Features

/bronze

/fabricatorspov

/pressbrake

#welding #weldlicious #weldeverydamnday #weldtime

From the

Senior Editor

Come Together

he U.S. economy officially hit a recession in February, according to the National Bureau of Economic Research. COVID-19 is reported to have started in December 2019 in China, soon making its way to the U.S. President Trump declared a pandemic and national emergency in mid-March.

It is not yet business as usual throughout the United States and in many places around the world. COVID-19 has no cure, no end date. Fabricators of all sizes are figuring out how to continue running their businesses while making workplaces safe for employees.

This month’s cover story highlights some of the challenges facing fabricators of varying sizes, from dealing with changing federal regulations, moving employees to remote work in their homes where possible, and maintaining overall social distancing between work stations on the shop floor. Today’s shops must also adjust as unforeseen customer or supplier hold-ups occur.

- HYDRAULIC IRONWORKERS

- CIRCULAR COLD SAWS

- TUBE & PIPE NOTCHERS

- MEASURING DEVICES

any aspects of metal fabricating may never return to normal after the COVID-19 pandemic. So fabricators should peer through the current fog of confusion toward the practical changes they can establish to create a safer shop environment.

Unlike office workers who can work remotely, production workers must attend to fabrication machinery. Suppliers and outside service vendors need on-site access, as well. How can guidelines, such as creating 6-ft. distances between employees, staggering or limiting the arrivals of employees and guests, PPE, daily symptom checking, and mandating daily disinfections be applied in this situation? And how can these safety guidelines not negatively affect productivity and profitability?

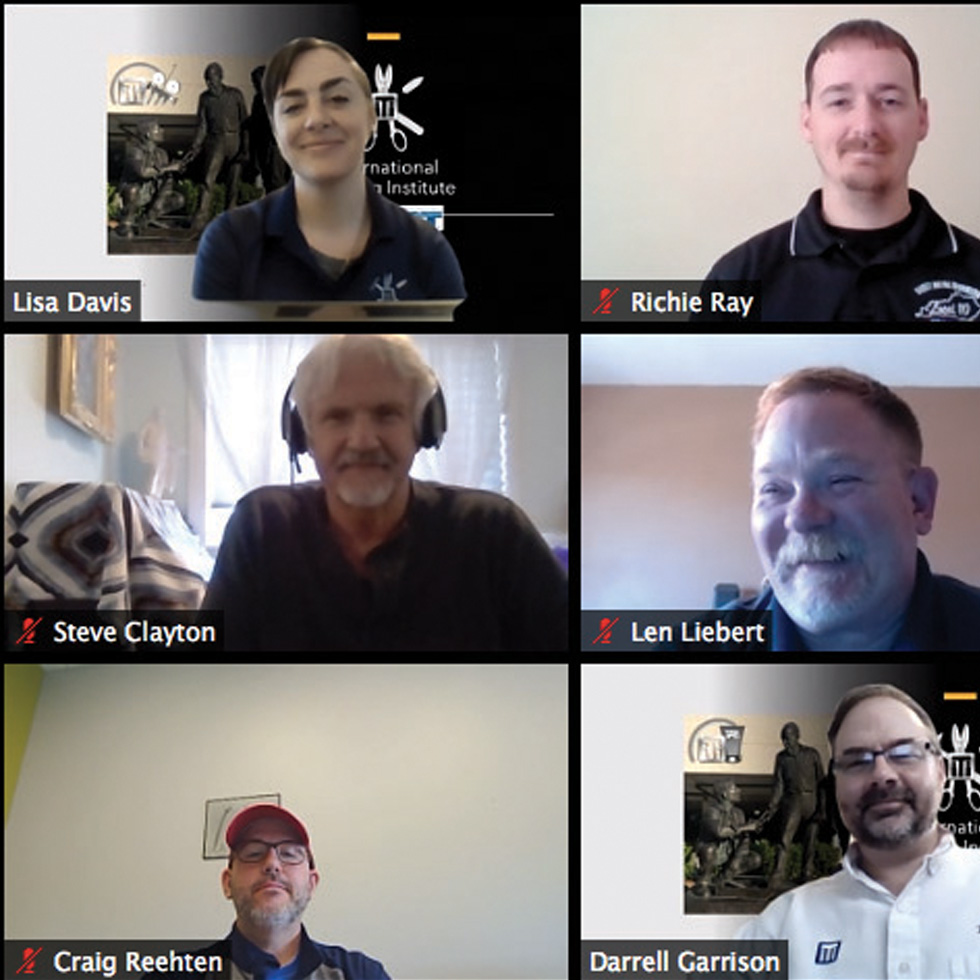

eeping learning up-to-date and accessible has taken on a whole new meaning during the COVID-19 pandemic. All types of educational institutions are quickly pivoting to online classes to ensure students stay on track while they are at home.

