Features

/customfabricator

/pressbrakestooling

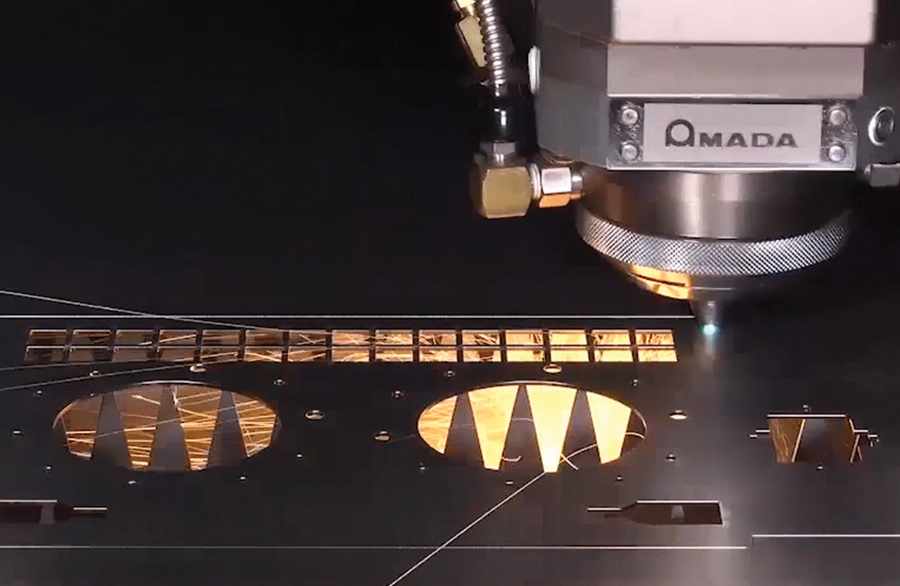

/laser

From the Editor

Being First

e’ve all heard the phrase, “an industry first.” It means to be the first in an industry to do something. History is rich with examples of pioneers who had the fortitude, curiosity and perseverance to explore new territory, test a theory or develop a product.

For example, Richard Trevithick invented the first high-pressure steam engine and the first operational steam locomotive at the turn of the century. Trevithick’s “Puffing Devil” became an icon of the industrial revolution. As a Buckeye, born and raised in Ohio, I would be remiss not to mention Wilbur and Orville Wright. The two got their start in the bicycle business but went on to achieve the first powered, sustained and controlled airplane flight in 1903. Two years later, they built and flew the first fully practical airplane.

usiness managers in industries such as energy, mining, shipbuilding, road and bridge, and water treatment came to Makita asking if a grinder could be engineered with a non-removable guard feature. In response, the company developed a first-in-concept hand-held angle grinder with a non-removable guard.

Right now, two Makita models are offered with this feature: the 4½ in. Paddle Switch Angle Grinder (model GA4553R) and the 4½ to 5 in. Paddle Switch Angle Grinder (GA5053R). These new grinders are part of the compact industrial class, which are widely used for grinding, surfacing and cutting applications in metal fabrication and construction.

mproper planning and unrefined processes are major factors in creating unnecessary downtime in a fabrication shop. A typical project can make its way through several stops and departments before it gets sent out the door, making communication and preparation among employees a necessary part of smooth operations.

“Planning how a job will be executed is critical for a cost-effective fabrication process,” says Spencer Garbs, director of manufacturing for WB Industries, a custom metal and structural fabrication, welding, and precision machining company based in O’Fallon, Missouri. “Improper or inconsistent planning can take the form of missing dimensions, inaccurate cut lists and incorrectly ordered material—among other things. These result in material supply issues, insufficient blueprints, quality concerns, which all lead to production downtime and negative financial impacts.”

