n 1543, Nicolaus Copernicus authored a paradigm shift in planetary motion when he presented his heliocentric theory in which the Earth and other planets rotated around the sun. Albert Einstein created a new paradigm when he moved beyond Newtonian physics, the description of mechanical events, with his theory of relativity and introduction of quantum physics, which is the study of atomic and subatomic particles.

As an exclusive North American distributor for bending rolls, ironworkers and tube punching equipment, Trilogy Machinery Inc. is also looking to change established patterns, in particular with new technology from its SweBend line of bending rolls. “Plate and angle bending rolls are traditionally machines that require an experienced eye,” says Matt Weeks, product manager for Trilogy. “SweBend is finding ways to offer solutions that break that paradigm by providing equipment that can roll perfect parts without the need for skilled operators.”

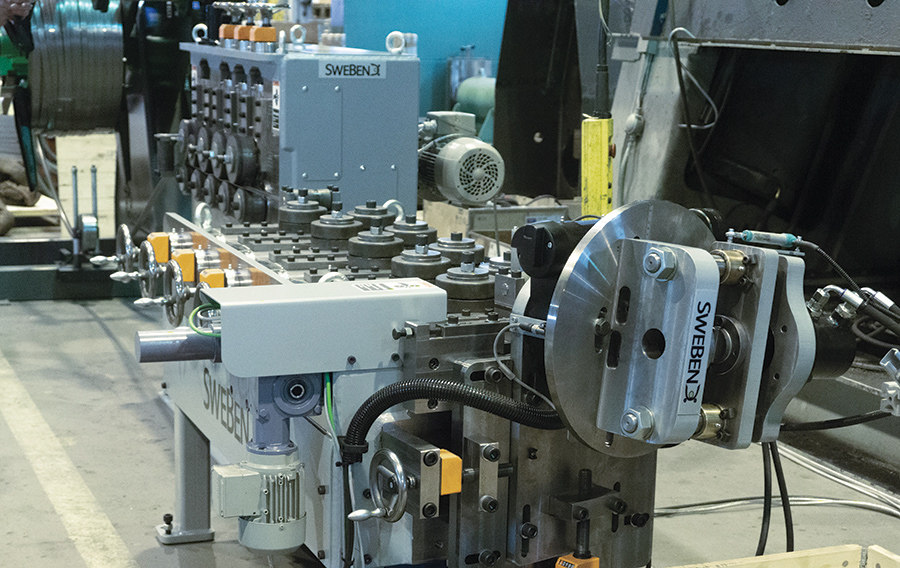

Weeks notes that certain SweBend models: the QF, quick forming 3-roll; PB2W, wedge style 2-roll; and LMB, complete rolling cell machine, have seen an increase in popularity over the last couple years due to several trends.

“Interest in technology that reduces operator skill requirements, while increasing output potential, has been a growing trend in our industry for the last few decades,” Weeks adds. “In 2020, these trends gained even more traction when labor shortages made skilled personnel even harder to find.”

These roll benders require little to no skill to run.

These roll benders require little to no skill to run.

“The specialty rolling machines from SweBend are geared to job shops and OEMs that have high production volume requirements spanning a more finite list of products,” he says. “Our PLC and CNC controls take the guesswork out of rolling. You don’t have quite as much flexibility, but you can make good parts with individuals who don’t have a lot of experience. With most of these systems, you just put your blank in, push the button and make a perfect part.”

This SweBend LMB System can roll and twist flat bar as well as shear to length.

In an industry where roll benders have remained relatively unchanged, “we continue to take steps to equip fabricators and job shops to tackle economic challenges by combining reliable bending machines with an intelligent algorithm-based bending system that is powered by our nearly limitless SEVEN CNC control,” Weeks says.