Deburring/Finishing

Machine for deburring and edge rounding processes sheet metal parts in a single pass

o manufacturer wants to ship laser-cut, punched or waterjet machined parts with sharp edges, vertical burrs or both. The primary reason for rounding edges or removing burrs is for safety and handling, according to Tim Corley. He is director of sales—metal processing for Mechanicville, New York-headquartered Lissmac Corp.

Industries such as food processing, telecommunications, medical, transportation and agricultural equipment are likely to want parts that are deburred and whose edges are rounded. For example, if an assembly line worker at a manufacturer of food processing or packaging equipment got a laceration from a sharp bracket, it could shut down the entire line for hours. Only after the area was cleaned and sanitized could the line be started again.

In addition, telecommunications equipment can have metal brackets or shelves that hold cables and wires. Frequently, there are holes in those components that wires or cables must go through. If the edges on those holes are sharp, it may cut or tear a wire or cable, which could cause a spark or short circuit and block transmission.

Lissmac also serves customers that manufacture medical research equipment. With millions of dollars invested in laboratory animals, manufacturers of lab equipment, such as metal cages, must produce parts with rounded edges. The rounded edges help prevent the caged animals from cutting themselves.

Edge quality also impacts parts that are painted. Corley says a properly rounded edge provides more surface area for the powder coat to stick to than a sharp edge. “That sharp edge will not have much paint adhere to it and is prone to rust prematurely,” especially in a salty, humid or otherwise harsh environment.

There is no hole that I’ve seen that couldn’t be rounded on the edge.

There is no hole that I’ve seen that couldn’t be rounded on the edge.

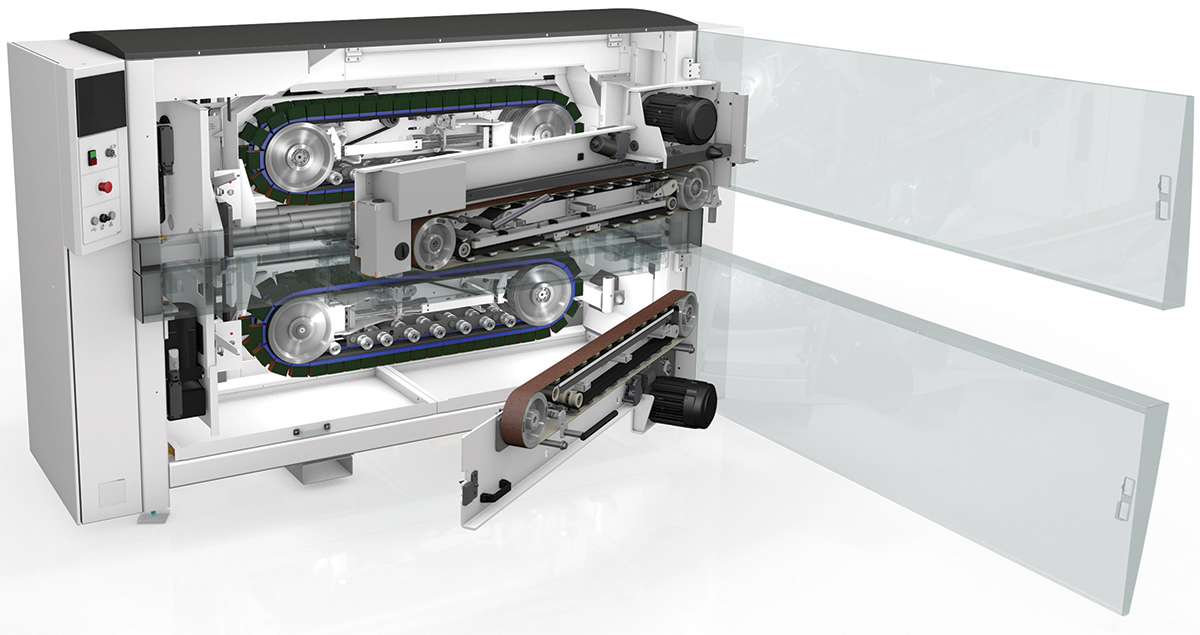

According to the company, the machine deburrs and rounds the interior and exterior contours of flat parts that measure from 6-in. long by 2-in. wide up to the full table width, which is either 1,500 mm (59 in.) or 2,000 mm (79 in.), depending on the model. It is suitable for processing parts from 0.0196-in. to 2-in. thick.