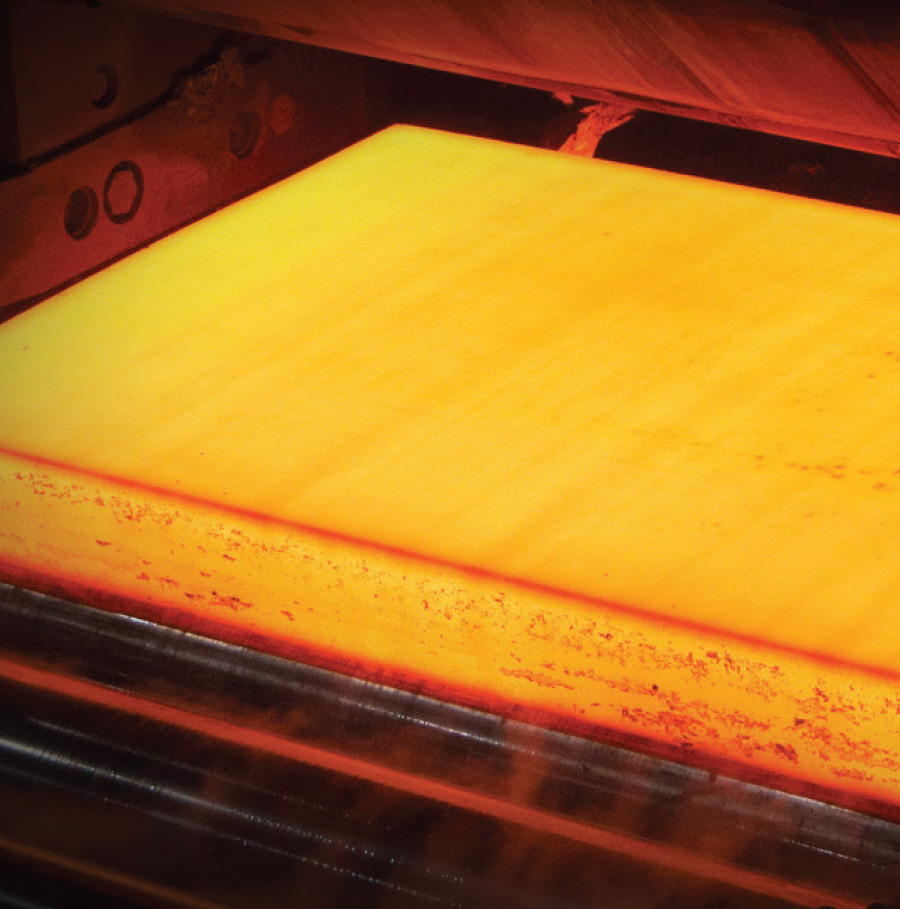

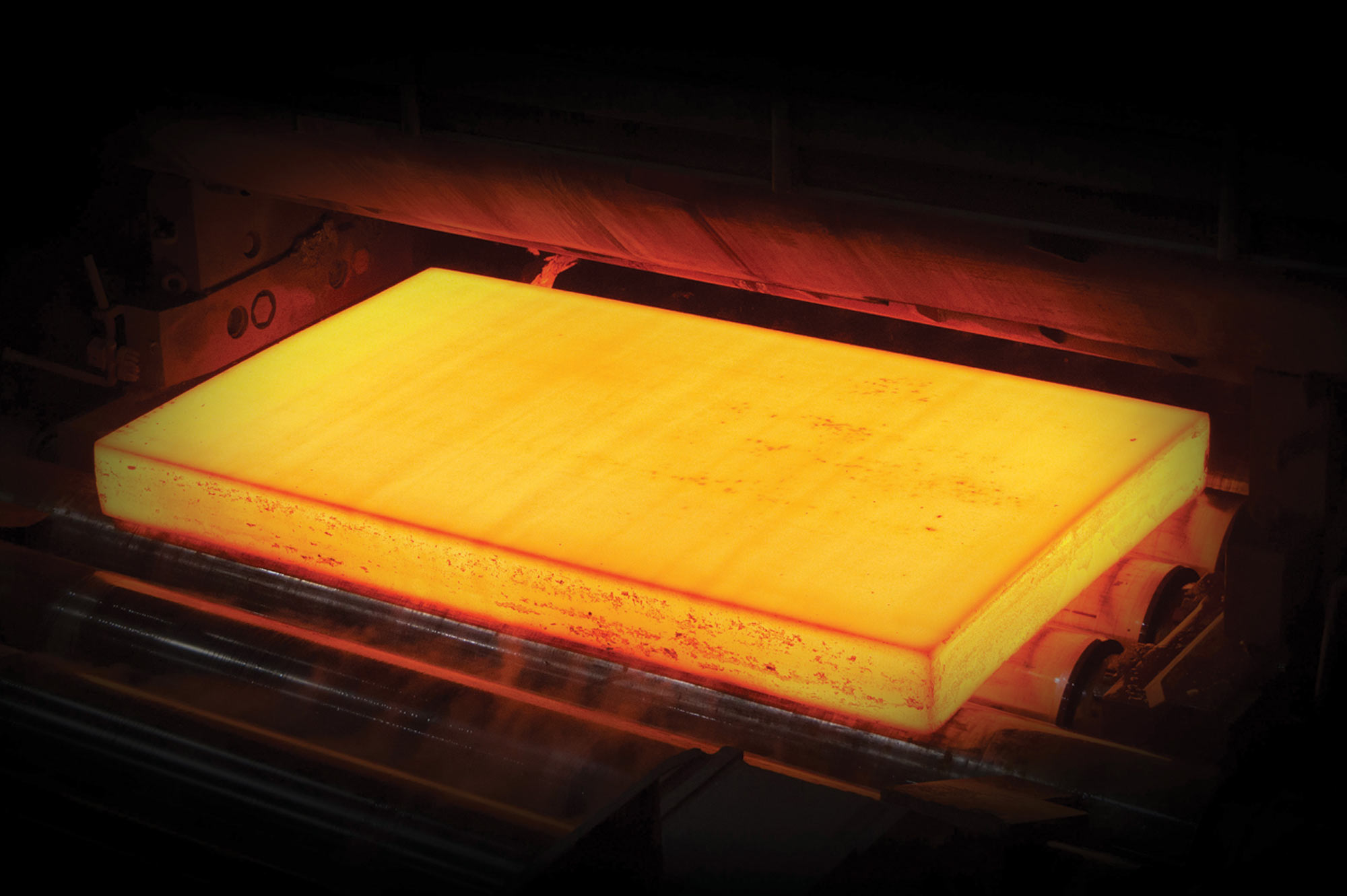

Steel

Mission

Force

un-dun-DUT-DUT-dun-dun-DUN-DUT… the iconic 5-beat tune first captured audiences’ attention as the theme song for the 1966 television series “Mission: Impossible,” and again in 1996 with the launch of the Mission: Impossible movie franchise. In both the TV show and the films, viewers heard the immortal words, “Your mission, should you choose to accept it…” The exciting opener ended with, “…This tape will self-destruct and the Secretary will disavow any knowledge…” The word ‘tape’ was changed to ‘message’ for the screen versions. Fans were then made privy to the mission’s directives and treated to dossiers on the members of the Impossible Mission Force (IMF).

Mission

Force

Mission

Force

un-dun-DUT-DUT-dun-dun-DUN-DUT… the iconic 5-beat tune first captured audiences’ attention as the theme song for the 1966 television series “Mission: Impossible,” and again in 1996 with the launch of the Mission: Impossible movie franchise. In both the TV show and the films, viewers heard the immortal words, “Your mission, should you choose to accept it…” The exciting opener ended with, “…This tape will self-destruct and the Secretary will disavow any knowledge…” The word ‘tape’ was changed to ‘message’ for the screen versions. Fans were then made privy to the mission’s directives and treated to dossiers on the members of the Impossible Mission Force (IMF).

n 1543, Nicolaus Copernicus authored a paradigm shift in planetary motion when he presented his heliocentric theory in which the Earth and other planets rotated around the sun. Albert Einstein created a new paradigm when he moved beyond Newtonian physics, the description of mechanical events, with his theory of relativity and introduction of quantum physics, which is the study of atomic and subatomic particles.

