fabricating & forming technologies

Features

/customfabricator

/grinding

/bending

Bar Stock Specialties, Houston, Texas, 713/849-0055

Belson Steel Center Scrap Inc., Bourbonnais, Illinois, 815/932-7416

Cambridge-Lee Industries, Reading, Pennsylvania, 800/523-8263

Central Steel & Wire Co., Chicago, Illinois, 800/621-8510

Churchill Steel Plate, Twinsburg, Ohio, 844/607-2775

Cincinnati Tool Steel Co., Rockford, Illinois, 800/435-0717

Cleveland Metal Exchange, Twinsburg, Ohio, 216/464-4480

Consolidated Metal Service Inc., Willoughby, Ohio, 800/535-4561

Crossroads Steel Supply LLC, Valparaiso, Indiana, 219/476-8595

Eastern Metal Supply, St. Charles, Missouri, 888/822-6061

ESP Specialty Steel Products, West Chicago, Illinois 888/377-4317

Falcon Steel Inc., Springfield, Missouri, 800/999-0987

Great Central Steel Co., Bridgeview, Illinois, 708/599-8090

Infra-Metals Co., Langhorne, Pennsylvania, 800/899-3432

Metalmen, Long Island City, New York, 800/642-1990

O’Brien Steel Service Co., Peoria, Illinois, 800/322-4450

Owen Industries, Carter Lake, Iowa, 800/831-9252

Paragon Steel, Butler, Indiana, 800/411-5677

Penn Stainless Products, Quakertown, Pennsylvania, 800/222-6144

Promet Steel, Frankfort, Illinois, 773/996-0317

Rapid Metals, West Bloomfield, Michigan, 248/855-9100

RHS Stainless, Bethlehem, Pennsylvania, 610/997-7604

SB Specialty Metals, Chicago, Illinois, 800/365-1116

Specialty Rolled Metals, Carol Stream, Illinois, 630/871-5765

Steel Manufacturing & Warehouse Co., Kansas City, Missouri, 816/842-9143

Steel Warehouse, South Bend, Indiana, 855/370-9049

Taylor Coil Processing, Lordstown, Ohio, 800/889-8601

United Metals, Cumberland, Rhode Island, 401/335-5300

Universal Steel Co., Cleveland, Ohio, 800/669-2645

Westfield Steel, Westfield, Indiana, 800/622-4984

Willbanks Metals, Fort Worth, Texas, 800/772-2352

American Alloy Steel, Ogden, Utah, 866/328-2905

Bar Stock Specialties, Houston, Texas, 713/849-0055

Churchill Steel Plate, Twinsburg, Ohio, 844/607-2775

Cleveland Metal Exchange, Twinsburg, Ohio, 216/464-4480

Far East Metals Inc., Carson, California, 310/549-3046

Kingmaker Steel West, Santa Fe Springs, California, 562/777-6668

Mega Steel & Tube, Gardena, California, 800/540-8823

Meridian Steel Company, Inc., Los Alamitos, California, 562/594-0571

Benedict-Miller, Kenilworth, New Jersey, 800/526-6372

Central Steel Supply Co., Marlborough, Massachusetts, 800/345-3232

Cleveland Metal Exchange, Twinsburg, Ohio, 216/464-4480

Cohen Steel Supply Inc., Concord, New Hampshire, 800/225-6643

Eastern Metal Supply, Newark, Delaware, 800/343-8154

ESP Specialty Steel Products, West Chicago, Illinois 888/377-4317

Infra-Metals Co., Langhorne, Pennsylvania, 800/899-3432

Penn Stainless, Quakertown, Pennsylvania, 800/222-6144

Premium Plate, Axis, Alabama, 251/602-7404

Production Metals, Monroe, Connecticut, 475/231-1090

Rapid Metals, West Bloomfield, Michigan, 248/855-9100

RHS Stainless, Bethlehem, Pennsylvania, 610/997-7604

