Features

/customfabricator

/welding

/stainless

#weldlicious #weldeverydamnday #welding

From the

Publisher

Going virtual

o say this has been an interesting year is an understatement. Since March, each of us has been impacted by the pandemic both at home and at work. In our industry, we all have had to learn to do things differently. Sales personnel have been unable to travel and talk with customers face to face. Instead, employees have had to connect through Zoom conferencing and learn to use platforms like YouTube to conduct equipment demonstrations. Trade shows have ground to a halt, including the metal fabricating industry’s premier events like IMTS and FabTech.

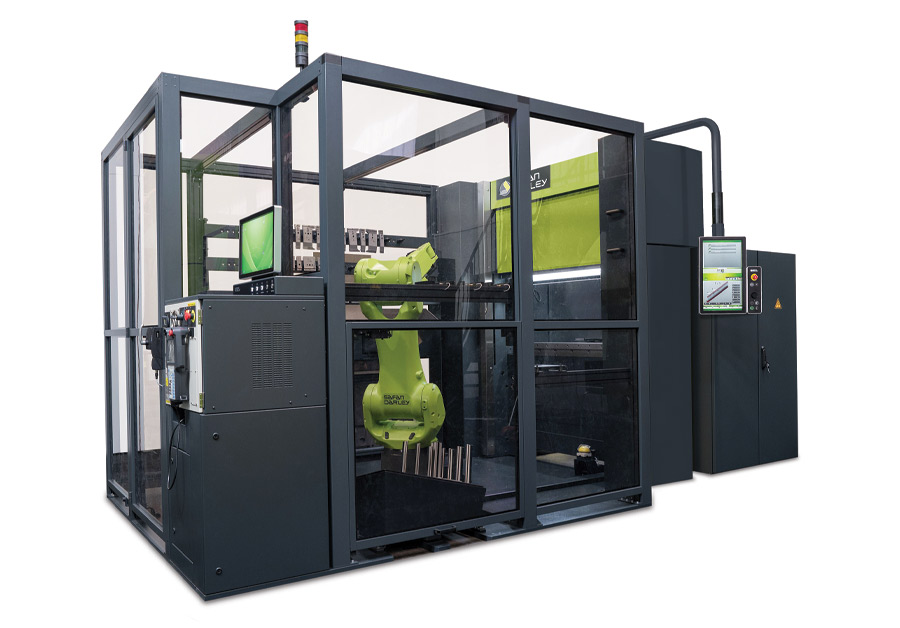

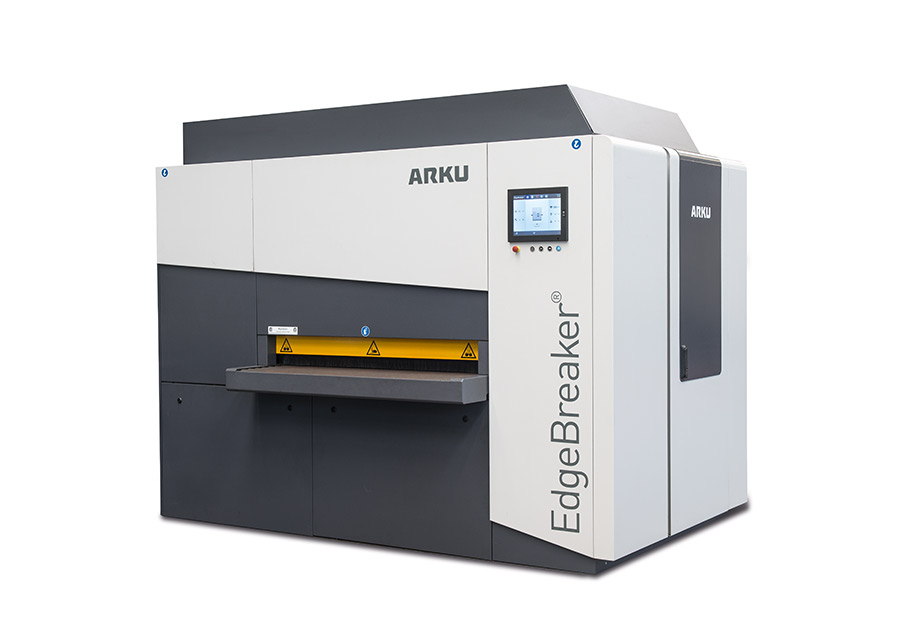

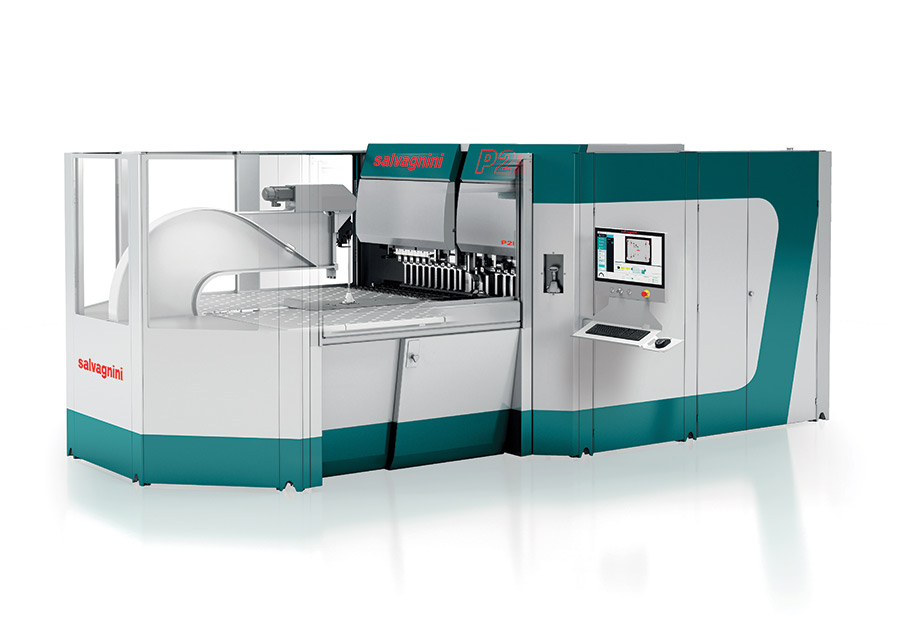

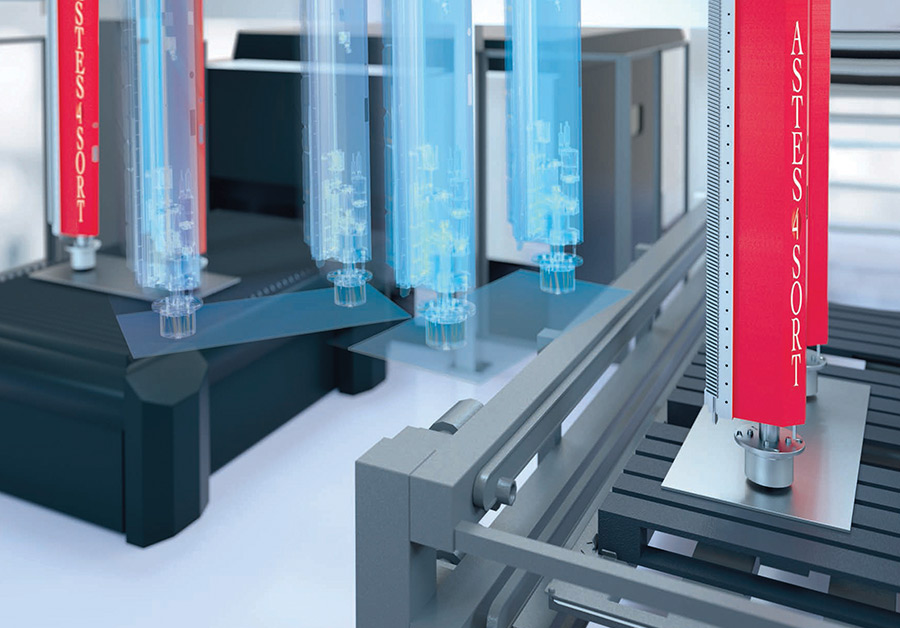

