off wear

off wear

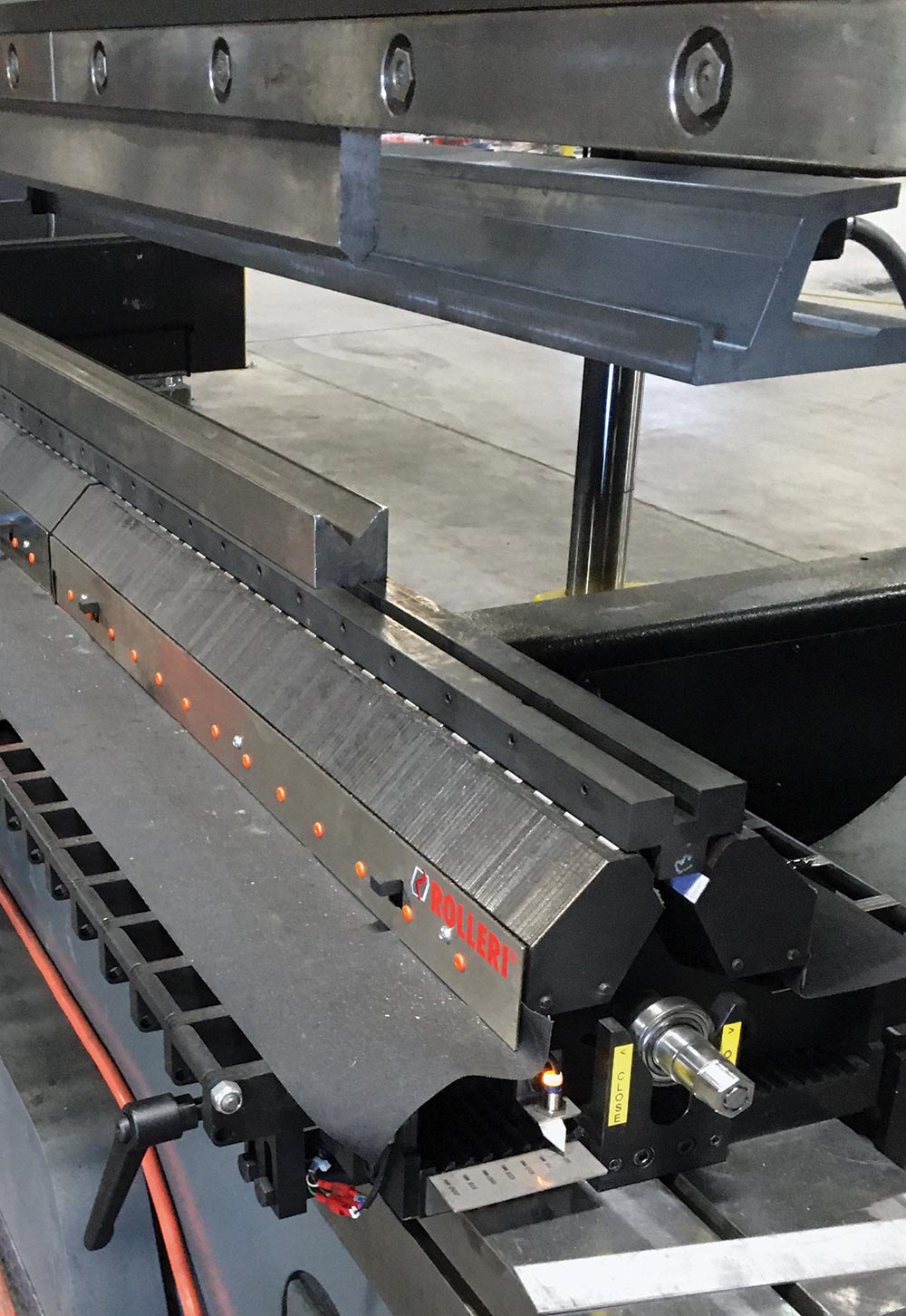

he sheet metal fabrication industry has used abrasion-resistant (AR) steels for almost two decades. The material is coveted primarily for its durability and resistance to wear. Understanding AR steels and what it takes to form them is critical for fabricators that want to use these alloys. Precision press brake tooling manufacturer Rolleri S.p.A., Vigolzone Italy, has designed and built precision press brake tooling since 1987. Offering a wide range of products and services for the sheet metal industry, Rolleri has 17 branches worldwide, including one in Avon, Ohio, opened in 2014.

The Avon branch stocks quality-certified precision tools produced in Italy. Through hands-on experience with AR steels and their different applications, Rolleri combines the right tools with education to help job shops harness the advantages of these specialized metals.

