Features

/customfabricator

/laser

/stamping

From the

Senior Editor

Mastering logistics

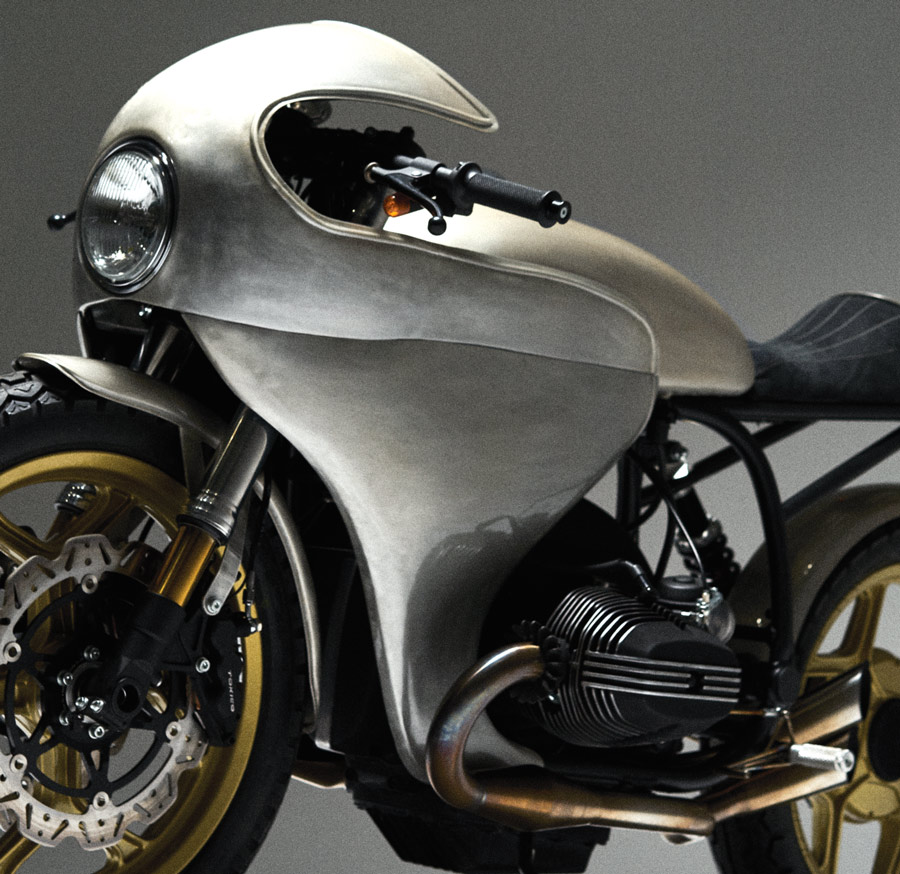

rom its headquarters in Wilmington, North Carolina, Bradford Products fashions buildings all over the world with its meticulously designed and fabricated stainless steel swimming pools. The manufacturer has a very specific criteria for its welders. To ensure it has a sufficient talent pool, the company works with Cape Fear Community College to train welders in skills specific to Bradford.

“Wilmington is not a huge town, so word of mouth has drawn a lot of interest and brought students to the area,” says Michael Brodeur, CEO. Once hired, these welders find themselves working anywhere from deserts, the sides of mountains or rooftops on high-rise buildings.

he trade war and COVID-19 pandemic have sent huge shock waves into the U.S. economy and manufacturing, but original equipment manufacturers are playing small ball by looking to shorten supply chains, as well as reduce processing runs and inventory—the little things that could add up in the long run.

“Even prior to COVID-19, there was an emerging trend to bring manufacturing back to this country,” says John Mazurek, director of sales and marketing for Metcam, the 2018 Georgia Manufacturer of the Year. “Based on the impetus of what the current administration was doing, far more people were looking to repatriate business here. COVID has sped that up dramatically.”

Weiler Abrasives, Cresco, Pennsylvania, 570/595-7495, weilerabrasives.com.

Kellye L. Walker

Lincoln expands board

Lincoln Electric Holdings Inc., Cleveland, elected Kellye L. Walker, executive vice president and chief legal officer of Eastman Chemical Co., to its board of directors. Walker was appointed to serve on the Nominating and Corporate Governance and the Compensation and Executive Development Committees. Walker’s appointment expands Lincoln Electric’s Board to 12 directors, 11 of whom are non-employee directors.

ithin the concrete monoliths in New York City lie pockets of respite in the forms of spas and swimming pools. Behind each high-rise oasis lies a long timeline of planning by architects, designers, engineers, fabricators and construction crews that take an idea and figure out the logistics behind making it a reality. At Bradford Products, stainless steel is used to create lighter, stronger and sleeker swimming pool designs, where fabricators bring architects’ visions to reality.

ithin the concrete monoliths in New York City lie pockets of respite in the forms of spas and swimming pools. Behind each high-rise oasis lies a long timeline of planning by architects, designers, engineers, fabricators and construction crews that take an idea and figure out the logistics behind making it a reality. At Bradford Products, stainless steel is used to create lighter, stronger and sleeker swimming pool designs, where fabricators bring architects’ visions to reality.

ground

ground

ground

N

Necessity is the mother of invention.” This proverb is an apt description of Orthman Manufacturing Inc. The Lexington, Nebraska, company has a string of inventions under its belt including its 1tRIPr strip-tillage system, which allows farmers to perform ideal seedbed preparation, precision nutrient placement and optimal root zone conditioning in one pass. Today, the company produces a range of agricultural equipment for OEMs like John Deere, as well as conveying systems for the food, chemical, power and manufacturing industries.

s a fourth grader, Brent Huey spent his days after school at his father’s job shop. Since then, he’s taken over operations at family-run Nanticoke Consulting Inc., Houston, Delaware, serving the manufacturing, aerospace, medical and equipment sectors.

