oet John Milton wrote about a “cloud with a silver lining” in 1637. The phrase has since been used to signal hope in an unfortunate situation. In the midst of a pandemic that shuttered businesses in March and prompted stay-at-home orders, Wila USA found its own silver lining. While the nation pushed pause, the manufacturer of clamping, crowning and tooling systems for press brakes went to work improving internal communications and identifying ways its products and services could help customers navigate the new normal.

“When you are faced with adversity you have two choices: hunker down and weather the storm or use it as an opportunity that can help you grow,” says Jordan Edwards, marketing and communications officer for Wila’s Hanover, Maryland, sales and warehouse facility. “Close to 90 percent of our personnel sheltered at home, so we used that time to reassess how we interact with each other, our ability to stay in touch, collaborate and work together as a team. Several advanced tooling designs have been borne out of sales team conversations. That’s a strength we want to continue to grow.”

Several factors have influenced Wila’s ability to weather the pandemic and underpin customer activities without interruption. Wila’s financial footing has remained sound despite the pandemic’s impact on the economy. Dave Bishop, business development manager for Wila, credits the company’s stability to its ongoing investment in technology.

“Our owner makes frequent investments of $10 million to $12 million—sometimes more—in new capital equipment, robotics, software, factory improvements and various technology advancements because we have to stay at the industry’s forefront,” he says. “At Wila, retaining our position as the technology leader is not just a business model, it’s a way of life.”

Retaining our position as the technology leader is not just a business model, it’s a way of life.

Retaining our position as the technology leader is not just a business model, it’s a way of life.

“All of our processes are subject to upgrades or complete replacement if they fall even the slightest bit behind and no longer represent the leading edge of technology,” says Bishop. “We focus on providing our customers with the tools to achieve the highest quality finished parts to come off their press brakes. This allows them to meet the requirements of their most demanding customers and also expand their business with new accounts in a wider range of industries. Job lots continue to get smaller and manufacturers can no longer afford to produce scrap parts. [Finished orders] simply must be right the first time.”

As manufacturing customers ramp back up in response to pent-up demand, Wila’s products, service and support are poised for maximum customer support.

“Our tooling systems are uniquely suited to aid in the implementation of COVID-19 health and safety procedures,” says Edwards. “Their ergonomic design supports social distancing because one person can load and unload the tooling in and out of a press brake in minutes versus requiring two or more employees. For customers that are financially able to get things up and running, re-entry is a good time to look at maintenance and consider retrofit options.

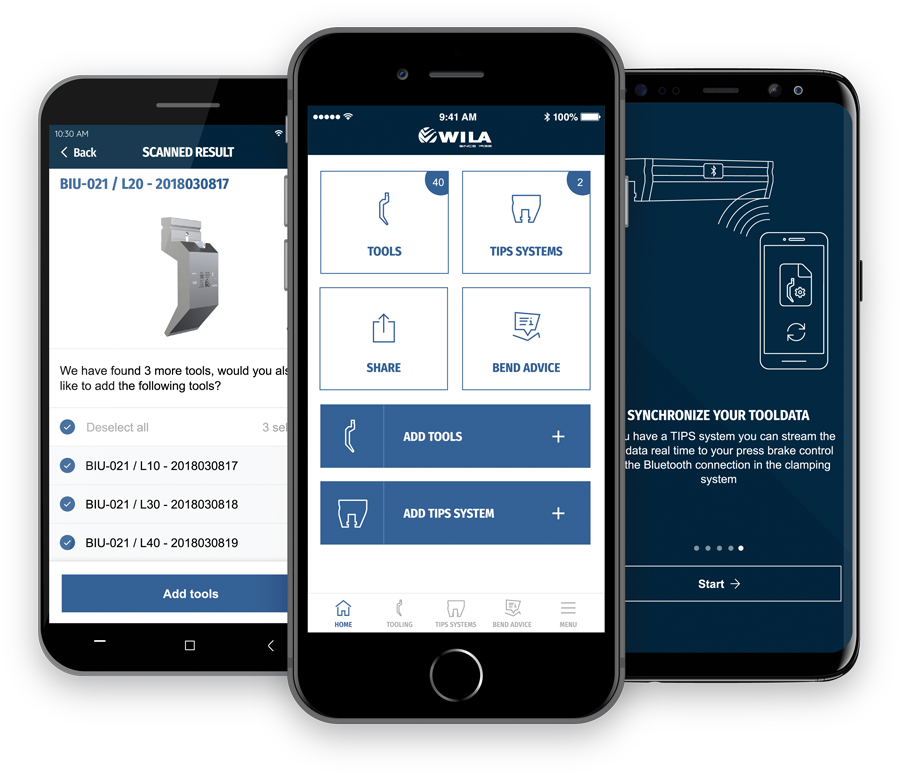

The digital side of tooling is also becoming more relevant as social distancing remains in place. “The digital aspect gives customers connectivity,” says Bishop. Examples include Wila’s Smart Tool Locator, an intelligent slide rule with built-in LEDs, which show the operator exactly where to place tools in the tool holder. The Tool Locator also directs personnel where to position the part prior to each bend.

Wila’s Tool Advisor provides an engineering application that allows the operator to make an online decision about which press brake tools are suited to a specific bending requirement. A smart tooling app gives customers access to tool data anytime, from any location for error-free tool data entry and simplified stock management.

Wila plans to establish an academy of tool-based knowledge for distributors, partners and end users. “Online virtual accessibility is being extended to the factory,” says Edwards. “There’s never been a better time to learn new skills.”

“Every situation—good or bad—is an opportunity,” Edwards adds. “It’s a big challenge for each of us to chart our course through this. But grit and determination, ingenuity and problem-solving skills are the character traits that will see us through.”