Features

/customfabricator

/plasma

/stamping

For many job shops it is understanding that automation is a journey, not a destination. You don’t have to immediately jump into expensive full automation. Do take stock of what is out there. Decide where your entry point is and go from there.

From the Editor

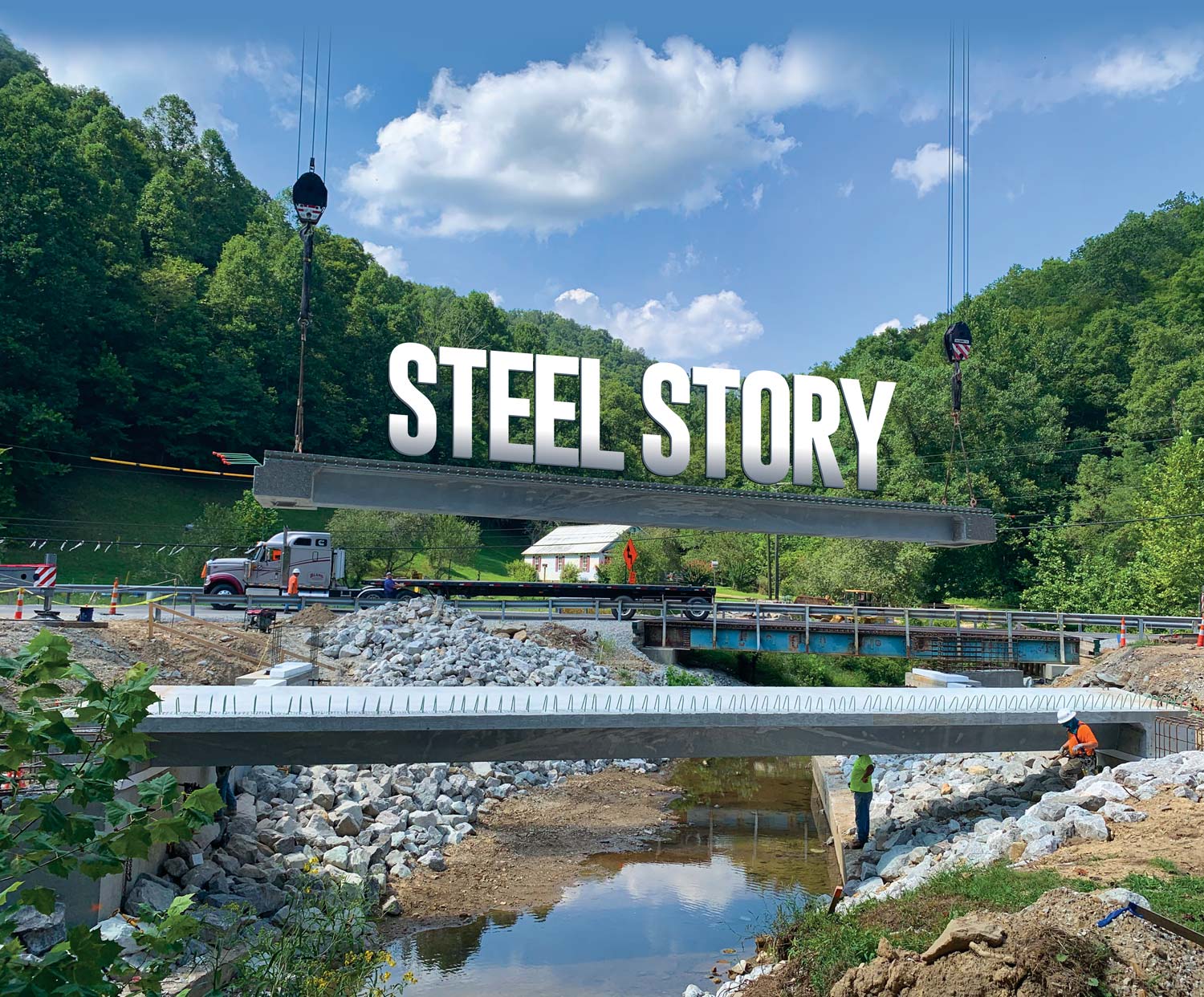

SUSTAINABLE STEEL

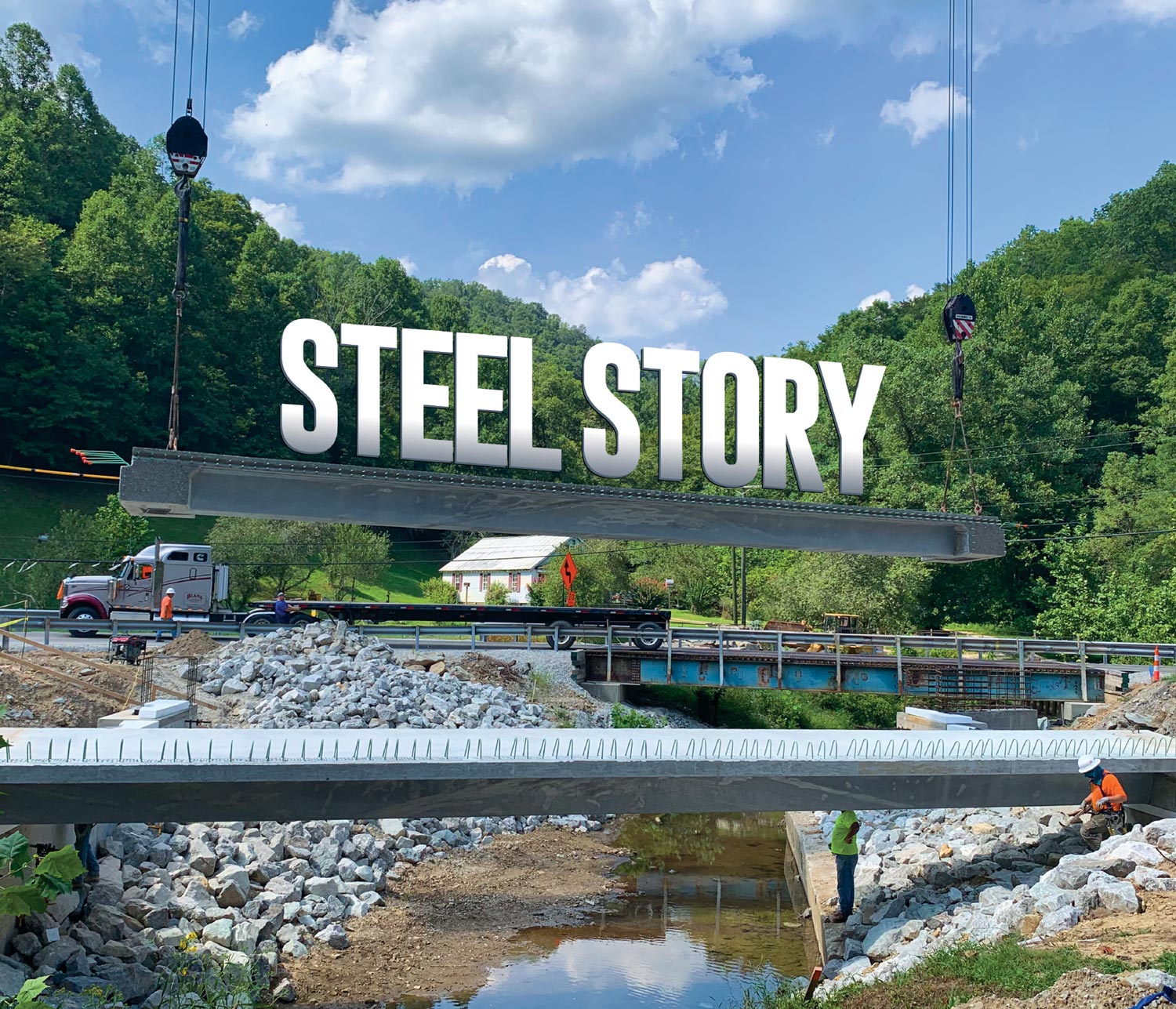

residents George Washington and Thomas Jefferson believed that a trans-Appalachian road was critical to the unification of a fledgling country. Bradford Road, which cut an 820-mile path through Illinois, Indiana, Maryland, Ohio, Pennsylvania and West Virginia, became the first federally funded road in U.S. history. Construction began in 1811 and was completed in 1834. Forty years later, the first major bridge built entirely of steel made its debut. Sporting three arch spans, the Eads Bridge was 6,444 ft. long and spanned the Mississippi River, connecting St. Louis, Missouri, and East St. Louis, Illinois.

