folding

Features

/customfabricator

/deburring

/laser

From the Editor

What’s Your Story?

f you look up the word “story,” it’s defined as an account of past events in someone’s life or in the evolution of something. When the World Wide Web was launched to the public in 1991, social networking services, video-sharing websites and apps followed at a dizzying pace. These electronic outlets made it possible for anyone with a computer, phone or tablet to “tell” their stories in real time.

But the art of storytelling goes far beyond that of a digital footprint. Visual storytelling can be traced to the Chauvet cave paintings, dated 30,000 BC. The first Biblical stories were passed down orally. The first photograph was followed by mass media outlets established for newspapers and magazines. Digital storytelling actually began in 1939 with the first network television broadcast.

with machines

antek Systems Inc. provides CAD, CAM, MES and ERP software solutions for the sheet metal and structural steel industry. Anupam Chakrabory, commercial director, talks with FFJournal about optimizing manufacturing processes with cloud-based technologies, AI and machine learning.

What are some current innovations in the digitization of business processes at metals companies?

Traditionally, there has been a gap between processes—estimation, engineering and fabrication. This gap was the result of the inability to access machine data in real time, and it often led to lower visibility of key performance indicators (KPIs) to management.

Abrasive Process Solutions Group, Norton | Saint-Gobain Abrasives

reater demands are being put on North American manufacturers to deliver high-quality products faster, all while facing skilled labor shortages. It is easy to see how proving out the most efficient abrasive process solutions, and in many cases automating them, is critical for success.

For over 130 years, Norton | Saint-Gobain Abrasives has worked collaboratively with its customers to solve tough grinding challenges. A recent extension of the Norton application engineering group is a new program called Norton Abrasive Process Solutions (APS). The APS team provides abrasive process development, optimization, automation and in-house testing. APS services could involve research and testing of new abrasives to improve quality or throughput, or it could be trying an entirely new and customized process for customers.

Industry News

Machinery builder celebrates 50 years of innovation in the United States

Based in High Point, North Carolina, the CTC is located on the same campus as the 197,000-sq.-ft. Carolina Manufacturing Center that produces AMADA’s newest line of press brakes—the HRB Series. Both facilities were built to support U.S. fabricators. Since opening in October 2020, AMADA’s technical staff welcomes visitors for one-on-one machine demonstrations and technical events.

n Madeline L’Engle’s 1962 novel “A Wrinkle In Time,” 13-year-old Meg Murry and her brother, 5-year-old child prodigy Charles Wallace, must attempt time travel with a tesseract. Their father, a physicist for a top-secret government agency, is missing. Charles Wallace explains that “tessering” is travel in the fifth dimension. Length, width and depth—elements of physical space—comprise three dimensions. The fourth dimension is Einstein’s concept of time. Tessering connects two distant points—a wrinkling of space and time—a series of shortcuts to reach faraway locations in a matter of seconds.

Like the tesseract, the hybrid metal art that springs from the imagination of sculptor John Lopez occupies a dimension of its own and has the power to instantly transport people to distant places, events and moments in history. His materials are a conglomeration of small cast bronze figures; scrap metal gleaned from discarded farm equipment; old tools; reclaimed relics and memorabilia. Lopez welds, plasma cuts, chop saws and hand forms seemingly unrelated pieces to a frame he builds from steel tubing. The larger-than-life animals and cowboys that emerge possess a kinetic energy that has captured the attention of people across the globe.

Welded from parts of early tractors, Black Hawk is a tribute to the draft horse that carried the weight of progress on its shoulders and an artistic expression of the history of agriculture.

n Madeline L’Engle’s 1962 novel “A Wrinkle In Time,” 13-year-old Meg Murry and her brother, 5-year-old child prodigy Charles Wallace, must attempt time travel with a tesseract. Their father, a physicist for a top-secret government agency, is missing. Charles Wallace explains that “tessering” is travel in the fifth dimension. Length, width and depth—elements of physical space—comprise three dimensions. The fourth dimension is Einstein’s concept of time. Tessering connects two distant points—a wrinkling of space and time—a series of shortcuts to reach faraway locations in a matter of seconds.

Like the tesseract, the hybrid metal art that springs from the imagination of sculptor John Lopez occupies a dimension of its own and has the power to instantly transport people to distant places, events and moments in history. His materials are a conglomeration of small cast bronze figures; scrap metal gleaned from discarded farm equipment; old tools; reclaimed relics and memorabilia. Lopez welds, plasma cuts, chop saws and hand forms seemingly unrelated pieces to a frame he builds from steel tubing. The larger-than-life animals and cowboys that emerge possess a kinetic energy that has captured the attention of people across the globe.

n the motion picture industry, a fixer provides a film crew with logistical support from permits, locations and equipment to transportation. In the steel industry, Dave Schott, regional fabrication manager for Kloeckner Metals York, is also a “fixer” who says he does “a little bit of everything.” The Kloeckner Metals Corp. Pennsylvania-based branch supplies and processes ferrous and nonferrous products. The service center also provides warehousing, logistics and materials management services.

