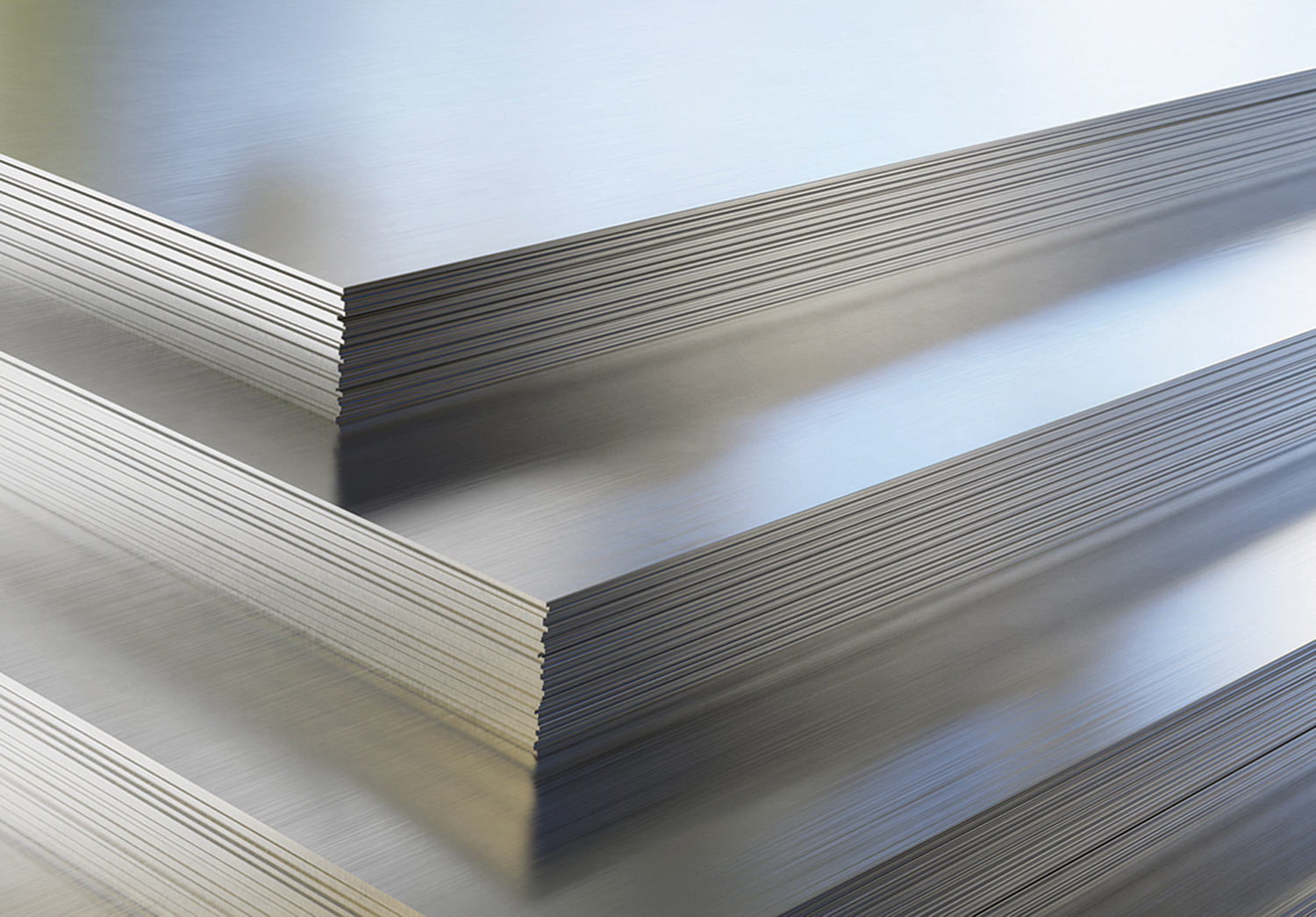

The Aluminum Association’s Aluminum Sheet Trade Enforcement Working Group filed petitions to investigate unfair trade practices on March 9, 2020. “This decision provides vitally needed relief from a second wave of unfairly traded imports from 16 countries that hammered domestic producers just as they were beginning to recover from an onslaught of imports from China,” said Aluminum Association President and CEO Tom Dobbins.

