Features

/customfabricator

/sawing

/pov

From the Editor

t’s a new year and the fact that 2020 wasn’t a hallmark time for so many people isn’t lost on anyone. New beginnings prompt us to think of possible resolutions or plans for the upcoming months. If 2020 taught us anything, it’s that we can lay all the groundwork for plans that are ultimately at the mercy of circumstances we can’t predict or control.

We can, however, reflect upon what we have learned and make informed decisions about how to approach the future, no matter the unknown. Although the economy has faltered and millions are out of work, the fabrication sector is a welcome bright spot. Countless fab shops are adapting to shifting demand, as drops and surges in the marketplace continue to be felt—and likely will be well into the new year.

s an essential business, in a right-to-work state, High Performance Alloys has been blessed to maintain its open status. One of the ways our company prepared for a downturn was to apply and receive assistance via the federal government’s Paycheck Protection Program (PPP). The PPP was designed to help companies survive a three-month shutdown, covering salaries and expenses, with 2019 numbers as the guide to those amounts.

Job shops are being asked to process and measure more complex parts amid stricter supply chain quality standards. Demand for 100 percent parts inspection for new product lines is also growing. AIMS Metrology, an OEM for coordinate measuring machines, has designed and introduced the new Summit 10.10.10 to put REVO-2 5-axis dynamic scanning and multisensor surface finish measurement [including video probing] into the hands of the operator. Engineered with 1 meter cubed capacity, the Summit provides high-volume large parts inspection. It can be automated with a robot load/unload system or pass through process with a conveyor.

VETERANS

VETERANS

A free education while earning a paycheck and learning a trade is becoming more appealing than a life of student debt.

A free education while earning a paycheck and learning a trade is becoming more appealing than a life of student debt.

Steps

fter serving for years in the military, the shift from active duty to civilian life can be daunting. Helpful programs exist during and after life in the military to help service members consider a career in the metal fabrication sector. FFJournal learns from those teaching, studying and organizing efforts to connect veterans with potential long-term career paths.

One of the biggest challenges facing the fabrication industry is finding qualified talent. “People coming out of the military make excellent candidates,” says Michael Harris, program administrator at the International Training Institute SMART workers program. “They’re used to working in a team environment, are dependable and take responsibility.”

Steps

A free education while earning a paycheck and learning a trade is becoming more appealing than a life of student debt.

A free education while earning a paycheck and learning a trade is becoming more appealing than a life of student debt.

fter serving for years in the military, the shift from active duty to civilian life can be daunting. Helpful programs exist during and after life in the military to help service members consider a career in the metal fabrication sector. FFJournal learns from those teaching, studying and organizing efforts to connect veterans with potential long-term career paths.

One of the biggest challenges facing the fabrication industry is finding qualified talent. “People coming out of the military make excellent candidates,” says Michael Harris, program administrator at the International Training Institute SMART workers program. “They’re used to working in a team environment, are dependable and take responsibility.”

