Industry News

Machinery builder celebrates 50 years of innovation in the United States

Based in High Point, North Carolina, the CTC is located on the same campus as the 197,000-sq.-ft. Carolina Manufacturing Center that produces AMADA’s newest line of press brakes—the HRB Series. Both facilities were built to support U.S. fabricators. Since opening in October 2020, AMADA’s technical staff welcomes visitors for one-on-one machine demonstrations and technical events.

AMADA’s growing network of U.S. manufacturing sites has established the company as a leading American manufacturer of sheet metal fabrication equipment. In California, a full line of 3kW to 12kW laser cutting systems and modular automation systems are built at the Brea Manufacturing Center. Tooling for the high-performance HRB Series is manufactured at AMADA TOOL AMERICA INC. in Batavia, New York. Coast-to-coast manufacturing capabilities give American fabricators advantages like expedited delivery of AMADA’s machine tool solutions.

Coast-to-coast manufacturing capabilities give fabricators advantages like expedited delivery of machine tool solutions.

Coast-to-coast manufacturing capabilities give fabricators advantages like expedited delivery of machine tool solutions.

Attendees at the 50th anniversary celebration participated in a variety of events, including facilities and factory tours. The CTC’s 24,000-sq.-ft. Verification Floor showcases the latest AMADA machines and automated systems. As a result, guests viewed equipment demonstrations. Attendees also toured the AMADA Press Brake Academy, established to address the need for experienced press brake operators. In addition to training, the 43-acre campus provides manufacturing, service and a state-of-the-art Technical Center all at one location. The event was meant to provide proof that AMADA is committed to support North American fabricators.

Founded in 1971 as a research and development company, AMADA AMERICA INC., plans to continually design and develop machine tool solutions and automated systems to maximize its customers’ productivity.