Steel Sales Inc., Sherburne, New York, 800/238-7833

Steel Warehouse, South Bend, Indiana, 855/370-9049

United Metals, Cumberland, Rhode Island, 401/335-5300

Churchill Steel Plate, Twinsburg, Ohio, 844/607-2775

Cincinnati Tool Steel Co., West Columbia, South Carolina, 800/845-7052

Cleveland Metal Exchange, Twinsburg, Ohio, 216/464-4480

Eastern Metal Supply, Lake Worth, Florida, 800/432-2204

Infra-Metals Co., Langhorne, Pennsylvania, 800/899-3432

Metals Inc., Mobile, Alabama, 800/817-8335

Premium Plate, Axis, Alabama, 251/602-7404

Rapid Metals, West Bloomfield, Michigan, 636/929-9000

RHS Stainless, Bethlehem, Pennsylvania, 610/997-7604

United Metals, Cumberland, Rhode Island, 401/335-5300

Belson Steel Center Scrap Inc., Bourbonnais, Illinois, 815/932-7416

Cleveland Metal Exchange, Twinsburg, Ohio, 216/464-4480

Delta Steel Inc., Houston, Texas, 713/635-1200

Eastern Metal Supply Inc., Houston, Texas, 800/996-6061

ESP Specialty Steel Products, Houston, Texas, 888/377-4317

Mega Steel & Tube Inc., Gardena, California, 800/540-8823

Metals 2 Go, Hewitt, Texas, 877/235-7703

Metals Inc., Houston, Texas 713/923-5524

Premium Plate, Axis, Alabama, 251/602-7404

SB Specialty Metals, Dallas, Texas, 800/365-1116

Steel Supply LP, Houston, Texas, 866/991-7600

United Metals, Cumberland, Rhode Island, 401/335-5300

Willbanks Metals, Fort Worth, Texas, 800/772-2352

From the Editor

Shaping

the future

he smartphone market in the U.S. is one of the largest in the world, with more than 290 million users, according to Statista. But the idea was first introduced decades earlier on the television series “Star Trek.” Captain Kirk and the ship’s complement were each equipped with a hand-held communications device. Kirk and Mr. Spock also used a device that could instantly translate the different languages of alien life forms. Today, we have products like Sourcenext’s Pocketalk and Skype’s new voice translation service.

Who can forget the iconic film “Star Wars: Episode IV – A New Hope” where we saw the holographic image of Princess Leia delivering a plea for help to Obi-Wan Kenobi. Brigham Young University researchers created a free-floating 3D hologram that employs a tiny particle suspended in laser light to create high-resolution, color images that can be viewed without a dedicated augmented reality (AR) headset. Bionic limbs, digital billboards, artificial intelligence, space stations and hoverboards are products that can also trace their roots to the rich imaginations of the individuals who helped create movies like “Blade Runner,” “2001: A Space Odyssey” and “Back to the Future.”

modern laser-cutting machine is not cheap. But many fabrication shops invest in them because they are well worth the price. With the ability to precisely cut everything from mild to stainless steel, titanium and more, the hefty investment is offset by a laser’s unmatched performance and reduced waste in the manufacturing process.

