Features

/stainless

/abrasives

/training

From the

Senior Editor

‘Fight tonight’

hile writing this, news reports bring word that new cases of COVID-19 in New York City—one of the hardest hit areas in the U.S.—are beginning to level out. Sheltering in place is working. Daily life around the world is inherently changed and each new week looks dramatically different from the last.

In the fabrication world, I’ve heard from shops managing with fewer people reporting to work while, in other cases, shops are ramping up production as their supply chains look locally instead of relying on vendors overseas. Still other shops are uncertain what their production schedules will look like in the coming months and are working to manage this new landscape.

- HYDRAULIC IRONWORKERS

- CIRCULAR COLD SAWS

- TUBE & PIPE NOTCHERS

- MEASURING DEVICES

More than 500 members joined in the first week, and tons of ideas are shared every day.

More than 500 members joined in the first week, and tons of ideas are shared every day.

AXYZ Automation Group

s the COVID-19 respiratory virus continues to spread, people around the world are adjusting to a new at-home lifestyle—working, learning and spending time with friends virtually instead of face to face. Despite the required physical distance, many communities are stronger than ever. Neighbors check in with each other, support local restaurants and businesses, and sing and shine lights every night to praise healthcare workers, first responders and other essential employees.

As COVID-19 was becoming an international pandemic, AXYZ Automation Group (AAG)—comprising AXYZ Routers, WARDJet waterjets and CNCShop—created an online LinkedIn group called Fabricators Fighting COVID-19. The company had noticed that many of its customers were eager to help in the fight against the virus by fabricating solutions for personal protective equipment (PPE) and other safety supplies.

ome manufacturers have automation requirements that are well-defined and documented. Others are uncertain about what automation solution to pursue or even how to get started.

The reasons for automating a press vary, and include working with cumbersome parts, hazardous materials, reducing repetitive movements, or freeing up operators for higher skilled work. Their goals can be realized by properly engineering automated solutions that can maximize productivity and improve parts quality and consistency, as well as reduce scrap.

Lincoln Electric, Cleveland, 216/481-8100, lincolnelectric.com.

John Tillman Co., Compton, California, 800/255-5480, jtillman.com.

he technology that moves us forward, affording people flexibility amid urgent situations, often makes its first inroads within the laboratory setting. Research continues to advance alloys to lighten the weight of vehicles as well as qualify more intricately printed parts. In metal fabrication, the military has installed its first metal printing solution to aid soldiers located far from the supply chain.

Where you really get the benefit of using additive manufacturing is you’re able to print crazy, organic designs that are both lightweight and structurally robust. You simply couldn’t create the part any other way.

Where you really get the benefit of using additive manufacturing is you’re able to print crazy, organic designs that are both lightweight and structurally robust. You simply couldn’t create the part any other way.

Where you really get the benefit of using additive manufacturing is you’re able to print crazy, organic designs that are both lightweight and structurally robust. You simply couldn’t create the part any other way.

Where you really get the benefit of using additive manufacturing is you’re able to print crazy, organic designs that are both lightweight and structurally robust. You simply couldn’t create the part any other way.

he technology that moves us forward, affording people flexibility amid urgent situations, often makes its first inroads within the laboratory setting. Research continues to advance alloys to lighten the weight of vehicles as well as qualify more intricately printed parts. In metal fabrication, the military has installed its first metal printing solution to aid soldiers located far from the supply chain.

he human heart is roughly the size of a large fist, weighing 10 to 12 ounces, yet it pumps blood throughout the body to feed organs and tissues with life-sustaining oxygen and nutrients.

For JIT Manufacturing Inc., Salvagnini L5 fiber laser technology is the heart that pushes parts to multiple operations 24/7 to support customer demand and nourish growth.

“We’ve had our eye on growth and looked at different ways we could capture new business,” says Nick Ricard, JIT Manufacturing’s vice president and general manager. “The fiber lasers have really helped to move us closer to those goals. These machines are the heartbeat of this company.”

hen prospective hires are brought in to tour G.A. Braun’s plant, many are struck by the general idea of how things are made. After touring the floor, they often view the machinery being used “as cool and exciting and they want to learn the technology behind it,” says Chad Perfetti, fabrication manager of the Syracuse, New York-based industrial laundry machine manufacturer.

After years of laying out sheet metal by hand and using various small tools to cut out part profiles, G.A. Braun’s leadership realized it should consider investing in laser and CNC press brake technologies. Perfetti’s crew found LVD Strippit’s team to be knowledgeable as well as close by in Akron, New York. “The layout of the laser with load/unload automation had a footprint that didn’t take up too much floor space,” he adds.

