he versatile fiber laser has been adopted by a diverse market base for myriad applications. Power, speed and machine features top most fabricators’ wish lists, but the number of different models on the market can pose a challenge for companies looking to invest in the technology. To help narrow the field, manufacturers should ask questions that will help identify the fiber laser with the capability to take shop floor production to the next level in a digitized environment.

Connected automation technologies—the backbone of Industry 4.0—continue to be deployed on shop floors. Considering a laser cutting system with features that support autonomous operation, such as AMADA AMERICA INC.’s REGIUS, gives manufacturers the ability to maintain operations with minimal operator involvement.

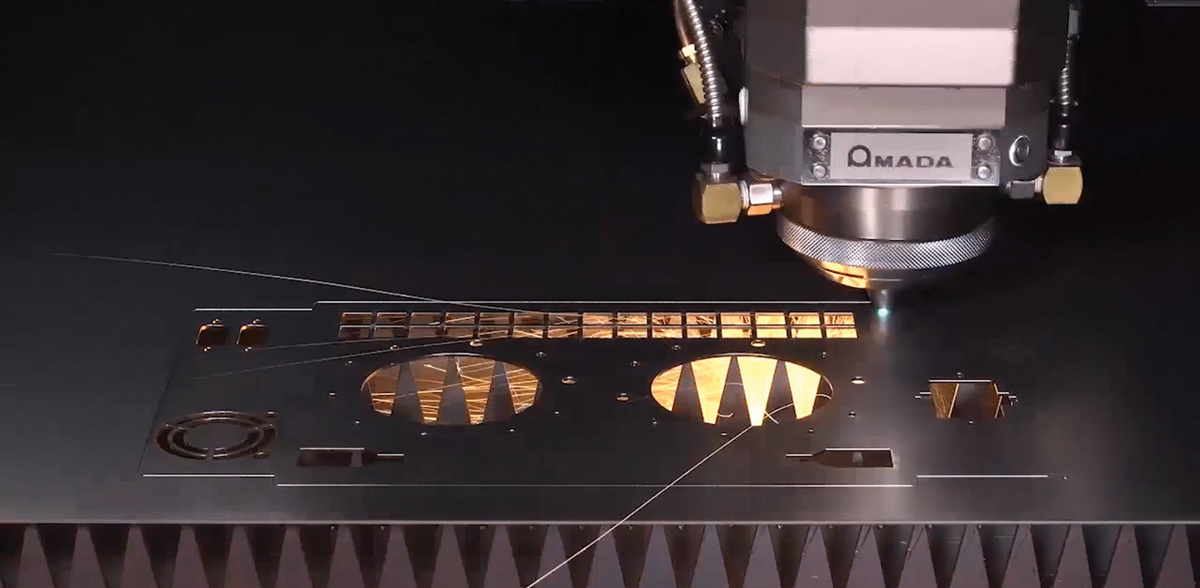

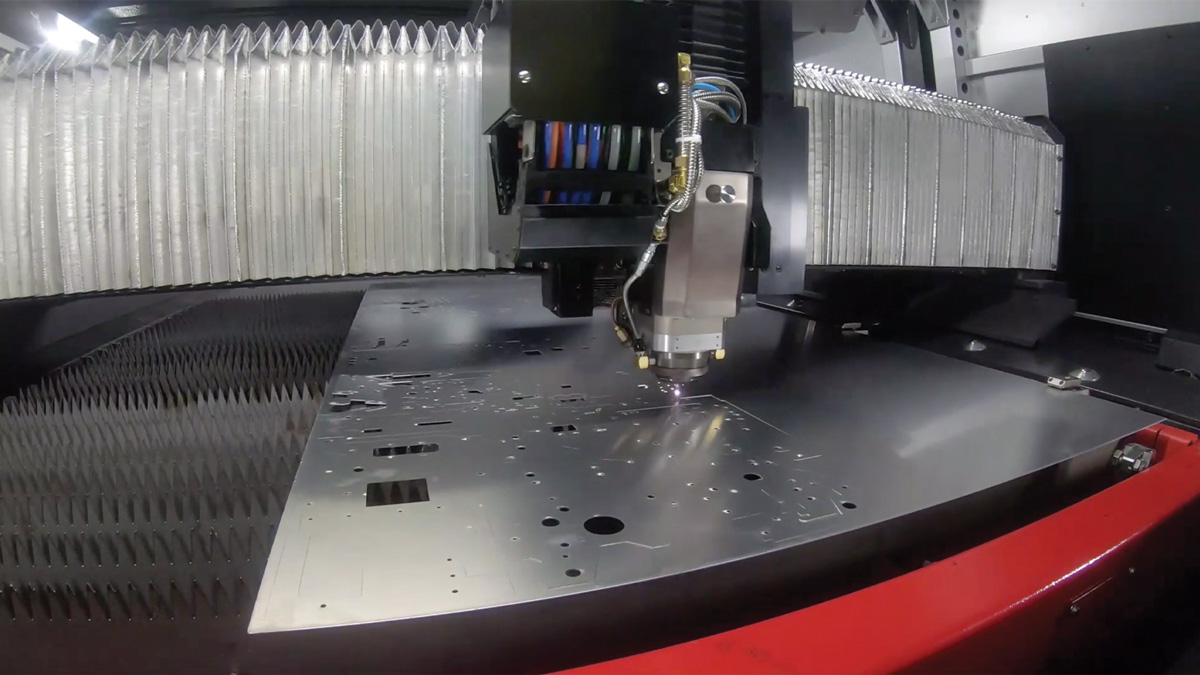

The REGIUS made its global debut at Fabtech 2019 in Chicago. AMADA’s linear driven machine uses vision and monitoring systems to support continuous operation. These systems also allow for ease of operation, better shop floor management capabilities, maximum productivity and reduced downtime.

The 3-axis linear drive system on the REGIUS softens the ramp up and ramp down traverse speeds to achieve high-speed, high-precision part processing. The linear drives communicate with a control processing unit that transfers information to the new Fanuc 3i-Ex control. The communication between the control processor and the drive system generating 5g of acceleration and traverse speeds of 13,300 in. per minute equates to a 15 percent reduction in common nest times over the previous linear-driven machine, the AMADA FOL-AJ.

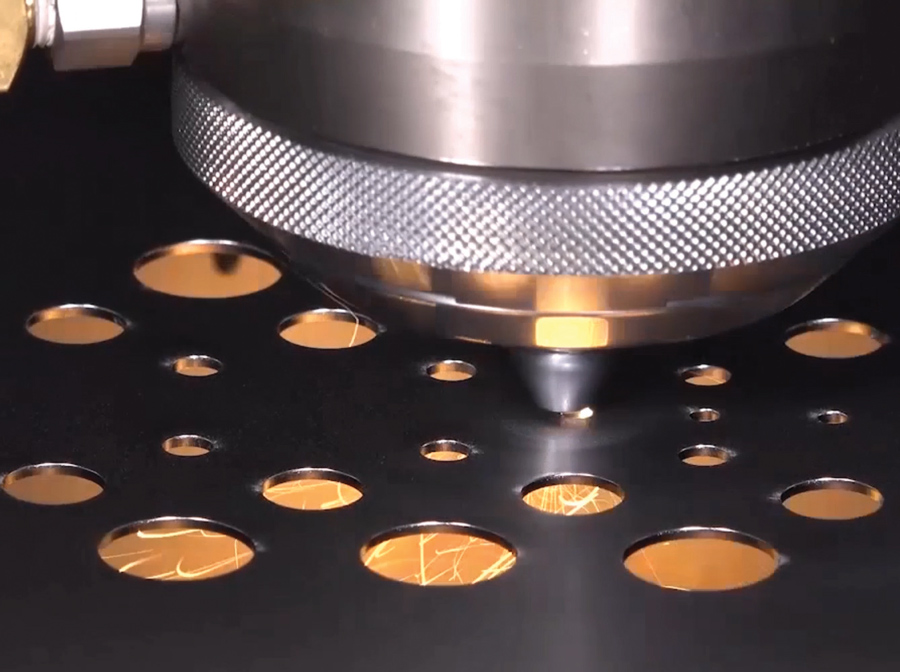

