merican novelist and short-story writer Jack London said, “You can’t wait for inspiration. You have to go after it with a club.”

In the 1980s, when computer numerical controls (CNC) and computer-aided design (CAD) software in manufacturing applications proliferated, Juan Luis Larrañaga thought, “Why not use a computer to automate programming to make the whole process faster and easier?”

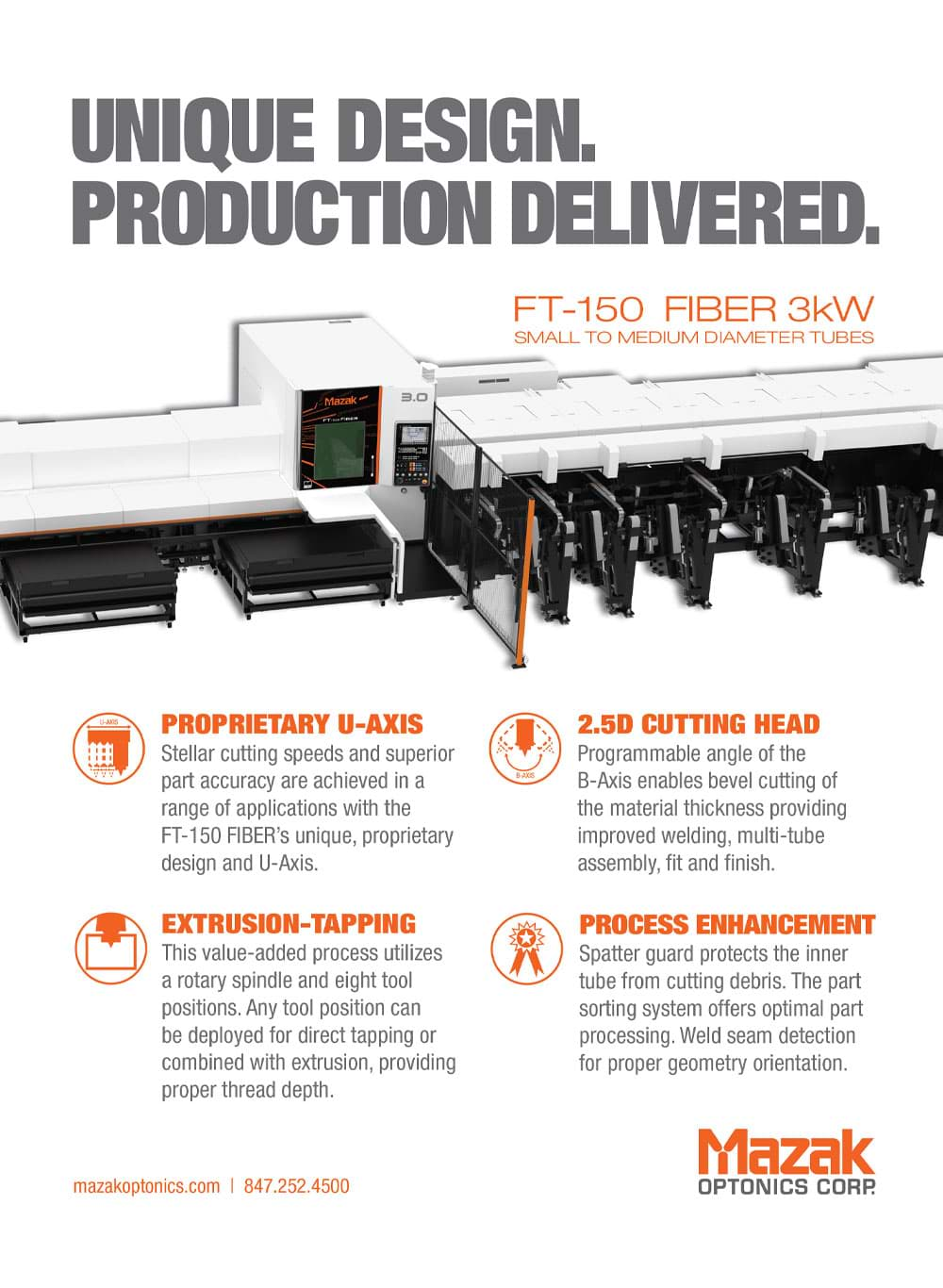

In 2009, Lantek opened a sales and support center in Mason, Ohio, under the name Lantek Systems Inc. It provides CAD, CAM, MES and ERP software solutions for U.S. manufacturers that use fiber lasers, plasma cutters, waterjets, shears and punches to process sheet metal, tubes and beams.