The SafanDarley 200-ton, 13-ft. E-Brake can process 3/16-in.-thick sheet up to ½-in.-thick plate. Its O-frame design minimizes deformation.

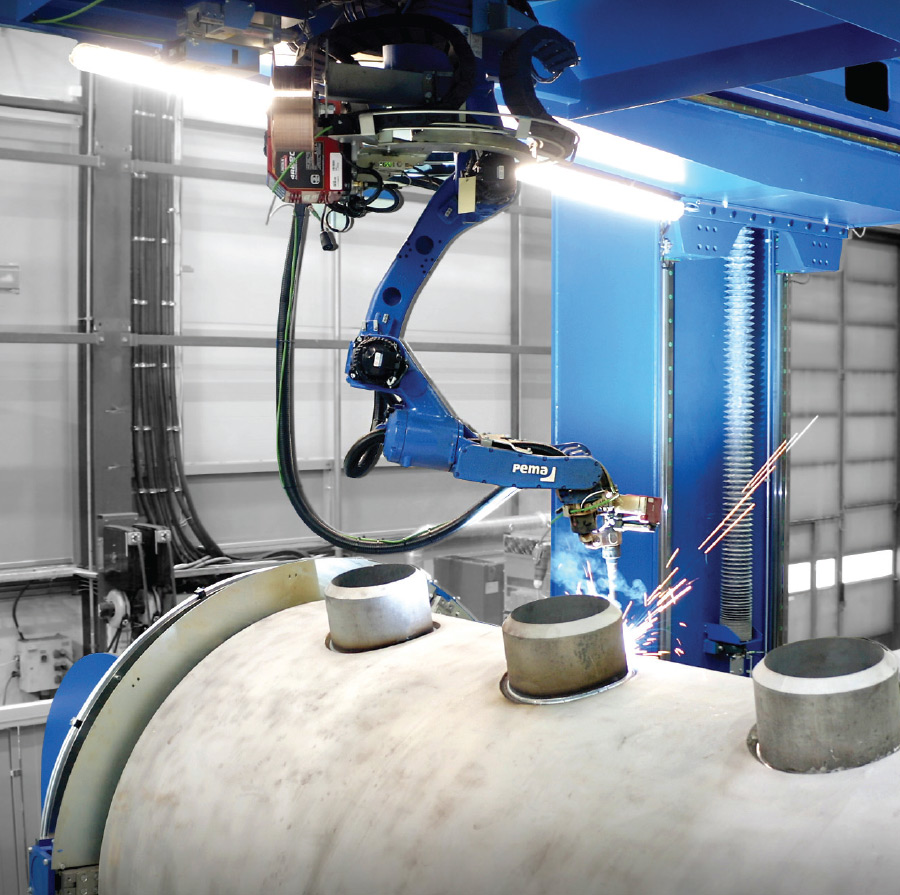

The PEMA WeldControl 300 product family is designed to save hours during automated welding processes via its three modules: OFFLINE, CREATE and SCAN.