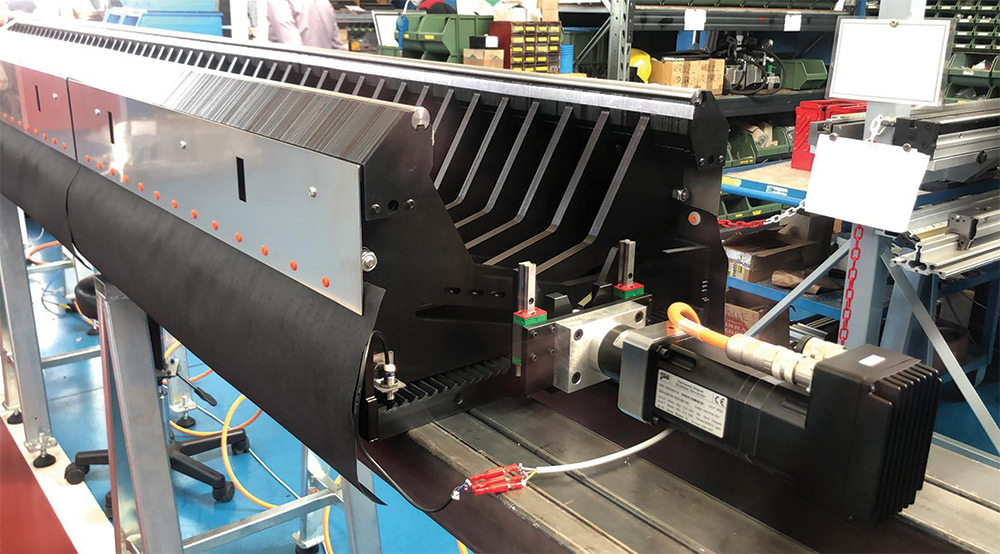

Bending Hardox (abrasion-resistant steel) in the Vario is easy.

Bending Hardox (abrasion-resistant steel) in the Vario is easy.

The punch radius/material thickness ratio is another consideration. Ratios typically start at four times and can go up to 12 or 14 times the thickness. Springback is also a factor. Operators may encounter springback as high as 15 or even 25 degrees. This means tools must be designed with acute angles for acute bends.

Bending with or against the grain is another critical factor. Before cutting the material, an operator must know how the part will be bent and what direction the grain will go compared to the bending line, then choose the appropriate tools and program the press brake accordingly.

Similar complications involve the selection of the correct die opening due to AR steels’ hardness and toughness factors. Using a V-die opening that is wider than recommended to reduce the pressure needed for part bending will result in greater springback. In some cases, the recoil can be strong enough to prevent the material from achieving plastic deformation and the specified 90-degree angle.

However, using a V-die opening that is smaller than recommended in order to reduce springback will increase the press brake force needed exponentially and may result in cracks in the part.

The solution is to bend the part using a V-die opening that respects the ratio given by the steel supplier and make sure the dies have enough resistance to withstand the force the press brake will apply. Such dies will allow the part to have a 15-degree to 20-degree springback.

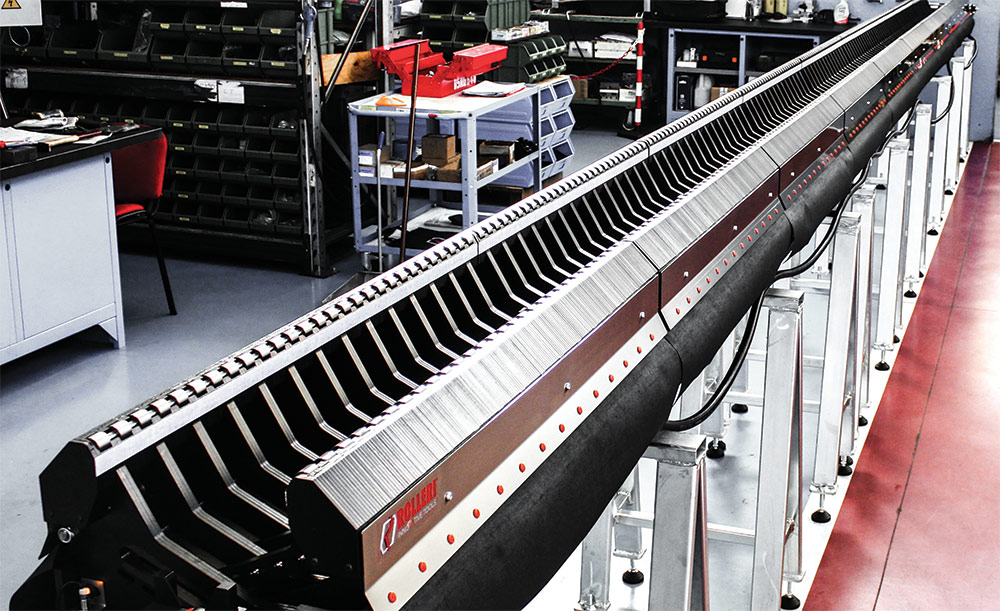

The standard Vario adjustable die goes from 2 in. to 8 in. and the heavy-duty version up to 16 in. The tooling solution is designed to resist press brake force from 85 tons to 100 tons per foot while offering 60-degree V openings.

“Bending Hardox in the Vario is easy,” says J.R. Romagnoli, plant manager for Scelzi. “The die withstands the pressure and we have no problem with the part opening since all the V-die openings are deep and acute.”

The Vario adjustable die was developed to give manufacturers one tool that could provide a number of V-die openings. It was also designed to give AR steel fabricators the ability to bend parts without cracks. The Vario can resist press brake force and eliminate the costs associated with lengthy setup times when changing V-die openings.

Plate fabricators running long press brakes understand the amount of time it can take to change a die to accommodate different gauges. A 20-ft.-long die change could require up to an hour. If an operator changes openings eight times in a week, one entire shift each week is not producing income but simply moving tools around. In the U.S., that adds up to roughly $2,000 a week in lost income.

The Vario adjustable die solves these inefficiencies even with manual operation. One operator can easily change a V-die opening on a 20-ft. press brake in 2 minutes, and be ready to bend thick plate or AR steel right away.