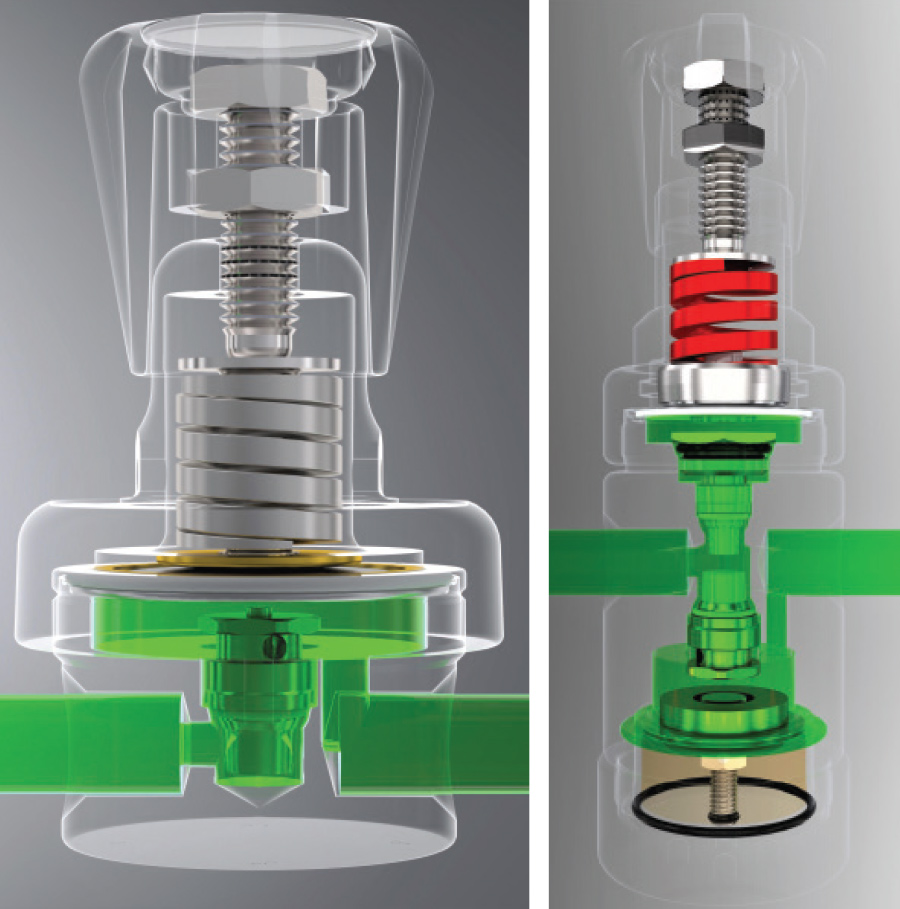

However, many fabrication shops are only using general-purpose, spring-loaded regulators to supply gas for this high-performance cutting, which is like putting snow tires on a sports car. They simply are not up to the task of providing the consistent, reliable gas pressure needed to provide optimal performance. Servo dome-loaded regulators are a better option.

Parts Inspection

Retrofit or Replace?

Job shops have options when it comes to tackling parts inspection in today’s volatile environment

n the early 1950s, Louisville, Kentucky, resident George Devol laid the foundation for the modern robotics industry when he invented the first programmable industrial robotic arm. It was installed at a General Motors plant in Ewing, New Jersey, to lift and stack hot metal parts. The robotic arm weighed 4,000 lbs. and cost $25,000. Devol’s manufacturing partner, Joseph Engelberger, found marketing the new technology to be difficult, citing opposition from U.S. labor unions and industrialists.

