Personal connections throughout our industry

Personal connections throughout our industry

Features

/customfabricator

/welding

/laser

From the Editor

The storytellers

fter nourishment, shelter and companionship, stories are the thing we need most in the world,” says fantasy author Philip Pullman, author of “The Golden Compass.” Stories are important. We seek them out to reassure us when we’re feeling anxious, as comfort when we’re down, or as a means to escape reality. I found stories to be a great comfort to me in the last year and a half when traveling to the Chicago lakefront beaches—traveling anywhere, actually—was prohibited due to the pandemic. From the confines of my home, I could pick up a book or magazine and enter into an entirely different world by reading another person’s words held in my hands.

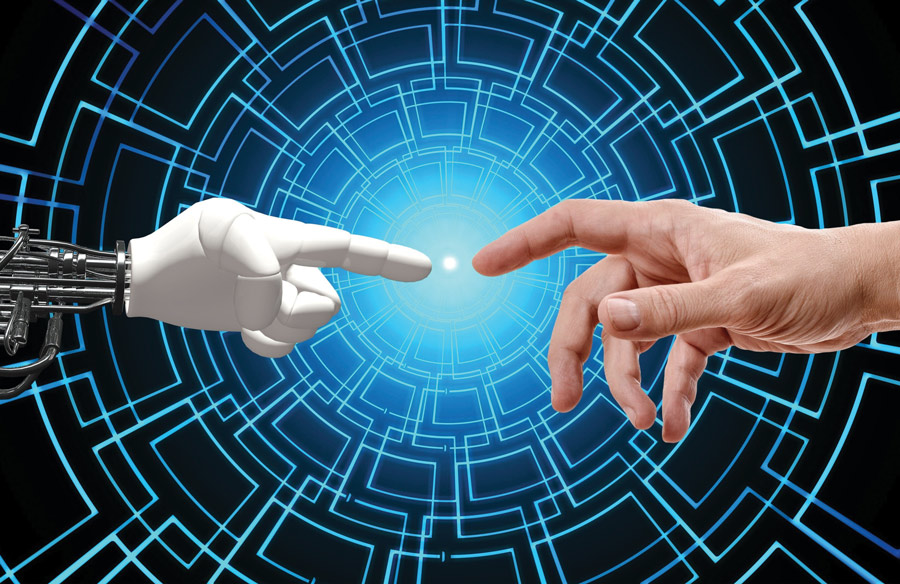

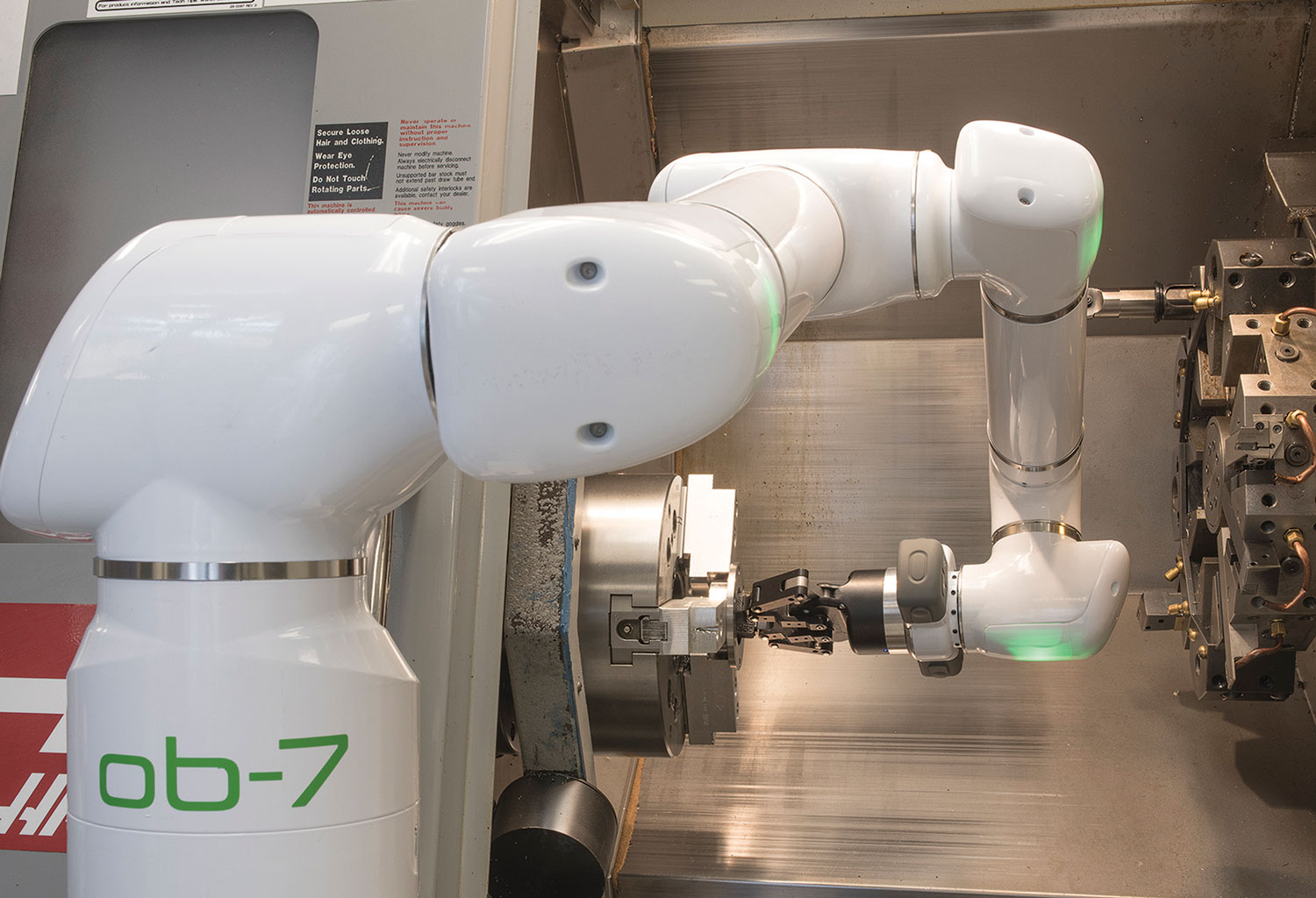

For many job shops it is understanding that automation is a journey, not a destination. You don’t have to immediately jump into expensive full automation. Do take stock of what is out there. Decide where your entry point is and go from there.

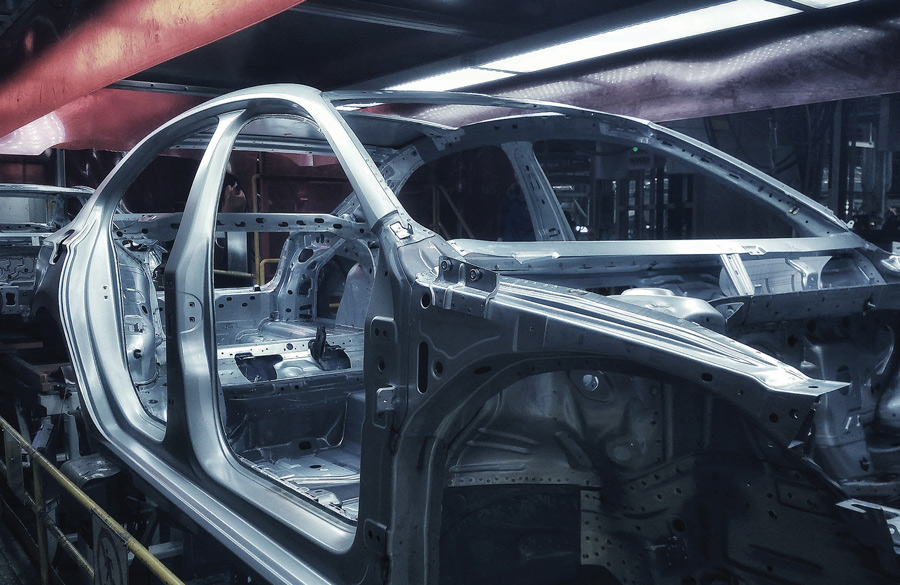

raditional manufacturing built the world we live in. When engineers introduced subtractive numerical control (NC) manufacturing in the 1940s, it empowered industries to mass produce more complex parts with even greater precision. It also drove a true paradigm shift in the way we innovate and create prototypes, allowing manufacturing processes to evolve into what they are today.