Reibus secures funding

Vorteq completes buyout

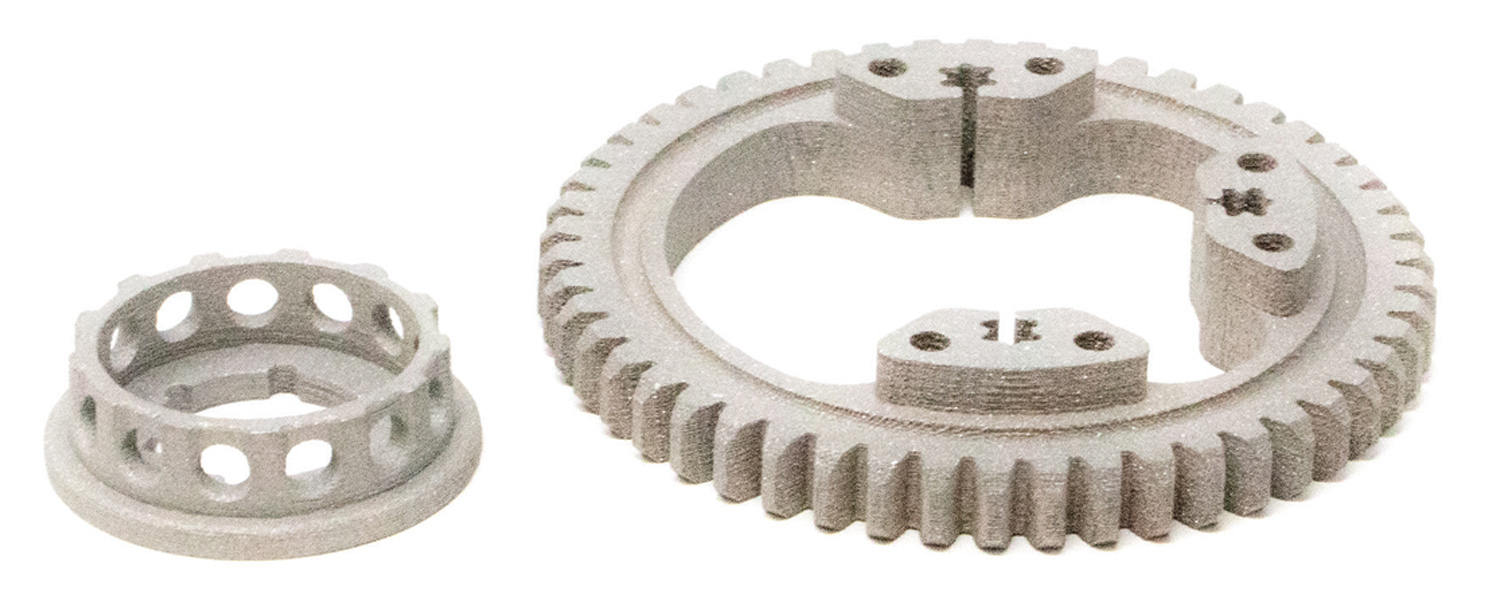

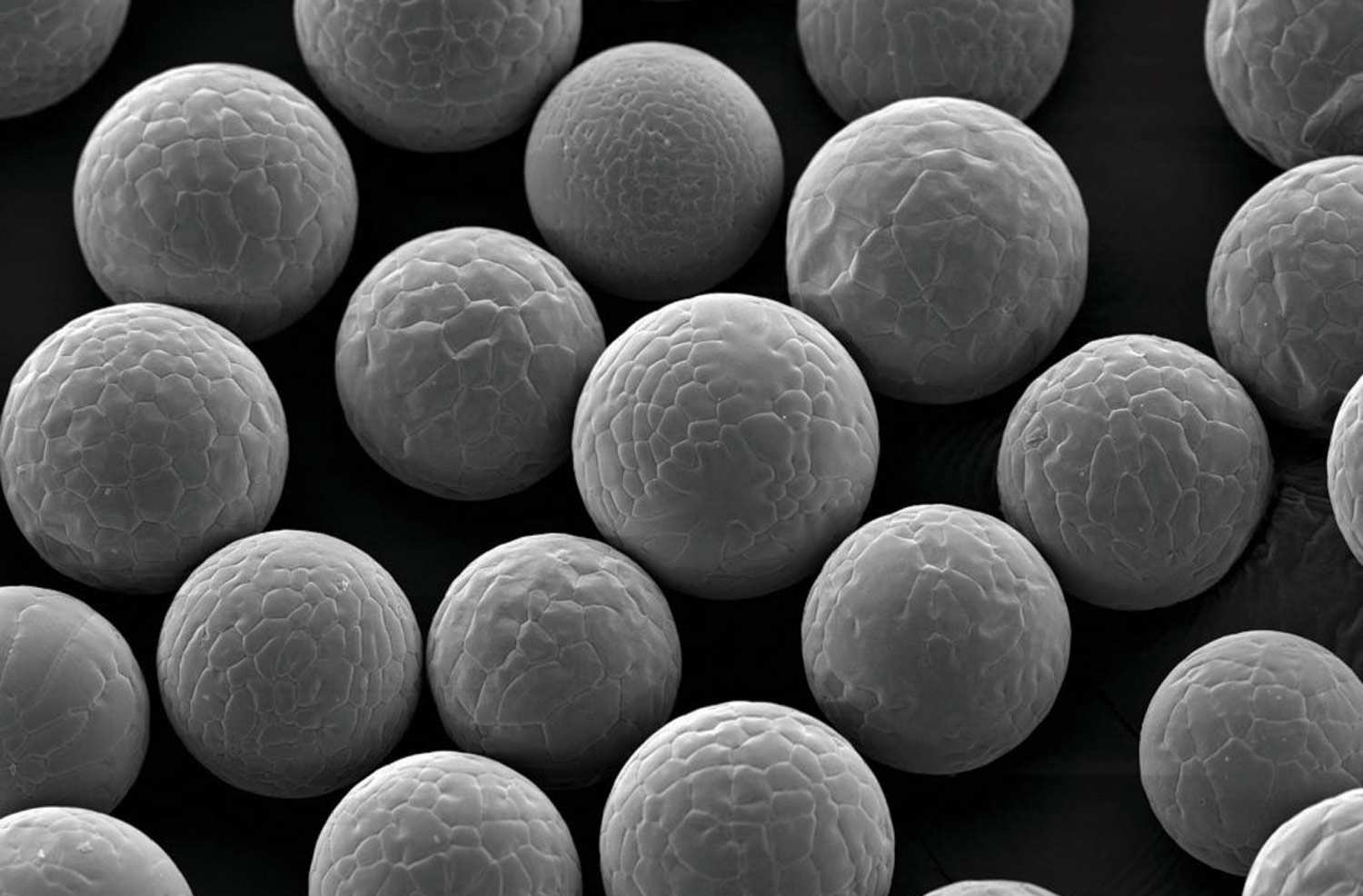

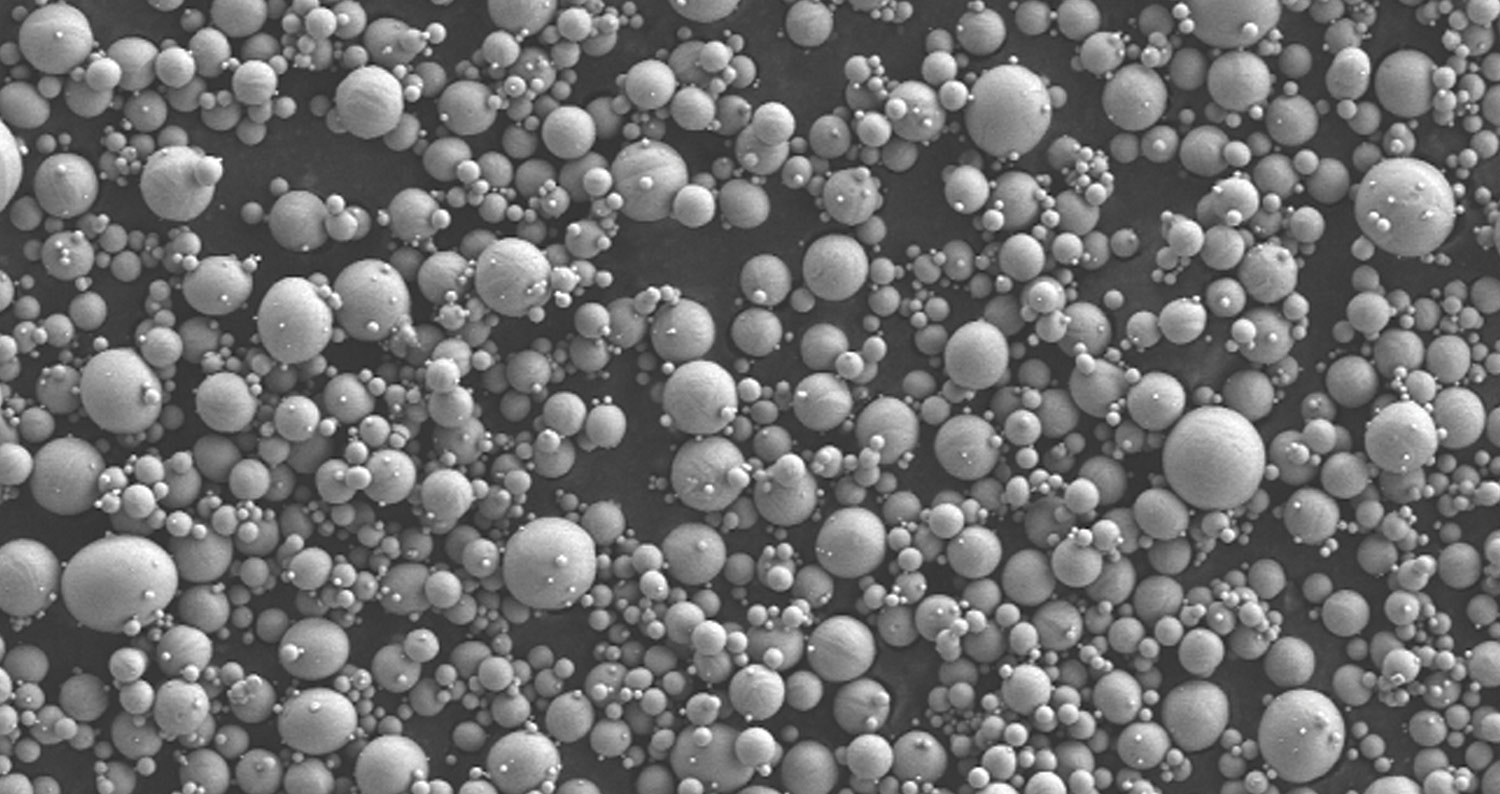

TRUMPF, Farmington, Connecticut, is working with Equispheres Inc., Ottawa, Ontario, to qualify its aluminum additive manufacturing powders on TRUMPF 3D printers. Equispheres offers three lines of AlSiMg10 powders optimized for laser powder-bed fusion manufacturing systems. TRUMPF reports positive initial results using Equispheres’ powders and expects to complete the qualification process early next year. Once the qualification process is complete, the company will be recognized as one of TRUMPF’s recommended powder suppliers, and the materials will be supported by applications engineers at both Equispheres and TRUMPF.

Protolabs names Stacy Greiner to board

GE Additive unit inks agreement with Airbus

BLM Group adds regional manager, Canada

on ffjournal.net