Features

/customfabricator

/welding

/sawing

From the Editor

Gretchen Salois, Senior Editor

Onward and Upward

n this month’s cover story, we speak to fabricators large and small about what the last year has been like working through a pandemic and all that that entails. They discuss shifts in demand, supply chain interruptions, reluctant customers, unexpected setbacks as well as surprising benefits and takeaways to use going forward.

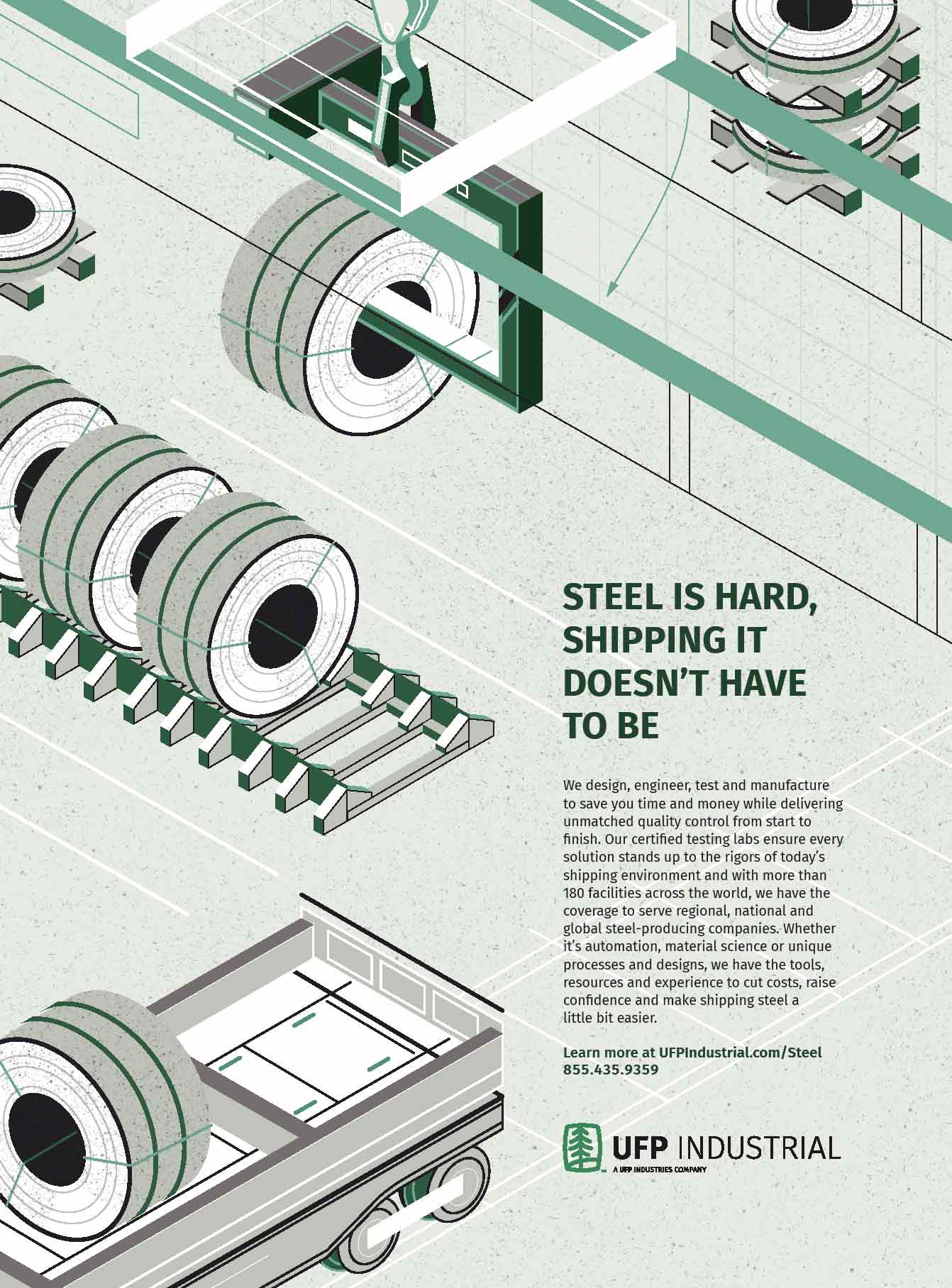

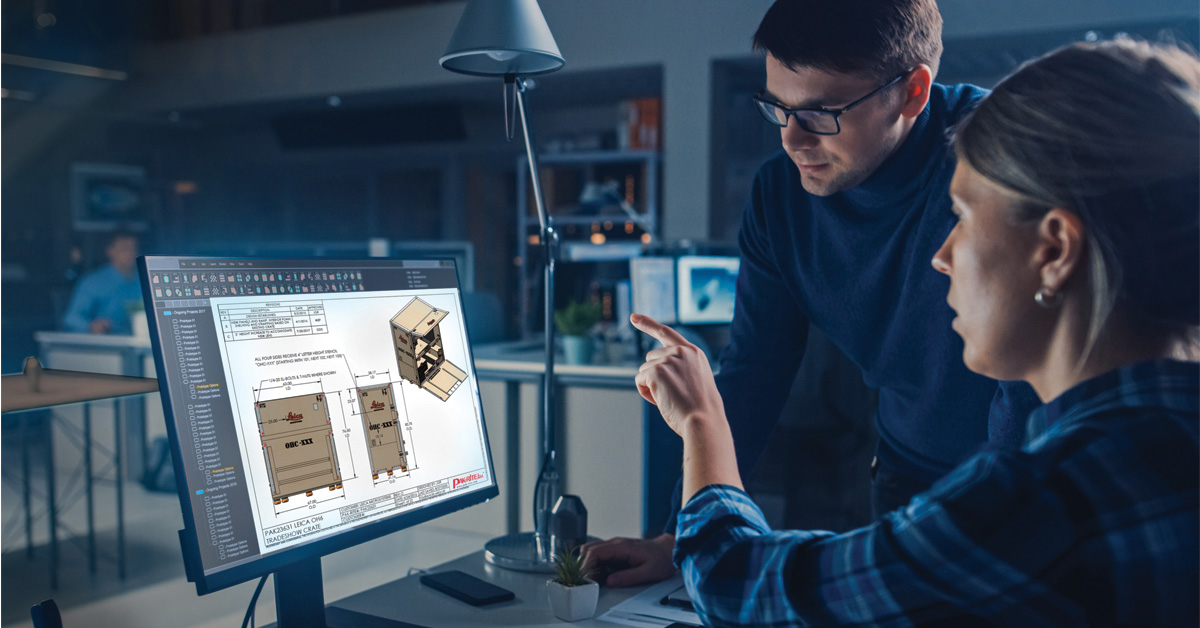

he team at UFP Industrial is experienced with the industrial packing and logistics needs of dozens of industries, including agricultural, manufacturing, energy, technology and transportation. Whether it’s wood, steel, mixed materials or hard cases, the company can support any custom packaging project—from one-time applications to sustainable programs—blending functionality, durability and cost control into each solution. Todd Droze, regional sales manager, and Dave Watson, director of national sales, discussed UFP’s problem-solving process with FFJournal.

Momentum Manufacturing Group LLC

Petty’s Welding Co. LLC

Petty’s Welding Co. LLC

ACE Metal Crafts Co.

Weldlogic Services Inc.

industry

he last year has tested fabricators in numerous ways. Market uncertainty, supply chain interruptions, personnel disruptions and spiking steel prices have helped to fuel a pandemic-wrought chaos throughout the world. After steep declines in manufacturing jobs over the last year, the industry gained 53,000 jobs in March, according to the Bureau of Labor Statistics. The rise is gradual but trending upward, and fabricators are already experiencing renewed investment and customer demand. FFJournal asks fabricators employing hundreds to a 3-employee operation to discuss how they’ve coped with unexpected changes, kept their doors open, and how they plan to move forward with the wisdom gained through a difficult period.

Momentum Manufacturing Group LLC

Petty’s Welding Co. LLC

Momentum Manufacturing Group LLC

ACE Metal Crafts Co.