In recent years, additive manufacturing (AM) has advanced exponentially and become increasingly cost effective and sustainable. As a result, many manufacturers have combined additive and subtractive techniques in their mass-production operations.

A study released by the International Federation of Robotics estimates there will be more than 3.5 million operational industrial robots by the end of 2021. Deloitte’s Manufacturing Industry Outlook for 2021 stated a monthly average of 400,000 job openings are being posted by manufacturers. To balance workforce shortages with the need to maintain consistent output, a growing number of companies have accelerated adoption of automation and robotics.

ARKU Inc.

BARTON International

BLM GROUP USA

Boschert USA

Butech Bliss

Combilift USA

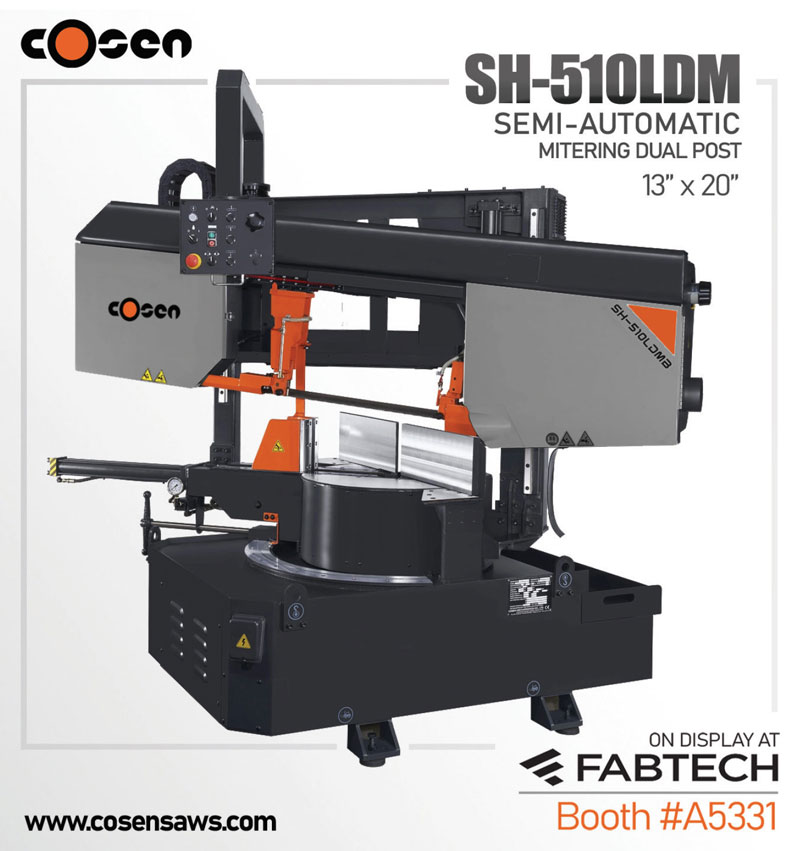

Cosen Saws, North America

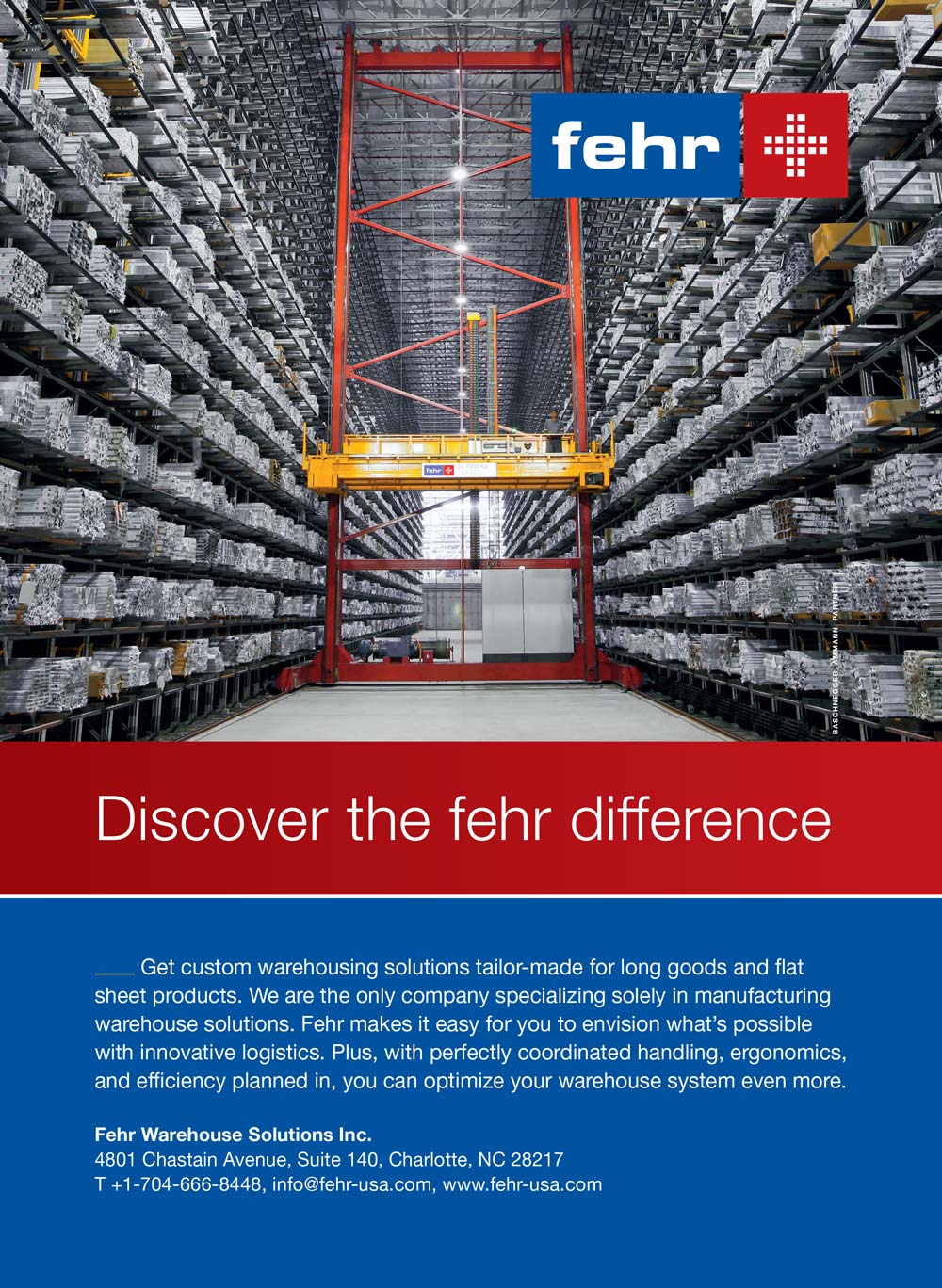

Fehr Warehouse Solutions Inc.

Gemtex Abrasives

Haberle/Ken Bergman & Assoc. LLC

HGG Profiling Equipment, Inc.