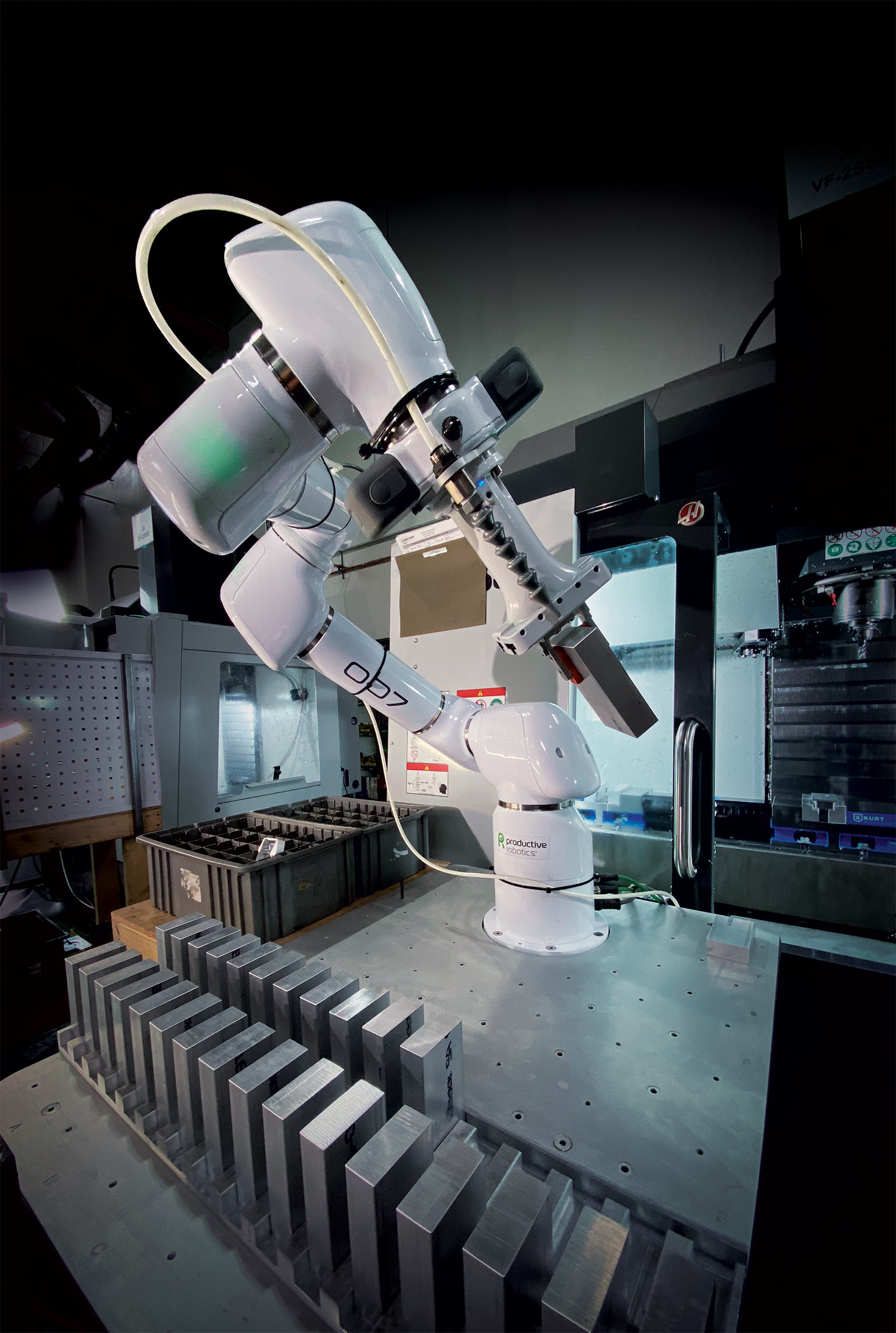

Productive Robotics’ teach-by-touch cobot OB7 picks up ABACORP parts from a bench and loads them into a CNC machine tool for processing.

Complex sheet metal part following the stamping process.

n December 2021, Master Fluid Solutions celebrated its 70th anniversary. The Perrysburg, Ohio, company was the first metalworking fluid manufacturer to introduce an environmentally friendly coolant recycling system. XYBEX supported customers’ sustainability requirements and helped reduce fluid waste by up to 80 percent. Master Fluid Solutions’ recycling process has since become the industry standard. Today, Master Fluid Solutions continues to work closely with the global metalworking community to create solutions that add to its line of specialty cutting and grinding fluids, cutting oils, concentrated washing and cleaning compounds, and rust preventives under the TRIM and Master STAGES brands.

utting 3D objects is essential to the production of pressure vessels and boilers. For fabricators that support this industry, there are several challenges, including the ability to provide fast processing, easy setup and accurate results that won’t dictate secondary, sometimes manual operations.

Dome applications require cutting openings in a vessel’s dished end (or end cap) to prepare the area for welding inlet pipes. Dished end edges must also be sliced or trimmed for welding to the vessel’s body. It is critical that cross-sections of the cut edges meet the requirements of these welding processes. Depending on wall thickness, V, X or K cuts with constant or variable bevels must be produced with precise accuracy.

