Hornet Cutting Systems’ high-performance CNC plasma pipe cutting machines are built for speed and accuracy.

n September 2020, while much of the world remained shut down and in limbo, Fab Tech Wastewater Solutions LLC invested in a new Roto Hornet 1000 CNC plasma pipe cutter to meet a new customer’s demand. “We have a new customer that is going to send a volume of pipes to work on—plus, [we wanted] a general upgrade as well,” says David Umphenour, administrative services manager at the Warrenton, Missouri-based fabricator.

Up until this equipment upgrade, Fab Tech Wastewater Solutions cut piping manually. “We [were already] using plasma technology and loved its application for our fabrication shop,” Umphenour says.

After a two-week installation period and some initial training, the Roto Hornet 1000 was up and running. “There was not much of a learning curve since we already own a plasma table,” Umphenour says. “Cross-training has been smooth. We use one [operator] mainly for those processes.”

In particular, the ability to scribe part numbers onto the piping proved beneficial and an easy transition for Fab Tech Wastewater Solutions’ plasma operator since he was already well-versed in the cutting method. “We can now handle and complete much more volume in a reduced time frame,” Umphenour says. “We can go after larger jobs with less lead time and still complete everything on time.”

We can go after larger jobs with less lead time and still complete everything on time.

We can go after larger jobs with less lead time and still complete everything on time.

“If needed,” he continues, “you can also import 3D CAD files for highly customized pipe cuts. The flexibility provided by the Rotary Tube Pro allows fabricators and manufacturers the ability to work efficiently, reducing costs and boosting productivity.”