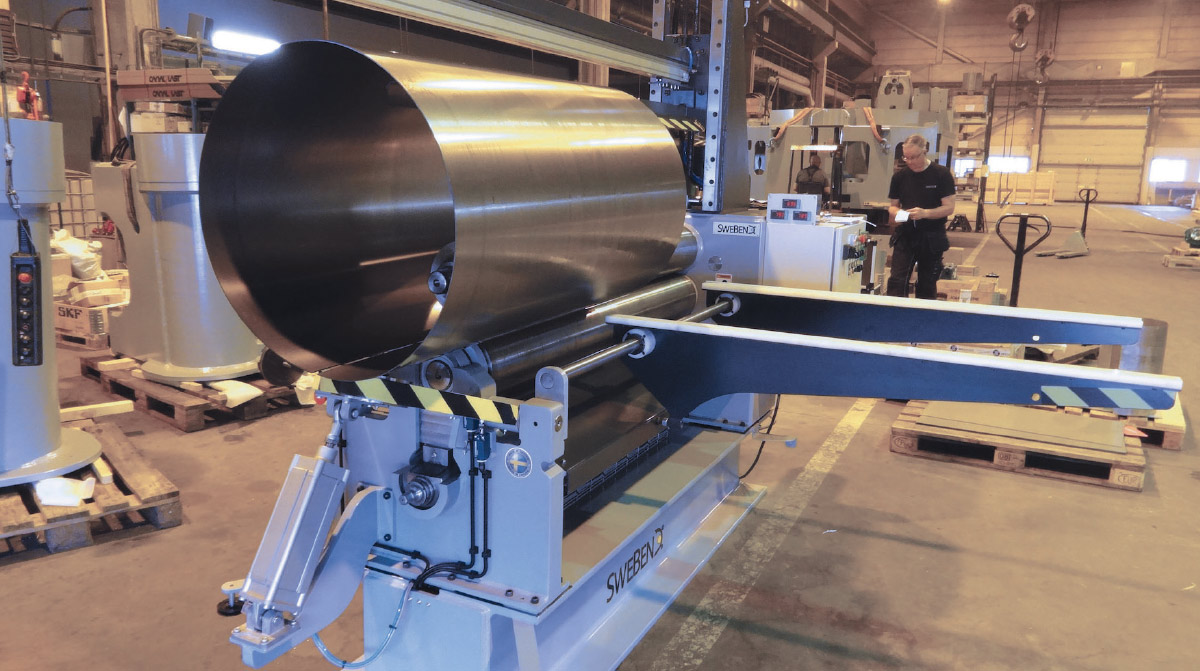

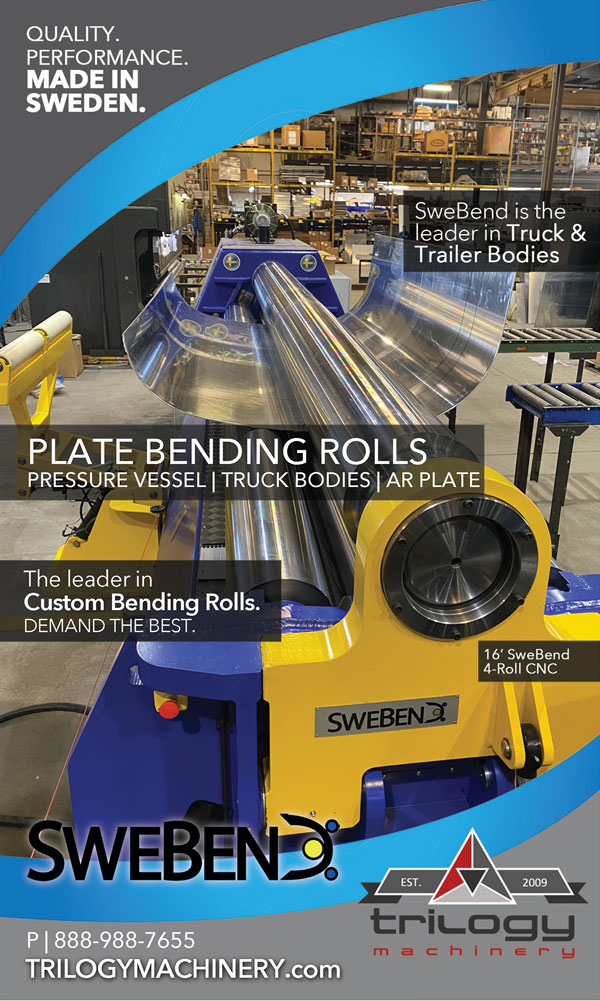

As an exclusive North American distributor for bending rolls, ironworkers and tube punching equipment, Trilogy Machinery Inc. is also looking to change established patterns, in particular with new technology from its SweBend line of bending rolls. “Plate and angle bending rolls are traditionally machines that require an experienced eye,” says Matt Weeks, product manager for Trilogy. “SweBend is finding ways to offer solutions that break that paradigm by providing equipment that can roll perfect parts without the need for skilled operators.”

