Steel

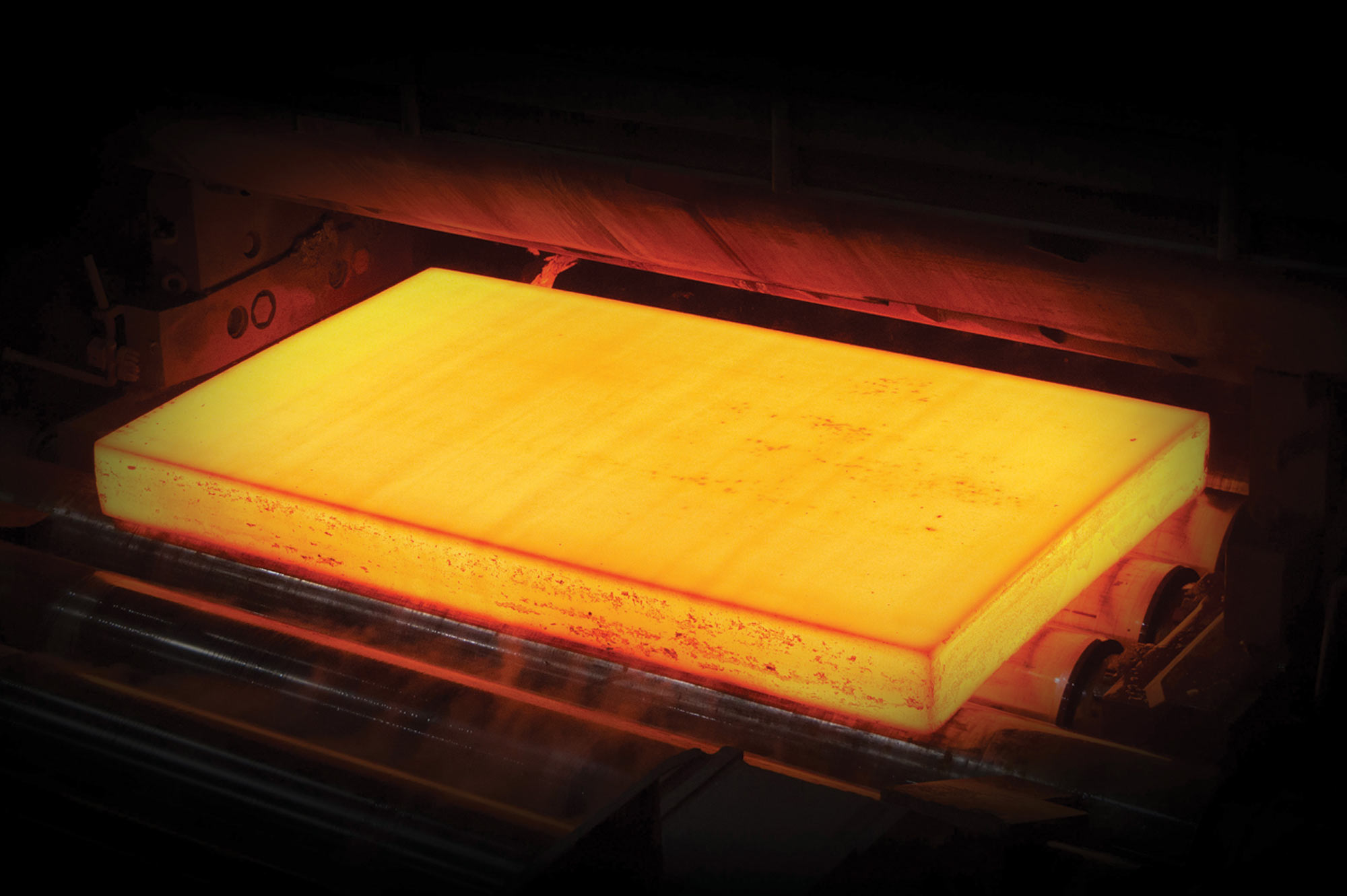

Politics and technology are shaping the way green steel takes hold. The Organization for Economic Cooperation and Development (OECD) Council notes that the “right level of arbitrage between the economic efficiency and the political and social sustainability of climate policies” is essential to maintain fair competition in the steel industry. Approximately 30 percent of steel is traded internationally, so policies that promote a level playing field to ensure that steel companies in one region are not favored over another are critical.

U.S. officials sent the European Union a proposal to end a three-year dispute over imported steel to be discussed on September 29 in Pittsburgh, according to Bloomberg. The object is to restore trade flows with World Trade Organization-compliant rules on trade.