LISSMAC Corporation

Mate Precision Technologies

Mazak Optonics Corp.

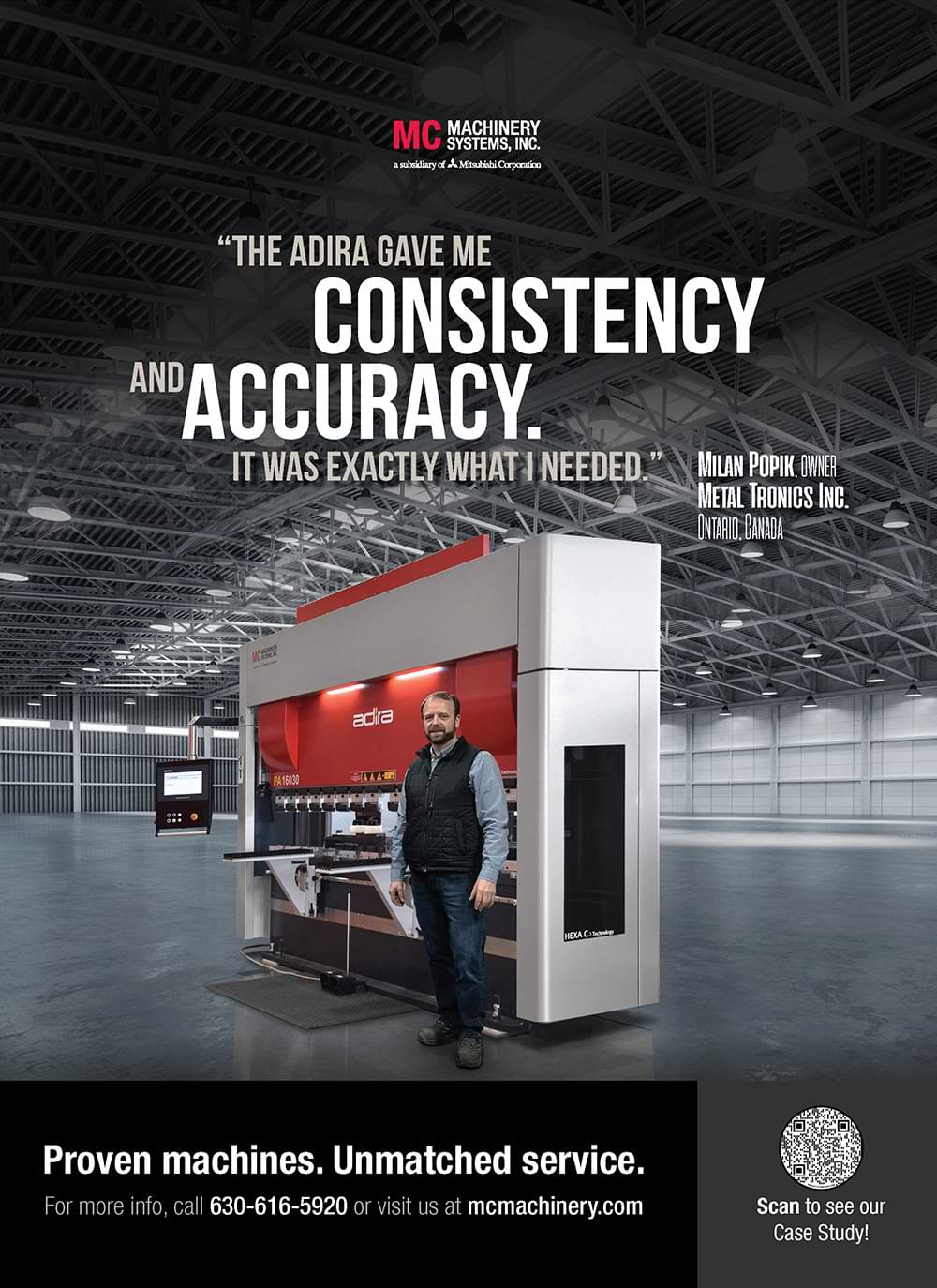

MC Machinery Systems, Inc.

MultiCam, Inc.

Nidec Press & Automation

Scotchman Industries, Inc.

Simonds Saw

T. J. Snow Company

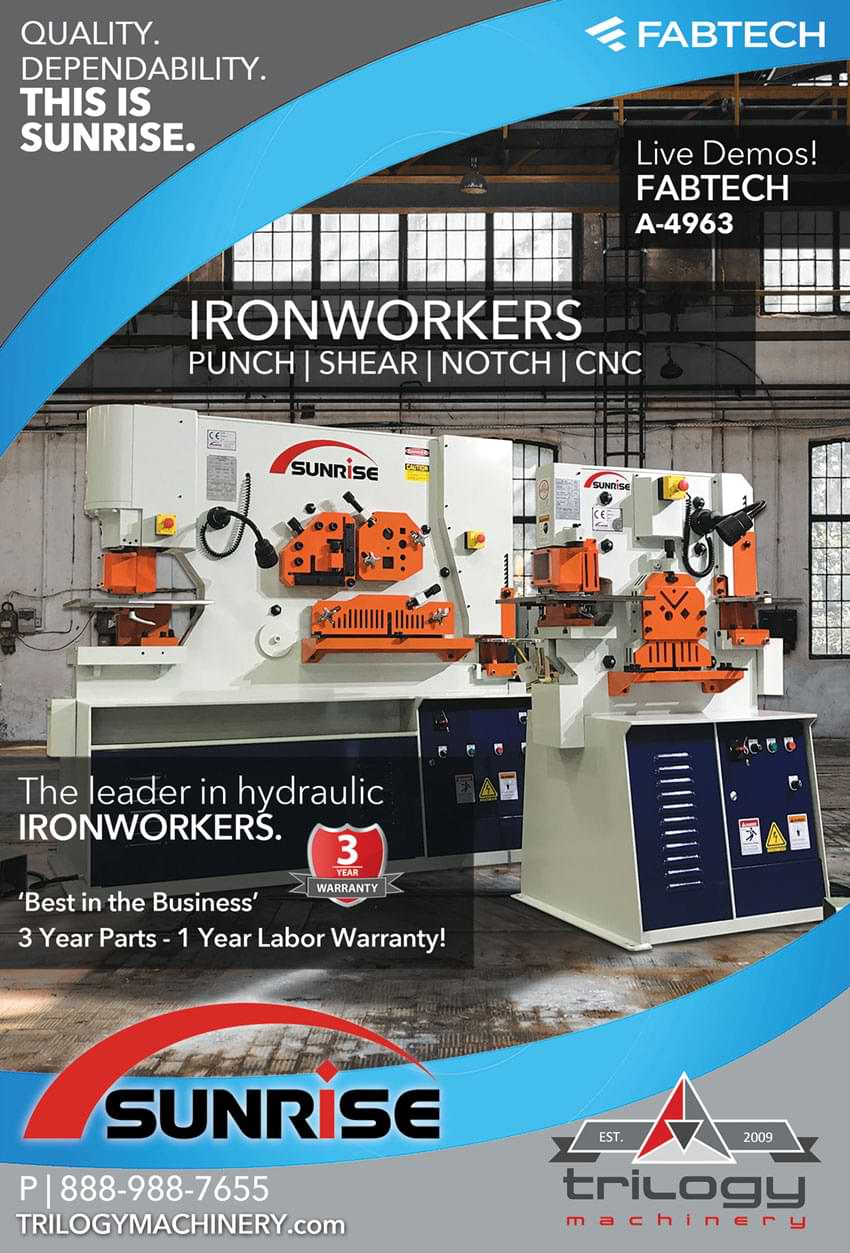

Trilogy Machinery, Inc.