The Interstate Highway System was authorized by the Federal-Aid Highway Act of 1956, with most of the system completed by 1990. The American Society of Civil Engineers, the country’s oldest national civil engineering organization, began issuing its quadrennial Infrastructure Report Card in 1998. Since then, marks for America’s framework have hovered at a D until 2021 when the country earned a C-. The bridge category scored a C.

What is driving the movement for carbon-friendly steel products?

The movement has certainly gained traction in recent years. Government commitment to sustainability at both the federal and state level has been a primary driver historically, and this still has an impact today. Investors also are increasingly considering sustainability a requirement, and sustainability drives more customer decisions than ever before. It is worth noting that we do not limit our scope of competition to other steel and tube producers. We consider alternative materials to steel as a significant threat to our business, and many of these are also striving for sustainable solutions. We are paying a lot of attention to this.

he technological advancements of the past couple of decades make it easy to overlook just how reliable weather forecasting has become. I can remember my father laughing at the local weatherman’s predictions on the 5 o’clock news because he was often just flat wrong. Over time, however, weather forecasting has become so precise that a severe storm’s arrival can be predicted almost down to the minute, allowing whole communities to better prepare. If my father were alive, I think he’d say it is pretty spiffy just how accurate weather forecasting is nowadays. What is driving this incredible progress? Machine learning.

ouston-based Steffani Metals has been in business for 40 years. At the start, the company received hand renderings for quotes and orders by phone and fax—items that are all electronic today. One thing that hasn’t changed, though, is the personal attention every customer receives.