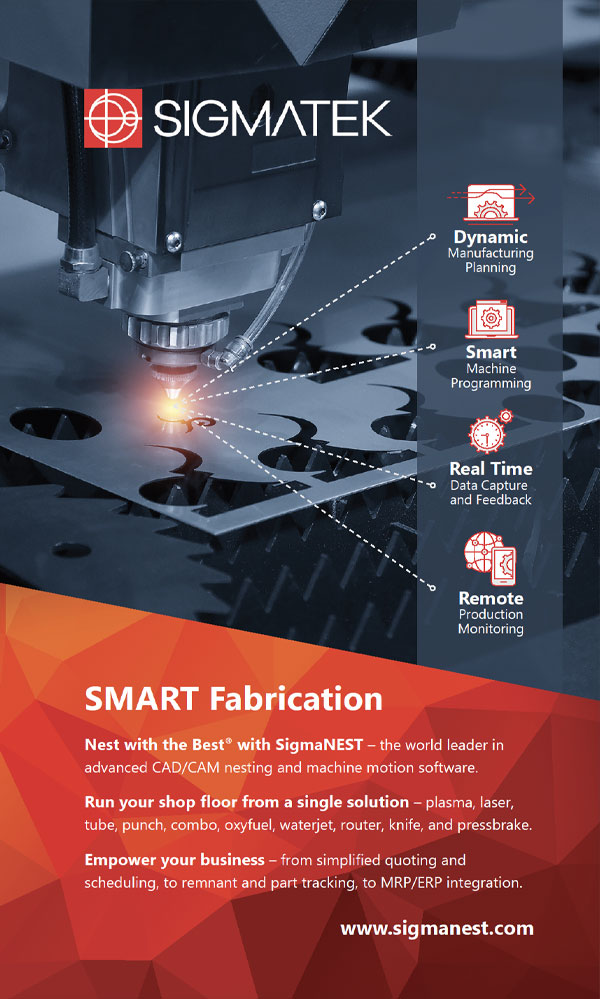

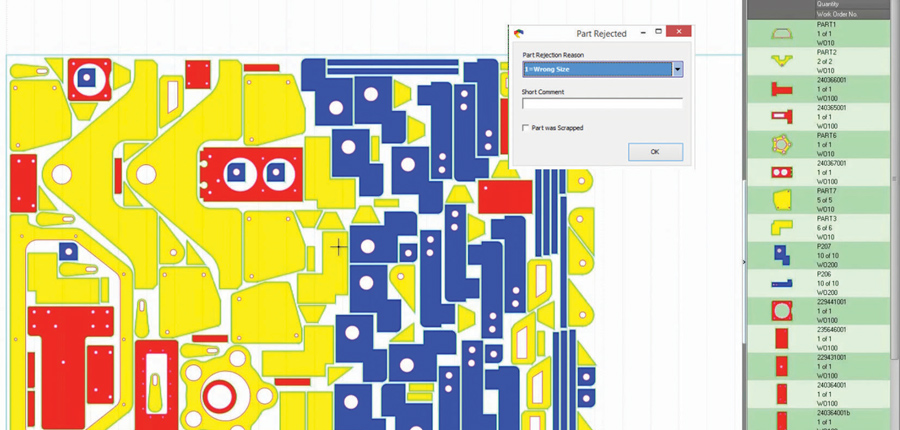

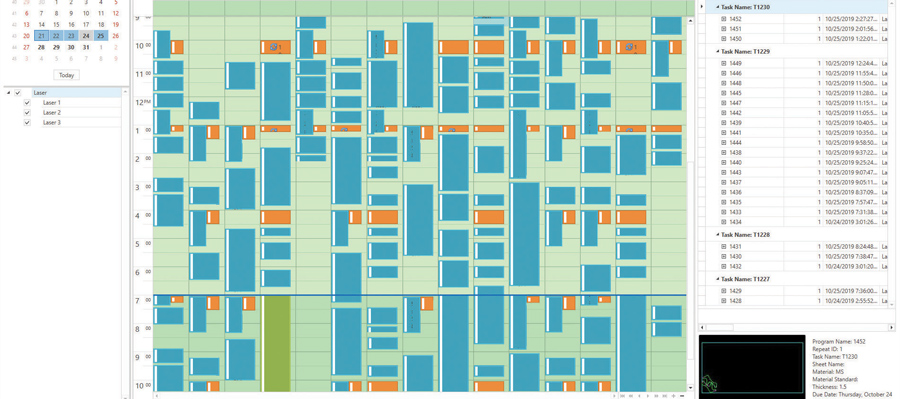

anufacturers must frequently generate up to five times more quotes to land jobs, making the need to understand machine time, material and labor costs more important than ever.