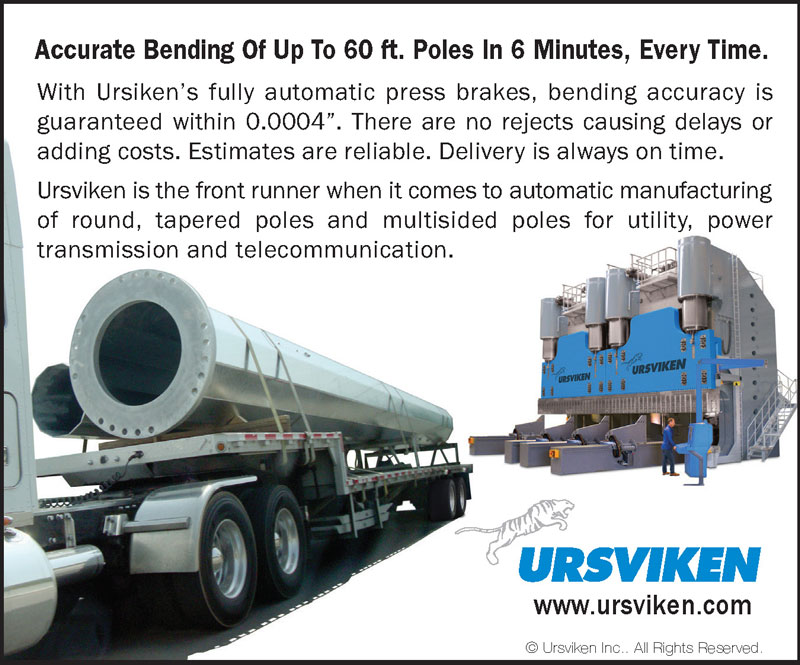

Ursviken Group

Buena Park, California

General Manager

connect with me for:

Lasers

Press Brakes

Welding

Cincinnati, OHIO

Sales Manager

connect with me for:

Precision Levelers

Deburring Machines

Coil lines

Glens Falls, New York

Waterjet Parts Manager

connect with me for:

Waterjet Parts and Bricks

Waterjet Abrasive Removal

Abrasive Transfer Hoppers

NOVI, MICHIGAN

Director of Sales

connect with me for:

Lasers

Tube and Pipe

Press Brakes

BUTLER, WISCONSIN

Vice President, Sales

connect with me for:

Sheet cutting & fabrication machinery

Copper bar processing machinery

Horizontal & profile bending machinery

Salem, Ohio

Vice President of Sales

connect with me for:

Coil Processing

Greensboro, North carolina

President, North America

connect with me for:

Material Handling Equipment

Forklift Trucks

Charlotte, North Carolina

Inside Sales and Marketing Manager

connect with me for:

Sawing

Fairview, TENNESSEE

President

connect with me for:

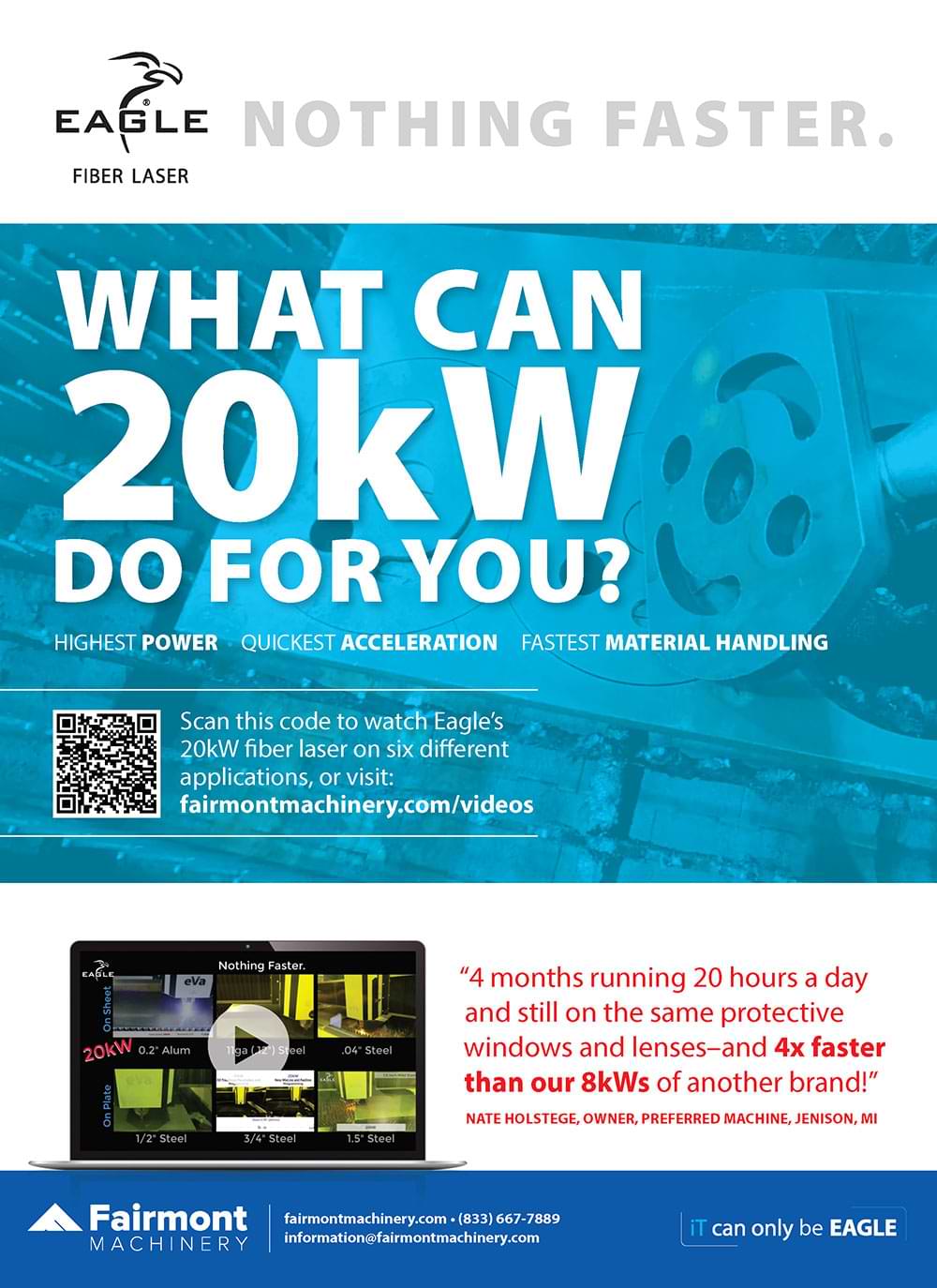

Lasers – Fiber

Press brakes—Hydraulic & Electric

Hydraulic shears

Charlotte, North carolina

President

connect with me for:

Material Handling

Automated Storage & Retrieval Systems

Robotic Equipment – Material Handling

Toronto, Ontario

V.P. Sales & Marketing

connect with me for:

Abrasives/Finishing

OAK LAWN, ILLINOIS

Sales Manager

connect with me for:

Circular Steel & Aluminum Cutting Saws

Deburring Machines

HSS and CBT/TCT Sawblades & Resharpening

Houston, Texas

Area Manager

connect with me for:

Plasma Cutting Machines & Components

Robotic Equipment – Cutting

Tube & Pipe CNC Pipe Cutting

Mechanicville, New York

Director of Sales

connect with me for:

Deslagging

Deburring and Surface Finishing

Top and Bottom Single Pass

Anoka, Minnesota

Regional Sales Manager, North

connect with me for:

Punch Press Tooling

Press Brake Tooling

Laser Consumables

ELGIN, ILLINOIS

Sales Administration Manager

connect with me for:

Lasers – Fiber and CO2 Lasers

Elk Grove Village, ILLINOIS

North American Sales Manager

connect with me for:

Laser Cutting Machines

Press Brakes

Software & Machine Controls

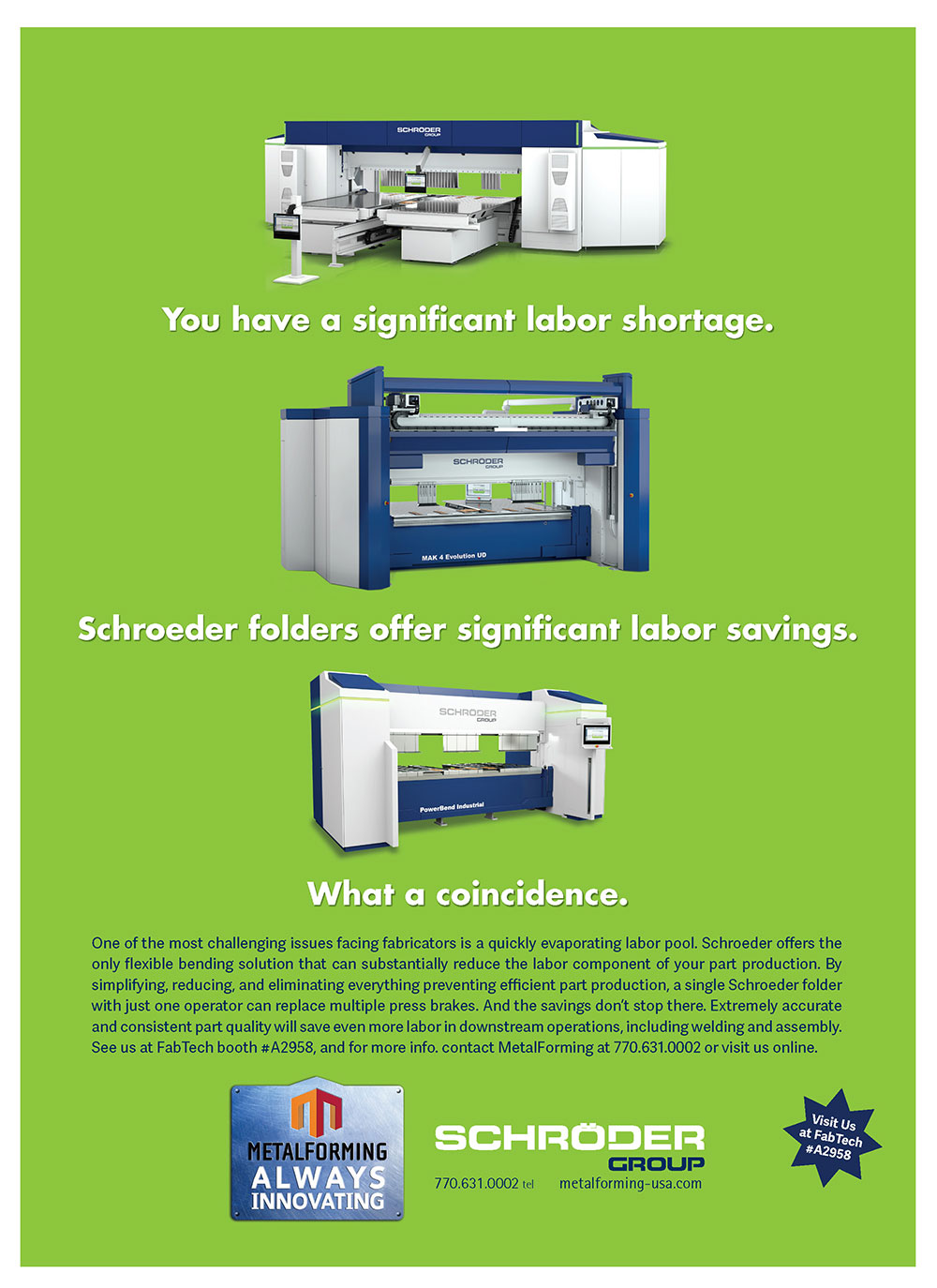

Peachtree City, GEORGIA

connect with me for:

Bending

Folding

Sheet Metal Storage

DFW Airport, Texas

Fabrication Product Manager

connect with me for:

Lasers Cutting Systems – Fiber and CO2

Waterjet Cutting Systems

Plasma Cutting Systems

Minster, Ohio

Auto Contract Segment Director

connect with me for:

Servo & Mechanical Presses

Coil Lines

Transfers

Philip, SOUTH DAKOTA

National Sales Manager

connect with me for:

Ironworkers

Circular Cold Saws

Hydraulic Presses

Leominster, Massachusetts

National Sales Manager

connect with me for:

SBX GP blades for the Fabricator

SBX One blades for Beams and Tubes

Siclone Blades for Hard Metals

Chattanooga, TENNESSEE

VP of Sales

connect with me for:

Resistance Welding

Water Chillers

Spot Welding

BELCAMP, MARYLAND

Vice President

connect with me for:

Sunrise Ironworkers

CNC

HBM

ELGIN, ILLINOIS

National Sales Manager

connect with me for:

Plate Bending

Automated Punching and Bending

Coil Fed Punching

chicago, illinois

sales representative

connect with me for:

Fabricators

Fabricators

I realized there were a lot of videos, [but] not an explanation behind how to do things.

I realized there were a lot of videos, [but] not an explanation behind how to do things.

Justin Merrill

I realized there were a lot of videos, [but] not an explanation behind how to do things.

I realized there were a lot of videos, [but] not an explanation behind how to do things.

Justin Merrill

I realized there were a lot of videos, [but] not an explanation behind how to do things.

I realized there were a lot of videos, [but] not an explanation behind how to do things.

Justin Merrill

abricators network, share articles, listen to podcasts and follow social platforms to find out what others are working on, many with the ultimate goal of attempting a project on their own. Wielding a welding torch can seem daunting to a novice fabricator, but a simple internet search can give a would-be metalworker access to educational resources for any level of experience.