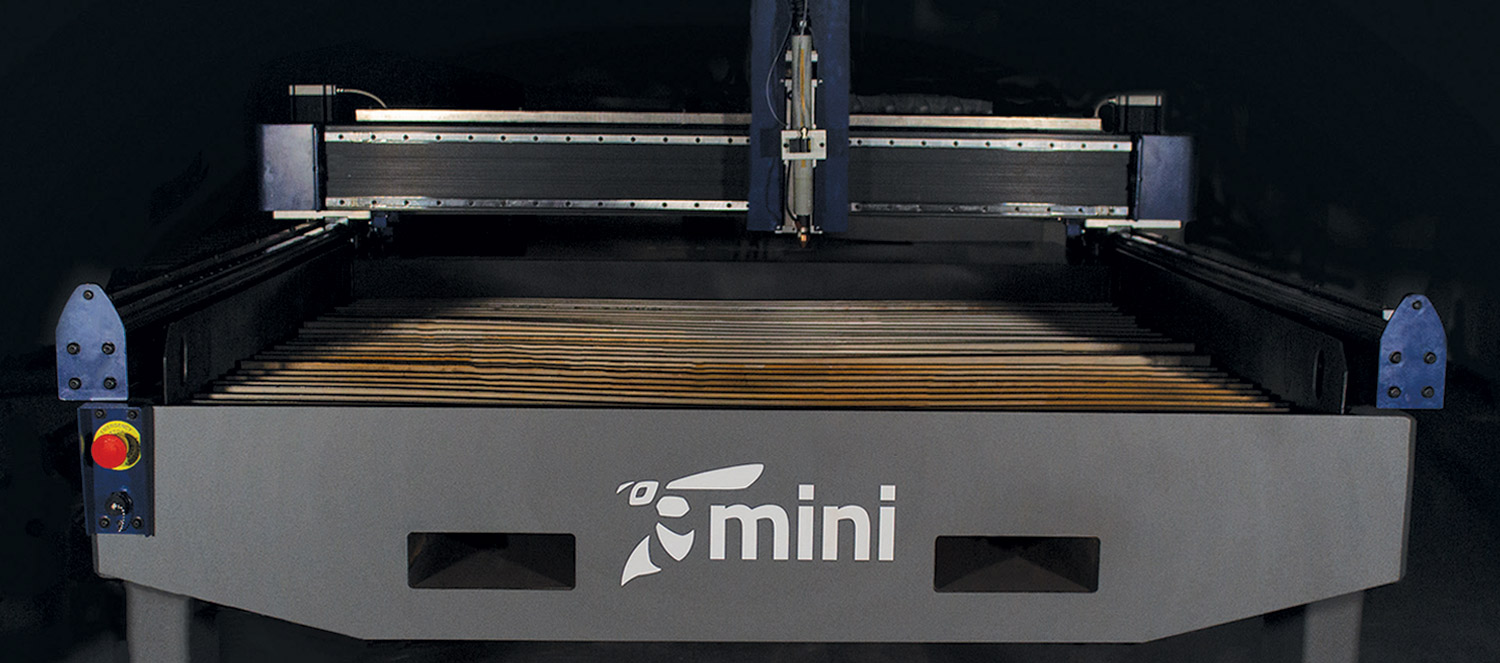

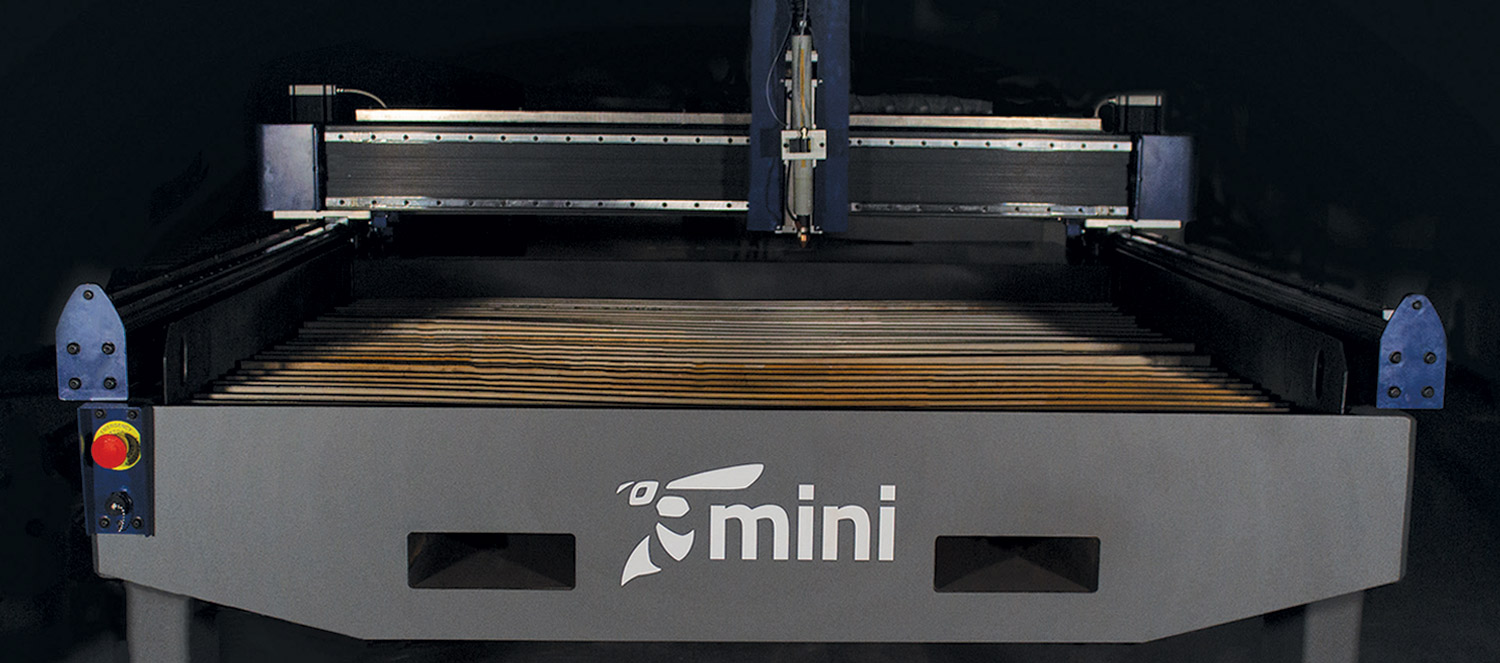

Hornet recently launched the Mini Hornet, a new product designed for smaller shops and schools. It comes in 4-ft.-by-4-ft. and 4-ft-by-8-ft. options. “These sizes allow for a smaller footprint while maintaining the quality and precision Hornet products are known for,” Turner says.