Weldlogic Services Inc.

industry

industry

he last year has tested fabricators in numerous ways. Market uncertainty, supply chain interruptions, personnel disruptions and spiking steel prices have helped to fuel a pandemic-wrought chaos throughout the world. After steep declines in manufacturing jobs over the last year, the industry gained 53,000 jobs in March, according to the Bureau of Labor Statistics. The rise is gradual but trending upward, and fabricators are already experiencing renewed investment and customer demand. FFJournal asks fabricators employing hundreds to a 3-employee operation to discuss how they’ve coped with unexpected changes, kept their doors open, and how they plan to move forward with the wisdom gained through a difficult period.

hris Foster is used to a challenge. What started as a two-person fabrication shop in his garage has transformed into a 5,000-sq.-ft. facility in Garden City, Idaho. Foster Weld began fabricating custom-made metal belt buckles, custom furniture and signage nearly 15 years ago. “We were small and hustling the first few years. [The business] began with my wife and I selling belt buckles on Etsy just as the handmade movement started becoming popular,” says Foster. “Then we started offering custom marquee lighted signage for small businesses and restaurants.

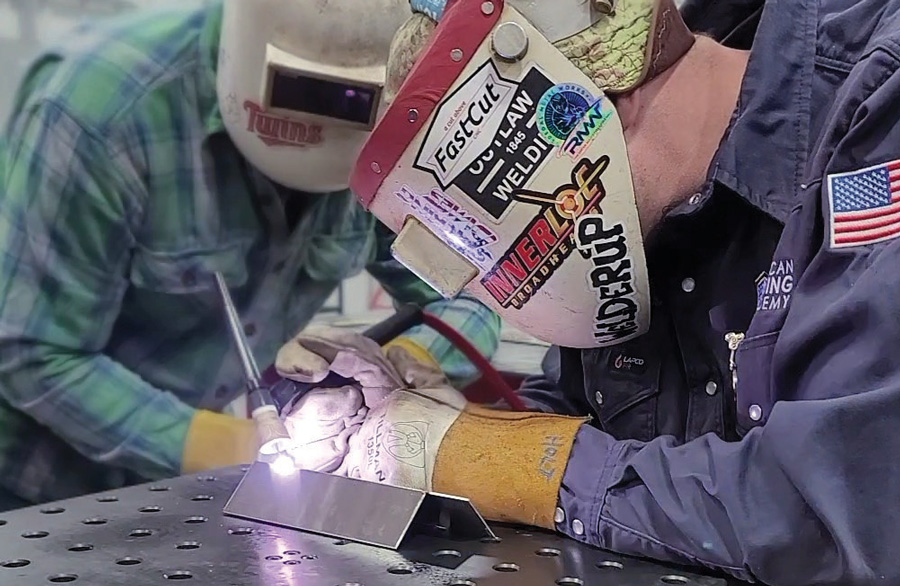

It takes quality equipment to do quality work.

It takes quality equipment to do quality work.

Southwest Welding LLC

outhwest Welding LLC took root in Wakarusa, Indiana, in 1985 under the skillful hands of owner John Martin. The fabricator learned to weld as a teenager under his Uncle Ray’s careful instruction. “A little 1,500-sq.-ft. shop became available, and I took it,” he recalls. “I moonlighted the first six years before I was able to quit my day job and take the business full time in 1991.”

urt Schie started WoodMaxx Power Equipment Ltd. in 2008 after his search for a compact PTO chipper robust enough to clear multi-acre lots proved futile. The Army infantry veteran filled the market gap by designing and building the first Hydrostatic Auto-Feed PTO wood chipper in 2015. WoodMaxx outsourced parts for the product at first. Its success soon led the Akron, New York, company to add PTO backhoes, snow blowers, flail mowers and rotary tillers as well as skid steer mounted snow blowers, wood chippers and stump grinders.

urt Schie started WoodMaxx Power Equipment Ltd. in 2008 after his search for a compact PTO chipper robust enough to clear multi-acre lots proved futile. The Army infantry veteran filled the market gap by designing and building the first Hydrostatic Auto-Feed PTO wood chipper in 2015. WoodMaxx outsourced parts for the product at first. Its success soon led the Akron, New York, company to add PTO backhoes, snow blowers, flail mowers and rotary tillers as well as skid steer mounted snow blowers, wood chippers and stump grinders.