he use of abrasives to shape, polish or grind material has a long and storied history. Use of the first circular grinding tool was recorded in 2100 B.C. when an Egyptian engineer mounted a wheel on a crude lathe and used it to grind bronze tools and ornaments. The first coated abrasives were comprised of crushed seashells affixed to parchment with an organic adhesive. In 2020, the global abrasive market was estimated at $34.41 billion.

Norton | Saint-Gobain Abrasives has been instrumental in modernizing the field and developing a wide range of innovative yet economical products. The abrasives manufacturer also invests in research and development and collaboration with customers to create solutions that deliver the performance, efficiency and productivity companies need.

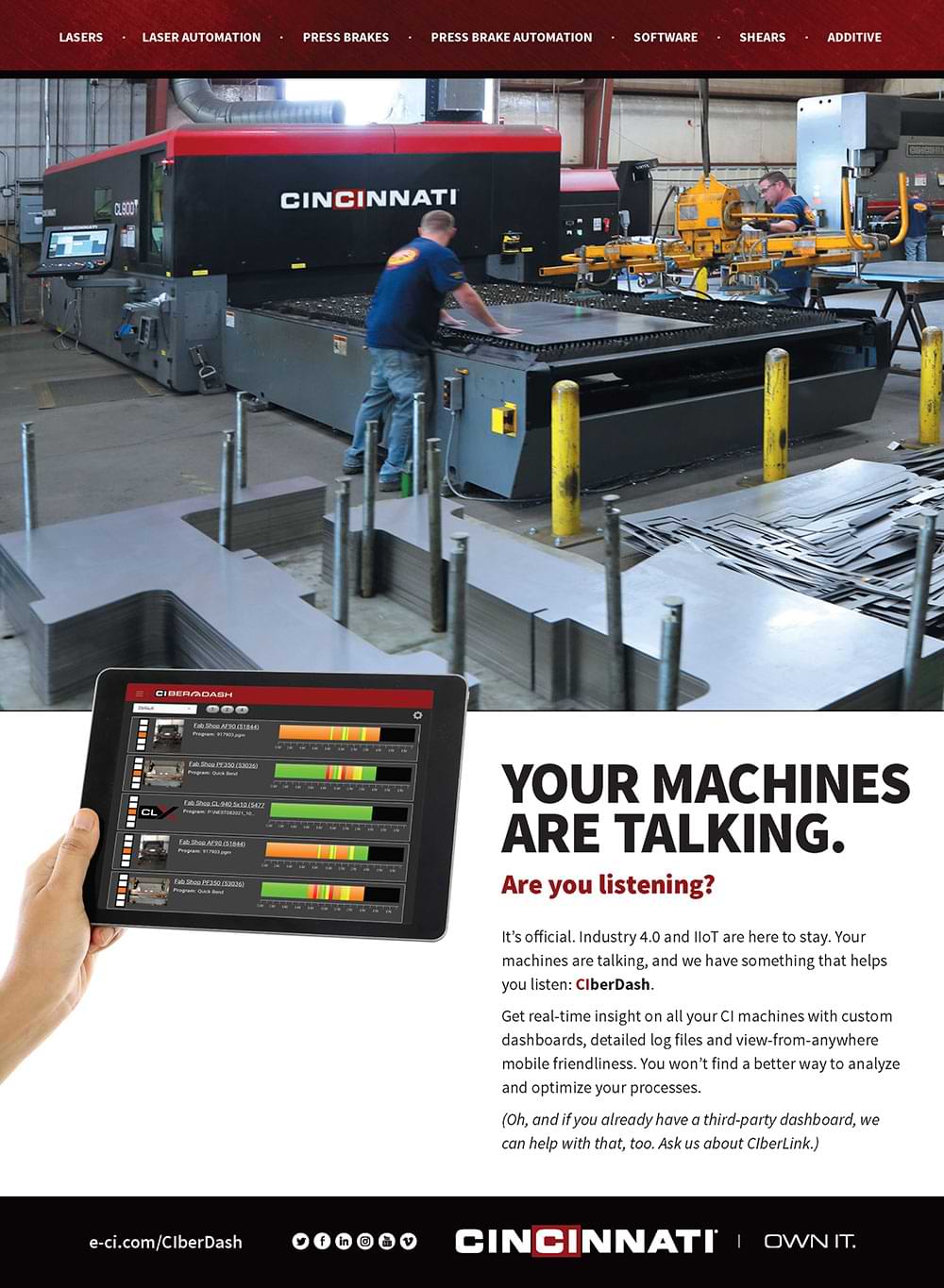

Software Solutions

f someone took a photo of the health of a manufacturing business, would it look like a “before” or “after” photo? In weight-loss advertisements, the before photo typically shows a tired and woefully out of shape person. In the after photo, the person exudes the model of good health—lean, fit and full of energy. In the manufacturing industry, companies without ERP generally resemble the before photo. Transforming an inefficient manufacturing business into a lean “after” version requires the power of ERP. From quote to cash, users can manage everything from one central location in real time.

Global Shop Solutions’ ERP software simplifies manufacturing by providing real-time data visibility.

Sawing

nventory cannot sit idle at Steel and Pipe Supply’s four service centers, which run 13 saws. “Your best money maker is to keep that steel moving,” says Ed Bare, service center manager, Catoosa, Oklahoma. “We need to get the steel on and off the saws quickly. The in- and out-feed step of our cutting process is crucial.”

