lthough HE&M Saw builds more than 70 standard saw models, the company also enjoys the challenges that accompany the uniqueness of custom projects. Fulfilling customers’ sawing needs is rewarding, regardless of which model fits their application, but offering the ability to engineer equipment tailored specifically to an individual company has been one of HE&M Saw’s strong points throughout its 56 years in business.

After completing a custom saw, the company is sometimes contacted by other companies that have the same or similar applications—often years later. In those instances, what was created as a custom saw, specifically designed and built for a single customer’s requirement, can become a “standard” saw after it is requested several times.

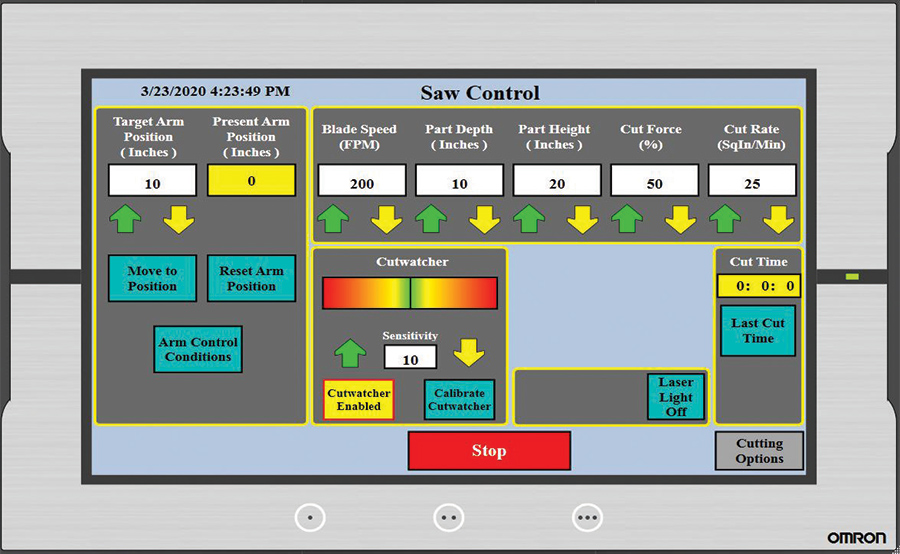

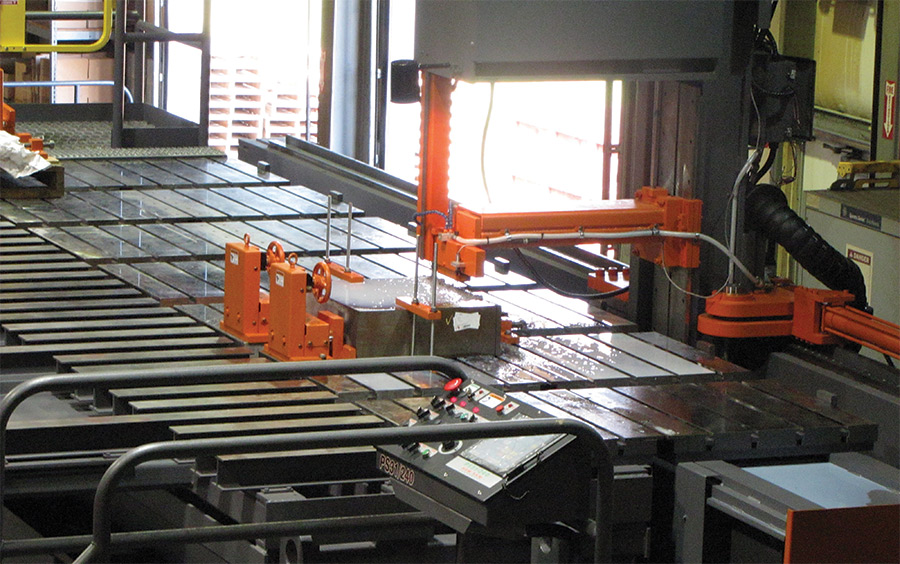

In 2014, we were contacted by a manufacturer whose needs were not reflected in the capabilities of any of our basic models. Our engineering team worked closely with the customer to accurately evaluate their needs. The resulting requirements produced a large plate saw that was capable of sawing blocks or slabs up to 25 in. high, and with a throat depth of 31 in., it could cut a broad swath of material.

At the end of 2019, we were contacted by another company that needed a saw with very similar requirements. About the only difference between the original application and the new one was the length of material the machine was required to support and cut. With a few additions and updates, the PS-31 was called upon again as the saw model that could fulfill the customer’s requirements. The new saw was updated and outfitted with a catwalk for easier operator access.

After completing a custom saw, HE&M Saw is sometimes contacted by others with the same or similar applications—

After completing a custom saw, HE&M Saw is sometimes contacted by others with the same or similar applications—often years later.

Incidentally, this servo cut control was prototyped and perfected on the machine built in 2014 and has been running well in a production facility now for over five years. Because of that success, the servo cut control has been implemented in a wide range of other machines such as our double-column series and our horizontal saw models. The wide- flange and vertical saws also have the potential for adopting this system.

No doubt, as time goes on, HE&M Saw will again have the opportunity to design and manufacture band saws and material handling systems that fit a customer’s specific needs and, in time, offer that design in our standard lineup.