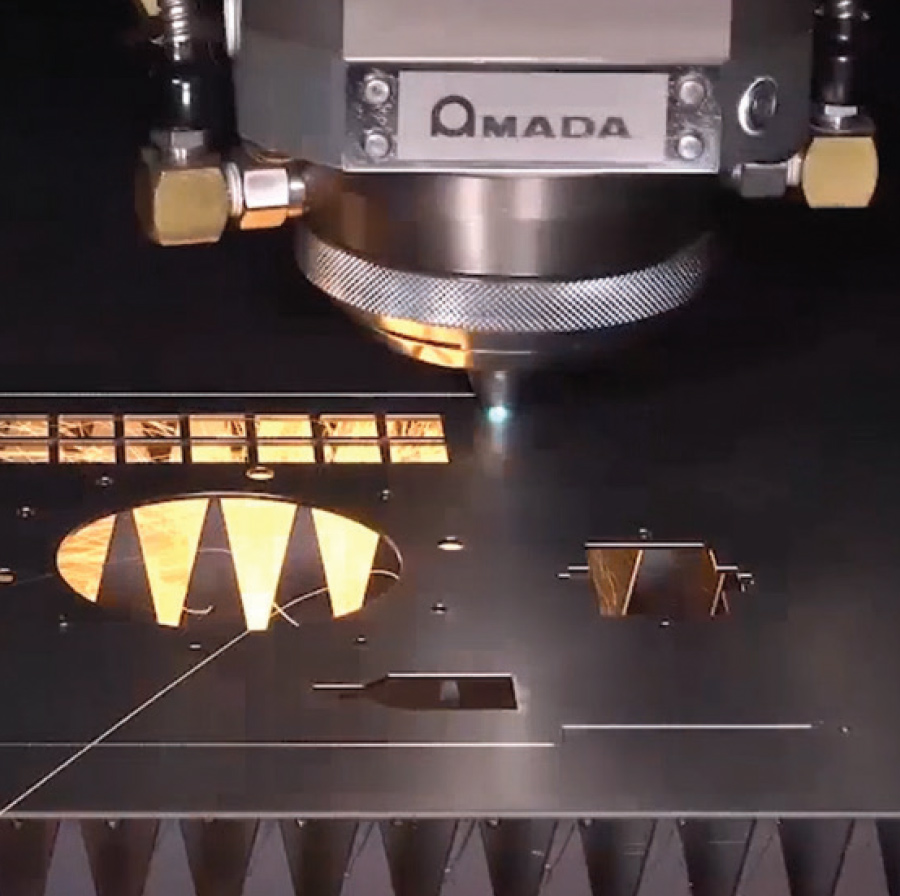

he versatile fiber laser has been adopted by a diverse market base for myriad applications. Power, speed and machine features top most fabricators’ wish lists, but the number of different models on the market can pose a challenge for companies looking to invest in the technology. To help narrow the field, manufacturers should ask questions that will help identify the fiber laser with the capability to take shop floor production to the next level in a digitized environment.

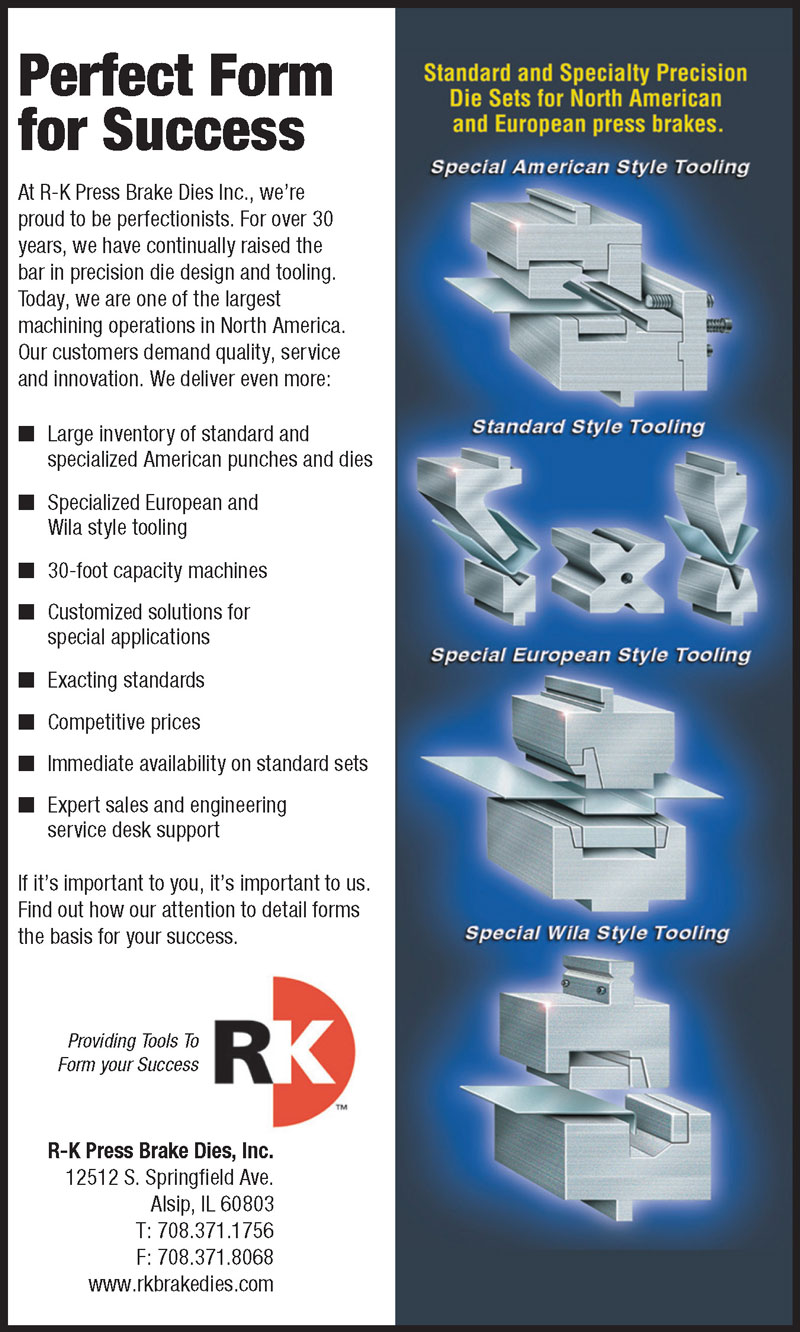

press brakes/tooling

fter researching what it would cost to upgrade existing equipment, Orbel Corp. President Ken Marino realized it made more sense to invest in new machinery. “The cost of the upgrade packages [for our existing machines] came pretty close to new machines—and you’re still dealing with wear and tear of older equipment without a warranty,” he says. “We realized we would be trying to take an old piece of equipment and make it new without the ability to produce the tolerances new machines are capable of making.”