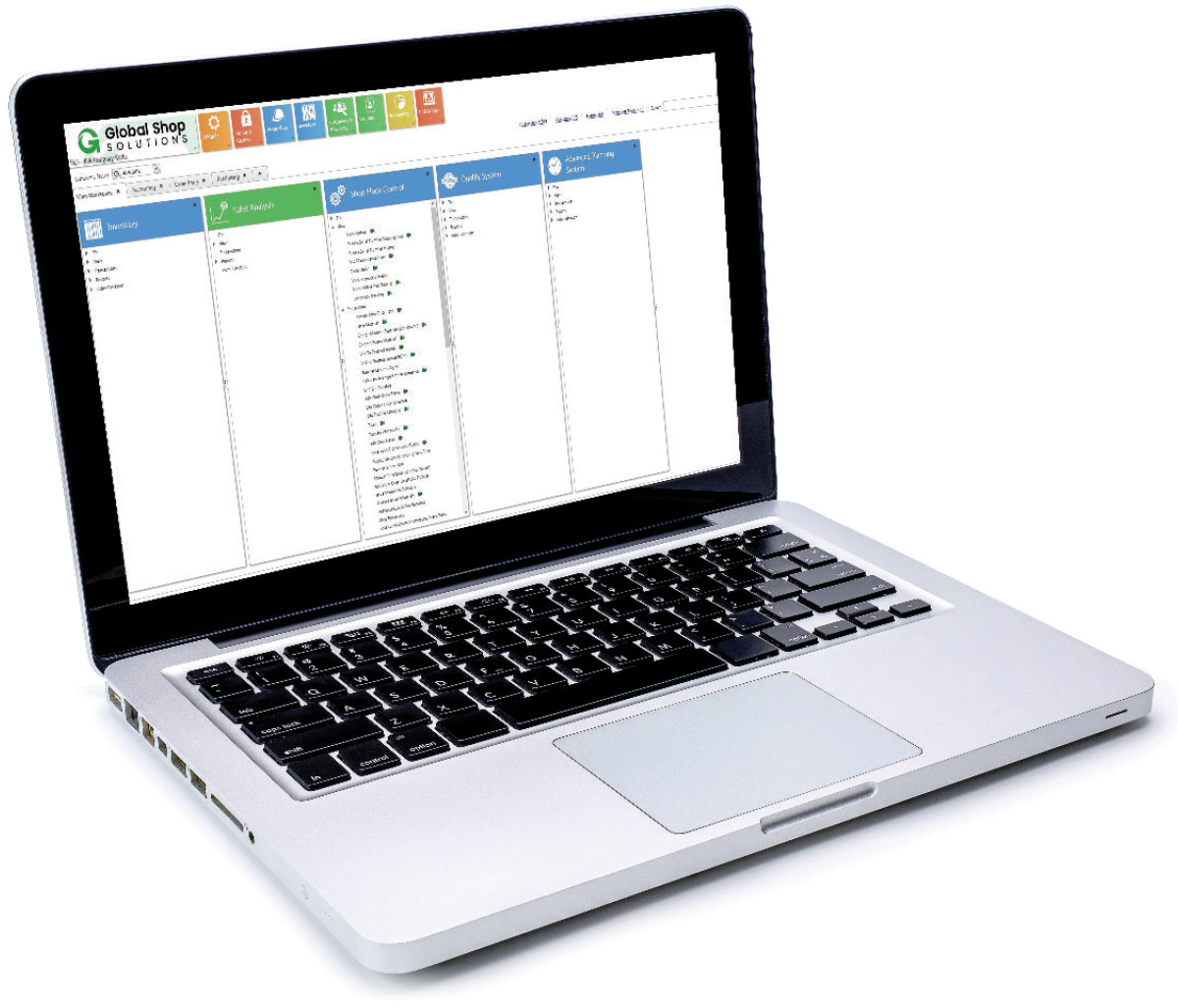

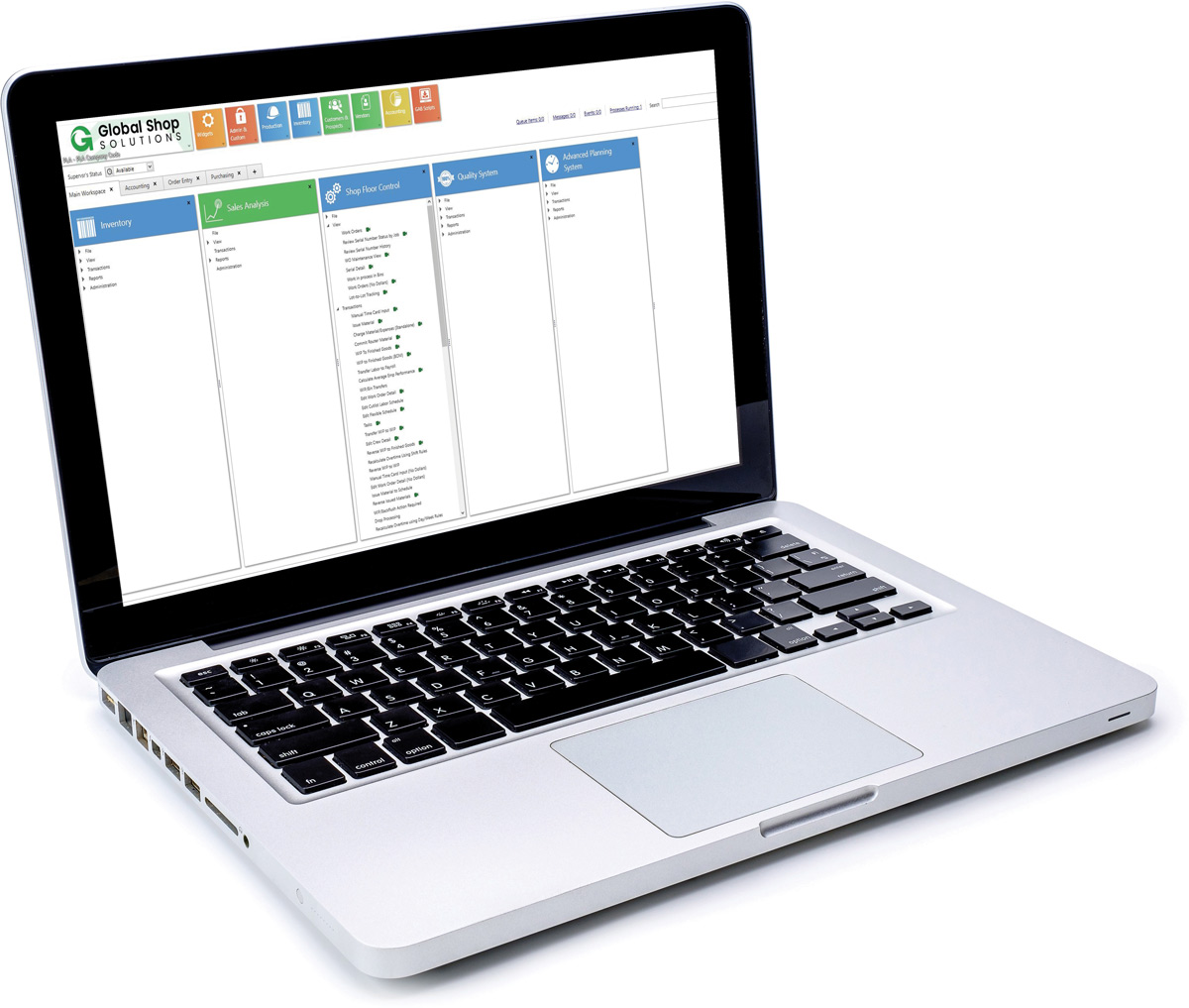

anufacturing elements are inextricably linked to each other, and low performance in one area negatively impacts all others. The “Great 8” essentials consist of the following:

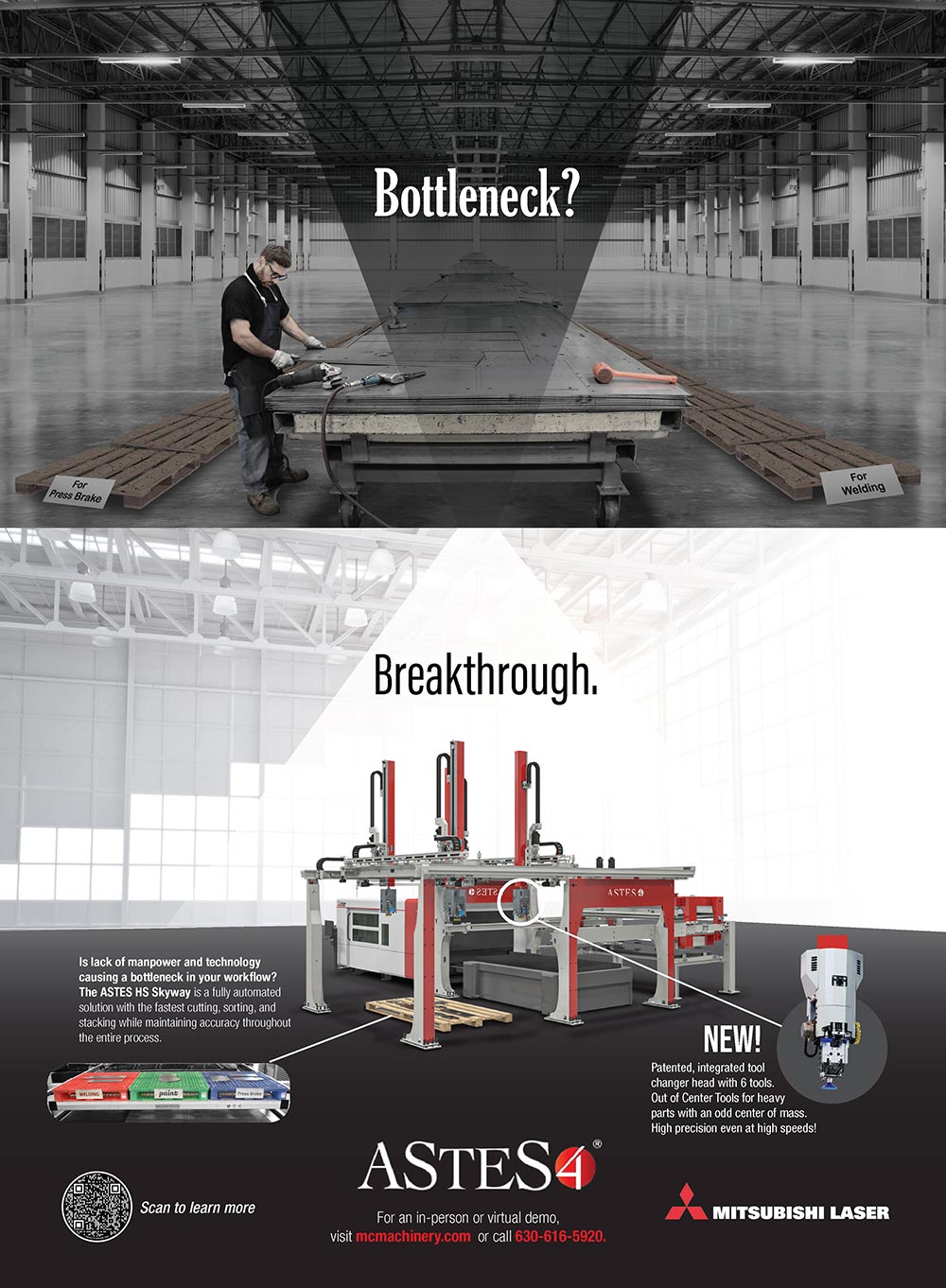

- Move parts through the shop quickly and efficiently. Having access to real-time production data facilitates fast, efficient movement of jobs through the shop floor. Developing schedules based on true capacity allows jobs to get started and completed on time. Machinists know which jobs to work on now and next, and having the right inventory on hand avoids delays. Electronically importing CAD/CAM, nesting and customer data eliminates time-consuming double data entry. When bottlenecks occur, the data indicates why it’s happening, allowing managers to take prompt action.

Sawing

Band saws increase efficiency in additive manufacturing work cells

printing is now a crucial part of the development process for many manufacturers. In the aerospace industry alone, the market for 3D printing is forecast to grow from $1.9 billion in 2021 to $4.7 billion by 2026, a compound annual growth rate of 19.4 percent, according to research firm MarketsandMarkets. Shorter production timelines, reduced extraneous use of materials, more control over designs and increased resilience in supply chains are just a few of the reasons why 3D printing of metal parts has become so popular.

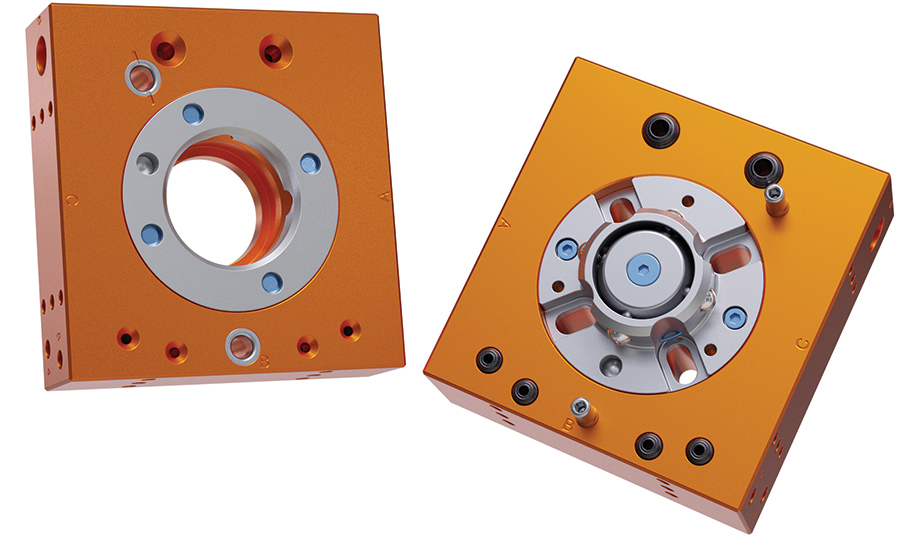

ATI Industrial Automation, Apex, North Carolina, 919/772-0115, ate-ia.com.