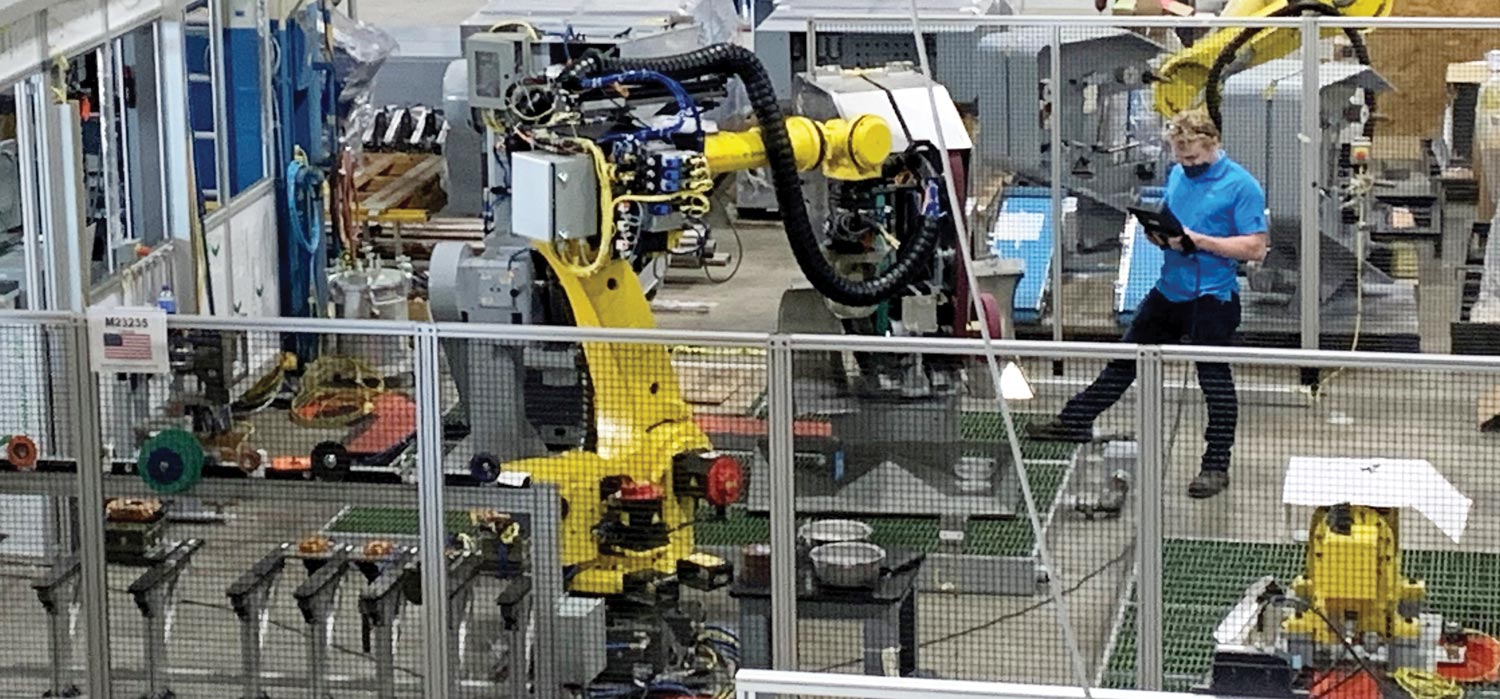

bout 314,000 new welding professionals will be needed by 2024, and an average of 78,500 welding jobs will need to be filled annually over the next two years, according to an American Welding Society report. “The shortage of welders is a global challenge that can be solved in part with robotics,” says Michael Bell, director of sales for Pemamek LLC. The family-owned company designs and manufactures automated welding and production solutions for industries that range from shipbuilding, power generation and wind energy to process equipment and general fabrication.

The GIGAbend’s automatic tool clamping system enables quick tool setups, such as for this segmented upper beam tool.

Metal products manufacturer boosts throughput with folding machines

n 1998, a few years after starting at Tiffin Metal Products Co. as a general laborer, Kenny Bauman, now plant manager, was tasked with helping the manufacturer find a metal bending and forming system that reduces setup times.

He says he was chosen for the job because “they wanted somebody fresh, young and eager to learn.”

The Tiffin, Ohio-based company produces chutes and other components for material handling equipment, lockers for police and fire departments, and custom products. In addition to forming with press brakes, panel benders and folding equipment, Tiffin Metal Products performs cutting, punching, welding, fastening, powder coating and assembly.