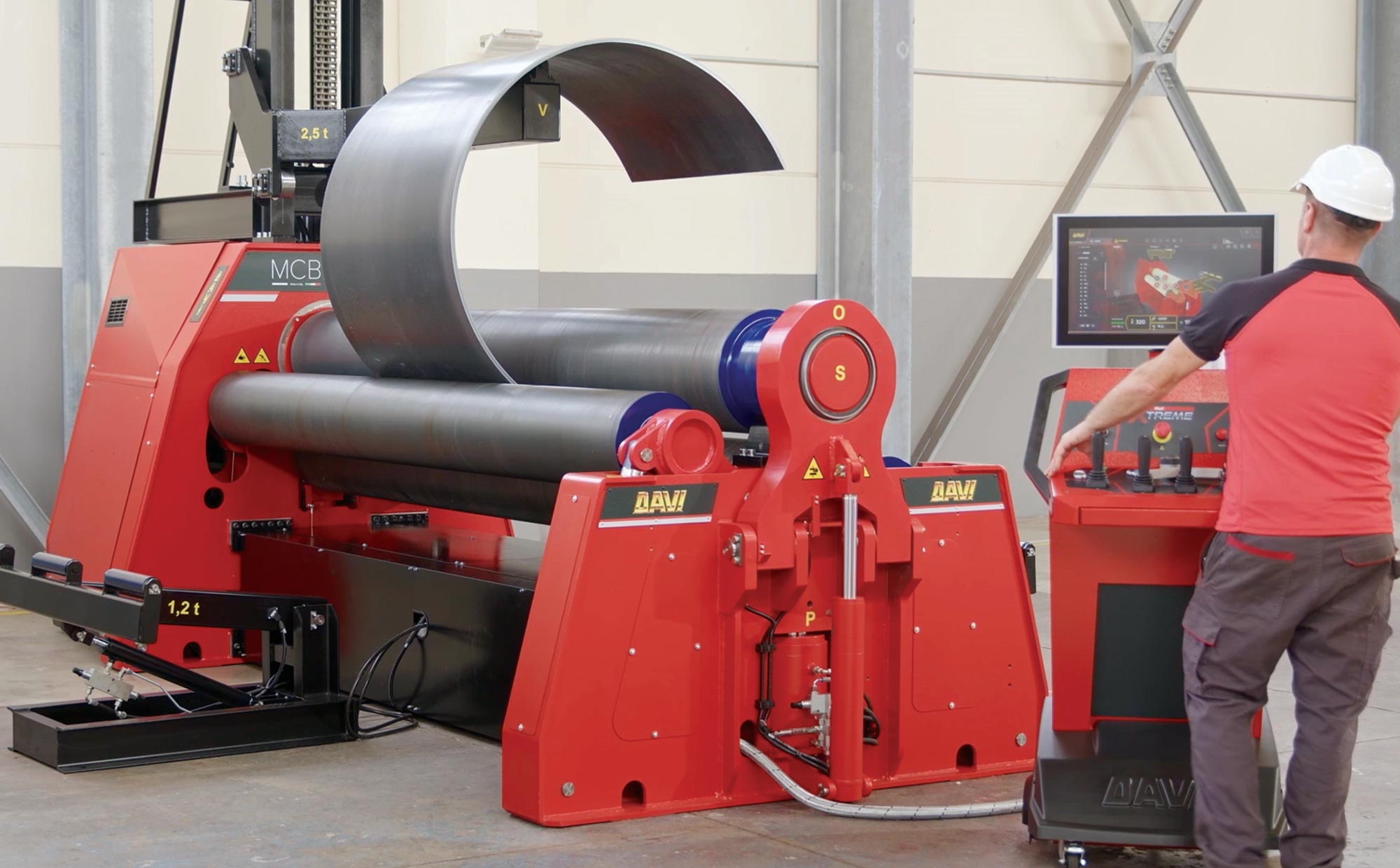

Plate & Angle Rolls

By Lynn Stanley, Senior Editor

The iRoll eXtreme can run a fully automated cycle, or operate in manual assisted or manual mode.

Extreme Makeover

New digitized control marries automation with smart technology to help manufacturers overcome skilled labor shortfall

hen it comes to rolling plate for heavy duty environments, there are a lot of variables to consider, from a material’s chemical composition and thickness to the strains associated with plastic deformation. In June 2021, DAVI Inc. introduced the iRoll eXtreme, a new digitized control that marries automation with smart, intuitive technology.

Delta Industrial works closely with machine manufacturers and customers to tailor press pits and machine foundations to specification.

Support Systems

Despite supply chain disruptions, press pit and machine foundation builder continues to complete projects on schedule

ike most companies that have weathered the events of the last 18 months, Delta Industrial has had to grapple with supply chain disruptions and worksite constraints, while continuing to meet customer demands. The Chesterfield, Michigan, company engineers and builds press pits and machine foundations, taking customers from design and construction to steel design and fabrication, concrete flatwork and contracting.

Fabricator expands its selling power by launching an online shop for consumers

ver the years, Southern Designs has refined its processes both on the fabrication floor and on the business side. In April 2021, the fabricator launched a Shopify store for its on-demand laser-cut metal wall art. Shopify allows Southern Designs to make its products available to other merchants. But before that could happen, CEO Tance Hughes had to make sure the company could meet demand and keep track of every step along the way.

igher grade, higher tensile material is the norm and bending heavy tonnage material can take a lot of time to manually set up, readjust and process. A press brake sophisticated enough to eliminate the need for excessive handling saves time and opens up new realms of possibility. “It takes so much tonnage to try and bend AR450 plate in particular, we were spending too much time working on each piece,” says Ryan Taylor, CEO, The Godwin Group, Dunn, North Carolina.

arnets, January’s birthstone, can be traced back to the Bronze Age, when they were used in burial jewelry and carved signet rings to indicate royalty. Egyptians coveted the gemstone, referring to it as the symbol of life or “heart’s blood.” In 1878, mineralogist Henry Hudson Barton found garnet on Gore Mountain in the Adirondack Mountains. He established Barton Mines Corp. and became the first to successfully process garnet ore into an industrial abrasive for sandpaper manufacturers.

Abrasives

By Gretchen Salois, senior editor

Specialty Welding and Fabricating of N.Y.’s fabricators can use upwards of 1,000 abrasive discs a week.

Specialty Welding and Fabricating of N.Y.’s fabricators can use upwards of 1,000 abrasive discs a week.

Beyond Reproach

Discs enable fabricator to affordably provide clean, smooth surfaces

unctionality, clean lines and a mirror finish. Specialty Welding and Fabricating of N.Y. Inc. can produce the desired aesthetic whether a spiral staircase for Microsoft’s corporate office in Atlanta or heavy-duty racks for conveyors used on loading freighters and barges transporting grains along the Mississippi. “We’re a job shop. We’ll build anything anyone asks us to build,” says Robert Hayes, purchasing agent.

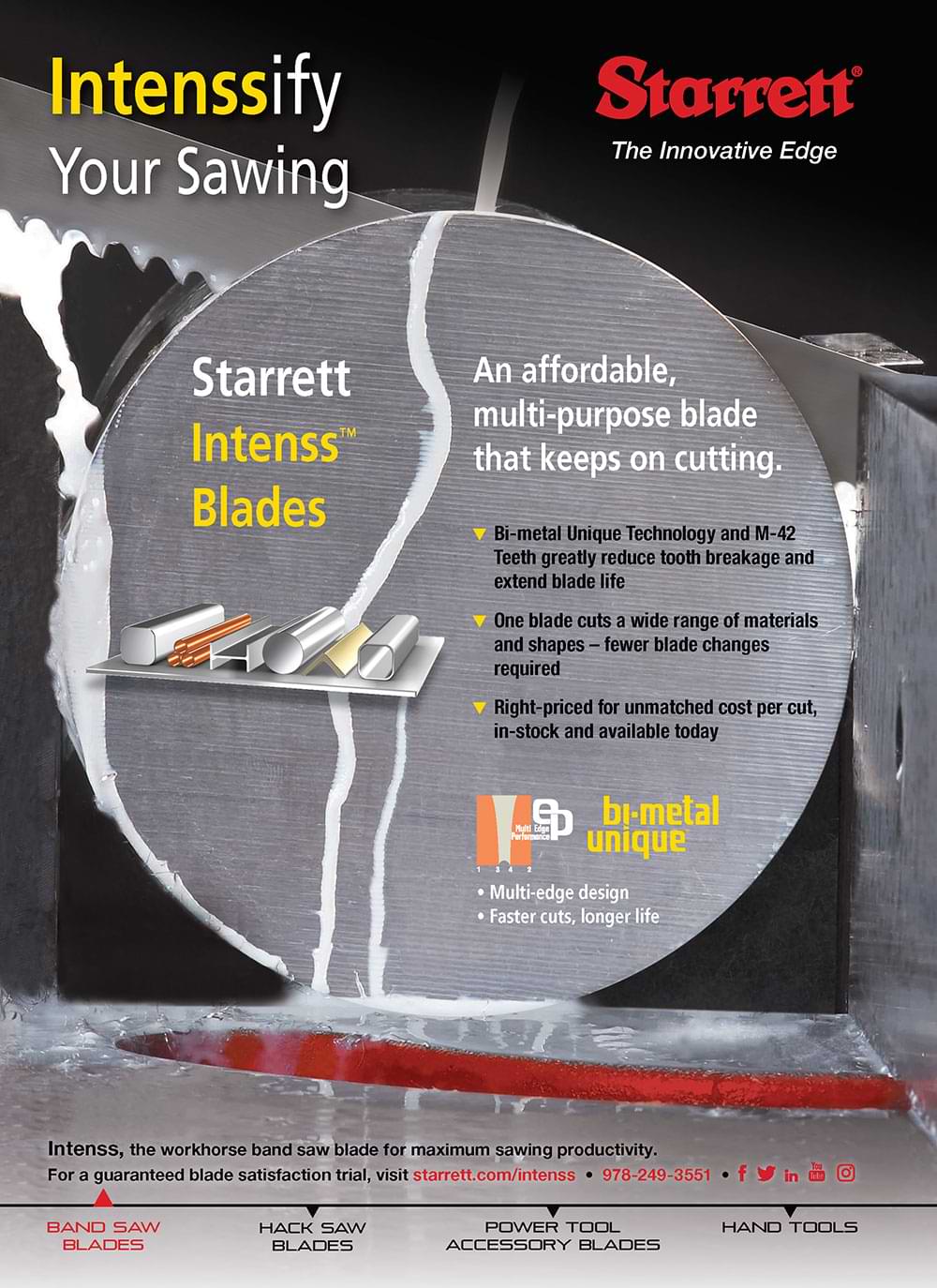

The L.S. Starrett Co., Athol, Massachusetts, 888/674-7443, starrett.com.