Creating accurate quotes is a serious challenge for manufacturers, says Valter Bonelli, director of product management business systems for SigmaTEK Systems LLC. “Only a few factors have a bigger impact on a company than the ability to predict costs. It can be difficult to sell products and services if they are priced too high, but we find that manufacturers tend to set prices too low. So the question becomes, how do they find balance?”

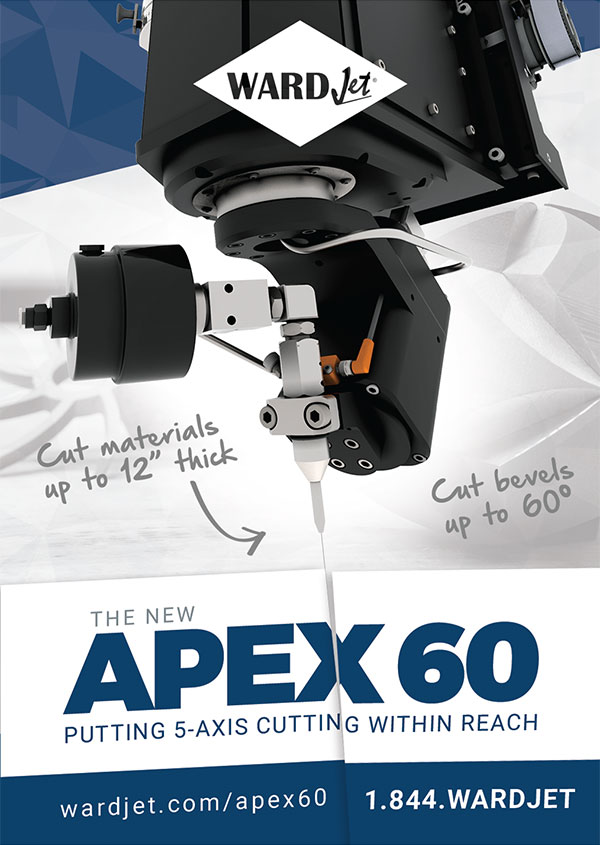

or the last decade, so much buzz about cutting metal has tended to revolve around fiber lasers. But according to MultiCam Inc.’s fabrication product manager, Rashad Galloway, some manufacturers have begun to sing a different tune that sounds oddly reminiscent of Elvis Presley’s hit, “Can’t Help Falling In Love.”