The International Training Institute (ITI), Fairfax, Virginia, a jointly administered training trust fund sponsored by the International Association of Sheet Metal, Air, Rail and Transportation Workers (SMART) and the Sheet Metal & Air Conditioning Contractors’ National Association (SMACNA), provides training, curriculum and other assistance to apprenticeship training centers across the United States and Canada.

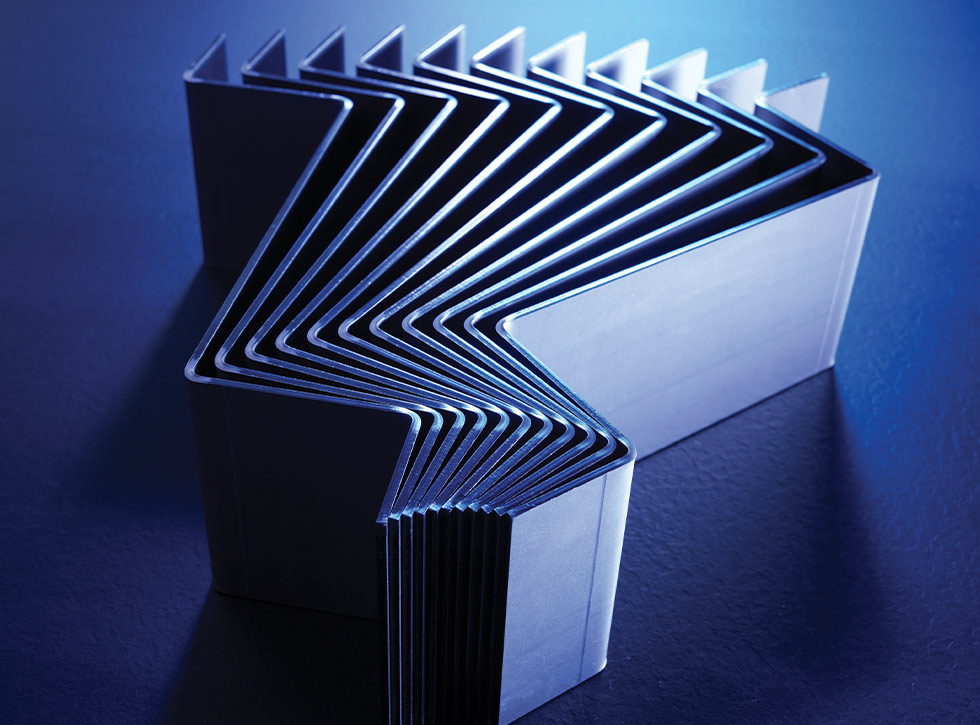

Fabricators were clamoring for a flexible, automated solution. Salvagnini talked with manufacturers and used their feedback to engineer the P4 panel bender. The alternative to hard tooling, roll forming and manual press brakes was quickly adopted.

Today, job shops are grappling with different problems like the skills gap, ongoing implementation of Industry 4.0 and 5.0 initiatives and new operation parameters created by COVID-19, but Salvagnini’s P2 and P4 panel bender series are more relevant than ever.

Hougen Manufacturing Inc., Swartz Creek, Michigan, 800/426-7818, hougen.com.

s the COVID-19 pandemic continues, the ripple effect on the metals sector emanates throughout the supply chain. Fabricators of varying sizes are coping with the new normal by allocating some personnel to work from home, adjusting lines of communication to keep operations running smoothly, coping with declines in revenue, all while planning for the future.

The virus presents a unique set of challenges different from financial crises past. The added component of fear for the health and safety of workers makes working amid a pandemic a complicated conundrum.

According to a survey by the National Association of Manufacturers, 35.5 percent of respondents reported facing supply chain disruptions, with 64.5 percent of those 558 respondents reporting they are not. Companies reported a near 50/50 split as to whether management had an emergency response plan in place to prepare their company and employees. This uncharted territory has resulted in companies taking swift action to instill order in circumstances out of their control.

s the COVID-19 pandemic continues, the ripple effect on the metals sector emanates throughout the supply chain. Fabricators of varying sizes are coping with the new normal by allocating some personnel to work from home, adjusting lines of communication to keep operations running smoothly, coping with declines in revenue, all while planning for the future.

The virus presents a unique set of challenges different from financial crises past. The added component of fear for the health and safety of workers makes working amid a pandemic a complicated conundrum.

According to a survey by the National Association of Manufacturers, 35.5 percent of respondents reported facing supply chain disruptions, with 64.5 percent of those 558 respondents reporting they are not. Companies reported a near 50/50 split as to whether management had an emergency response plan in place to prepare their company and employees. This uncharted territory has resulted in companies taking swift action to instill order in circumstances out of their control.

hen Randy Williams opened his job shop, he was already a seasoned fabricator. “I grew up with metal fabrication,” explains Williams. “My dad was an aerospace engineer who built trampolines part time when I was 10 years old, and I helped build parts in the basement. His business evolved into making Ferris wheels and other portable amusement rides, but eventually the liability insurance became too challenging.”