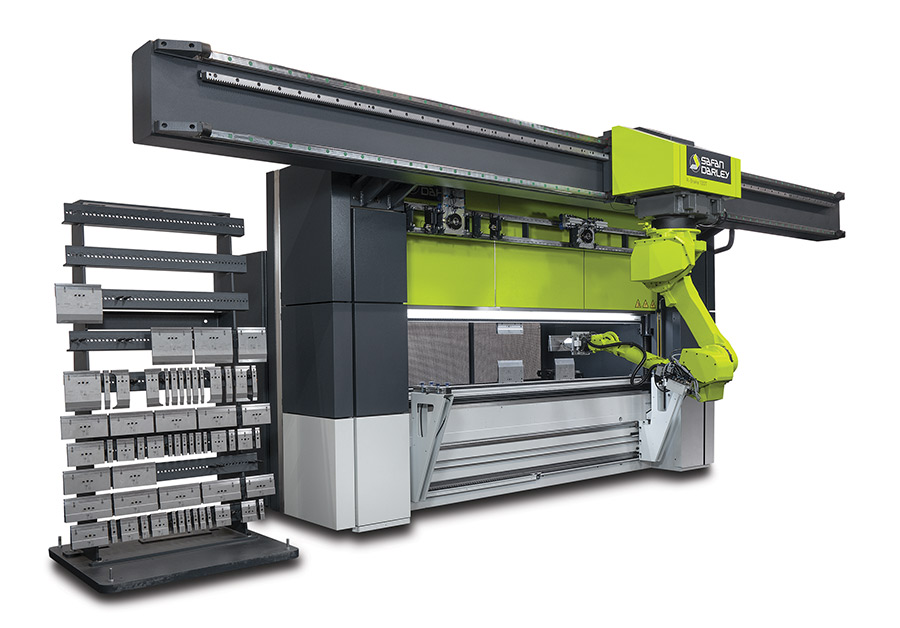

anufacturing companies are living in a much different reality than they were 20 years ago. Expectations are exponentially more demanding than before due to increased competition, market conditions, access to markets and materials, and globalization. To serve these increased customer demands, manufacturers have started on a quest for automation.

Not everybody understands that automation goes beyond acquiring more equipment and machinery. It is a blend of having the right people involved, rethinking the process and using the data available. When I look at our customer base, those that are growing all have three things in common—a continuous improvement plan, a willingness to invest in technology and software, and a willingness to get uncomfortable and trust parts of their business to automation.

aving instructors who still work in the field helps ensure that students are being taught what is necessary to succeed,” says Bob Dak, a 2020 inductee into the Testing and Balancing Bureau (TAB) Hall of Fame.

Prior to retiring in October, Dak taught beginning and intermediate TAB classes, the Title 24 classes, and mentored other TAB teachers at the Southern California Sheet Metal JATC.

Dak’s Hall of Fame nomination package was full of glowing words from those he’s worked with. “I believe Bob symbolizes the very spirit in which this award is given,” says Lance Clark, administrator for the Southern California Sheet Metal Joint Apprenticeship Training Committee (JTAC).

merican novelist and short-story writer Jack London said, “You can’t wait for inspiration. You have to go after it with a club.”