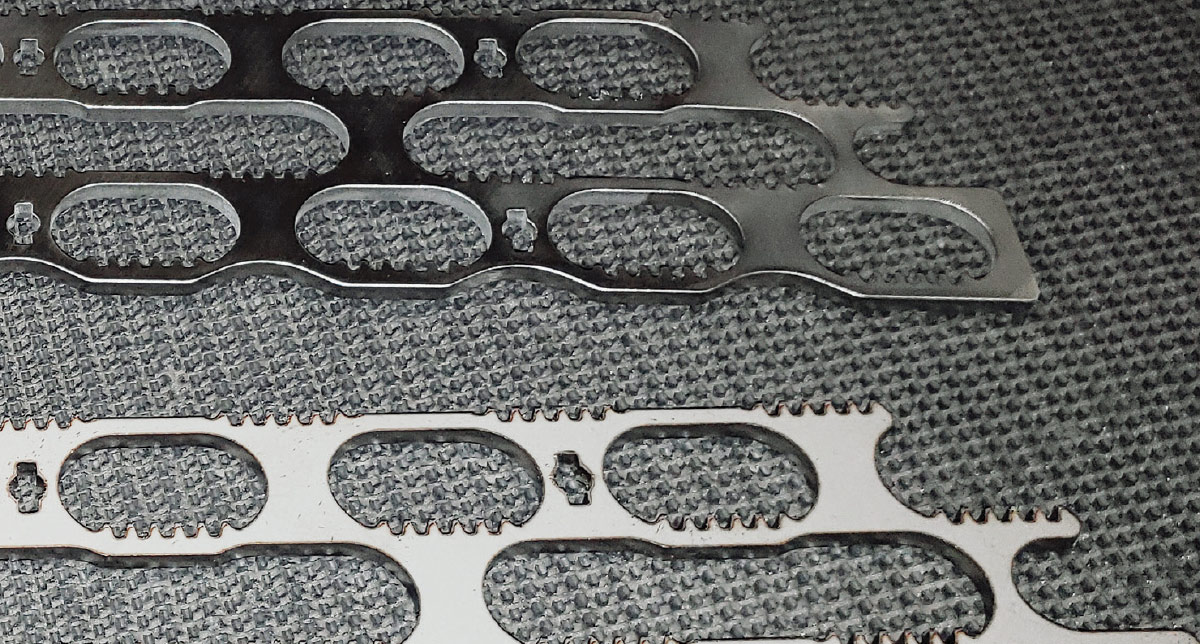

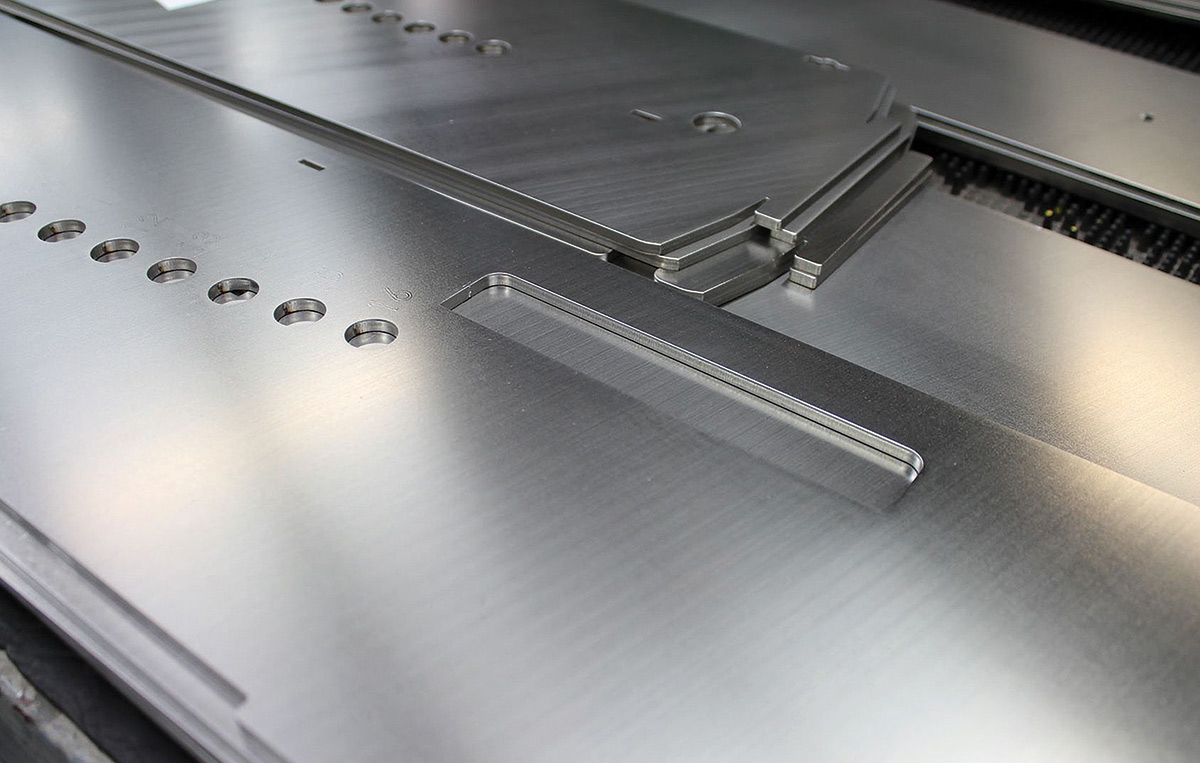

As metal alloys become scarce, raw materials expert helps fabricators evaluate alternatives

The Yonkers, New York, company produces standard and custom precision miniature to small stampings for markets that include automotive OEMs and aftermarket applications, EMI/RFI shielding, telecommunications, power protection, lighting and oil and gas exploration. CEP is using its rapid prototyping and engineering skill sets along with its experience in a broad range of alloys to help customers consider other options.

t took 7.6 million lbs. of steel, 2,000 men and 2,200 days of on-site labor to complete the Golden Gate Bridge in 1937. A $25 million grant from President Franklin Roosevelt’s New Deal program made construction possible for what is still considered an engineering marvel. Annual tolls and fees averaging $145 million help offset the Golden Gate’s yearly $85 million maintenance bill.

he on-demand service economy has grown exponentially over the past 10 years. Today, consumers can quickly and easily order rides, groceries, meals and book vacations through platforms like Uber, Airbnb, Doordash and Instacart. Analysts predict these services will continue to expand in the coming years; the healthcare market jumped on board during the COVID-19 pandemic, and other industries aren’t far behind.

GRG Design fabricates poles on its Model SPC 500 R from HGG Profiling Equipment, integrated with a Hypertherm PowerMax 125-amp plasma system.

ltra-fast fifth-generation cellular networks bring bigger channels, lower latency and the ability to connect more devices at once to accommodate every business and household’s thirst for smart technology. According to JP Morgan Research, 5G adoption reached one-third of global smartphone volumes in the fourth quarter of 2020, helped along by the launch of the 5G iPhone and is expected to reach 1 billion subscribers faster than the approximately two years it took for 4G.

And 5G’s potential growth doesn’t stop at the consumer level. JP Morgan analysts assert that the biggest opportunity for the technology is in enterprise-use cases, such as factory-floor automation and fixed wireless.

killed labor shortages, material quality issues and equipment availability are just some of the problems Dave Bishop sees fabricators wrestling with these days. Wila USA’s business development manager covers the 11 contiguous Western States.

