Training & Education

hile working, people often run into problems. And those problems need solutions. This basic concept is at the root of Sawblade.com CEO Chris Luke’s new online manufacturing training library, Sawblade University. Luke says he began to assess the idea of a collection of educational videos when talking with students at trade shows. “They’re a pulse on what’s going to happen in the future.”

Sawblade.com was already producing videos for customers detailing how best to cut specific materials, Luke says. For instance, if an aerospace manufacturer showed interest in how to successfully cut a specific grade of titanium, “they send us a small piece, we put it on the saw and produce an entire video for that company—a video they can keep and review and show employees.

“We have so much footage where we explain to people how to do things that we decided to make it a school.”

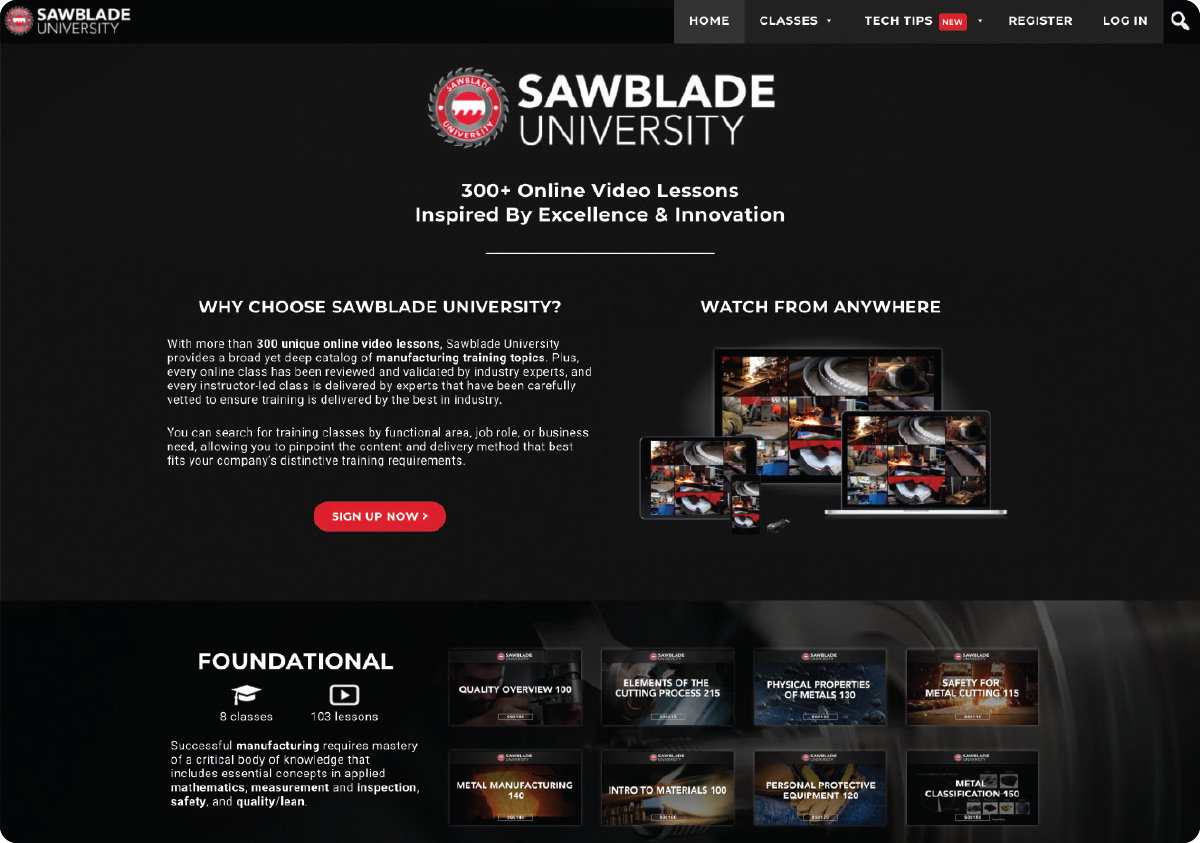

At first, Luke envisioned the training site consisting of these “Tech Tips” plus a few additional lessons, but over the past two years, the project has grown to more than 300 video lessons covering precision metalworking topics from training in tool and die making to welding and sheet metal working. “It had a mind of its own,” he says.

Each video is a short (about a minute and one-half to two minutes long) “mini lecture” on the subject. For instance, in the category of safety, there will be about 16 video modules, including one on how to decipher earplug ratings. “The idea was to make it easy so people would want to watch it and absorb it,” Luke says.

“We’ve grouped classes together: quality overview, metal manufacturing, elements of the cutting process, introduction to metal, physical properties of metals, personal protection and safety, how to classify metals, and so forth. Each of these classes are clearly defined.

If you just want to know the characteristics of metal, you can go to Intro to Metals, which has 18 lessons, and select number four to view the information you need.”

Digital communication and learning has grown and improved impressively over the last year, and Luke thinks the model is here to stay—after people have recovered from Zoom fatigue. “I think people are going to want to get off the screen for a little bit [post-pandemic]. But when the opportunity comes to go back to school, they know this works.”