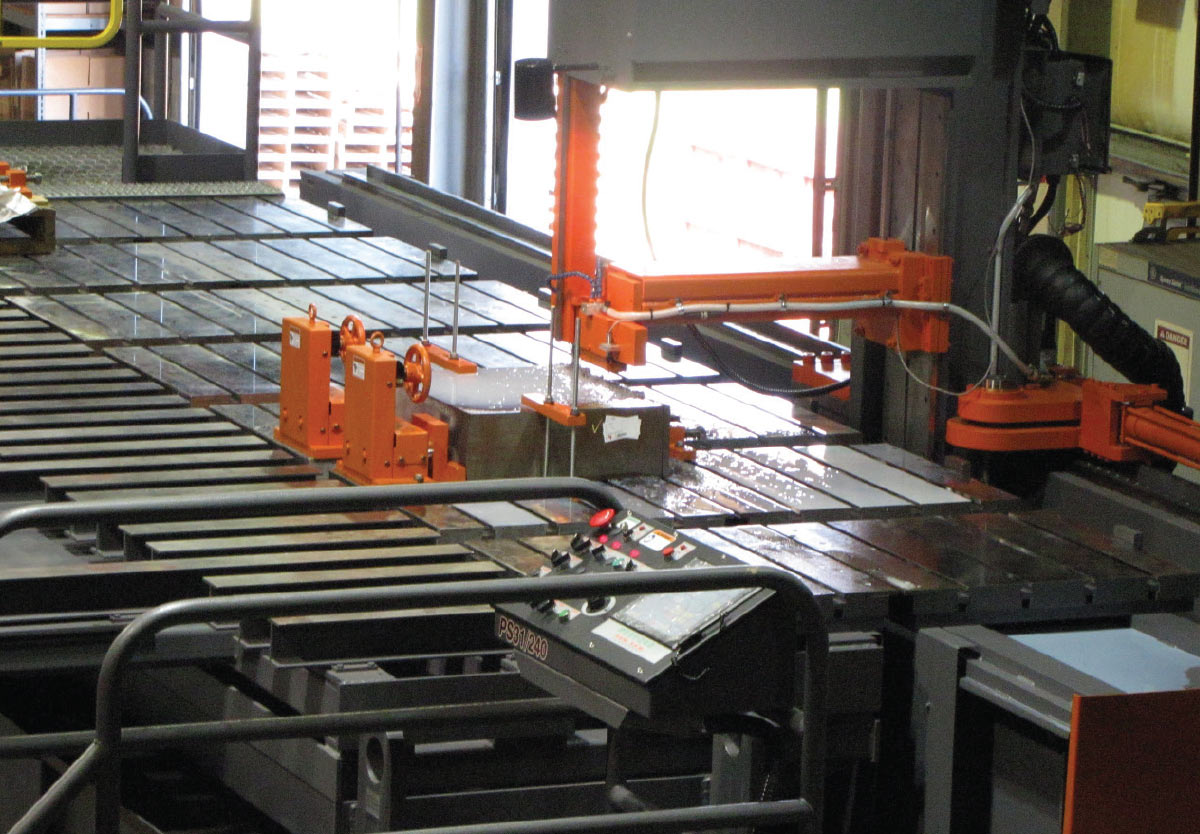

MultiCam demonstrated its V-Series CNC waterjet technology during a 2019 trade show, cutting carbon and stainless steels, titanium and Inconel. “When people saw the value adds they could realize with the final product, they fell in love with the waterjet all over again,” says Galloway.

utomation, data collection, artificial intelligence and robotics aren’t just for smart factories and job shops anymore. These technologies are migrating to construction sites, crop fields and the design/build of new heavy equipment. Industry 4.0 and the Industrial Internet of Things (IIoT) notwithstanding, the construction, heavy equipment and agriculture industries are turning high-tech for reasons that sound familiar. The skills gap, a shrinking labor pool, demand for higher productivity and the need for machine-to-machine and machine-to-human communication are some of the drivers behind these changes.

The Associated General Contractors of America (AGC) conducted a survey that revealed respondents are optimistic about growth—particularly in the bridge/highway, transit, rail, power, water and sewer construction sectors—but scrambling to address the work shortage. Fifty-four percent of participants indicated increases in base pay rates for 2019. Sixty-two percent of respondents revealed plans to increase investments in training. Nearly 32 percent of participants reported that their companies will look to purchase labor-saving equipment such as drones, 3D printers and GPS-guided equipment.

