hen COVID-19 hit, Kloeckner Metals UK became the first SigmaNEST customer to switch its entire operation to a completely cloud-based infrastructure, and the change has proven to be invaluable. In 2020, fabricators of all sizes were forced to adapt to a world in shutdown. Many businesses scrambled to establish remote options for employees while others were more prepared with remote desktop or similar applications to continue operations away from the job site. But a full-cloud solution, which includes both the company and clients in the cloud, can be accessed anywhere with little to no latency.

Kloeckner has many locations throughout the U.K. Previously, employees logged in to a server in Germany to access orders and production process updates. “Users logged in to SigmaNEST software using a remote desktop app, and that worked quite well for a while,” says Darren Craven, engineer. “But the pandemic forced the majority of us to work remotely. We quickly realized it was time to consider a faster solution so the decision was made to transition to a cloud-based solution.”

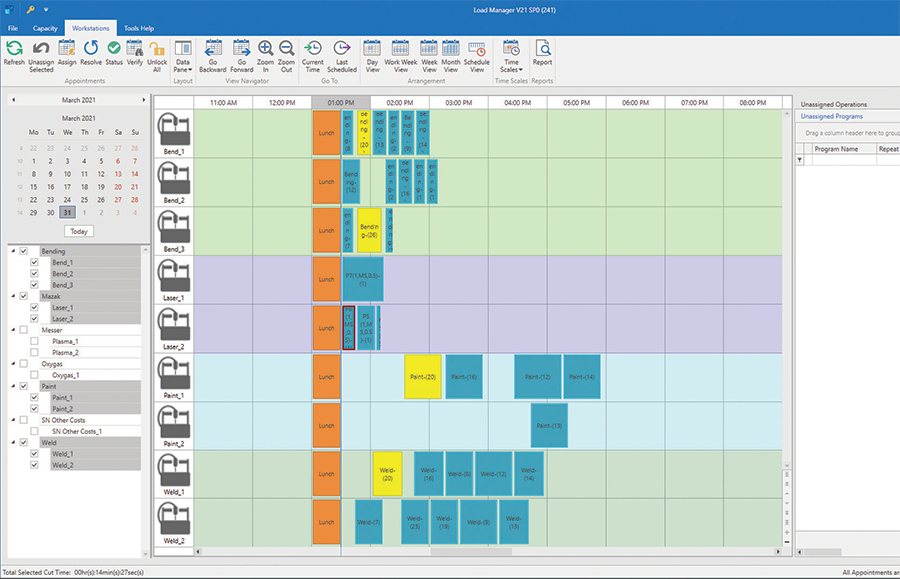

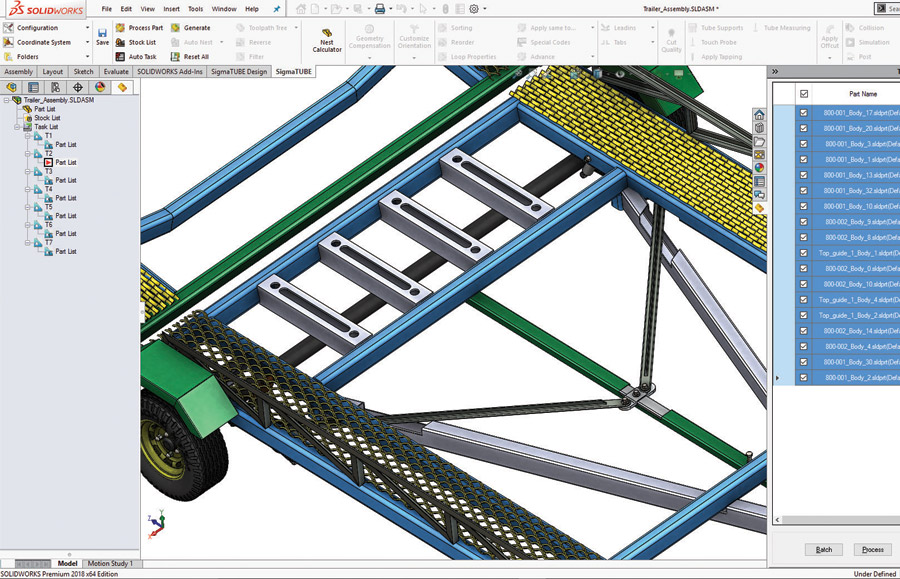

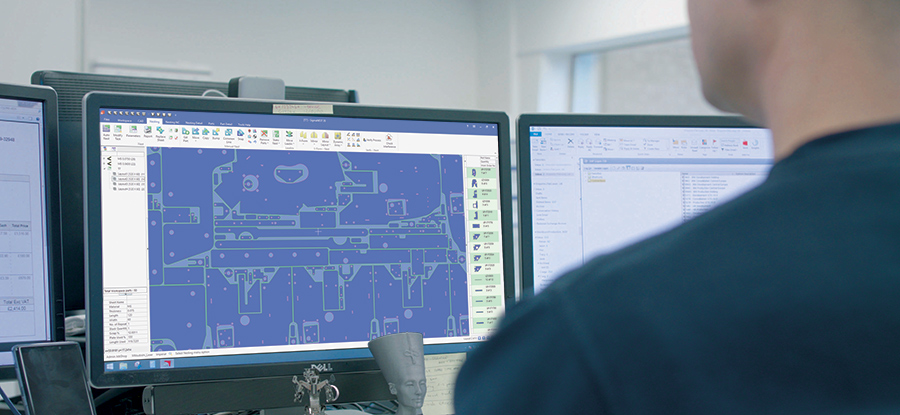

SigmaNEST offers end-to-end solutions and advanced CAD/CAM, giving users advanced industry nesting algorithms used for nearly every type of cutting, punching and bending machinery. Shop floor management solutions give the user complete control and access to real-time data on production status, quoting and transactions. The software also provides customer, supplier and inventory information, as well as calculates true cost of shop floor operations. Business system tools integrate directly with SigmaNEST and provide a full range of fabrication workflow, from quoting to production to shipping.

