Features

/customfabricator

/plasma

/facetime

Learn more

@UnionLeader

From the Editor

Sustainable steel

ccording to the American Institute of Steel Construction (AISC), steel remains the leading green construction material. When it comes to environmentally safe phrases, it seems that more and more products are being touted as “green,” “eco-friendly” or “sustainable.” I wondered if the terms were interchangeable so I looked them up. Oxford Languages defines the word green as a label that refers to all aspects of environmentally friendly products from fashion to buildings. The term eco-friendly is attached to products or practices that won’t hurt the environment. Sustainability speaks to the idea that what we do today won’t exhaust resources for future generations.

ehind every great custom fabricator is an even better training program set in motion by the senior fabricators and shop managers. Ci Metal Fabrication, a custom industrial metal fabrication shop based in Meridian, Mississippi, has long relied on detailed training and education programs within its shop.

Ci Metal Fabrication uses talented and experienced mentors, averaging more than 30 years of industry experience in presswork, power forming, welding, cutting and shearing, to usher in the next generation of metalworkers.

Training & Education

hile working, people often run into problems. And those problems need solutions. This basic concept is at the root of Sawblade.com CEO Chris Luke’s new online manufacturing training library, Sawblade University. Luke says he began to assess the idea of a collection of educational videos when talking with students at trade shows. “They’re a pulse on what’s going to happen in the future.”

Sawblade.com was already producing videos for customers detailing how best to cut specific materials, Luke says. For instance, if an aerospace manufacturer showed interest in how to successfully cut a specific grade of titanium, “they send us a small piece, we put it on the saw and produce an entire video for that company—a video they can keep and review and show employees.

he offshore wind energy industry will be a “major contributor” to the post-COVID-19 economic recovery worldwide, according to the Global Wind Energy Council. Through 2030, the council forecasts that more than 205 gigawatts of new offshore wind capacity will be added globally—a 15-gigawatt increase from GWEC Market Intelligence’s pre-pandemic forecast.

However, the development of new technologies, manufacturing and construction procedures, and the increase in the size of wind farms and turbines, means new installations are being set up farther from the coastline. As a result, the design for the structures that support the turbines has evolved to become bigger, thicker, longer and heavier to accommodate these great ocean depths.