It’s an advantage to be able to almost instantly generate a quote.

It’s an advantage to be able to almost instantly generate a quote.

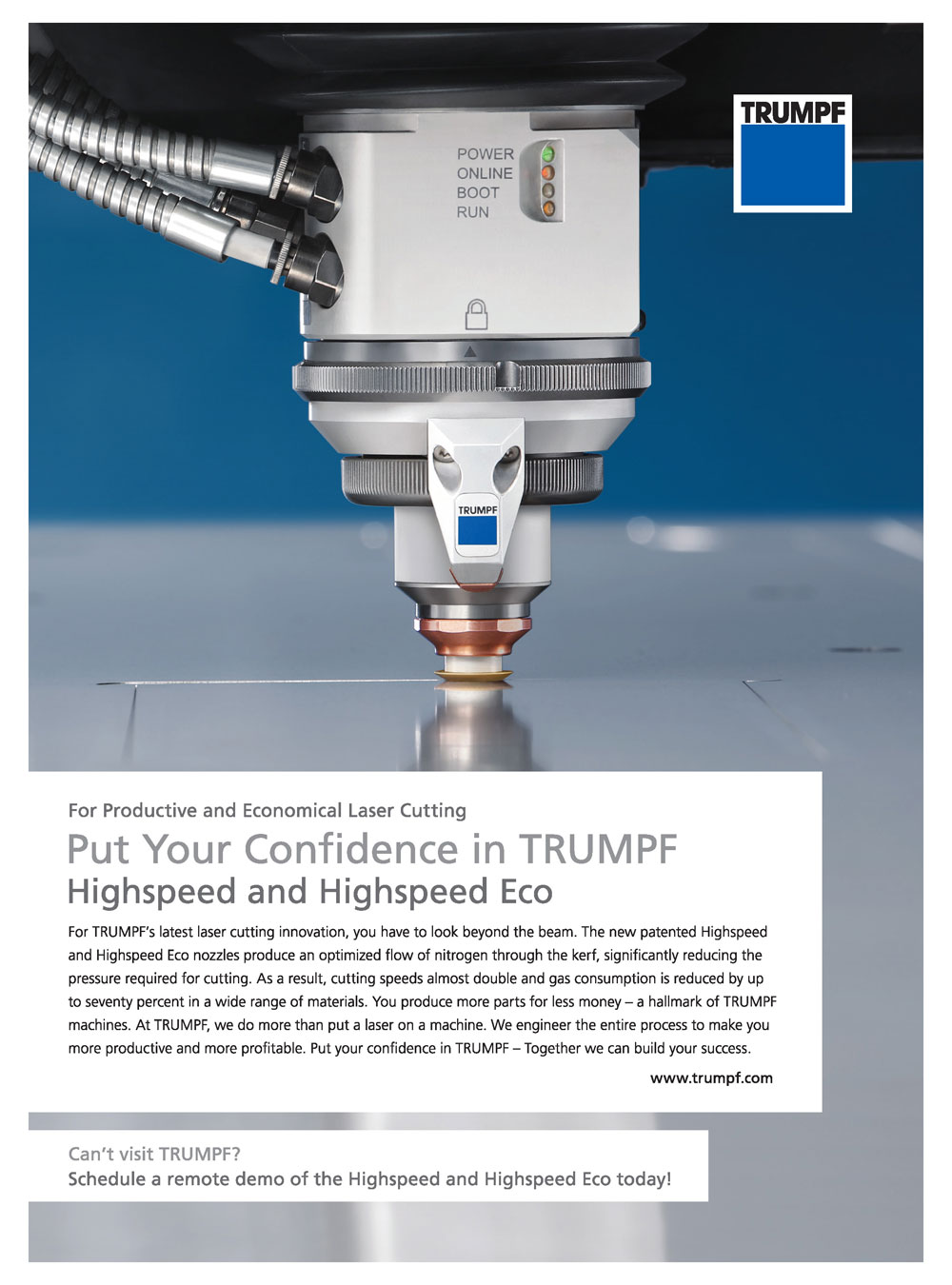

The product line can integrate new machines like fiber lasers with legacy equipment. “We are a third-party vendor that can work with the majority of machines in the marketplace,” says Must. “Our library has more than 1,200 different post processors for cutting machines that we’ve completed successful installations with.” Post processors convert toolpaths into programs that can be read by a machine’s controller.

Facilitating machine-to-machine communication is only the first step. The software products streamline complex tasks that trickle through the supply chain.