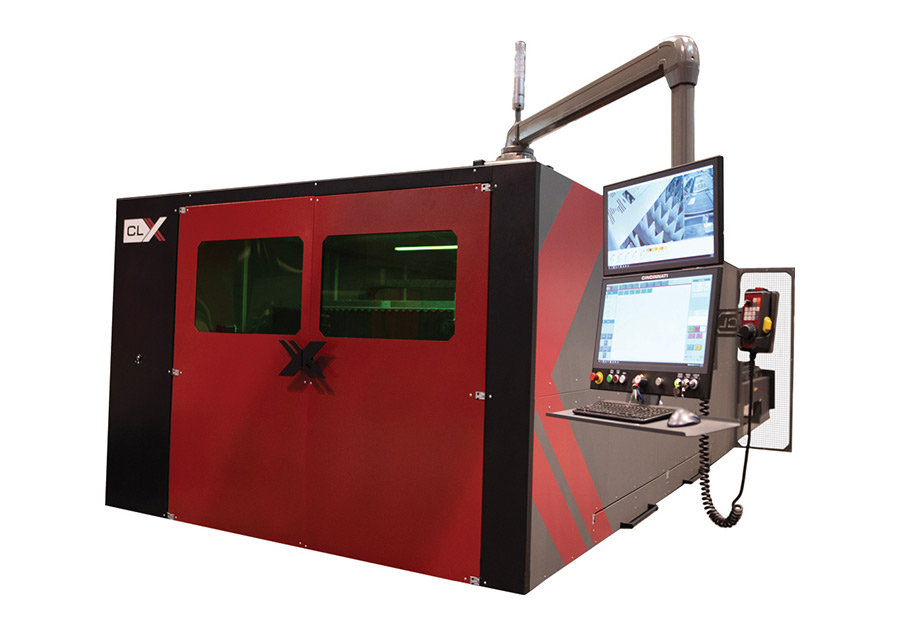

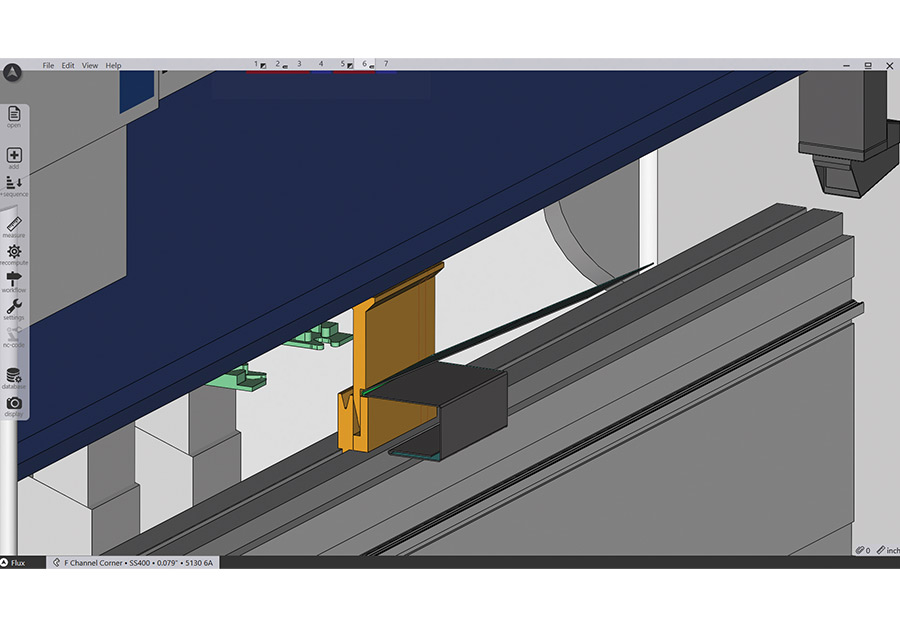

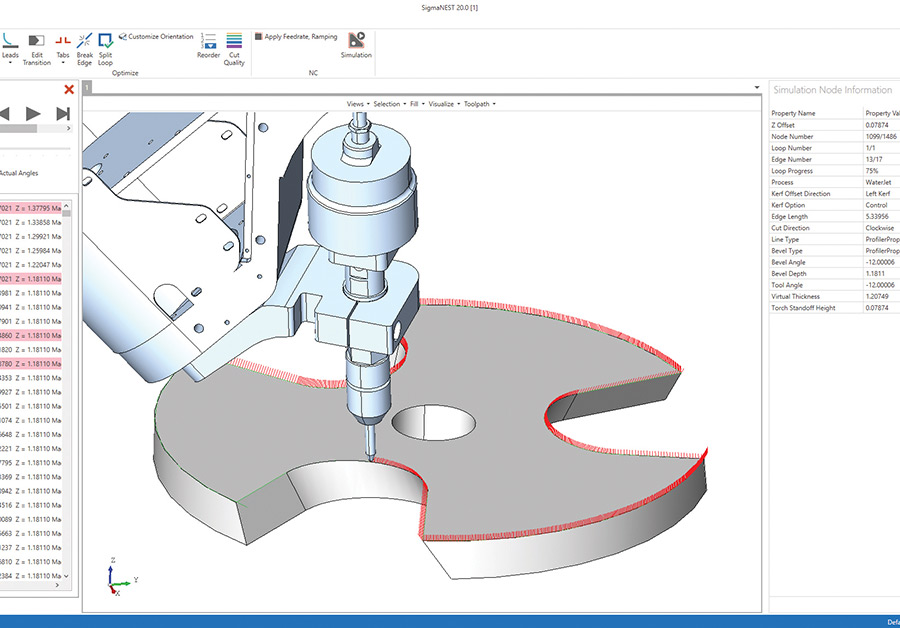

In the 1980s, when computer numerical controls (CNC) and computer-aided design (CAD) software in manufacturing applications proliferated, Juan Luis Larrañaga thought, “Why not use a computer to automate programming to make the whole process faster and easier?”