We are extremely happy to welcome Mercedes-Benz as a partner for fossil-free steel products.

We are extremely happy to welcome Mercedes-Benz as a partner for fossil-free steel products.

Other automakers continue to implement innovative measures to cut back on the industry’s carbon footprint, while producing more efficient, lightweight vehicles. Stricter fuel-efficiency standards for new cars and light trucks, as well as a growing focus on electric vehicles by General Motors, Ford and Stellantis, continue. Automakers plan to expand electric vehicle (EV) sales to 40 to 50 percent of U.S. sales by 2030.

Daimler, AG’s Mercedes-Benz, signed a deal with SSAB in September, to ensure it becomes entirely carbon neutral by 2039, according to the company. “We are extremely happy to welcome Mercedes-Benz as a partner for fossil-free steel products. Together, we are building an entirely fossil-free value chain all the way to the end customer,” said Martin Lindqvist, president and CEO of SSAB. “We are proud to reduce global carbon dioxide-emissions in collaboration with our new partner.” General Motors has pledged to be entirely carbon neutral by 2040 and Toyota Motor Corp. by 2050.

INSTALLATION

EDUCATION

RECOGNITION

M&A

ENTERTAINMENT

ESAB provides welding equipment for “Metal Shop Masters”

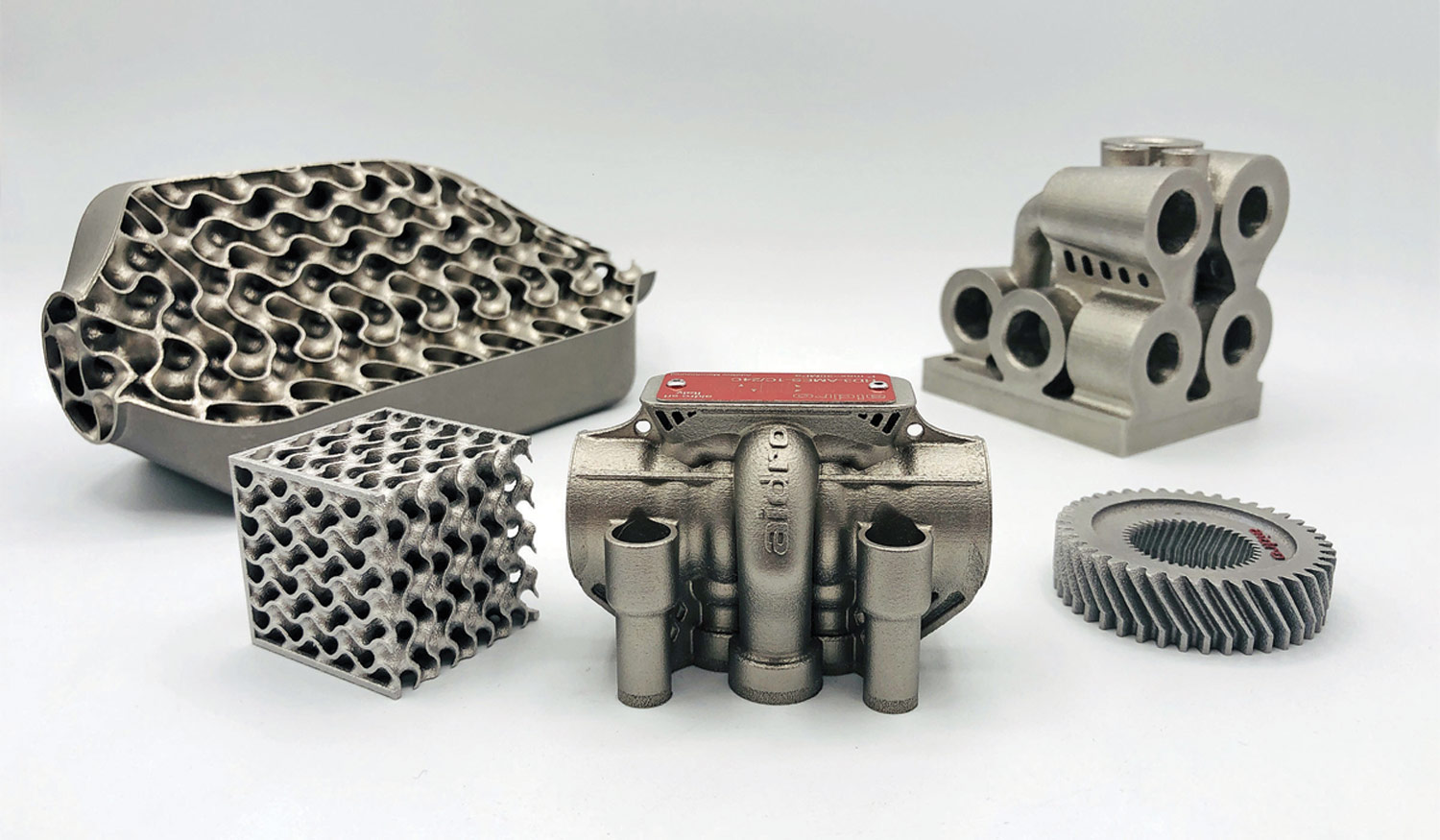

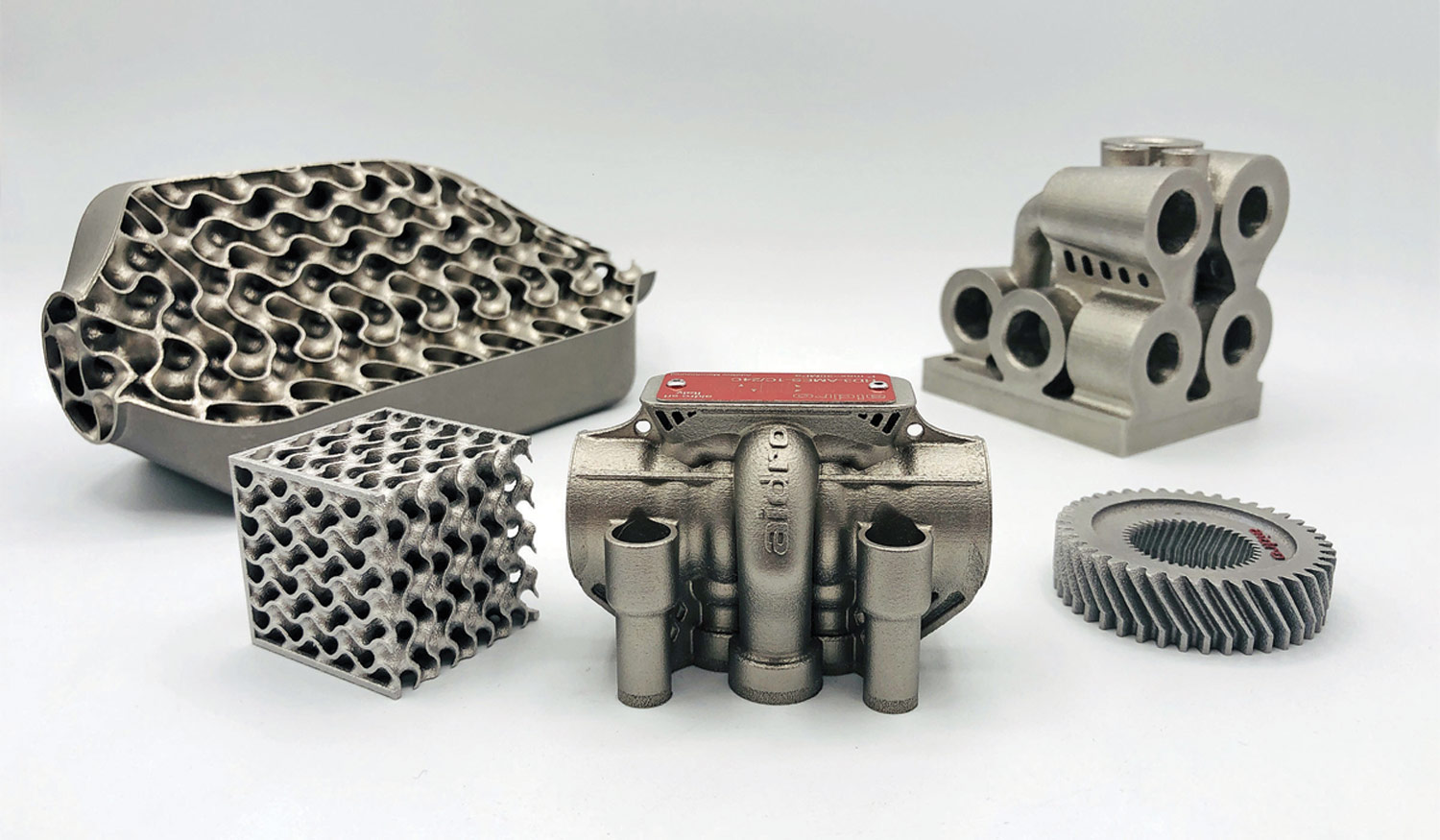

Desktop Metal acquires Aidro

RESOURCES

LVD launches innovation tour