This decision will help ensure that domestic producers can make full use of more than $1 billion in capital investments made in recent years.

This decision will help ensure that domestic producers can make full use of more than $1 billion in capital investments made in recent years.

Tom Dobbins

Aluminum Association

According to the USITC, the result of the decision will result in the U.S. Department of Commerce issuing antidumping duty orders on imports from 16 countries. The commission also made negative critical circumstances findings with regard to subsidized imports of this product from Turkey and dumped imports of this product from Indonesia. As a result, these imports will not be subject to retroactive countervailing or antidumping duties.

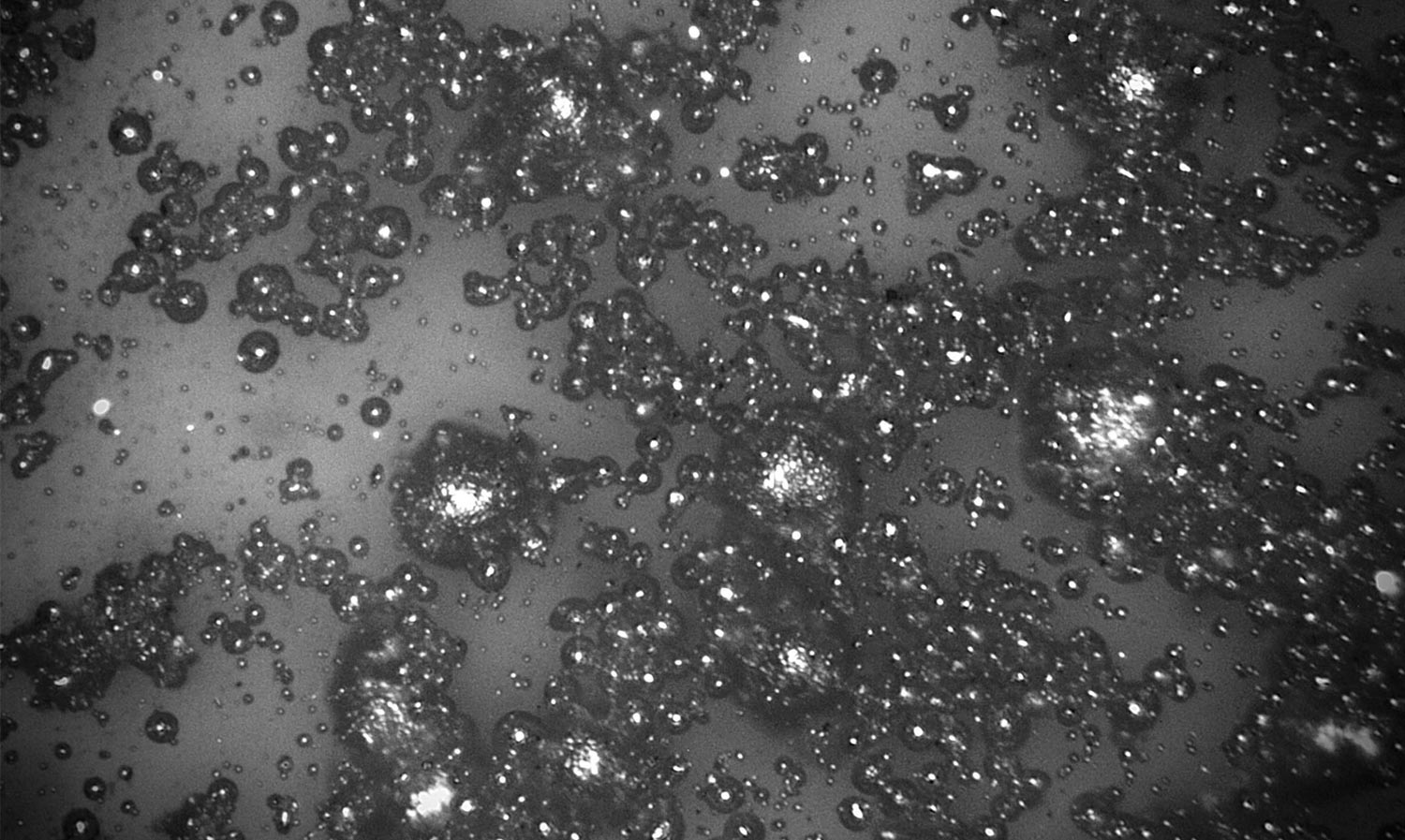

Common alloy aluminum sheet (CAAS) is a flat-rolled aluminum product having a thickness of 6.3 mm or less, but greater than 0.2 mm, in coils or cut-to-length, regardless of width. CAAS includes both not clad aluminum sheet, as well as multi-alloy, clad aluminum sheet. With respect to not clad aluminum sheet, common alloy sheet is manufactured from a 1XXX-, 3XXX-, or 5XXX-series alloy