With just a laser and a press brake, Williams opened his own job shop in 2001. Today, Lasertech Metal Works Inc. is transitioning from a 40,000-sq.-ft. production space in Fayetteville, Georgia to a 60,000-sq.-ft. facility in Peachtree City, Georgia, with plans to add another 20,000 square feet later this year.

Lasertech Metal Works supports industries that range from food service, energy, auto racing and shooting ranges to architectural components. The company has an arsenal of metalworking equipment including laser cutting, forming, punching, welding, machining, grinding and powder coating. Its most recent purchase was the Prima Power EBe Express Bender in 2019.

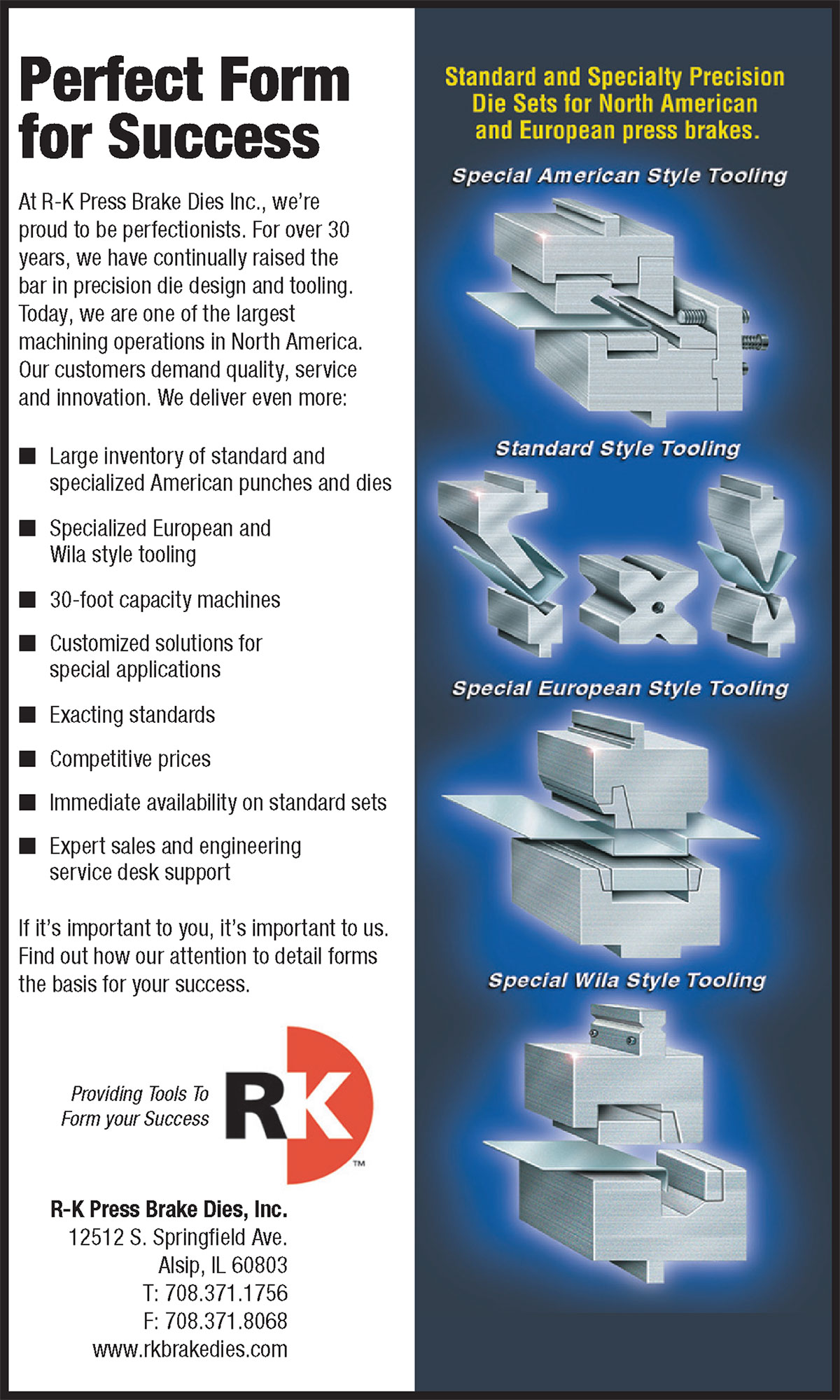

oet John Milton wrote about a “cloud with a silver lining” in 1637. The phrase has since been used to signal hope in an unfortunate situation. In the midst of a pandemic that shuttered businesses in March and prompted stay-at-home orders, Wila USA found its own silver lining. While the nation pushed pause, the manufacturer of clamping, crowning and tooling systems for press brakes went to work improving internal communications and identifying ways its products and services could help customers navigate the new normal.