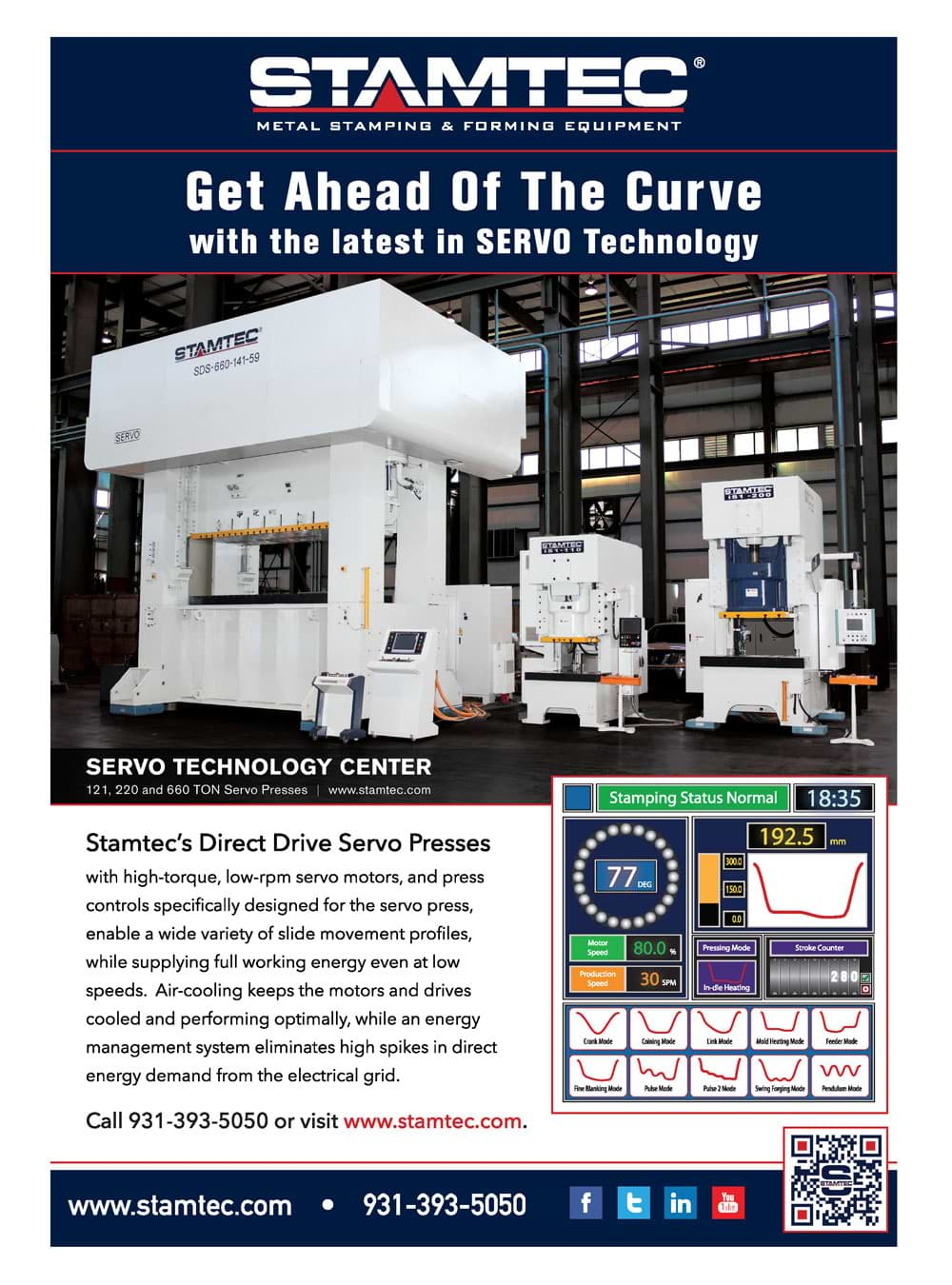

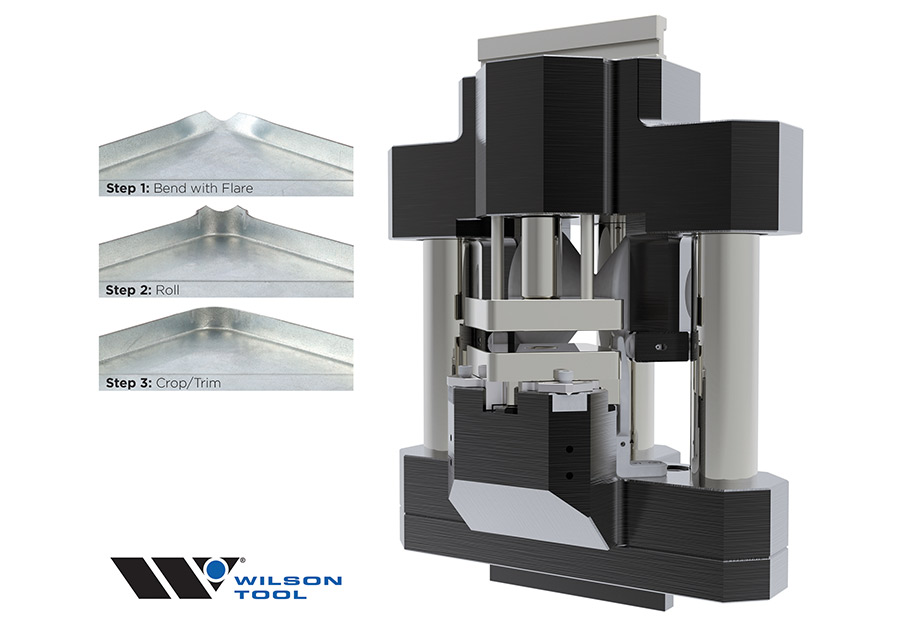

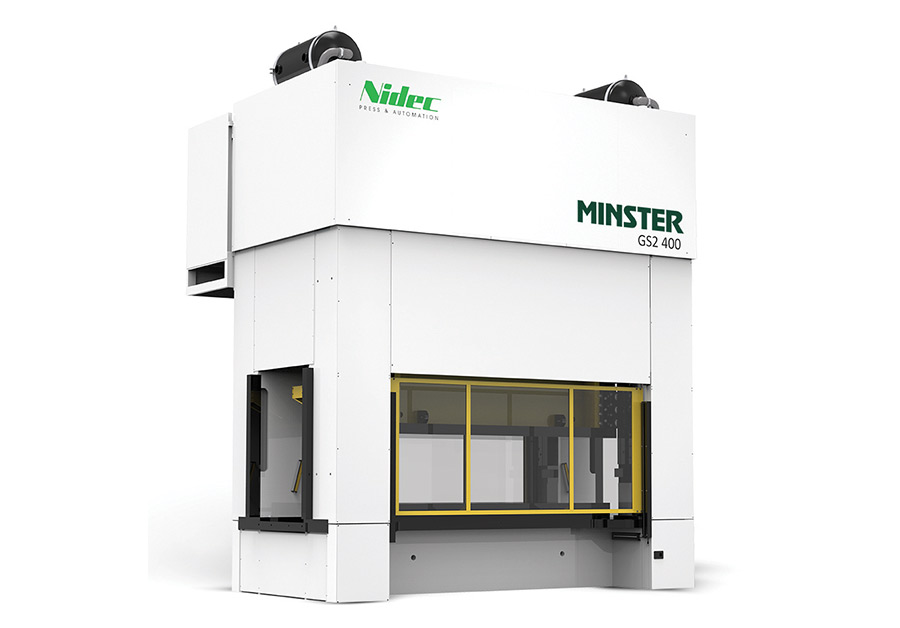

he quest to make vehicle components lighter while improving safety continues to push the development of advanced high-strength steels (AHSS). New grades of third-generation AHSS are undergoing qualification and gaining production-ready status. These materials surpass dual-phase steels in their ability to cold stamp complex shapes, but also promise efficiency in the era of electric and autonomous vehicles.

On the equipment side of the equation, these trends have helped servo press technology evolve from a niche product to the gold standard—particularly among automotive stampers.