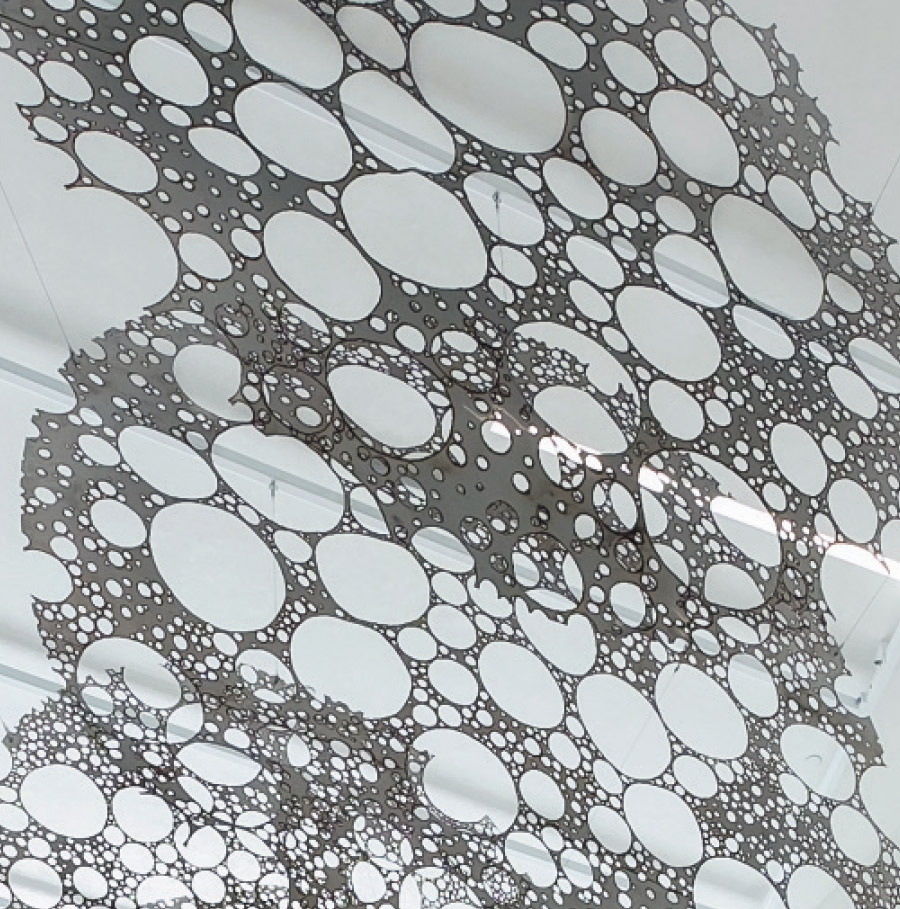

Artist LINDY LEE was commissioned to create a site-specific installation for the foyer of a commercial mixed-use development in the central business district of Brisbane, Australia. Drawing from her cultural influences of Buddhist and Taoist cosmology and philosophy, Lee created Moonlight Deities, a series of suspended perforated disks that are emblematic of elemental energy, permeability and interconnection. The work is comprised of five highly textural large circular elements with individual patterns created by plasma-cut openings. Suspended overhead, the work is a highly dramatic and distinctive element of the space, also visible from the street to draw in pedestrians. Fabricated in stainless steel, each unique disk produces a continually changing shadow play as light conditions change through the day and night.

Artist LINDY LEE was commissioned to create a site-specific installation for the foyer of a commercial mixed-use development in the central business district of Brisbane, Australia. Drawing from her cultural influences of Buddhist and Taoist cosmology and philosophy, Lee created Moonlight Deities, a series of suspended perforated disks that are emblematic of elemental energy, permeability and interconnection. The work is comprised of five highly textural large circular elements with individual patterns created by plasma-cut openings. Suspended overhead, the work is a highly dramatic and distinctive element of the space, also visible from the street to draw in pedestrians. Fabricated in stainless steel, each unique disk produces a continually changing shadow play as light conditions change through the day and night.

Editor-in-Chief

Michael D’Alexander

Lynn Stanley

J. Neiland Pennington

Lauren Duensing

Alan Richter

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323

www.ffjournal.net

Carlotta Lacy

Matthew LaFleur

Mark Koenig

Michael D’Alexander

Jim D’Alexander

Wayne Krusen

Traci Fonville

Bill D’Alexander

312/654-2309, Fax: 312/654-2323

mdalexander@ffjournal.net

Alaska, Arizona, Arkansas, California, Colorado, Hawaii, Idaho, Montana, New Mexico, North Dakota, Oklahoma, Texas, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@ffjournal.net

Alabama, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Pennsylvania, South Carolina, South Dakota, Tennessee

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@ffjournal.net

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@ffjournal.net

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Valerie Treiber, National Sales Manager

203/894-5483

valerie@modernmetals.com

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@ffjournal.net

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to: Omeda – FFJournal – 4 Overlook Pt., Ste. A25E, Lincolnshire, IL 60069. Printed in the USA.

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to: Omeda – FFJournal – 4 Overlook Pt., Ste. A25E, Lincolnshire, IL 60069. Printed in the USA.