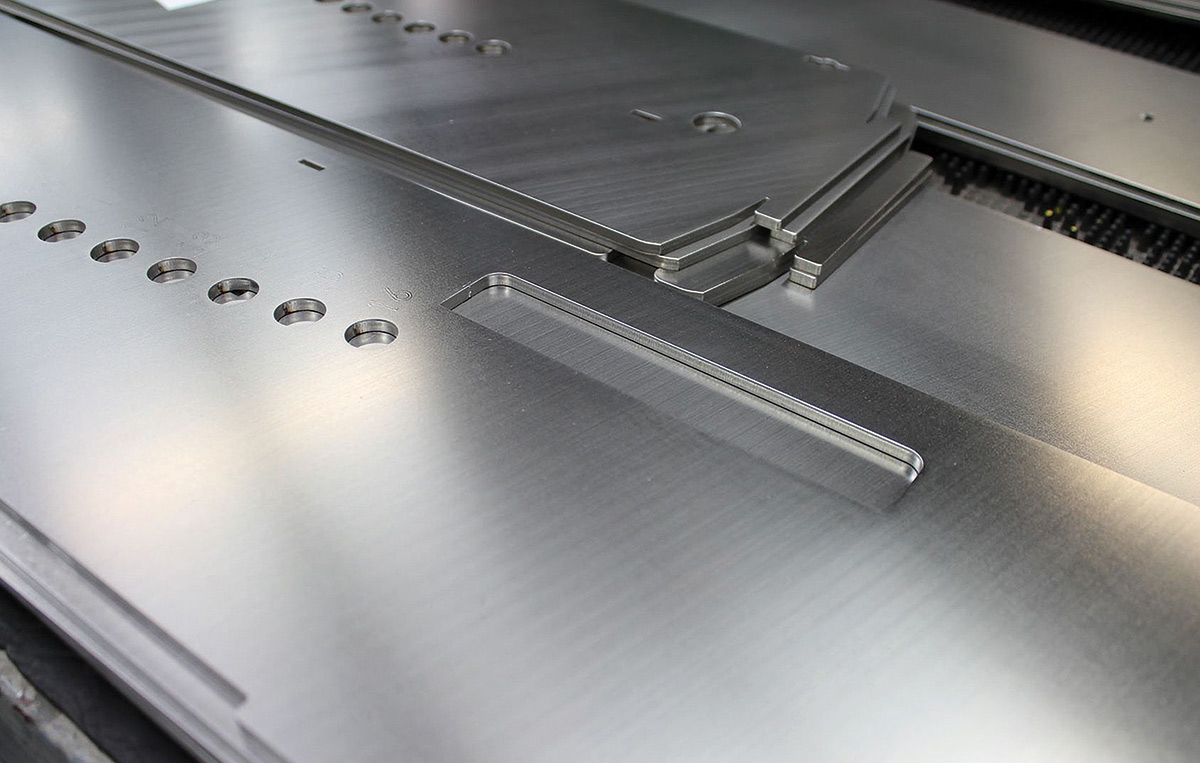

As the grinding belts and sand blocks contact the workpiece, they drop into any holes or other cutout part features of varying sizes and perform the finishing operations, Corley says. “There is no hole that I’ve seen that couldn’t be rounded on the [interior] edge. We have been able to round the edges of a very small punched hole.”

The machine design is primarily intended for edge rounding, not grain surface finishing, he adds. As a result, end users can run parts that have a No. 4 finish with a polyvinyl chloride coating through the machine and the PVC laser film will not be removed during processing.

In contrast, vertical burrs on waterjet cut parts are smaller than the ones on laser cut parts, and the edges are typically quite straight and sharp, he adds. “Some companies don’t mind that. Other companies want that to be rounded, and we can do that with our machine.”