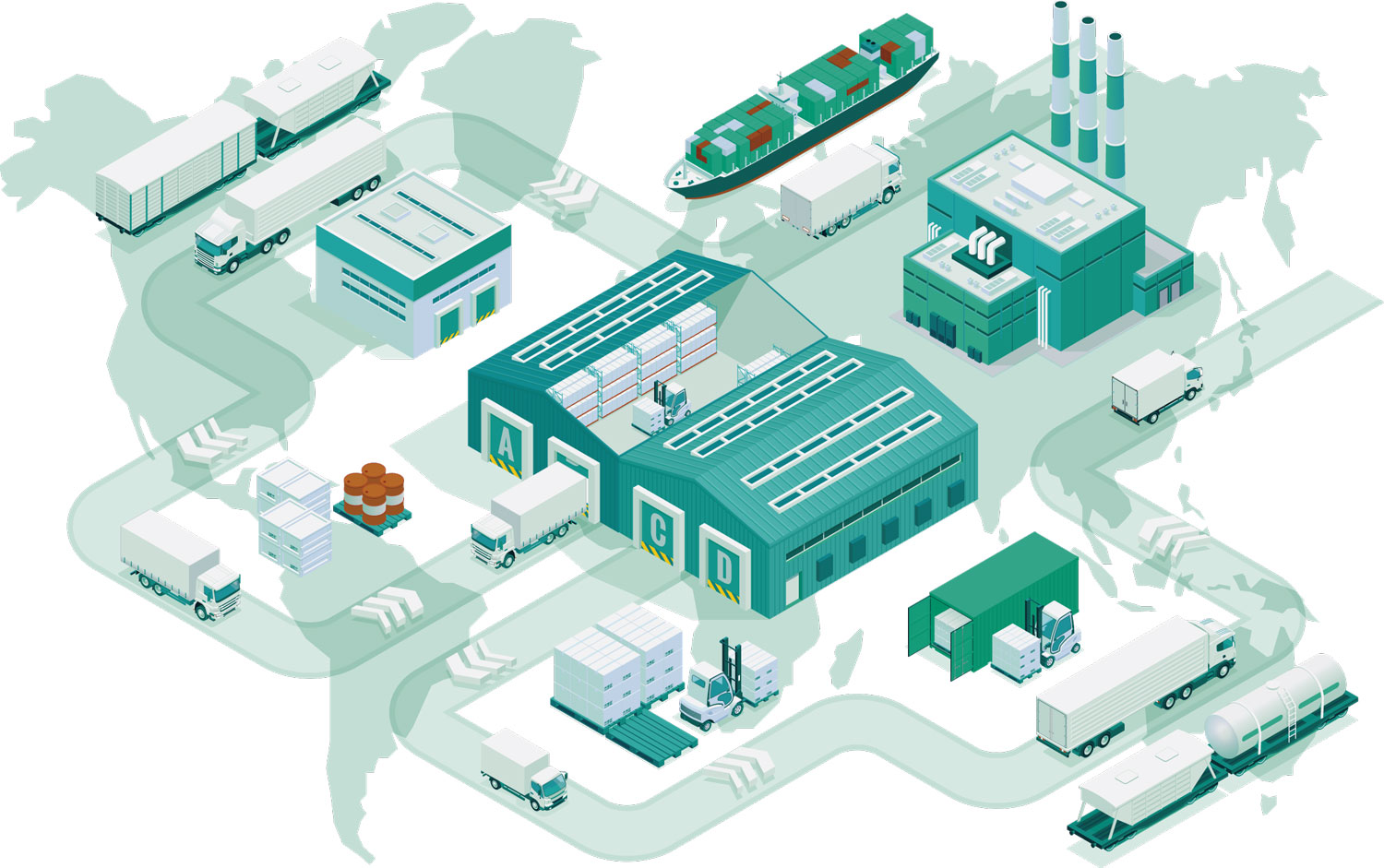

The pileup between supply chain bottlenecks and vigorous demand is putting the brakes on U.S. manufacturing. In May 2021, the Institute for Supply Management (ISM) reported “record-long lead times, wide-scale shortages of critical basic materials, rising commodities prices and transportation difficulties.”

n the U.S., San Francisco is the undisputed king of tech IPOs with startups securing more than $31 billion in early stage venture capital funding between 2010 and 2020. Last year, the city was also recognized by the Wealth-X report as the third city in the world with the most billionaires—77 to be exact. Iconic landmarks like the Golden Gate Bridge and the former Alcatraz Federal Penitentiary, along with Chinatown, the San Francisco Giants, Fisherman’s Wharf and the Maritime National Historic Park make the Bay Area an eclectic mix of cultural, entertainment and commercial attractions. The city is also a dichotomy of the rich and homeless.

ow many job shops could lose a customer that accounted for 98 percent of their business and recover in just a few years? Elm Machining was faced with that scenario several years ago. The company confronted this threat by making some hard decisions, placing additional emphasis on fabrication, investing in the proper equipment and dedicating itself to the hard work that it took to not only survive but also prosper.

n March, the Denver area was devastated by a record-breaking snowstorm that razed structures, forced businesses and schools to close, and left thousands of residents without electricity. A portion of Triple-S Steel Holdings Inc.’s Colorado facility was no exception. About 40,000 sq. ft. of its 234,000-sq.-ft. facility collapsed.

Hornet Cutting Systems’ high-performance CNC plasma pipe cutting machines are built for speed and accuracy.

n September 2020, while much of the world remained shut down and in limbo, Fab Tech Wastewater Solutions LLC invested in a new Roto Hornet 1000 CNC plasma pipe cutter to meet a new customer’s demand. “We have a new customer that is going to send a volume of pipes to work on—plus, [we wanted] a general upgrade as well,” says David Umphenour, administrative services manager at the Warrenton, Missouri-based fabricator.