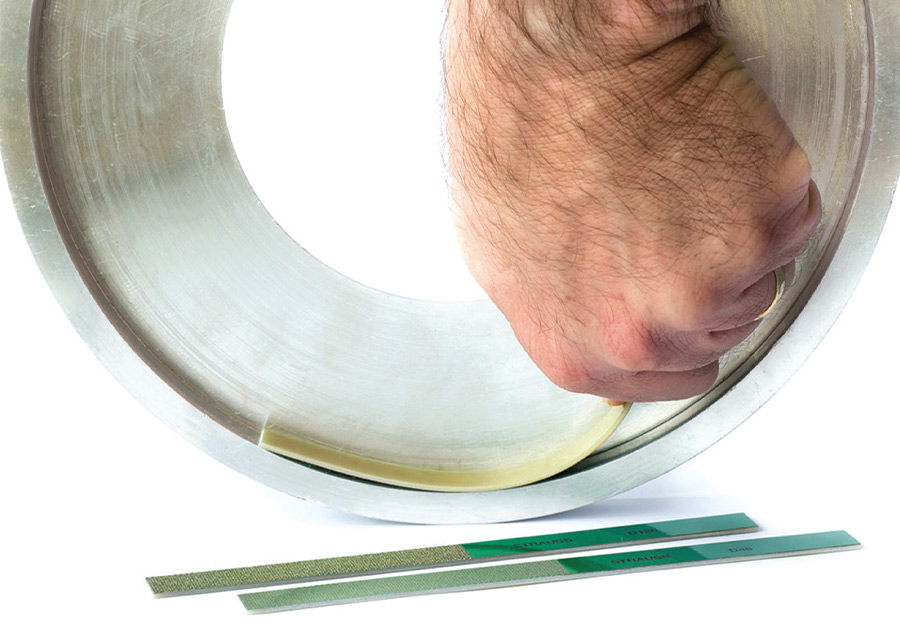

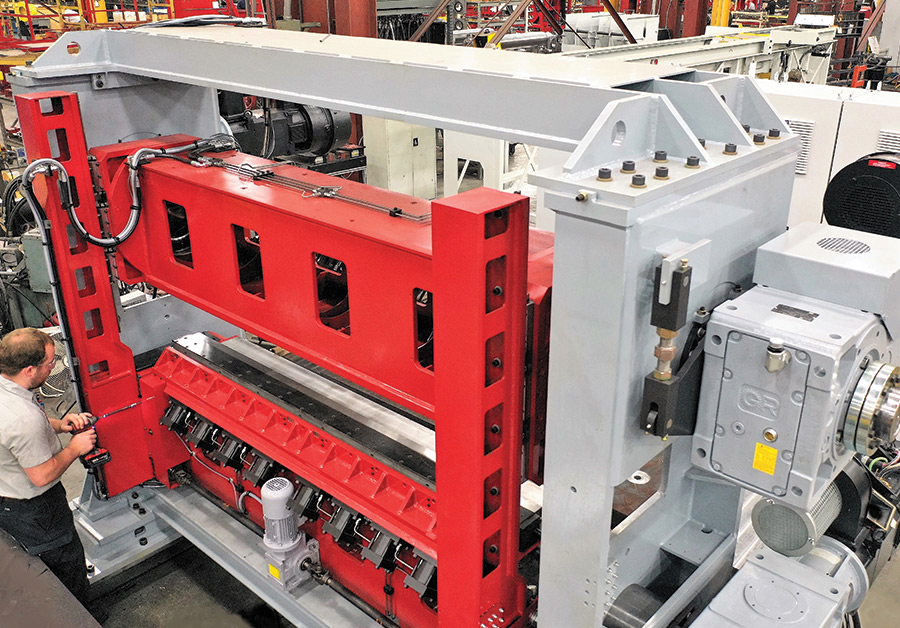

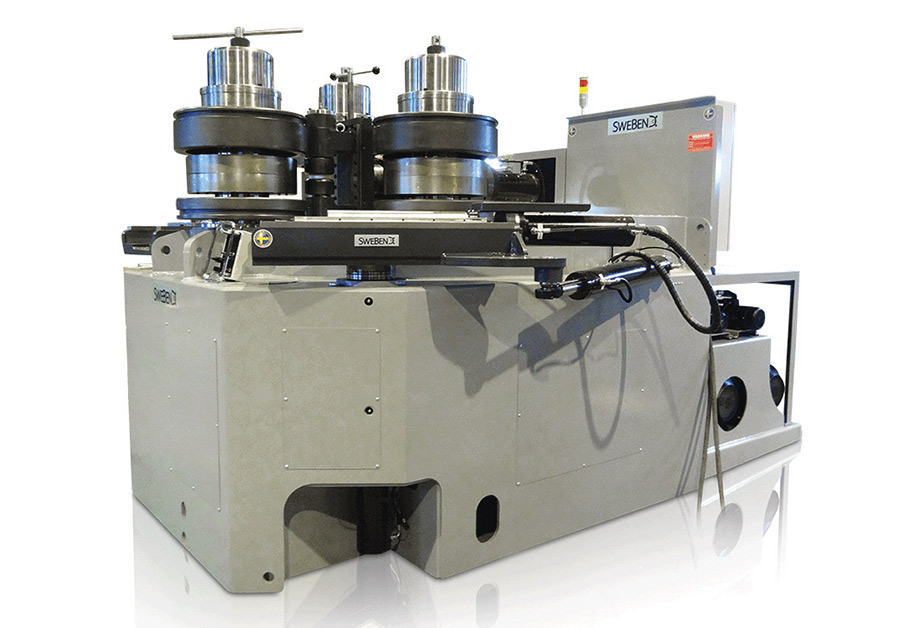

uclear power remains an alternative to fossil fuels, and while the global economy adjusts to fallout from COVID-19, several countries are looking for ways to boost a faltering economy. Davi recently engineered and installed its largest rolling machine for a customer making nuclear reactor components. It had to navigate supply chain challenges as well as logistics to build a machine capable of bending 7,300 tons.

Few forges in the world are able to handle a roller with a top roll measuring 20 ft. long, with an 80-in. diameter, and weighing 140 tons. Finding forge shops capable of handling the massive size—while adhering to quality and production requirements—proved challenging, says Dario Mulazzani, project manager.

or most people, “throwing in the towel” means to quit. The idiom derives from the boxing ring of the 1900s when a trainer threw a towel into the ring to signal early defeat. Today, the ritual is still used in professional boxing but the referee has the option to throw the towel back to the trainer if he thinks the decision to quit is premature.