Steel and Pipe Supply most recently purchased an HE&M WF190 saw that can cut 40-in.-wide steel beams. “We bought the saw from HE&M but decided to have a different manufacturer make the in-feed and out-feeds to save on costs. It turned into a disaster,” says Bare. “We had to shut down cutting operations [on that saw] while HE&M came in and retrofitted it with their feeds. After that, we were immediately up and running.”

Material Handling

Heavy handling

Magswitch’s Telescoping Lifting System adjusts to plate length. The below shows 10 ft. to 40 ft., 24,000-lb. lifting capacity.

One fabricator decides to upgrade its plate moving methods away from cumbersome hooks and chains

t takes careful timing and skill to maneuver steel plate ranging in size from 10 ft. to 70 ft. long. A process of hooks and chains to handle plate created a standing bottleneck for one fabricator specializing in everything from manufacturing boilers to structural steel building components. “We found we were creating the bottleneck when offloading the supply truck, as well as loading and unloading the cutting table,” says Zach Mendenhall, Vancouver facility manager at Greenbery Industrial. Delays as well as worker safety concerns led the manufacturer to Magswitch.

After speaking to Magswitch, Greenbery found that a fail-safe system would be capable of lifting the range of 3/16-in. up to 2-in.-thick plate. “We explored electromagnets and understood there was a concern with dropping the plate when a power failure occurs,” Mendenhall says. “We also looked at vacuum systems but the longevity—or lack of—and maintenance that comes with it was not appealing.”

