he human heart is roughly the size of a large fist, weighing 10 to 12 ounces, yet it pumps blood throughout the body to feed organs and tissues with life-sustaining oxygen and nutrients.

For JIT Manufacturing Inc., Salvagnini L5 fiber laser technology is the heart that pushes parts to multiple operations 24/7 to support customer demand and nourish growth.

“We’ve had our eye on growth and looked at different ways we could capture new business,” says Nick Ricard, JIT Manufacturing’s vice president and general manager. “The fiber lasers have really helped to move us closer to those goals. These machines are the heartbeat of this company.”

With close to $1 million in revenue a month, the Woodinville, Washington-based manufacturer has built its business based on its ability to produce precision, high-tolerance sheet metal and machine parts for a diverse group of customers.

Ricard will mark 16 years with the company in June. He took the position of vice president in 2019, crediting his mom with mentoring him for the general manager position.

We had four punch presses but found that one Salvagnini fiber laser could outperform those machines.

We had four punch presses but found that one Salvagnini fiber laser could outperform those machines.

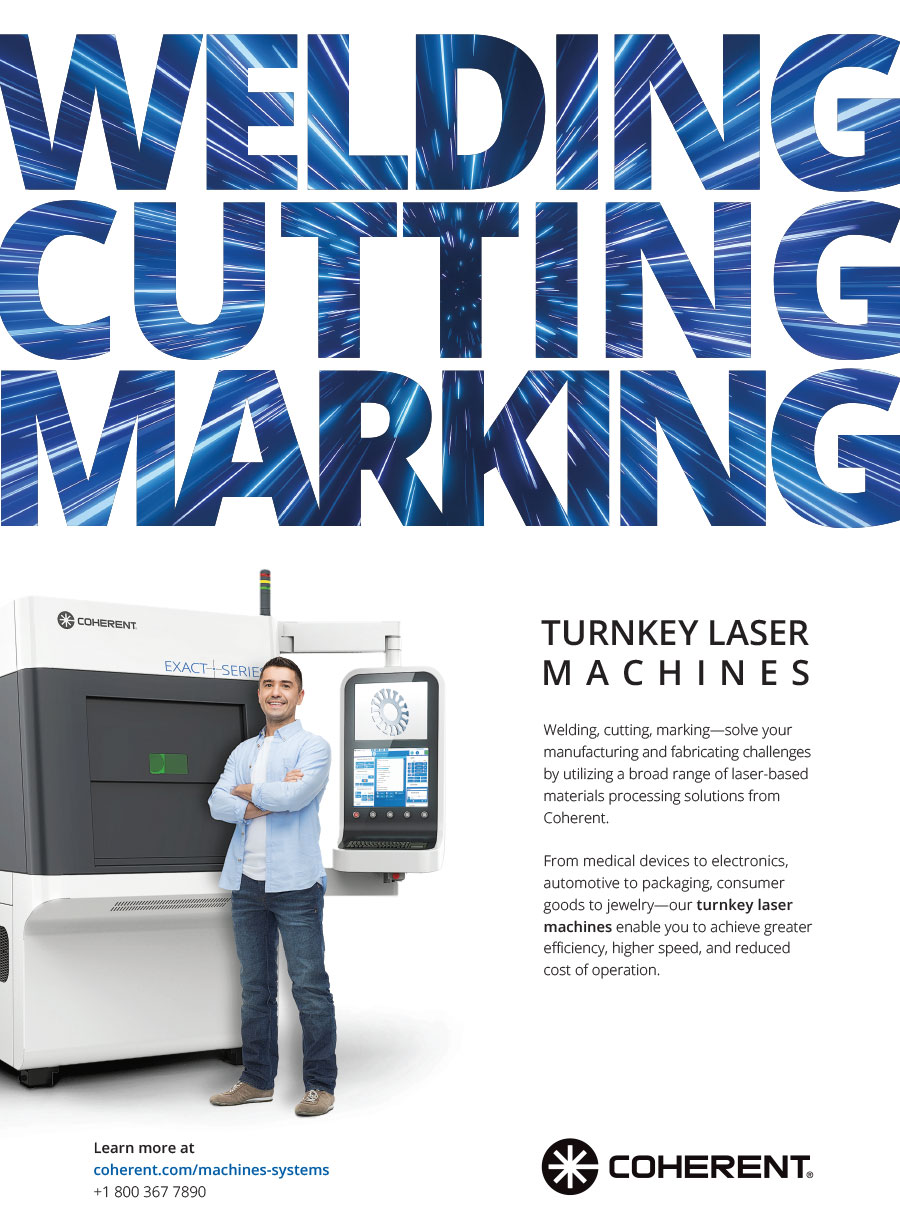

The manufacturer purchases 4-ft. by 10-ft. sheets that are automatically fed to the fiber lasers, which cut and push parts downstream to other processing operations. “The fiber lasers are cleaner, simpler and more accountable,” says Ricard. “That’s what we love about them.”

The L5 systems use a single optics head that provides precision cutting across a range of material thicknesses. Salvagnini’s dry cooling technology cools the optics without the use of gas or liquids for real-time control of lens temperature.

Three cutting functions—Standard, PowerCut and DynamicCut—allow the operator to use the mode best suited to the job at hand. The fiber laser holds a positioning accuracy of 0.003 in., a feature that Ricard found attractive.

JIT Manufacturing runs three shifts—a day crew, night crew and weekend crew—to support production of about 80,000 parts per month. “The fiber lasers pretty much run 24/7,” he says. “They have to.”

With variable lead times, Ricard adds that JIT Manufacturing has its finger on the pulse of the economy. “We’re seeing an uptick in business but we’re also the first to feel changes in the marketplace.”

Despite the added challenges of a pandemic, JIT is committed to its personnel and its customers and the fiber lasers are a key component. “Our heartbeat has to keep pumping,” he says.

425/487-0672, jit-mfg.com.