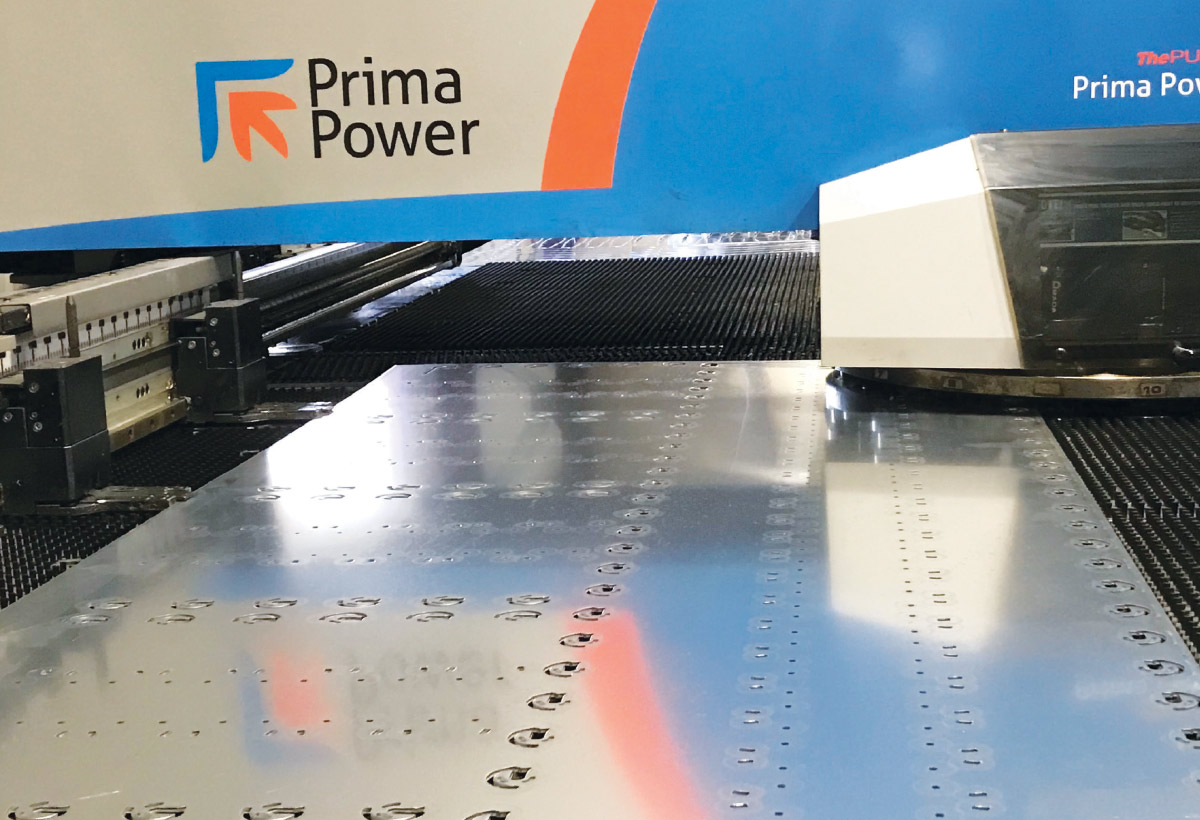

A robot-operated Ermaksan 6-axis Speed Bend press brake provides production rates twice that of conventional machines.

sales call, a downpour and a missed cutoff outside Greenville, Texas, changed the course of events for Steve Lester, his wife, Sherrill, and his father, Pat.

“I was in the metals business at the time,” says Steve Lester. “I worked for a mill. I decided to visit QMF Steel Inc. It was a mom-and-pop operation with two barns full of metal. A terminal cancer diagnosis prompted the owner’s wife to try and persuade me to buy their business. At the time, I thought it was the worst idea I’d ever heard.

enderson Stamping & Production Inc. has been making decorative and non-decorative parts and assemblies for carmakers and appliance brands for 40 years. On any given day, 20 production lines hum with presses (110 tons to 1,375 tons) stamping everything from small automotive brake components to deep drawn cook tops out of stainless, carbon, high-strength and aluminum steels. Three plants total 165,000 sq. ft. of manufacturing space. Plant 1 also houses a tool room and a five-stage powder coating system. Plant 3 is used for warehousing and value-added assembly processes.

gains

We’re planning on adding more customers into the fold as we get our four points of distribution to full speed.

We’re planning on adding more customers into the fold as we get our four points of distribution to full speed.

hen Bill Taylor founded Continental in Los Angeles in 1960, the company became a go-to abrasives manufacturer for distribution houses across the west. Years later, the company was sold and subsequently, dissolved. In 2013, Taylor’s daughter Cindy; son-in-law Gary; and his grandsons, Graydon, Gavin and Garrett, relaunched Continental Abrasives, thus reestablishing its presence on the West Coast with plans to go nationwide.