Production Manager Tucker Smart was tasked to bring production for the PTO chipper in house and set up a domestic assembly line. It was a “huge undertaking,” he says. “In the beginning, I handled everything from purchasing, programming, running cutting and bending operations, and overseeing the assembly line. I was running from one job to the next. If I had some help, we were processing 24,000 lbs. of steel a day. If I was running the line by myself, I was cutting and forming 8,000 lbs. of steel per day.”

umans breathe oxygen produced by plants and exhale carbon dioxide. Plants use the carbon dioxide to create oxygen. The link between humans and plants is an example of mutualistic symbiosis—where different species benefit from a relationship with one another.

hen COVID-19 hit, Kloeckner Metals UK became the first SigmaNEST customer to switch its entire operation to a completely cloud-based infrastructure, and the change has proven to be invaluable. In 2020, fabricators of all sizes were forced to adapt to a world in shutdown. Many businesses scrambled to establish remote options for employees while others were more prepared with remote desktop or similar applications to continue operations away from the job site. But a full-cloud solution, which includes both the company and clients in the cloud, can be accessed anywhere with little to no latency.

udding music artists are often cautioned about the importance of knowing their niche—their selling point. It’s advice that America’s Got Talent judge Simon Cowell gave to a 15-year-old country singer from Utah during the show’s 2020 season when he said, “I love artists who know what kind of lane they want to go down.”

Richard Keeton, president of Houston-based Plasma Systems Inc., learned the value of staying in his lane when he identified a niche and nurtured it. This year, the company celebrates its 30th anniversary.

To improve performance and productivity in MIG and pulsed MIG aluminum welding applications, or when feeding wire long distances and around obstacles, Tweco, an ESAB brand, has launched the PullMaster2 push-pull MIG gun. The updated version of this pistol-grip-style gun improves ergonomics through an angled cable-to-gun connection combined with a ball-and-socket strain relief that enhances balance and reduces perceived cable weight. The easy-to-grip handle features a short-stroke trigger for easier activation, while an aluminum unibody reduces parts for greater reliability, easier repair and weight reduction.

Tweco/ESAB, Florence, South Carolina, 843/669-4411, esabna.com.

Motion is the central principle behind this public artwork, planned especially for Chicago’s Willis Tower. The dynamic pattern on the wall is activated by the motion of people walking, driving or biking past; by the motion of the Earth in relation to the sun as light moves across it; and by changes in the season and weather. Viewing the work from various positions and at various times of day produces a dramatically different experience. The artwork, designed by artist Olafur Eliasson, covers the wall with a pattern of powder coated steel tiles based on Penrose tiling. Discovered by mathematician and physicist Sir Roger Penrose in the 1970s, this approach produces a system of non-periodic tiling that is based on five-fold symmetry. Each tile is curved, a fragment of the inner surface of a sphere, and the main tones used in the work—blue, deep green, and white—are redolent of the surfaces of nearby Lake Michigan and the Chicago River. The massive piece measures roughly 30 ft. by 60 ft. and covers the exterior wall with a pattern of 1,963 tiles.

Editor-in-Chief

Michael D’Alexander

Lynn Stanley

Gretchen Salois

J. Neiland Pennington

Lauren Duensing

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323

www.ffjournal.net

Carlotta Lacy

Matt LaFleur

Mark Koenig

Michael D’Alexander

Jim D’Alexander

Wayne Krusen

Traci Fonville

Bill D’Alexander

312/654-2309, Fax: 312/654-2323

mdalexander@ffjournal.net

Alaska, Arizona, Arkansas, California, Hawaii, Idaho, Montana, New Mexico, North Dakota, Oklahoma, Texas, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@ffjournal.net

Alabama, Colorado, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Pennsylvania, South Carolina, South Dakota, Tennessee

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@ffjournal.net

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@ffjournal.net

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Valerie Treiber, National Sales Manager

203/894-5483

valerie@modernmetals.com

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@ffjournal.net

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJOURNAL® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJOURNAL® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.