umans breathe oxygen produced by plants and exhale carbon dioxide. Plants use the carbon dioxide to create oxygen. The link between humans and plants is an example of mutualistic symbiosis—where different species benefit from a relationship with one another.

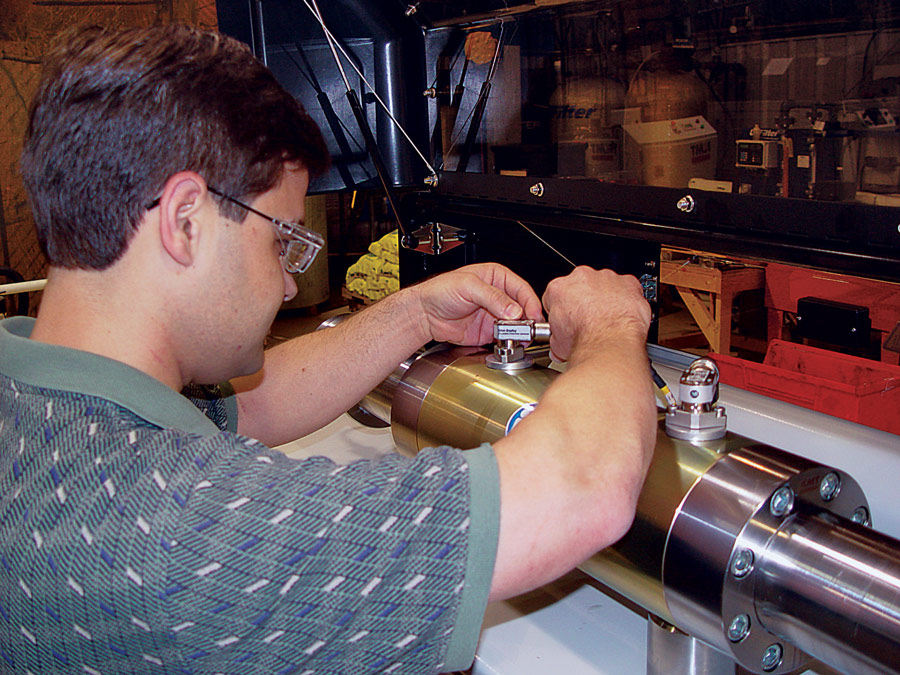

The science of mutualism could also apply to MultiCam Inc. and KMT Waterjet Systems Inc. Texas-based MultiCam is a CNC cutting machine manufacturer with plasma, fiber laser, router, digital finishing knife and waterjet systems. KMT, Baxter Springs, Kansas, specializes in the design and manufacture of waterjet cutting pumps and technology. Since opening its doors in 1989, MultiCam has sourced KMT pumps for its CNC waterjets. “Their pump technology can cut anything—soft substrates, food, composites, glass,” says MultiCam Fabrication Product Manager Rashad Galloway. “KMT doesn’t look at a waterjet machine and say, ‘we’re only going to cut metal.’ That latitude gives us a lot of avenues to pursue.”

Both companies recently marked important milestones. MultiCam installed its 14,000th waterjet at Kimbrell’s Kustom Machine Shop in December 2020. KMT is celebrating its 50th anniversary.

Like KMT, MultiCam has built its business by helping customers to have confidence in their capital equipment investments. Its application team includes a waterjet expert, a materials specialist and a master fabricator, each with over two decades of experience. “We do our homework to vet the right cut solution for the customer,” Galloway says. “We’ll take their test parts and cut them on our fiber laser, plasma cutter and waterjet to identify which method most closely meets their needs.”

“Waterjet is a tool in a fabricator’s toolbox,” agrees Sanders. “Our pumps can cut everything from celery to 12-in.-thick titanium. Heat affected zones are eliminated, and the parts don’t require any secondary finishing. It’s a versatile tool. We’re in the business of helping manufacturers and job shops make money. Downtime, inefficiency and poor performance are the enemies. Everything we do is focused on giving the customer improved productivity and uptime. Companies need to look at capital equipment purchases through this lens and ask themselves, ‘Can the OEM deliver support and service over the life of the machine?’ ‘Can they evolve with our business?’ Not every equipment manufacturer can. We have the product depth to do that and so does MultiCam.”

Waterjet is a versatile tool in a fabricator’s toolbox.

Waterjet is a versatile tool in a fabricator’s toolbox.

The two companies make an effective team when it comes to customer service but they also support one another. “KMT has our back and not just from a service standpoint,” says Galloway. “Even during the pandemic they reached out to let us know about markets that were exploding versus those that were in decline. “

Collaboration also helps ensure customers get the right cutting solution. “There is a difference between cutting and cutting correctly,” says Galloway. “When customers look at a waterjet, we have to evaluate their entire fabrication process and help them consider what they may need down the road.”

MultiCam and KMT have observed spikes in demand as customers work to stay ahead of current trends and maintain a level of readiness that will allow them to adjust quickly to market changes. Others, like Kimbrell, have taken bold steps to invest in technology versus holding on to their checkbook. “I’m amazed at what Scott has achieved,” Galloway says. “When most people weren’t spending capital equipment dollars due to COVID-19 uncertainties, Scott came to us and said, ‘I need a waterjet.’”

MultiCam and KMT have matured in the areas of reliability, serviceability and performance. “The product is important but in the long run it’s the people that support that technology,” adds Sanders, pointing to KMT’s company culture and its personnel as the reasons for the company’s longevity. Galloway agrees that a work culture made up of dedicated employees is crucial. “We push each other hard to improve and we extend that to our customers,” he says. “When a customer buys from us, we don’t just tell they are part of the MultiCam family, we show them.”