Wila’s customers pose this one question more than any other: How do I find qualified press brake operators? According to the U.S. Labor Department’s labor turnover report, the number of people quitting their jobs hit a record high of 4.5 million in November 2021. Economists have dubbed the mass exodus The Great Resignation. Bishop points to a couple contributing factors.

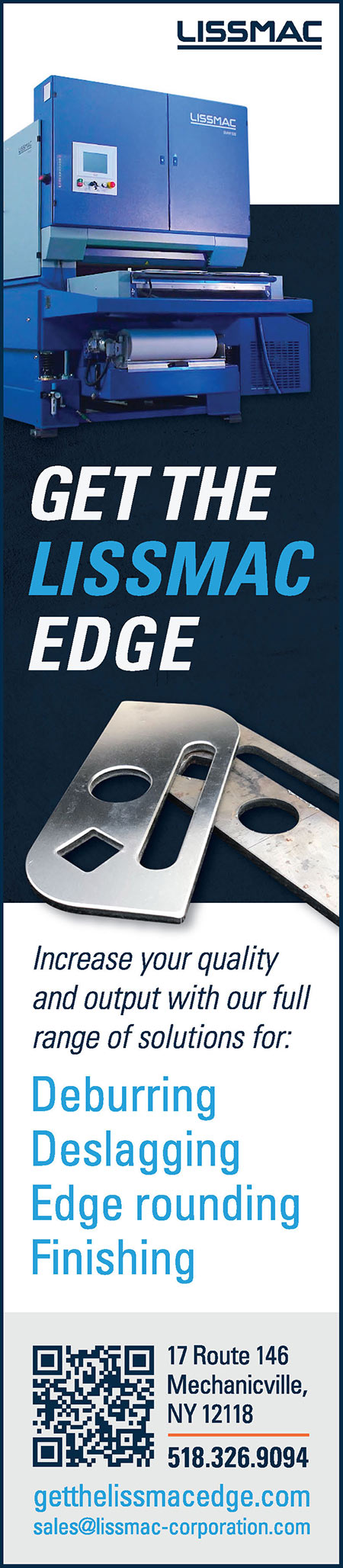

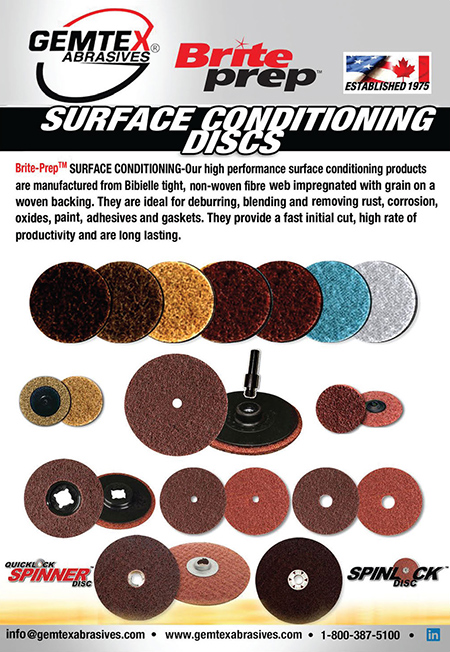

Deburring/Finishing

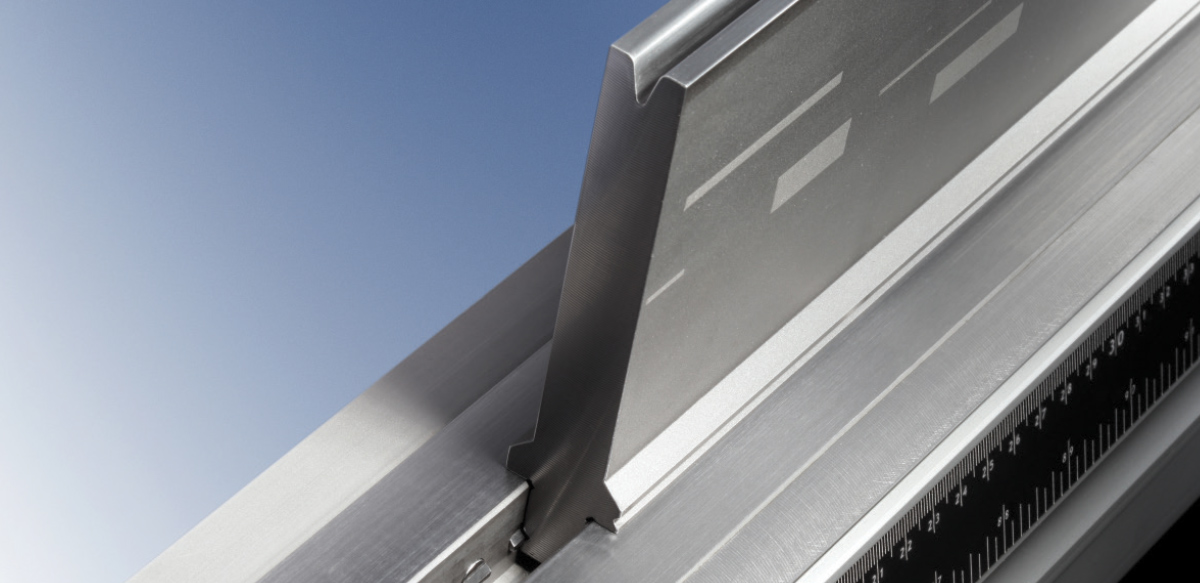

Machine for deburring and edge rounding processes sheet metal parts in a single pass

o manufacturer wants to ship laser-cut, punched or waterjet machined parts with sharp edges, vertical burrs or both. The primary reason for rounding edges or removing burrs is for safety and handling, according to Tim Corley. He is director of sales—metal processing for Mechanicville, New York-headquartered Lissmac Corp.

Hypertherm Inc., Hanover, New Hampshire, 800/737-2978, hypertherm.com.

Convergence, a project by the JANNY SABIN STUDIO, celebrates the thriving, vibrant and rich heritage of excellence at the University of Nebraska Medical Center, Omaha, through materialized concepts that embed change, transformation and contemplation. The project integrates advanced methods and innovations in digital and robotic fabrication with timeless and contextually sensitive materials. The project features stainless steel wire arc additive manufacturing through robotic 3D printing, CNC polycarbonate panels laminated with wavelength dependent dichroic film, and stainless steel rings. The design for Convergence incorporates part-to-whole 3D printed and machined component strategies to realize a work that celebrates lightness, dynamic structure and equilibrium through equal and opposite forces. Taking inspiration from the medical center’s role in global health through its response and leadership in both the Ebola epidemic and now the coronavirus pandemic, Convergence celebrates people coming together from around the world.

