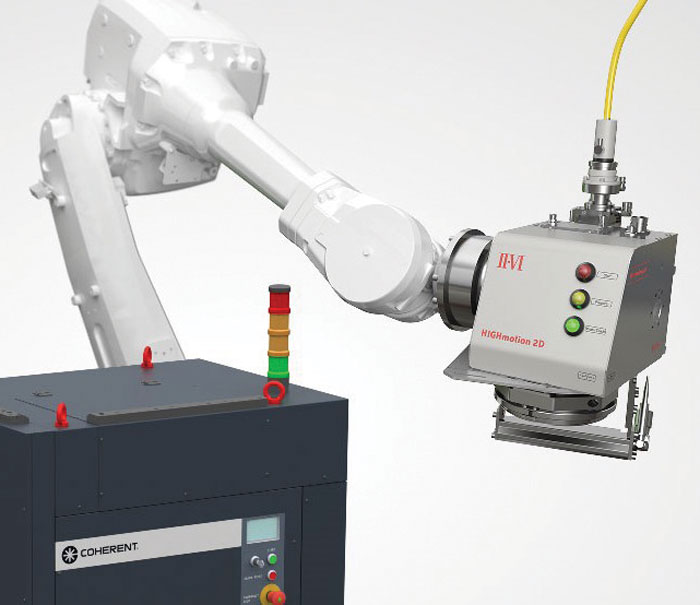

Job shops are being asked to process and measure more complex parts amid stricter supply chain quality standards. Demand for 100 percent parts inspection for new product lines is also growing. AIMS Metrology, an OEM for coordinate measuring machines, has designed and introduced the new Summit 10.10.10 to put REVO-2 5-axis dynamic scanning and multisensor surface finish measurement [including video probing] into the hands of the operator. Engineered with 1 meter cubed capacity, the Summit provides high-volume large parts inspection. It can be automated with a robot load/unload system or pass through process with a conveyor.

Honda Transmission Manufacturing of America Inc. adopted two of the first Summits for installation in a new automated production line that requires 100 percent parts inspection. “One for one-to-one knock hole inspection of transmission cases … and a second to measure less critical hole features [one out of every 30 parts] at the end of our line,” says Engineering Coordinator Dan Sokolow. “It’s a critical measurement because the location of these knock holes dictates the location of the rest of the features that will be processed … during downstream operations. We will be inspecting every hole for every part, something we haven’t done before.”

Honda expects to have the first Summit cell operational in February 2021 and has ordered additional CMMs.

We will be inspecting every hole for every part, something we haven’t done before.

Dan Sokolow

AIMS Metrology

The Summit provides the industry’s largest workpiece weight of 2,200 kg while preserving valuable floor space. The REVO-2 provides measuring speeds up to 500 mm/second and data collection rates of up to 4,000 points per second for increased part throughput. Rapid calibration for all positions expands uptime. Infinite positioning and 5-axis motion offer easy access to difficult features while flexible tip sensing aids accuracy and flexibility.

Dual linear motors work off permanent magnets that don’t wear out. Conventional belt and pulley mechanisms have a tendency to break, resulting in costly service calls and extensive downtime. AIMS’ design minimizes wear and tear for zero maintenance and enhanced uptime.

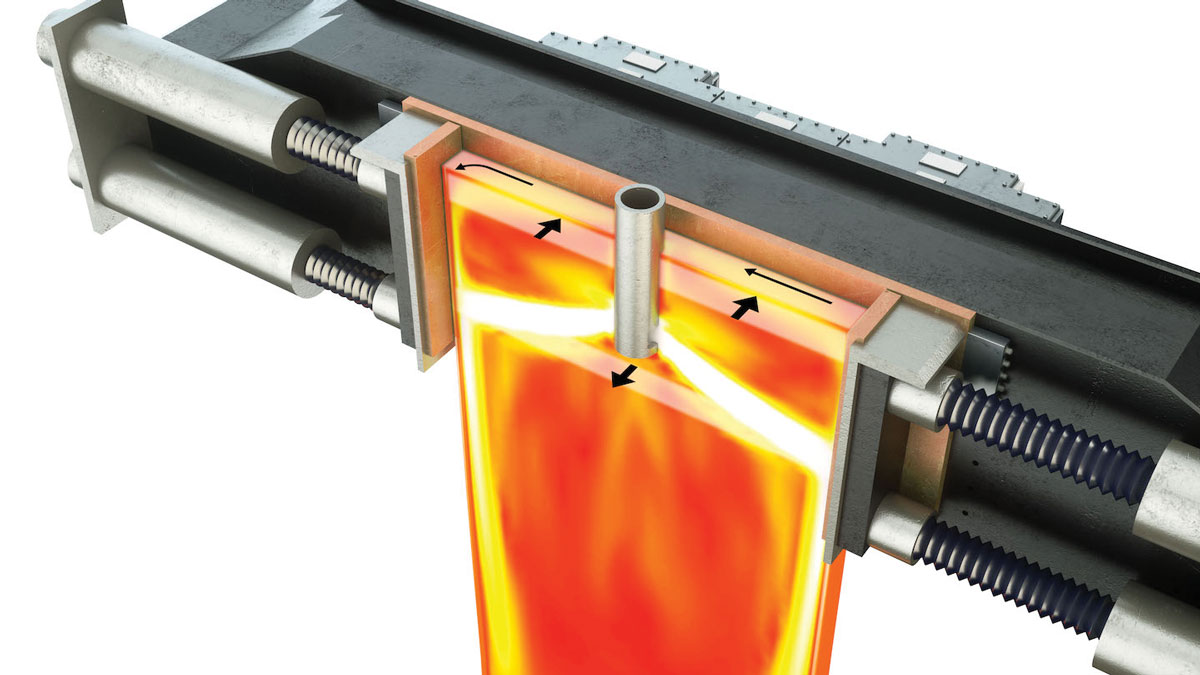

Summit’s polymer-cast base has built-in vibration resistance and thermal stability for longer life and greater accuracy, unlike granite shop floor machines. The CMM uses standard 110/220 volt outlets, eliminating the need for shop air.

Read more about resources for veterans wanting to enter the metals industries.

38,000 jobs