as designated by the Aluminum Association. With respect to multi-alloy, clad aluminum sheet, common alloy sheet is produced from a 3XXX-series core, to which cladding layers are applied to either one or both sides of the core. CAAS does not include aluminum can stock.

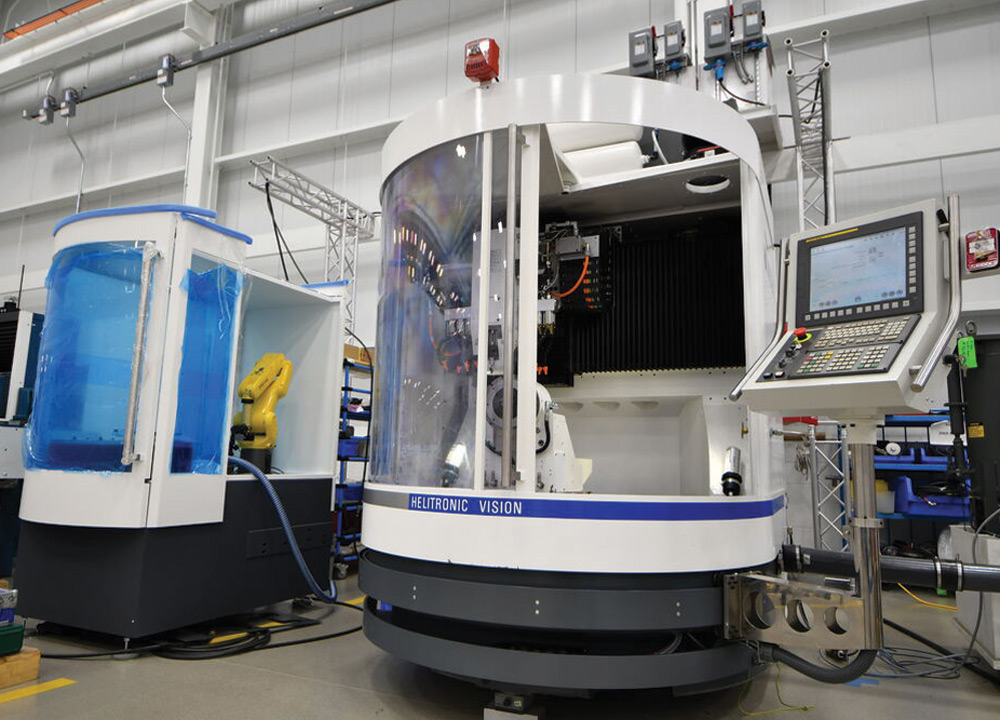

Josh Peace to materials planner and Matt Shetler

Josh Peace to materials planner and Matt Shetler  to director of marketing. In his new role, Peace coordinates the purchasing, scheduling and inventory management of all assembly related parts and materials, as required for production, in order to fulfill customer requirements. Shetler is responsible for planning and implementation of all AIDA-America marketing efforts, as well as coordination with other AIDA Group companies.

to director of marketing. In his new role, Peace coordinates the purchasing, scheduling and inventory management of all assembly related parts and materials, as required for production, in order to fulfill customer requirements. Shetler is responsible for planning and implementation of all AIDA-America marketing efforts, as well as coordination with other AIDA Group companies.

at ffjournal.net