Convergence, a project by the JANNY SABIN STUDIO, celebrates the thriving, vibrant and rich heritage of excellence at the University of Nebraska Medical Center, Omaha, through materialized concepts that embed change, transformation and contemplation. The project integrates advanced methods and innovations in digital and robotic fabrication with timeless and contextually sensitive materials. The project features stainless steel wire arc additive manufacturing through robotic 3D printing, CNC polycarbonate panels laminated with wavelength dependent dichroic film, and stainless steel rings. The design for Convergence incorporates part-to-whole 3D printed and machined component strategies to realize a work that celebrates lightness, dynamic structure and equilibrium through equal and opposite forces. Taking inspiration from the medical center’s role in global health through its response and leadership in both the Ebola epidemic and now the coronavirus pandemic, Convergence celebrates people coming together from around the world.

Editor-in-Chief

Michael D’Alexander

Lynn Stanley

J. Neiland Pennington

Lauren Duensing

Alan Richter

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323

www.ffjournal.net

Carlotta Lacy

Matthew LaFleur

Mark Koenig

Michael D’Alexander

Jim D’Alexander

Wayne Krusen

Traci Fonville

Bill D’Alexander

312/654-2309, Fax: 312/654-2323

mdalexander@ffjournal.net

Alaska, Arizona, Arkansas, California, Colorado, Hawaii, Idaho, Montana, New Mexico, North Dakota, Oklahoma, Texas, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@ffjournal.net

Alabama, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Pennsylvania, South Carolina, South Dakota, Tennessee

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@ffjournal.net

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@ffjournal.net

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Valerie Treiber, National Sales Manager

203/894-5483

valerie@modernmetals.com

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@ffjournal.net

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to: Omeda – FFJournal – 4 Overlook Pt., Ste. A25E, Lincolnshire, IL 60069. Printed in the USA.

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to: Omeda – FFJournal – 4 Overlook Pt., Ste. A25E, Lincolnshire, IL 60069. Printed in the USA.