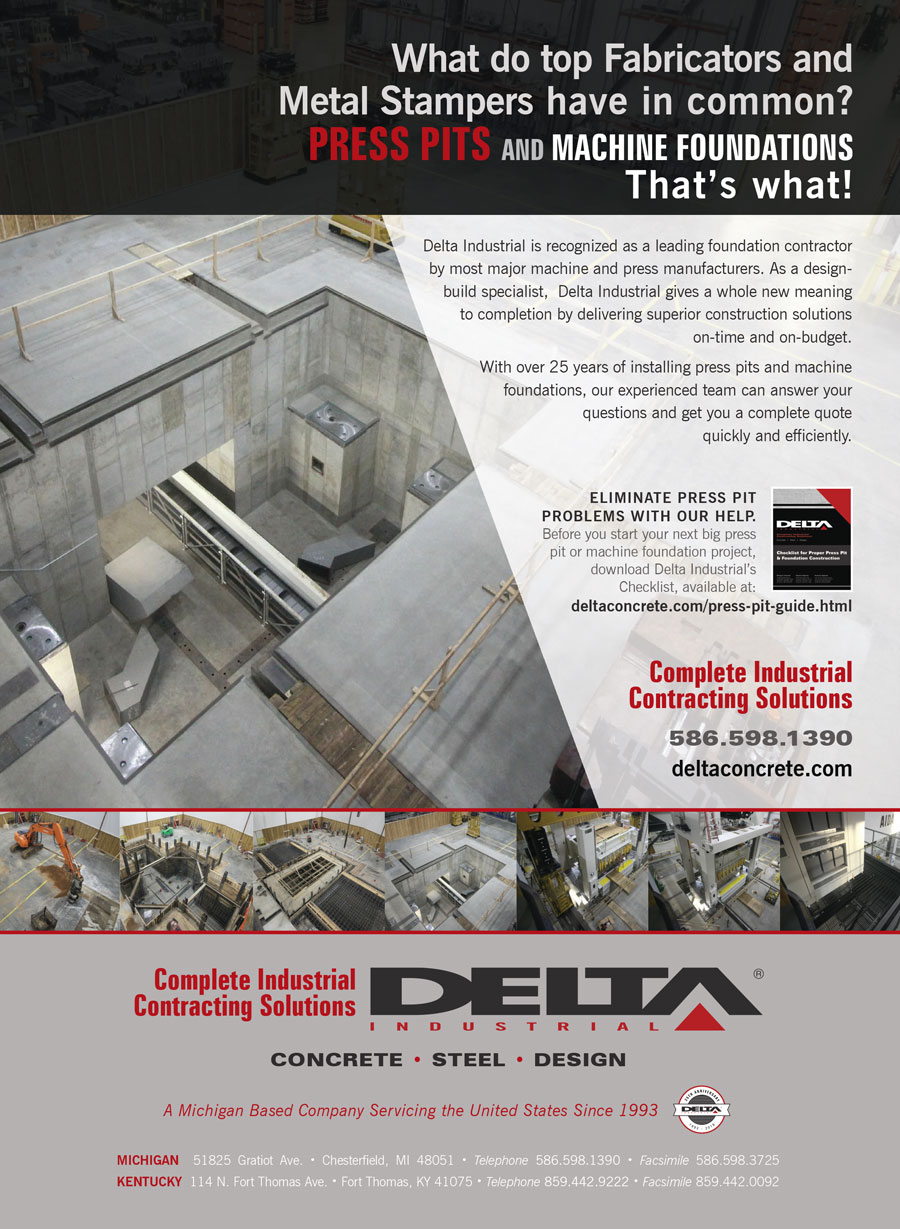

hole lotta shakin’ goin’ on” may be a popular Jerry Lee Lewis song, but it is not a popular tune when it comes to press pits and machine foundations.

Having a proper foundation that can hold a press that, when running, exerts extreme force and weighs many tons is absolutely essential, especially considering the complexity and power of today’s stamping presses.

This is why large-scale manufacturers and fabricators turn to Delta Industrial. The company offers a variety of professional contracting services, including machine foundations, press pit foundations, slitting line foundations, general building maintenance and construction, concrete flatwork, and steel fabrication and construction.

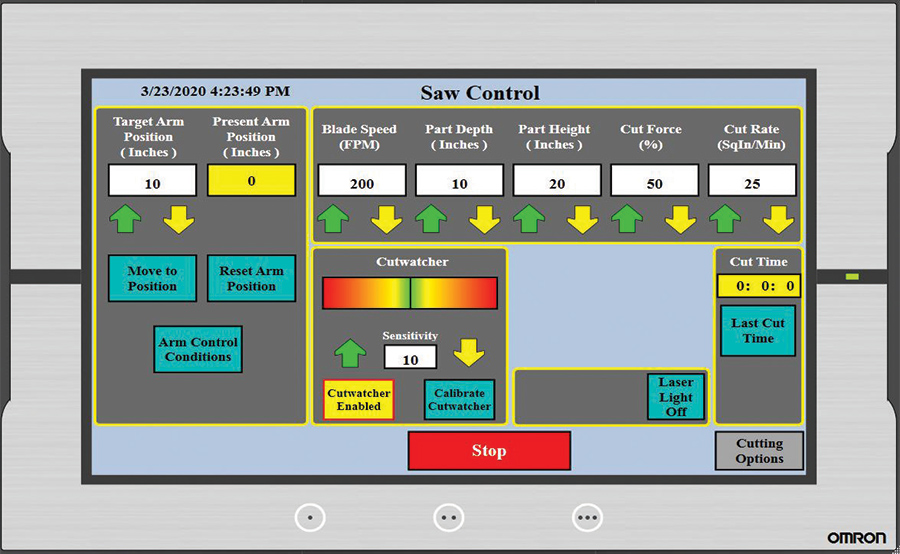

lthough HE&M Saw builds more than 70 standard saw models, the company also enjoys the challenges that accompany the uniqueness of custom projects. Fulfilling customers’ sawing needs is rewarding, regardless of which model fits their application, but offering the ability to engineer equipment tailored specifically to an individual company has been one of HE&M Saw’s strong points throughout its 56 years in business.

After completing a custom saw, the company is sometimes contacted by other companies that have the same or similar applications—often years later. In those instances, what was created as a custom saw, specifically designed and built for a single customer’s requirement, can become a “standard” saw after it is requested several times.

View Index

Editor-in-Chief

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323, www.ffjournal.net

312/654-2309, Fax: 312/654-2323

mdalexander@ffjournal.net

Alaska, Arizona, Arkansas, California, Hawaii, Idaho, Montana, New Mexico, North Dakota, Oklahoma, Texas, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@ffjournal.net

Alabama, Colorado, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Pennsylvania, South Carolina, South Dakota, Tennessee

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@ffjournal.net

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@ffjournal.net

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@ffjournal.net