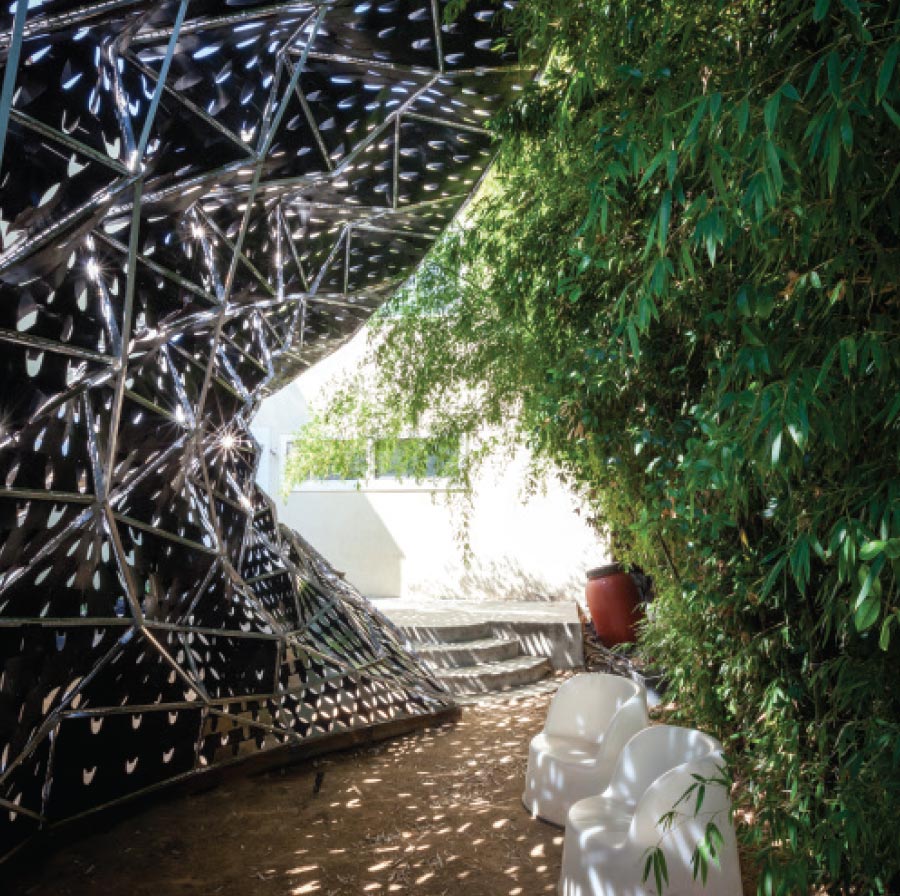

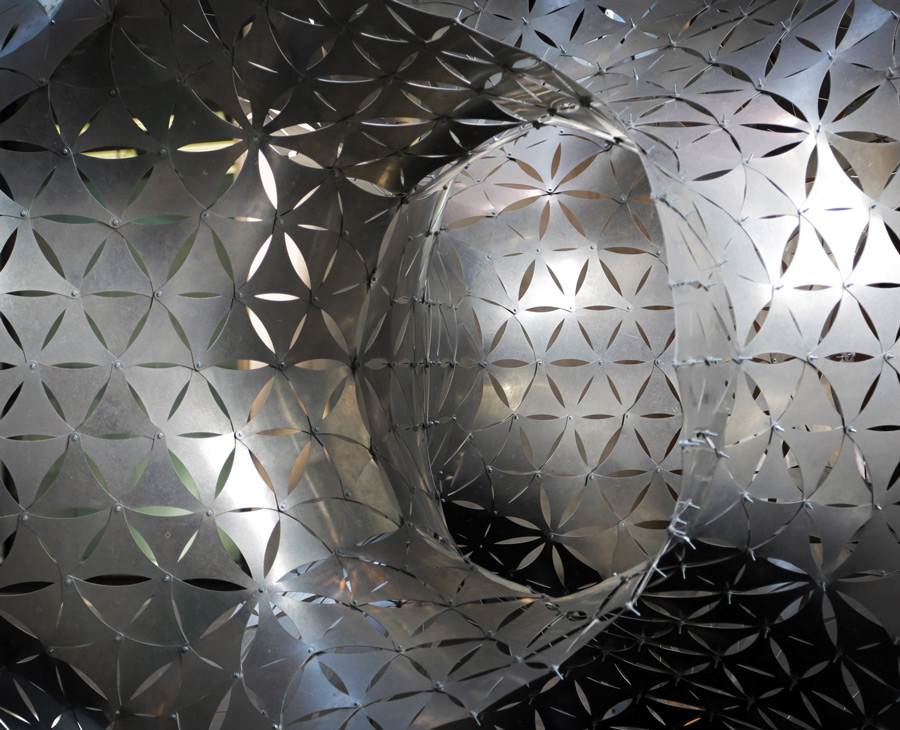

A sun-tracking instrument indexing time and temperature, Bloom stitches together material experimentation, structural innovation, and computational form and patternmaking into an environmentally responsive form. Its shape alludes to a woman’s Victorian-era undergarment and is made primarily out of a smart thermobimetal, a sheet metal that curls when heated (no controls, no energy). The form’s responsive surface shades and ventilates specific areas under the shell as the temperature rises. When used on a building’s surface, the thermobimetal will reduce dependency on costly air conditioning and delay the heat island effect. Thermobimetal is an example of increased complexities for building envelope design with new, smart and dynamic materials and will be a factor in the new era of facade aesthetics and urban expression.

A sun-tracking instrument indexing time and temperature, Bloom stitches together material experimentation, structural innovation, and computational form and patternmaking into an environmentally responsive form. Its shape alludes to a woman’s Victorian-era undergarment and is made primarily out of a smart thermobimetal, a sheet metal that curls when heated (no controls, no energy). The form’s responsive surface shades and ventilates specific areas under the shell as the temperature rises. When used on a building’s surface, the thermobimetal will reduce dependency on costly air conditioning and delay the heat island effect. Thermobimetal is an example of increased complexities for building envelope design with new, smart and dynamic materials and will be a factor in the new era of facade aesthetics and urban expression.

Editor-in-Chief

Michael D’Alexander

Lynn Stanley

Gretchen Salois

J. Neiland Pennington

Lauren Duensing

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323

www.ffjournal.net

Carlotta Lacy

Matthew LaFleur

Mark Koenig

Michael D’Alexander

Jim D’Alexander

Wayne Krusen

Traci Fonville

Bill D’Alexander

312/654-2309, Fax: 312/654-2323

mdalexander@ffjournal.net

Alaska, Arizona, Arkansas, California, Hawaii, Idaho, Montana, New Mexico, North Dakota, Oklahoma, Texas, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@ffjournal.net

Alabama, Colorado, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Pennsylvania, South Carolina, South Dakota, Tennessee

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@ffjournal.net

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@ffjournal.net

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Valerie Treiber, National Sales Manager

203/894-5483

valerie@modernmetals.com

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@ffjournal.net

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJOURNAL® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJOURNAL® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.