“When you are faced with adversity you have two choices: hunker down and weather the storm or use it as an opportunity that can help you grow,” says Jordan Edwards, marketing and communications officer for Wila’s Hanover, Maryland, sales and warehouse facility. “Close to 90 percent of our personnel sheltered at home, so we used that time to reassess how we interact with each other, our ability to stay in touch, collaborate and work together as a team. Several advanced tooling designs have been borne out of sales team conversations. That’s a strength we want to continue to grow.”

he oil and gas industry has a stronghold in Texas but Laser Masters Inc. in Houston has avoided dedicating its entire operations to one industry. COVID-19 has affected nearly all sectors but oil in particular is floundering as downward demand reflects continuing shelter in place orders in much of the country.

“We’ve always tried to serve a variety of industries that would keep us afloat no matter what happens. During times like these, variety has helped us stay afloat,” says Steve Doll, president. The 15-year-old shop works on jobs requiring thousands of fabricated parts in one run. Until recently, Laser Masters would use two to five people to manually grind burrs and round edges with a right-angle grinder.

“We found that even with great care we had wavy type finishes on parts, even when we avoided touching the surface,” Doll says. “The time it took and the inconsistent results left us looking for an automated way to achieve a consistent finish.”

ummer is upon us but the usual bustle is muted this year, an inescapable new norm as the world adjusts to living through COVID-19. Those adhering to guidelines that are meant to prevent the spread of the virus are sheltering in place. As restrictions relax with time, the public will resume its usual activities. Amusement and public parks, zoos and other gathering venues sit empty as operations behind the scenes continue on in preparation for when visitors can return.

While some of the world stalls, fabricators like Petty’s Welding Co. continue at a steady pace. The two-man operation in Knoxville, Tennessee, is working on projects that will inspire as well as ensure the safety of animals and visitors at the Zoo Knoxville and Dollywood.

Petty’s Welding fabricates custom feeders, enclosures and artificial habitats for animals as well as decorative fixtures that serve other functional purposes. Dollywood projects vary from gates and hand rails to roller coaster repairs.

ike Allen believes in do unto others as you would have them do to you. Dubbed the Golden Rule in the 17th century, the New Testament scripture is a simple idea about the ethical treatment of others. When Allen talks about his reasons for starting Precision Flange and Machine Inc. in 1989, he says, “I wanted to open a company, hire all-star welders and burning machine operators and treat them with the respect they deserve.”

In addition to cultivating a sound work environment and a strong customer base, Allen learned the value of a good vendor.

Growing the business meant 20-hour work days and jobs that required short delivery windows. The Houston manufacturer had to cut parts in house to support demand, prompting it to shop for a plasma cutter. That’s when Allen crossed paths with Houston-based Plasma Systems Inc. and found a like-minded partner in its president, Richard Keeton.

www.consumablesmagazine.net

Gemtex, Toronto, 416/245-5605, gemtexabrasives.com.

Metabo Corp., West Chester, Pennsylvania, 800/638-2264, metabo.com.

Safety, efficiency and the ability to maintain cost savings during grinding operations is tied to training.

Safety, efficiency and the ability to maintain cost savings during grinding operations is tied to training.

INSET: Analysis can reveal whether an operator is using the right abrasive for the job.

ne man’s trash is another man’s treasure,” says Ron McCarthy, referring to one of the tools he uses to help manufacturers uncover cost saving options in their grinding operations. An abrasives specialist for Cresco, Pennsylvania-based Weiler Abrasives, McCarthy says he can tell a lot about a company’s processes by looking at the condition of abrasives that operators have thrown away.

“Whether we’re talking about sheet metal or airplane parts, the goal is to manufacture products in a safer, faster, more productive manner,” he continues. “But that means being willing to take advantage of improvements. Understanding how to choose and use the right abrasives can reduce grinding cycles, save dollars and guarantee better results.”

View Index

Editor-in-Chief

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323, www.ffjournal.net

312/654-2309, Fax: 312/654-2323

mdalexander@ffjournal.net

Alaska, Arizona, Arkansas, California, Hawaii, Idaho, Montana, New Mexico, North Dakota, Oklahoma, Texas, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@ffjournal.net

Alabama, Colorado, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Pennsylvania, South Carolina, South Dakota, Tennessee

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@ffjournal.net

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@ffjournal.net

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@ffjournal.net

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJOURNAL® c/o Creative Data Services,Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJOURNAL® c/o Creative Data Services,Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.