Since switching in March 2021, Kloeckner has used its cloud-based SigmaNEST system without interruption. “The team can easily log in to the cloud, add profiles, monitor at what stage the order is and most importantly, our customers get a lot quicker response when they require tailored solutions,” Craven says.

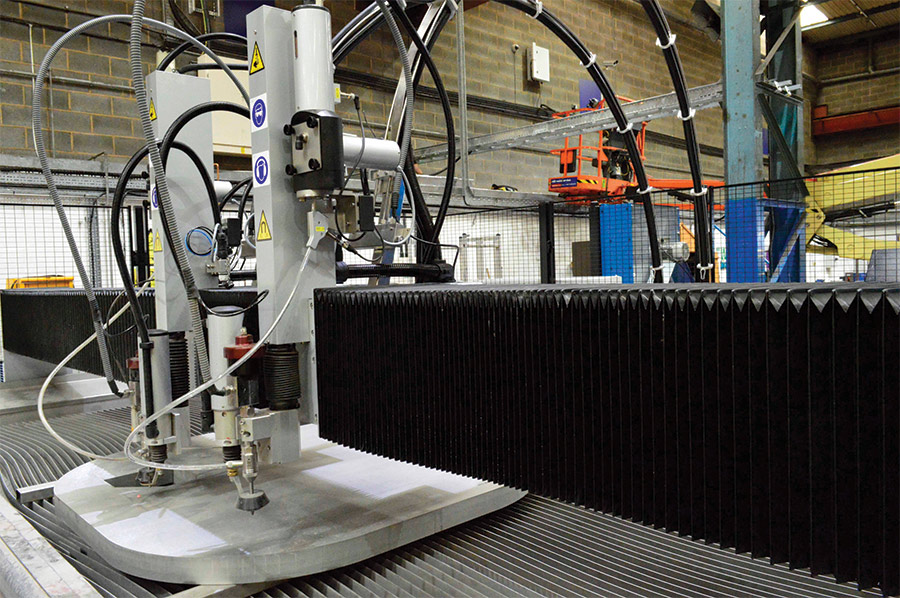

Kloeckner Metals is one of the largest mill-independent multi-metal stockholders and distributors in the U.K. offering a wide range of ferrous and nonferrous products sourced from mills throughout Western Europe. It provides services including tube laser cutting, profiling (laser, plasma, oxy-fuel and waterjet), de-coiling, drilling, fabrication, sawing, shotblasting and painting.

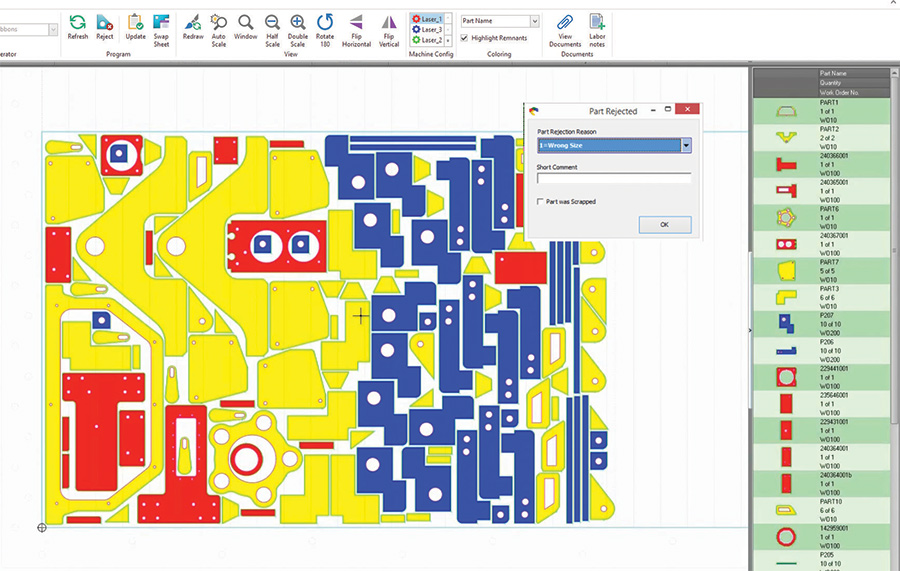

Easily track, unload and resubmit any damaged parts for recutting.

Shifting away from remote desktop and similar apps is catching on, and SigmaNEST expects more interest in its cloud-based software going forward. “More and more larger clients are investigating [a cloud-based system],” Cooper says. “Smaller clients won’t really justify the cost [to switch] yet.”

Kloeckner Metals UK provides services including tube laser cutting, profiling, de-coiling, drilling, fabrication, sawing, shotblasting and painting.

“The metals industry continues to lag behind other industries, but as IT and AI technologies advance, innovators and early adopters seize a competitive and sustainable advantage,” Craven says. “Companies and industries that don’t evolve run the risk of falling behind or potentially no longer existing at all.”

We quickly realized it was time to transition to a cloud-based solution.

We quickly realized it was time to transition to a cloud-based solution.

Kloeckner Metals UK