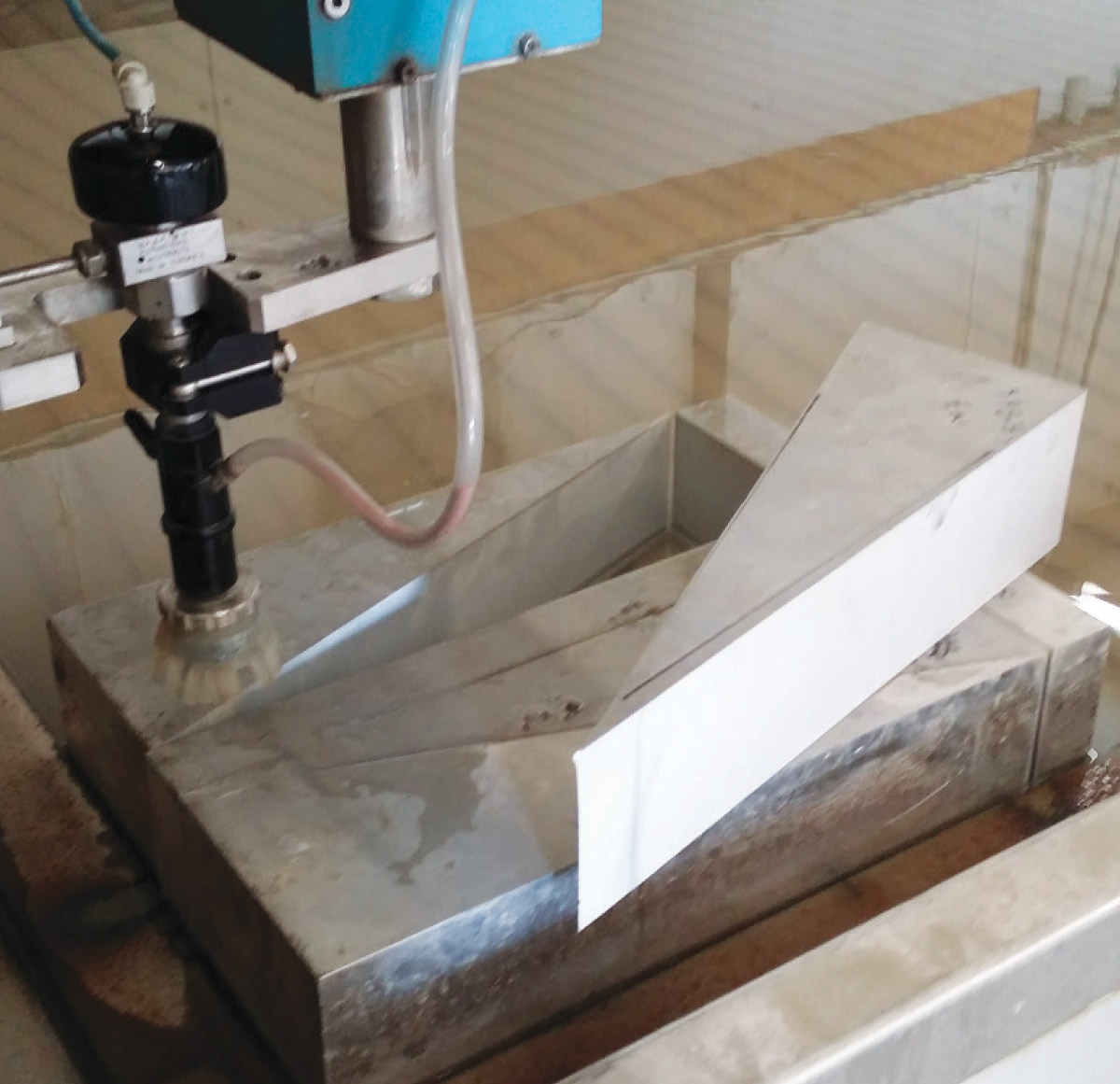

In 2015, Weible purchased a Flow Mach 4c 3070 equipped with a HyPlex Prime direct drive pump with 60,000 psi cutting pressure and a 10-ft. by 22-ft. cutting travel. The machine gave the job shop the largest table cutting capacity in San Antonio and South Central Texas. Weible built a 10,000-sq.-ft. building to house the two waterjets.

The company recently upgraded its Mach 4c with a new Flow HyperJet pump with 87,000 psi cutting pressure for higher throughput, faster cut times, and reduced abrasive consumption.

In September, Weible installed a Flow Mach 500 3080 with a 10-ft. by 26-ft. cutting travel and a Flow HyperJet pump with 87,000 psi cutting pressure. The Mach 500 waterjet is equipped with a Dynamic Waterjet XD 5-axis (3D) cutting head with active tolerance control and taper compensation. The dual-purpose machine can be used as an abrasive jet for cutting hard materials or as a pure waterjet for cutting soft materials.

The job shop continues to be heavily involved in aerospace parts production but also serves construction, oil and gas, defense, truck builders, and applications for bulletproof material and solar panels. The work keeps the waterjets running eight hours a day, five days a week. Customer demands sometimes dictate running second shifts and weekends.

“We chose waterjet processing over plasma and fiber laser equipment because I understand metallurgy,” says Weible. “With plasma and fiber laser cutting methods, you introduce heat to the metal and change its mechanical properties. You also have to sand and clean parts before you weld.”

“With Flow waterjets, we don’t have those [cleanup] issues and part accuracy is as close to perfect as you can get,” he continues. “The waterjet is an active problem solver. If a customer needs help with a part design, we can do first-article work. With software like FlowXpert, we build a part with them. We can go to the computer, pound out a program for a tool and make a one-off.

“We don’t have the luxury of time,” Weible continues. “We need to get parts out as fast as we can. We are not always the cheapest, but we deliver what we say we will. We’re trying to build long-term relationships with our customers and Flow waterjet technology helps us do that.

“And we continue to rely on our faith.”

flowwaterjet.com.

weebzwelding.com.