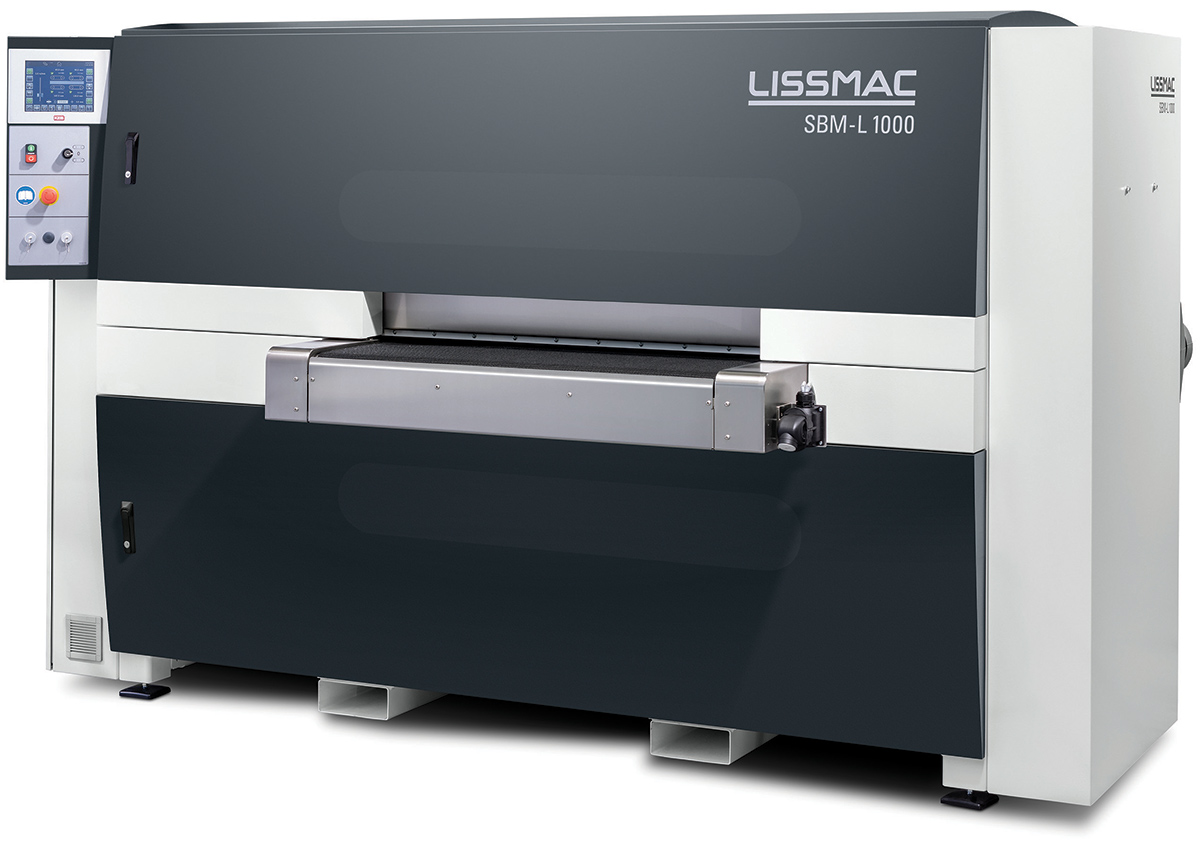

The Lissmac SBM-L G1S2 machine provides simultaneous deburring and edge rounding of interior and exterior contours.

When dealing with the metal particles from deburring and grinding carbon and stainless steel parts, a dry dust collector is needed. “If you process aluminum or a mix of parts, we would suggest a wet dust collector,” Corley says.

Those end users typically connect one table to the front or the back of the machine, but some add two tables to stage parts. “If it’s a one-person operation, then the person can load some parts on it and walk to the back of the machine, or a company can have two people operating it and one is constantly loading parts and the person on the back is constantly removing parts.”

Another option for a one-person operation is to install a conveyor that transfers finished parts 180 degrees from the back to near the front of the machine, Corley notes.

Similar to many other types of machine tools, a robot is an option for loading and unloading parts. As the U.S. labor shortage continues, Corley says Lissmac is receiving more inquiries from customers about automated part loading and unloading.

To enhance finishing consistency and extend the life of the sand block belts, Corley says Lissmac recently added the photo eye feature to the machine. The photo eye reads the top of a belt to determine how much it has worn, and the machine control adjusts the amount of pressure belts exert on the workpiece to maintain consistent edge rounding without operator intervention.

“These sand blocks can go 300 to 500 hours before having to change them, depending on how much pressure you put on them for edge rounding,” he says.

With the SBM-L G1S2 machine for grinding, deburring and edge rounding sheet metal parts on both sides in a single pass, Lissmac reports that manufacturers can reduce processing time by up to 60 percent while producing components that feature the “Lissmac edge.”