FACE TIME

Protecting Products

Softening the blows for high-end component shipping

T

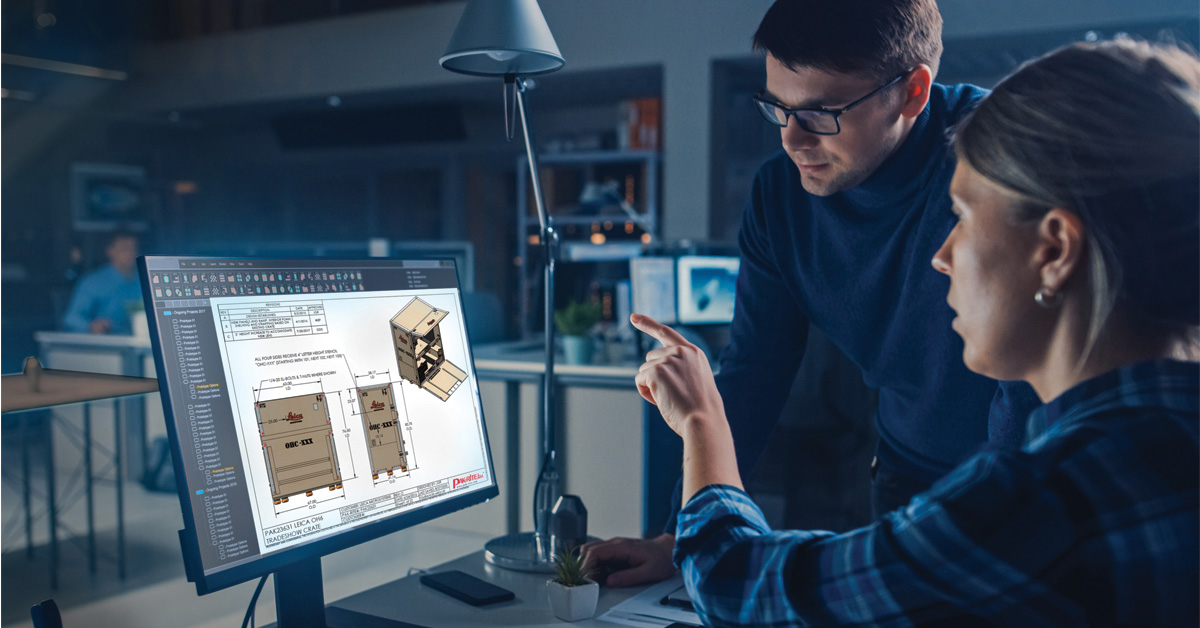

he team at UFP Industrial is experienced with the industrial packing and logistics needs of dozens of industries, including agricultural, manufacturing, energy, technology and transportation. Whether it’s wood, steel, mixed materials or hard cases, the company can support any custom packaging project—from one-time applications to sustainable programs—blending functionality, durability and cost control into each solution. Todd Droze, regional sales manager, and Dave Watson, director of national sales, discussed UFP’s problem-solving process with FFJournal.

Q: What sets UFP Industrial apart?

Q: What sets UFP Industrial apart?

Droze: We help organizations design, produce and deliver smart product storage and packaging solutions. There are three things that separate UFP Industrial from others: First and foremost is the fact that we are a one-stop shop. One size fits all is not part of our vocabulary. Every client is different, and every client packaging solution is unique. Secondly, our global reach helps in sourcing and logistics, and it exposes us to packaging best practices from a wide variety of sources. Lastly, our clients know that we are with them all the way. We hold our ourselves accountable for results over a long period of time.

Q: What are some consequences that can result from using the wrong packaging?

Droze: One of our customers, a manufacturer of premium automobiles, came to us recently with a costly shipping problem at its components facility in South Carolina. This company was using corrugated and wood hybrid packaging to ship high-end steel exhaust assemblies to its various manufacturing plants around the world and was experiencing high damage rates—ranging from 25 to 50 percent. The damaged exhaust assemblies resulted in plant shutdowns, poor internal customer satisfaction and, of course, higher costs. The automaker turned to UFP Industrial and the UFP Salisbury, North Carolina plant for a solution. Our design and engineering team mapped out various alternatives and ran them through a barrage of tests, and the customer selected an all-wood structure solution.

Q: How did the all-wood packaging perform?

Q: How did the all-wood packaging perform?

Watson: The all-wood structure both reduced damage to the assembly and provided a significant overall cost improvement to the client. And that first program success with this customer has led to another—and another. UFP Industrial has since developed improved packaging solutions for shipping other auto subcomponents, such as sunroofs and EV battery assemblies.

UFP Industrial,

Grand Rapids, Mich., 855/435-9359, ufpindustrial.com.