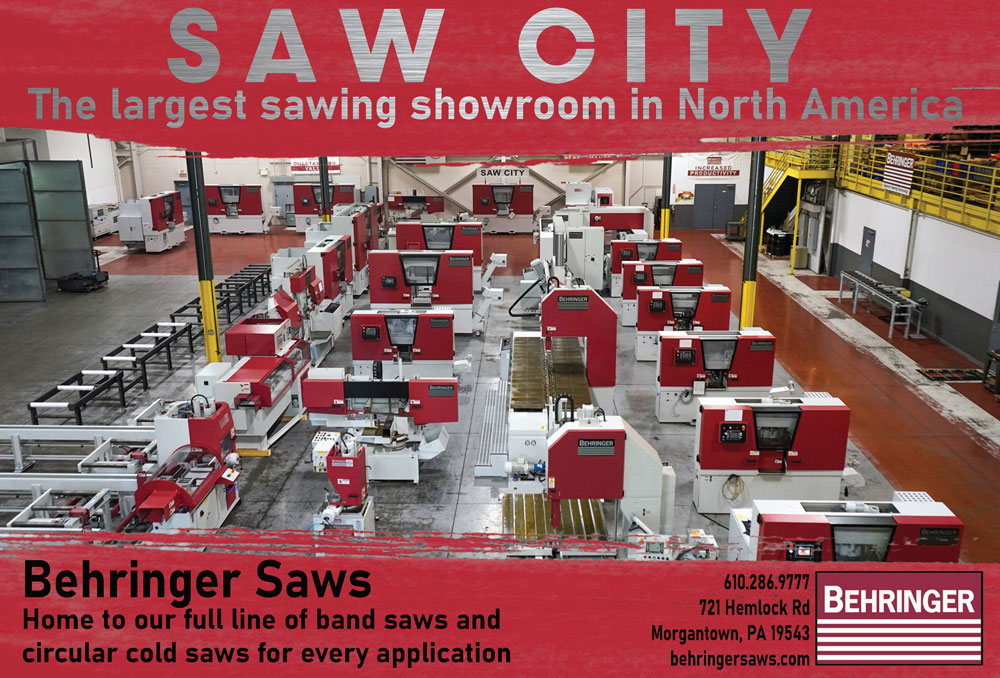

Hornet is a service-disabled veteran-owned small business (from the Department of Defense initiative for veterans and service-disabled veterans who own small businesses) and its products are 100 percent American-made. The company is also ISO 9001:AS9100D certified and is a Hypertherm authorized OEM and service center. Hornet pairs its equipment with efficient nesting software to optimize plate use and ease handling for the machine operator out on the shop floor. “Our CNC cutting machines are designed to be dependable and accurate,” Turner says. “The CAM nesting software is ideal for the metal fabricator, with robust features and options for plate cutting and pipe cutting machines, including our CNC plasma, oxy-fuel and waterjet cutters.”

Prospective customers that outsource metal fabrication often come to Hornet in search of ways to bring capabilities in-house as lead times and shipping costs increase. “For customers who haven’t owned a plasma table before, they often don’t know all of the questions to ask,” Turner says. “This isn’t an issue for Hornet, as we are able to tailor the machine build to support their business functions best. This isn’t an option for many of our competitors.”

“Looking back a year later,” he continues, “we are grateful for the support we have received from our customers, employees and communities during lockdown.”

As the world continues to open up, Hornet is ready. “Looking back, I am also grateful for the perspective shift we were given an opportunity to embrace,” Turner says. “Remembering things that we may have forgotten in the bustle of life just a year ago—the value of maintaining a healthy work-life balance; spending time with your spouse, kids and family; having genuine relationships; and valuing our most important business asset—our employees.”