“It’s a daunting process to quote jobs because a number of manufacturers still use Excel,” Must says. “Because our software stores information digitally, it can instantly access the data to reveal whether or not a company is realizing its profit potential. A company can email a quote to a customer the same day and improve its chance of winning a job. It’s a big advantage to be able to almost instantly generate a quote when you consider that conventional methods can take up to a week. Companies can’t afford that kind of time if they want to be competitive,” he adds.

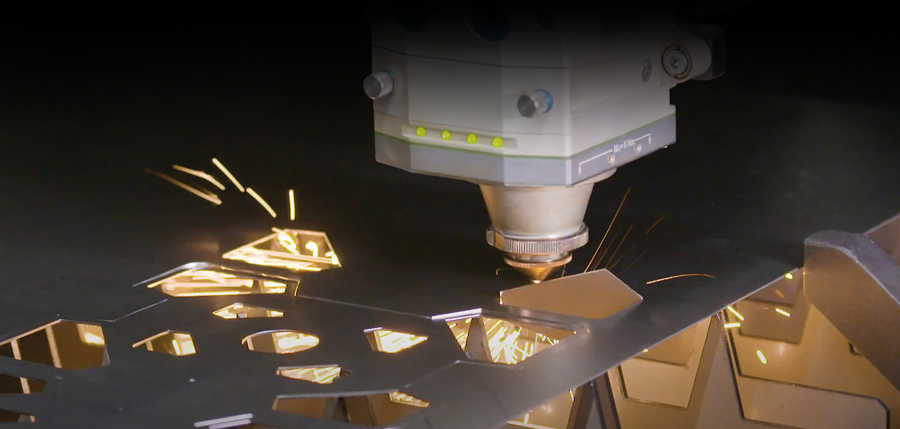

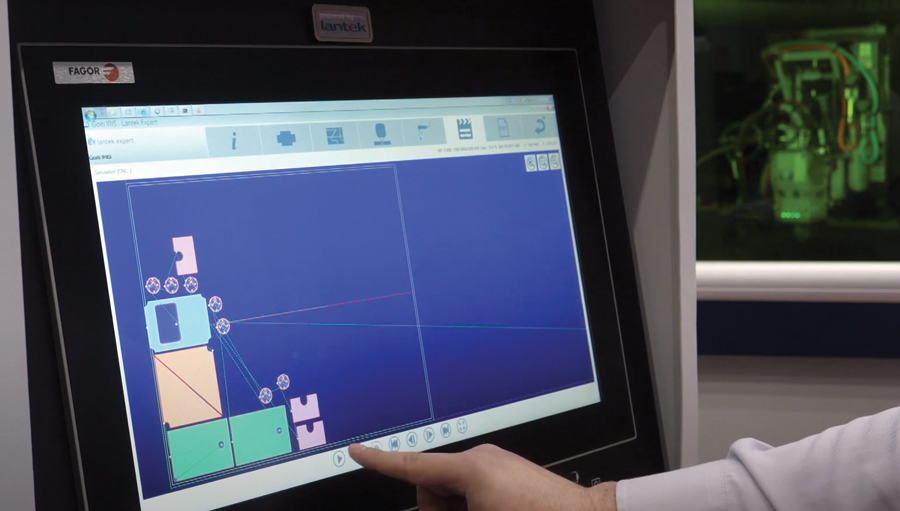

The program’s Do-All function allows programmers to automatically nest all pending jobs and make alterations to part flow, giving them control over orientation, positioning as well as machine selection for parts and management of scrap to support safe operating practices. The Do-All feature can support multiple machines and material processing as well.

Autonest will automatically seek the best way to nest parts for each operation. Parts can be nested right before fabrication, versus taking days to program code.

This year, Lantek released a new feature called Intelligent Collision Avoidance (ICA). The proprietary algorithm combines different strategies designed to avoid collisions between a fiber laser’s cutting head and parts that have been processed.

Lantek’s software solutions undergo stringent testing and must meet rigorous quality standards. Support services are geared to optimize customers’ production processes. “Our goal is to see that manufacturers save time and money in production and realize an ROI on their software purchase as quickly as possible,” he says.

While the industry continues to grapple with the effects of COVID-19, Lantek products have demonstrated an unexpected advantage. “The pandemic and its initial shelter-at-home order made the industry aware of different ways of working,” Must observes.

“Many employees continue to work remotely, and the circumstances have companies asking, ‘How do we do this?’ Engineers and technicians can program from home and send files to an operator who loads them on the machine, but if that machine is connected with software and internet access, we can send files straight to the machine control and have parts cut—that’s the ultimate goal,” says Must.