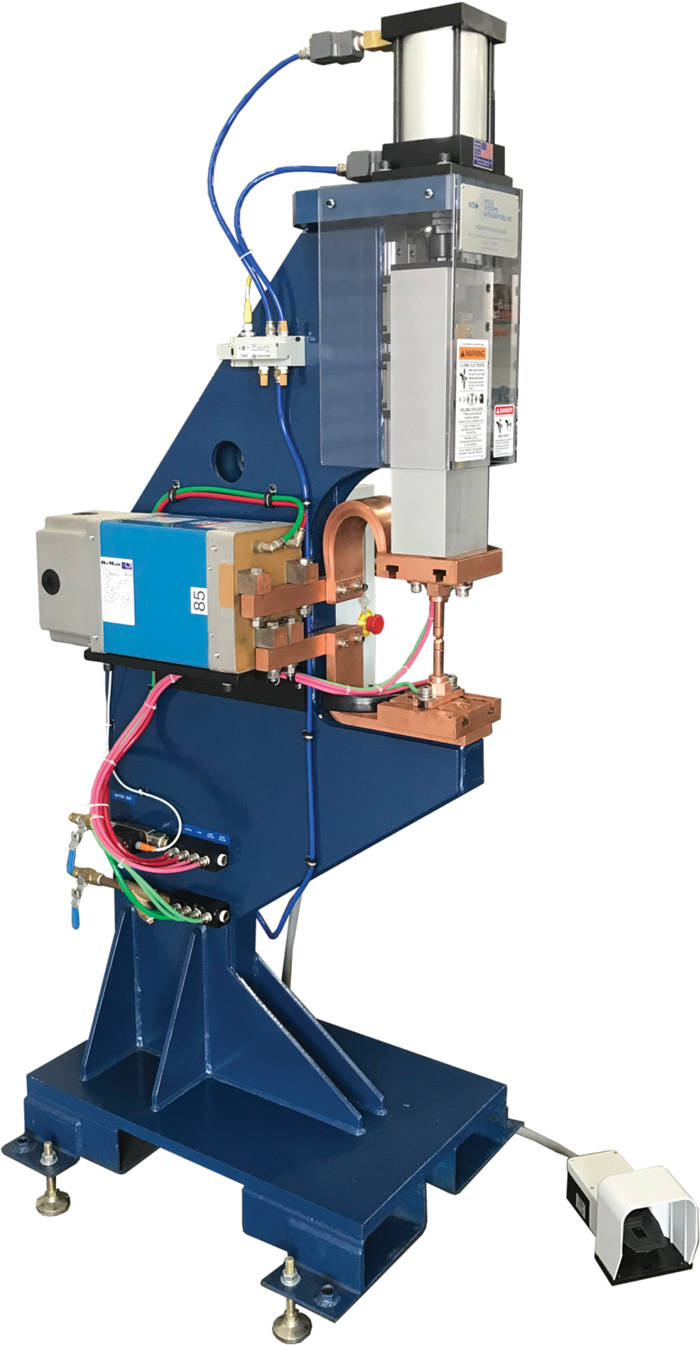

Weld Systems Integrators Inc., Warrensville Heights, Ohio, 844/974-9353, wsiweld.com.

Netherlands-based custom shop Moto Adonis Motorcycles revealed its first EV model with a Harley-Davidson LiveWire, called The Rule Breaker. The customer’s assignment was to build a battery-powered sportbike with LiveWire’s performance. The build began with a conceptual hand-drawn sketch and a digital rendering before the team started the 3D build process using cardboard and tape. Once the lines and angles were complete, the team set out to make new body panels out of hand-formed aluminum. Using traditional methods and tools such as hammers, English wheels and many welds, the bike took shape. For a modern touch, Moto Adonis added several LED lights into the bodywork and seat, which can be operated by the rider’s smartphone. Moto Adonis finished the Harley LiveWire custom by painting it in semi-gloss black, spotlighting the design’s batcycle style, its dynamic look and shielded layers.

Editor-in-Chief

Michael D’Alexander

Lynn Stanley

Gretchen Salois

J. Neiland Pennington

Lauren Duensing

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323

www.ffjournal.net

Carlotta Lacy

Matthew LaFleur

Mark Koenig

Michael D’Alexander

Jim D’Alexander

Wayne Krusen

Traci Fonville

Bill D’Alexander

312/654-2309, Fax: 312/654-2323

mdalexander@ffjournal.net

Alaska, Arizona, Arkansas, California, Hawaii, Idaho, Montana, New Mexico, North Dakota, Oklahoma, Texas, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@ffjournal.net

Alabama, Colorado, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Pennsylvania, South Carolina, South Dakota, Tennessee

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@ffjournal.net

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@ffjournal.net

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Valerie Treiber, National Sales Manager, Metal Service Centers

203/894-5483

valerie@modernmetals.com

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@ffjournal.net

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJOURNAL® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJOURNAL® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.