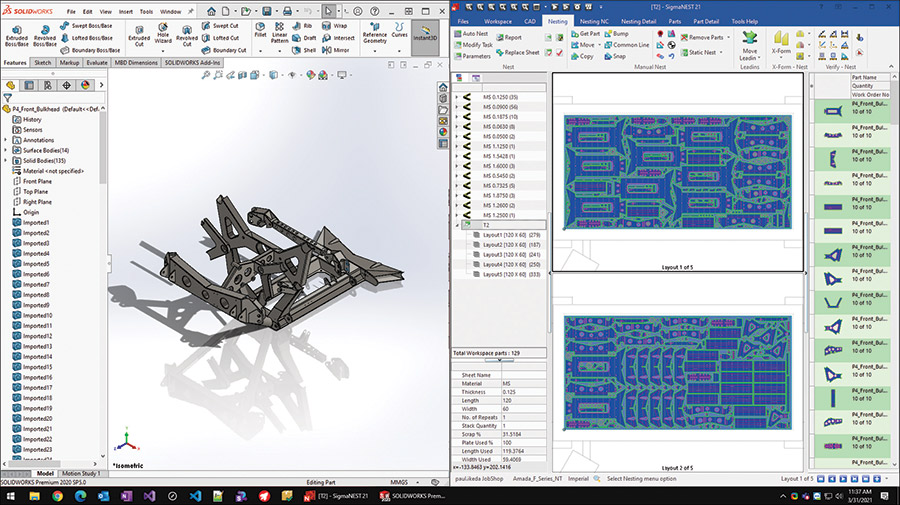

SigmaNEST, Cincinnati, 513/674-0005, sigmanest.com.

The Sound That Light Makes by Australian artist Alexander Knox forms the exterior screen to the newly developed 300 George Street precinct in Brisbane, Australia. The work creates an iconic visual signature wrapped around the podium at the base of the three-tower site. Spanning 2,660 sq. m. and composed of over 2,500 3D-pressed and planar aluminum panels, the future landmark for the soon-to-be-completed high-end commercial area uses geometric and organic shapes to explore the effect of light shimmering on the surface of water. Its 3D metallic surface is designed to catch and mimic the kinetic nature of light on water, bringing the influence of natural forces into the highly urbanized setting of Brisbane’s central business district. The art façade’s title refers to the shimmer of light on water as a whisper from the site’s pre-urban epoch.

The Sound That Light Makes by Australian artist Alexander Knox forms the exterior screen to the newly developed 300 George Street precinct in Brisbane, Australia. The work creates an iconic visual signature wrapped around the podium at the base of the three-tower site. Spanning 2,660 sq. m. and composed of over 2,500 3D-pressed and planar aluminum panels, the future landmark for the soon-to-be-completed high-end commercial area uses geometric and organic shapes to explore the effect of light shimmering on the surface of water. Its 3D metallic surface is designed to catch and mimic the kinetic nature of light on water, bringing the influence of natural forces into the highly urbanized setting of Brisbane’s central business district. The art façade’s title refers to the shimmer of light on water as a whisper from the site’s pre-urban epoch.

Editor-in-Chief

Michael D’Alexander

Lynn Stanley

Gretchen Salois

J. Neiland Pennington

Lauren Duensing

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323

www.ffjournal.net

Carlotta Lacy

Matthew LaFleur

Mark Koenig

Michael D’Alexander

Jim D’Alexander

Wayne Krusen

Traci Fonville

Bill D’Alexander

312/654-2309, Fax: 312/654-2323

mdalexander@ffjournal.net

Alaska, Arizona, Arkansas, California, Hawaii, Idaho, Montana, New Mexico, North Dakota, Oklahoma, Texas, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@ffjournal.net

Alabama, Colorado, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Pennsylvania, South Carolina, South Dakota, Tennessee

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@ffjournal.net

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@ffjournal.net

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Valerie Treiber, National Sales Manager

203/894-5483

valerie@modernmetals.com

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@ffjournal.net

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJournal® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJournal® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.