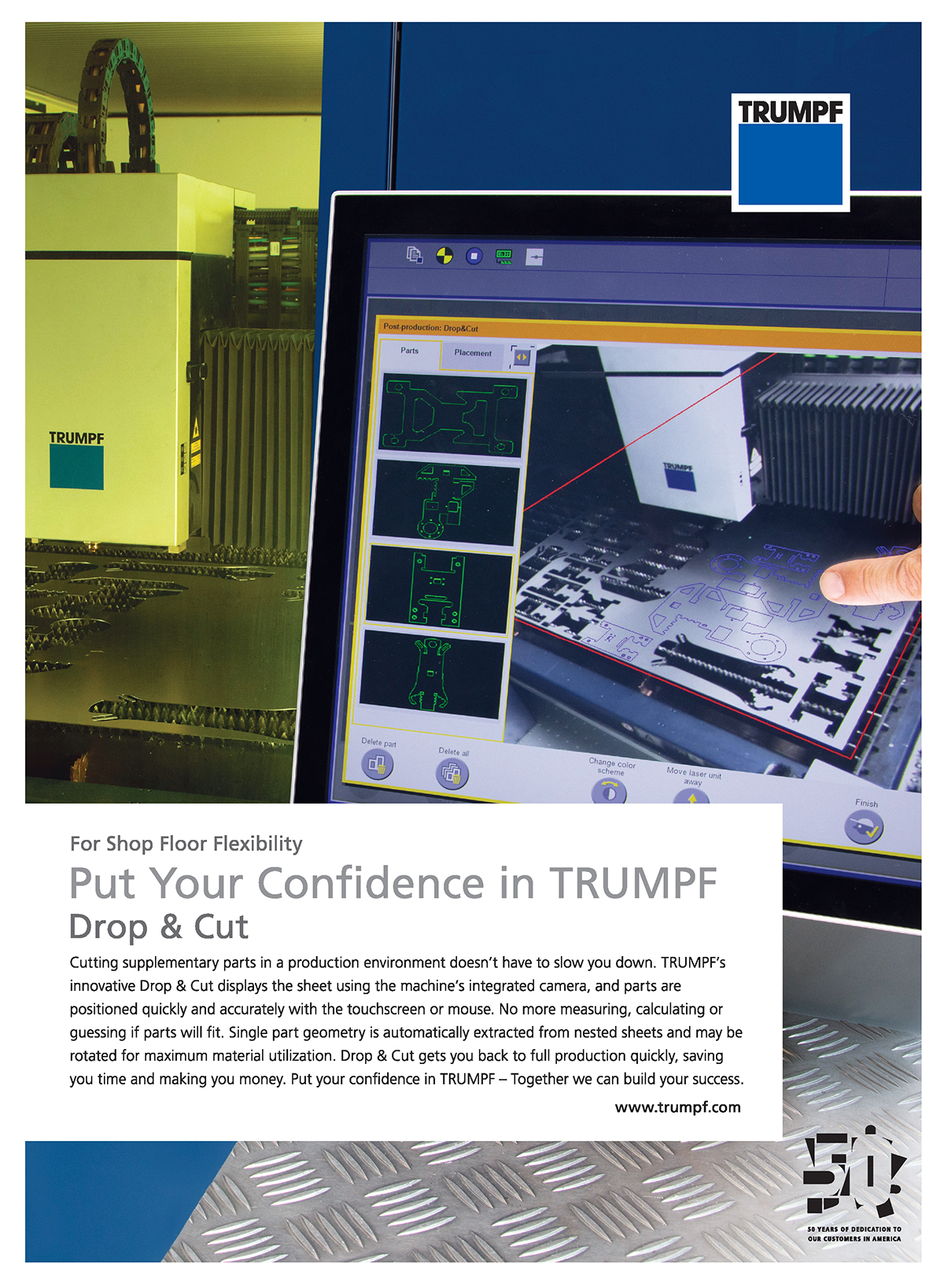

n 1849, thousands of people faced boom or bust when they left their homes and jobs to pan for precious metal in the California Gold Rush. These days, depending on the industry, manufacturers are facing a boom or bust cycle of a different sort. “Due to COVID-19, markets such as food equipment are seeing declines in products like stainless cookware,” says Brett Thompson, sales engineer for Trumpf Inc.