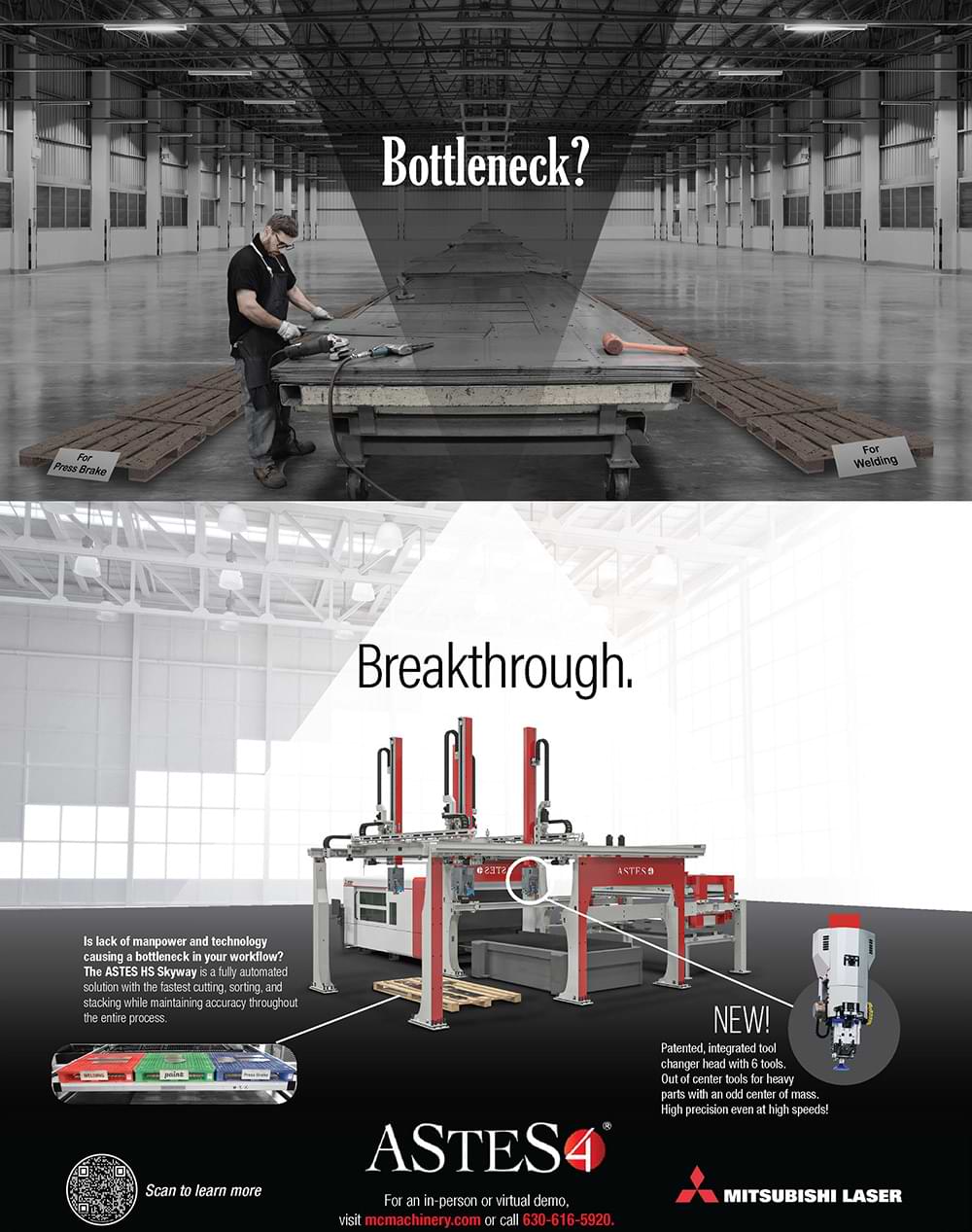

ressure equals productivity. When abrasive waterjet cutting, the higher the water pressure, the more productive the machining operation is, according to Tim Fabian, vice president of marketing and product management at Flow Waterjet.

Although some machine tool builders still offer 40,000-psi waterjets, Fabian says ultra-high pressure generally starts at 55,000 to 60,000 psi, the range of most waterjet pumps. With Flow’s envelope-pushing HyperPressure technology, ultra-high pressure waterjetting extends well past 75,000 psi.

eld grinding is the removal of excess stock from welds. It’s a process that can produce variable results and impart high stress on employees’ bodies from both the vibration and awkward body positioning, such as outstretched arms.

Automating the grinding process traditionally has been difficult; however, Lincoln Electric and 3M have teamed up, combining robotic integration and abrasives expertise to create the Fab-Pak OmniClean system—an all-in-one robotic grinding cell that is pre-engineered to automate and optimize pre- and post-weld applications and has a single base design for easy installation and setup.

Weldcote, Kings Mountain, North Carolina, 704/739-4115, weldcotemetals.com.

With Mirri, Australian artist Reko Rennie’s work references traditional indigenous culture in his signature use of bold geometric patterns and vivid colors. At more than 6.5 meters tall, the sculpture features a contemporary representation of indigenous icons—a shield and two boomerangs with their center points touching. The palette of neon pink and black in geometric patterning creates a striking contrast to the natural surroundings, provoking discussion about contemporary indigenous culture and identity. Mirri was fabricated in laser cut aluminum sheet, finished by hand using a 2-pack vehicle wet spray, and is located in Point Leo Estate Sculpture Park on Victoria’s Mornington Peninsula, south of Melbourne, Australia.

Editor-in-Chief

Michael D’Alexander

Lynn Stanley

J. Neiland Pennington

Lauren Duensing

Alan Richter

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323

www.ffjournal.net

Carlotta Lacy

Matthew LaFleur

Mark Koenig

Michael D’Alexander

Jim D’Alexander

Wayne Krusen

Traci Fonville

Bill D’Alexander

312/654-2309, Fax: 312/654-2323

mdalexander@ffjournal.net

Alaska, Arizona, Arkansas, California, Colorado, Hawaii, Idaho, Montana, New Mexico, North Dakota, Oklahoma, Texas, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@ffjournal.net

Alabama, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Pennsylvania, South Carolina, South Dakota, Tennessee

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@ffjournal.net

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@ffjournal.net

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Valerie Treiber, National Sales Manager

203/894-5483

valerie@modernmetals.com

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@ffjournal.net

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to: Omeda – FFJournal – 4 Overlook Pt., Ste. A25E, Lincolnshire, IL 60069. Printed in the USA.

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to: Omeda – FFJournal – 4 Overlook Pt., Ste. A25E, Lincolnshire, IL 60069. Printed in the USA.