The PEMA WeldControl 300 product family is designed to save hours during automated welding processes via its three modules: OFFLINE, CREATE and SCAN.

bout 314,000 new welding professionals will be needed by 2024, and an average of 78,500 welding jobs will need to be filled annually over the next two years, according to an American Welding Society report. “The shortage of welders is a global challenge that can be solved in part with robotics,” says Michael Bell, director of sales for Pemamek LLC. The family-owned company designs and manufactures automated welding and production solutions for industries that range from shipbuilding, power generation and wind energy to process equipment and general fabrication.

“Custom robots have jump-started a new era in welding automation,” says Bell. “A well-designed robotic welding cell means higher productivity and cost efficiencies. It strengthens a fabricator’s competitive position in the marketplace. And it addresses another priority in the welding world—workplace safety. Robots can work in challenging environments and low temperatures with zero rest time.”

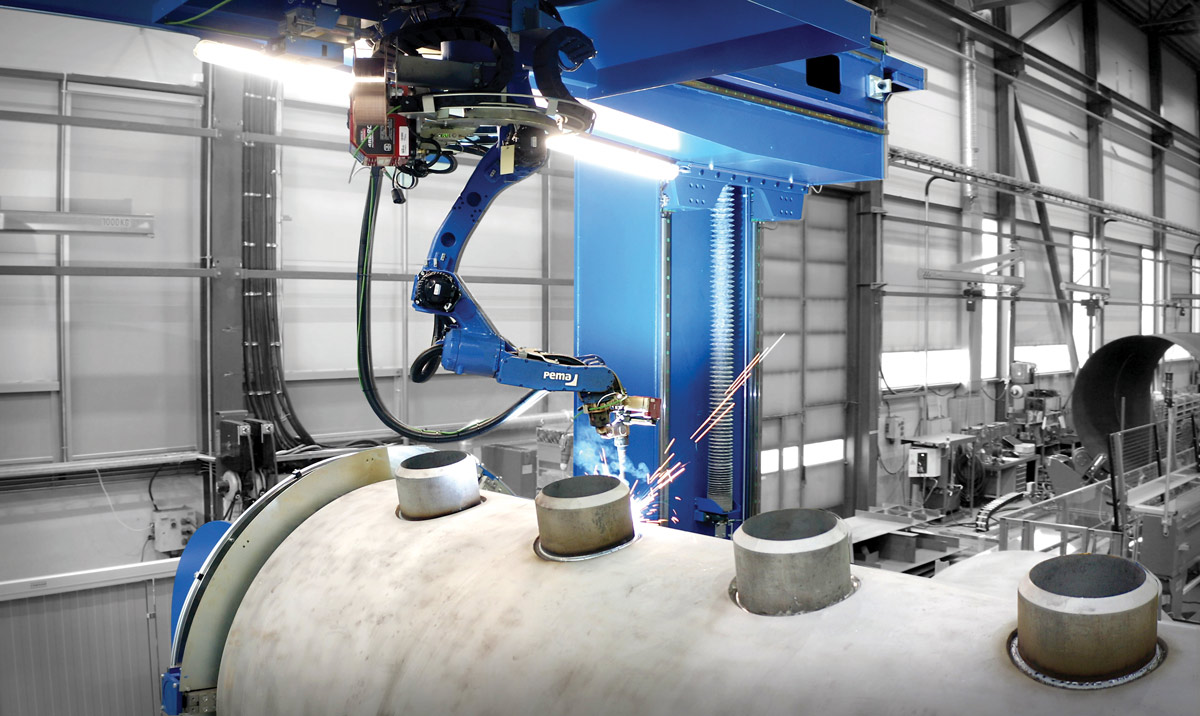

PEMA robotic welding packages—which include column and booms, welding positioners, rollerbeds and assembly stations— allow manufacturers to adapt production processes for greater flexibility and throughput increases. For example, the robot “reads” the weld at the start of a job and creates a program while it is welding. This capability significantly increases the arc-on ratio. With the majority of programming functions automated, manual work steps are eliminated. Typically, one robot can replace three to five welders, allowing a company to reassign its human talent to more high-value tasks.

Pemamek’s Nozzle Welding technology uses built-in lasers to scan groove geometry in the workpieces to automatically create robotic welding programs that adapt to varying groove layers by continuously welding the grooves until a solid bond is formed.

“For the last 24 months, we’ve done nothing but plant seeds,” he continues. “That investment is beginning to bear fruit.”

We did whatever it took to see people and keep the manufacturing train running.

We did whatever it took to see people and keep the manufacturing train running.

“We’ve done ourselves a disservice by neglecting the trades in favor of the college culture,” he says. “We’ve taken proud American professions like welding and plumbing and turned them into specialties. We need to repopulate those positions again and teach our youth that there is nothing wrong with taking up a trade. Tracing a piece of steel plate you welded to the completion of a full battleship can be a big mental paycheck.”

Robotics Applications Engineer Teemu Rusi edits welds and robot configurations in the WeldControl 300 OFFLINE software.

For example, welding a 5-in. gap can be challenging if an operator is using a manual process. Building out welds in a Y or X groove can take 70 passes or more. Pemamek’s welding positioners support the welder with better ergonomics and a safer work environment. Available in four product families, the welding positioners can handle a loading capacity from 550 lbs. up to 500,000 lbs. PEMA Skymaster PRO is an intelligent software tool that allows pre-programming of work cycles and handling positions. It also records and saves data such as heat input range and number of passes for future jobs.

“Our software bridges the skills gap,” says Bell. “The average age of a welder is 57 years old. He has a lot of knowledge and experience. If we can digitally retain the tribal knowledge of the older generation, we can build those connections between past and present. Our equipment is designed so that an older welder can understand it, but we’ve incorporated features that the joystick generation will embrace.”

A user-friendly control system with a one-touch screen provides full control over PEMA column and booms, produces accurate reports and saves welding programs for later use.

On a global scale, much of the activity in offshore wind is centered in Europe where nearly 2,300 megawatts of capacity is installed. According to the U.S. Department of Energy, states have established targets to procure close to 30,000 MW of offshore wind energy in the U.S. by 2035.

Offshore wind turbine towers are generally built from tubular steel sections. Subsea monopoles and jacketed foundations also lend themselves to automated welding applications. “These foundations have T, K and Y joints,” says Bell. “Each joint is called a node. We can automate the welding processes these nodes require.”

Floating offshore wind turbines are making inroads along the West Coast. The turbine sits on a platform with mooring lines that connect to anchors in the seabed.

“The people who will wire, build and install these offshore mills represent a new category of skill sets,” Bell says. “We’ve minimized the importance of skilled labor and now we have to come out of that retraction. We have to help companies to work smarter.”