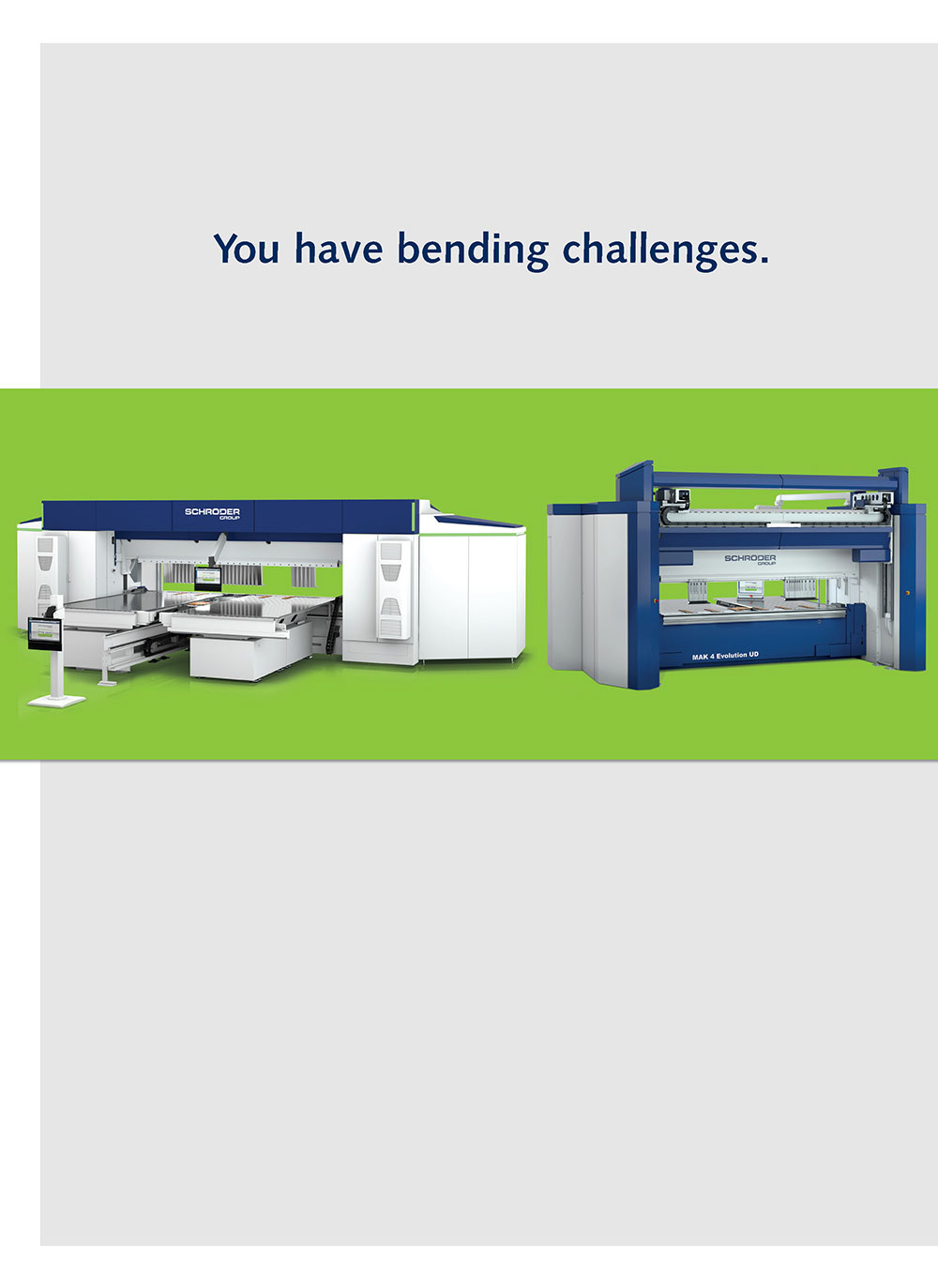

odern products and the technology required to make them have changed the face of supply chains across the U.S. An era of specialists has emerged to perform work that used to belong exclusively to vertically integrated manufacturers like Ford or General Motors. For job shops with bending operations, it means managing multiplex parts, shrinking lot sizes and shorter delivery windows.

RTT Engineered Solutions found the Schröder PowerBend Industrial 4m metal folding machine increased part quality and operator safety.

PROCESSING

ending is still a nightmare for most job shops,” says MetalForming Inc. Executive Vice President David Prokop. “Sustainability is a huge issue. An aging workforce coupled with an evaporating labor pool means a manually intensive process is no longer feasible. Instead, you want an ergonomically sound machine that eliminates the need for operators to manhandle parts. Repetitive motion injuries and worker safety also point employers to a process that can create sustainable, controllable output.”

& SMARTER

ultiple industries are recognizing the importance of workers being able to do their jobs with less fatigue, more comfort and greater efficiency. Working better and smarter requires the right tools and processes in order to repeatedly achieve the desired finish—especially when working with stainless steel. The abrasive used for the job, the grit type, grain and operator technique all affect surface finish.

An equipment manufacturer in Wisconsin was experiencing excessive labor and cost waste, a common issue in the metalworking industry. The grinding wheel needed to be dressed to maintain its removal rate and grinding angle. As a result, the operator had to manually discard the wheels prematurely, resulting in higher production costs and longer output times.

“Prior to introducing the Enduro-Flex Turbo, we had a flap disc, but not a good one,” says the plant supervisor. “It worked ok, but we didn’t know what we were missing.”

t’s a nightmare scenario: you sign the contract for a new waterjet cutter and the following week the country is shut down due to a pandemic. “I signed up for my new machine right before COVID-19 hit and everything went into lockdown,” recalls Tom Racicot, owner of T.R. Welding & Fabrication LLC. His fear didn’t linger, however. Within a week he was back to focusing on the survival of his business with the help of his new machine.

Weldcote, Kings Mountain, North Carolina, 704/739-4115, weldcotemetals.com.

View Index

Editor-in-Chief

Michael D’Alexander

Lynn Stanley

Gretchen Salois

J. Neiland Pennington

Lauren Duensing

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323, www.ffjournal.net

Carlotta Lacy

Matt LaFleur

Mark Koenig

Michael D’Alexander

Jim D’Alexander

Wayne Krusen

Traci Fonville

Bill D’Alexander

312/654-2309, Fax: 312/654-2323

mdalexander@ffjournal.net

Alaska, Arizona, Arkansas, California, Hawaii, Idaho, Montana, New Mexico, North Dakota, Oklahoma, Texas, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@ffjournal.net

Alabama, Colorado, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Pennsylvania, South Carolina, South Dakota, Tennessee

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@ffjournal.net

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@ffjournal.net

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Valerie Treiber, National Sales Manager

203/894-5483

valerie@modernmetals.com

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@ffjournal.net

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJOURNAL® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJOURNAL® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.