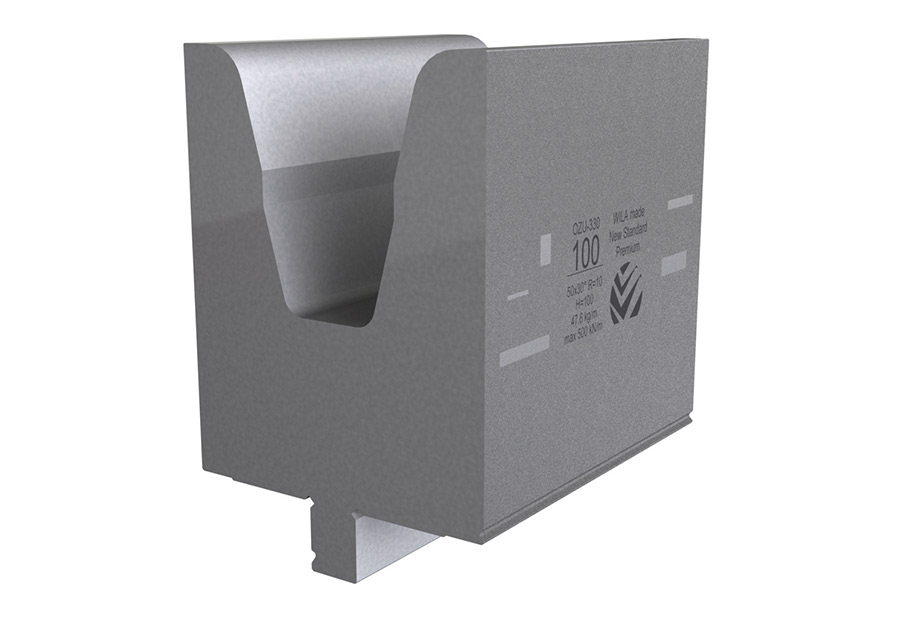

When it comes to determining whether a legacy press brake can go another few rounds, Bill Helinski, president of Automec Inc., says, “You don’t have to throw in the towel on your existing press brake. If a machine meets required tolerances and accuracy, a retrofit project can give you virtually everything you would get on a new press brake at a significantly lower cost.”

capotasto, better known as a capo, is a small device designed to quickly change the pitch of a stringed instrument. Used by virtually every musician, from famous touring professionals to campfire players, a capo is an essential tool for every kit.

Kyser Musical Products, founded in 1980 by Milton Kyser, has made a name for itself as the worldwide leader in capo manufacturing. Kyser has distributed its product throughout the world of music and into the hands of many well-known musicians. From George Strait and Katy Perry to John Mayer and Bon Jovi, Kyser capos are a staple for guitarists, bassists, banjoists and other musicians.

- HYDRAULIC IRONWORKERS

- CIRCULAR COLD SAWS

- TUBE & PIPE NOTCHERS

- MEASURING DEVICES

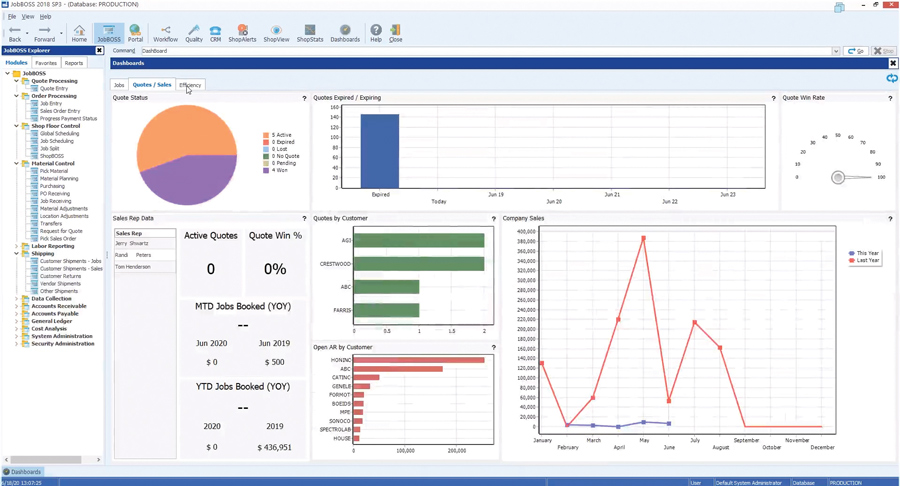

complete software suite overhaul can seem daunt-ing and risky during normal circumstances. When the COVID-19 pandemic tied up the econ-omy, Crafts Technology in Elk Grove Village, Illinois, chose to add two soft-ware modules to its existing ERP system to streamline operations and communi-cation between remote and on-premise departments.

“We needed to take incremental steps in order to adjust to an unprecedented work-from-home situation,” says Joe Ab-bate, technical sales manager. “We had to consider that a lot of our workers have gone into work for 40 years and working from home seemed awkward. It wasn’t an easy change for them to make.”

View Index

Editor-in-Chief

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323, www.ffjournal.net

312/654-2309, Fax: 312/654-2323

mdalexander@ffjournal.net

Alaska, Arizona, Arkansas, California, Hawaii, Idaho, Montana, New Mexico, North Dakota, Oklahoma, Texas, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@ffjournal.net

Alabama, Colorado, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Pennsylvania, South Carolina, South Dakota, Tennessee

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@ffjournal.net

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@ffjournal.net

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@ffjournal.net

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJournal® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJournal® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.