Another feature designed to support autonomous operation is the automatic collision recovery system. In the event of a collision, the laser head damage prevention mechanism will retract the Z-axis, and use the iNozzle checker to inspect, replace and center the nozzle. The system automatically registers the NC coordinates where the collision occurs. When processing is resumed, the registered coordinates will be avoided and the next part will be processed. This system also allows the cutting head to have a tilt angle during a part tip-up to prevent any damage to the cutting head itself.

The REGIUS allows manufacturers to maintain operations with minimal human interaction.

The REGIUS allows manufacturers to maintain operations with minimal human interaction.

AMADA AMERICA INC.

The REGIUS is powered by AMADA’s ENSIS fiber engine technology. This patented technology allows for automatic adjustment of the beam quality to maintain low operation cost and high speeds in thin material. ENSIS technology also provides excellent edge quality and speeds on thick plate, previously only achievable by CO2 lasers. The mode is changed automatically to optimize the cut quality throughout the entire range of the materials being processed. The REGIUS can be purchased in a 6 kW, 9 kW or 12 kW. The Auto Collimation Unit (ACU), is another unique feature of the REGIUS when it comes to cut quality and speed. This system allows for instant changes in beam diameter and depth of field for fast pierce times as well as superior edge quality.

AMADA developed the REGIUS laser system to integrate different technologies that support autonomous operation. The technology equips job shops that need to improve efficiency and productivity in today’s manufacturing environment, and prepares companies for Industry 5.0, which will leverage advances in automation, IoT and big data.