udding music artists are often cautioned about the importance of knowing their niche—their selling point. It’s advice that America’s Got Talent judge Simon Cowell gave to a 15-year-old country singer from Utah during the show’s 2020 season when he said, “I love artists who know what kind of lane they want to go down.”

Richard Keeton, president of Houston-based Plasma Systems Inc., learned the value of staying in his lane when he identified a niche and nurtured it. This year, the company celebrates its 30th anniversary.

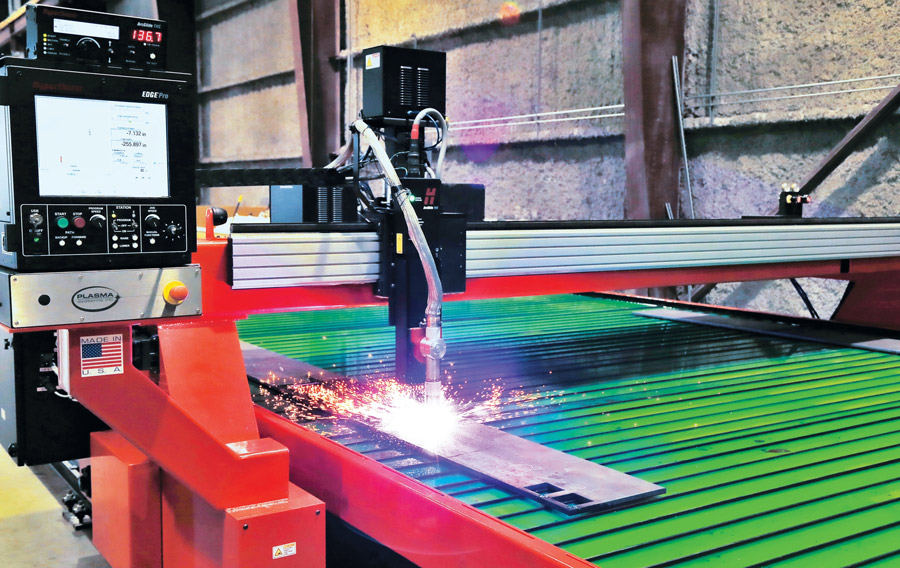

“In 1991, there were only a handful of OEMs selling and servicing X-Y plate cutting machines,” he says. “Most customers had to fly a technician in for equipment repairs or maintenance. There was a need for a service company like ours in Houston. At first, we focused on the plasma part of the machine itself. Before long, we gained the experience to repair the entire machine. That led to retrofit work and selling new equipment for different OEMs. In 1995, we designed, built and launched our own plasma cutter, Cutting Edge Design.”

Cut quality, productivity and the ability to automate process cut parameters have pushed the evolution of plasma equipment in general. New CNCs with touchscreens, software-generated improvements in cut-to-cut cycle times, plate beveling and edge quality, along with the addition of functions like drilling, milling or tapping, have also pushed equipment advances.

In addition to its core technology, Plasma Systems is dedicated to listening to customer feedback. “You reach out to customers and ask them what they want,” he says. “We do a really good job of that.” Those requests have included higher accuracy, an operator-friendly controller, real automatic plate alignment versus manual automatic plate alignment, and remote monitoring from different devices.

Plasma Systems understands that skilled operators can contribute to scrap savings and higher throughput if they are equipped with the right tools. The machine builder’s CNC Cutting Edge Design plasma cutter gives the operator the ability to take an active role at any point in the process from creating a drawing in CAD to cutting or nesting parts at the shop floor level. “With our system, a production floor manager can ask an operator to skip to an area of the nest that contains a part that production requires immediately,” Keeton says. “Instead of counting the pierce points to find that part, the operator can simply touch the part they want to jump to on the controller’s [screen]. The floor manager can also check a nested part and have the operator adjust hole, slot, inner diameter or outer diameter on the fly to save secondary operations.”

While Plasma Systems has built its business staying in its lane, the company also embraces change within the parameters it has set for itself. “We don’t try to be everything to everybody,” he says. “We have standard models with a capacity range of 8 ft. to 12 ft. wide. But if a customer wants something special, we can do it. We are constantly looking for ways to do things better.”

“If a customer says ‘I’m cutting 8-ft. plate and that’s all we do,’ I will make sure they can cut 9-ft. plate,” says Keeton. “You want to give them that extra room. Competitors don’t do that. And we don’t add dollars to the equipment’s price tag to give them that added cutting space. We try to make the process painless.”

We want to save customers money by helping them make better parts at higher production levels.

We want to save customers money by helping them make better parts at higher production levels.

Plasma Systems Inc.

“We’ve eliminated 35 percent of our service calls by implementing remote access,” Keeton says. “We can take calls up to 10 p.m. at night. If it’s a second-shift operator that needs help, I can log in to their machine from my phone, look at everything on the plasma cutter and troubleshoot, saving the customer a service call.”

The operator-friendly machine is as easy to use as it is to troubleshoot. “We can have someone programming a K bevel in five minutes, even if they have never done it before,” he says. “If you can use a computer or a cell phone and email a photo, then you are a natural to operate our plasma cutting machine. And because we use an open-architecture controller, if that goes down, an operator can run the machine with a laptop device that is loaded with our software.”

The machine builder is evaluating where plasma technology is headed. In addition to an advanced design, the Plasma Systems team is analyzing data collection. Currently, its Cutting Edge Design equipment uploads data to the cloud. The machine builder wants to enable each plasma machine to automatically upload data daily. Parts cut, operating times and other details will be gathered in the information transfer. “These statistics will help our customers make decisions in real time and reduce machine down time,” notes Keeton. “It will also mean our plasma cutters can talk to other machines such as shuttle tables or plate autoloaders. We’ll never be a big company but I’m okay with that. Our accuracy can be compared to that of a waterjet. We’re a step ahead of the competition, and that’s where we are going to stay.”