To become more versatile and cut more materials, Nanticoke invested in a TJ4000-X3 waterjet from Techni Waterjet. “We needed a [machine] that could cut everything from metal to thermo plastics to upholstery,” says Huey. “The Techni can run up to 8-in.-thick materials so being a job shop, we knew this would help us meet customer demand.”

off wear

off wear

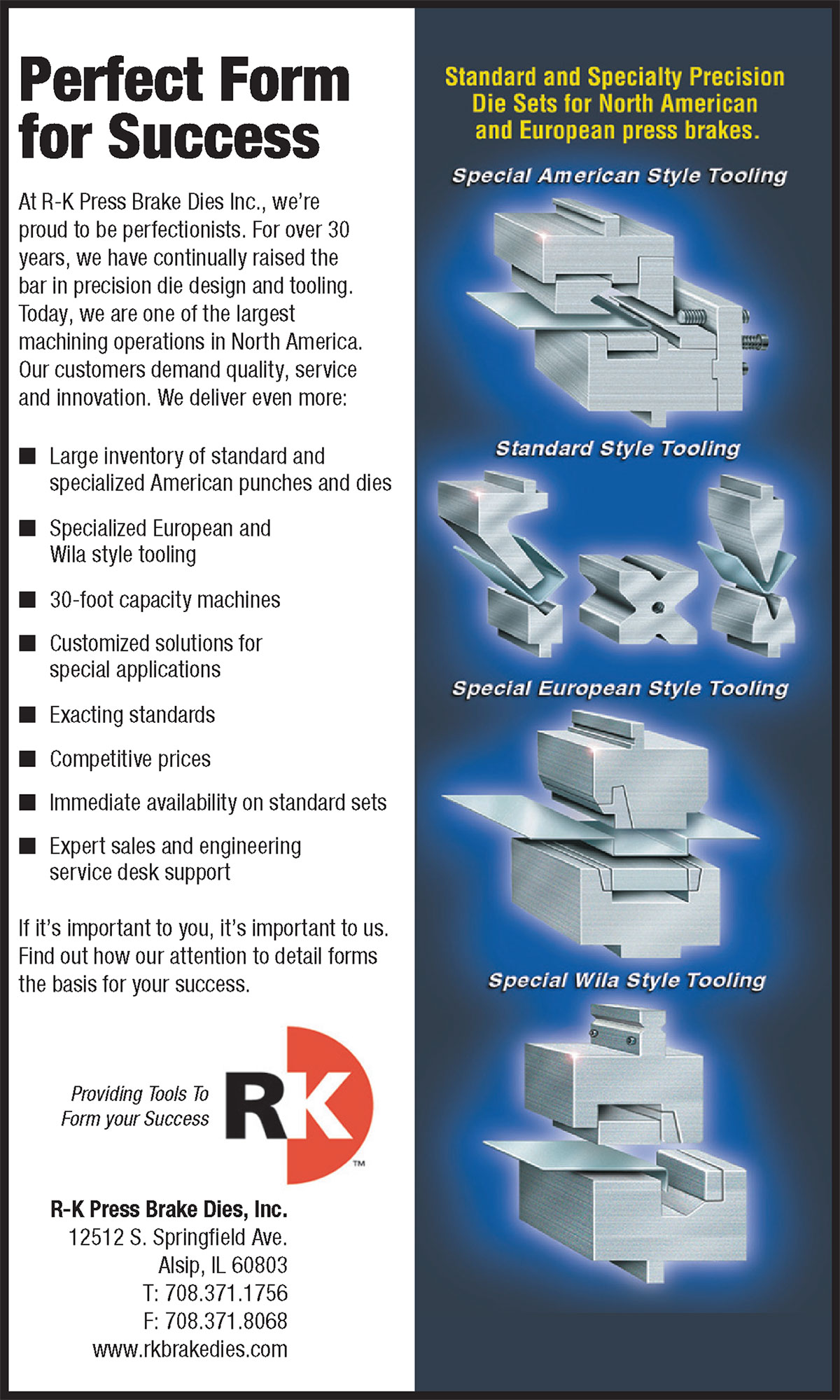

he sheet metal fabrication industry has used abrasion-resistant (AR) steels for almost two decades. The material is coveted primarily for its durability and resistance to wear. Understanding AR steels and what it takes to form them is critical for fabricators that want to use these alloys. Precision press brake tooling manufacturer Rolleri S.p.A., Vigolzone Italy, has designed and built precision press brake tooling since 1987. Offering a wide range of products and services for the sheet metal industry, Rolleri has 17 branches worldwide, including one in Avon, Ohio, opened in 2014.

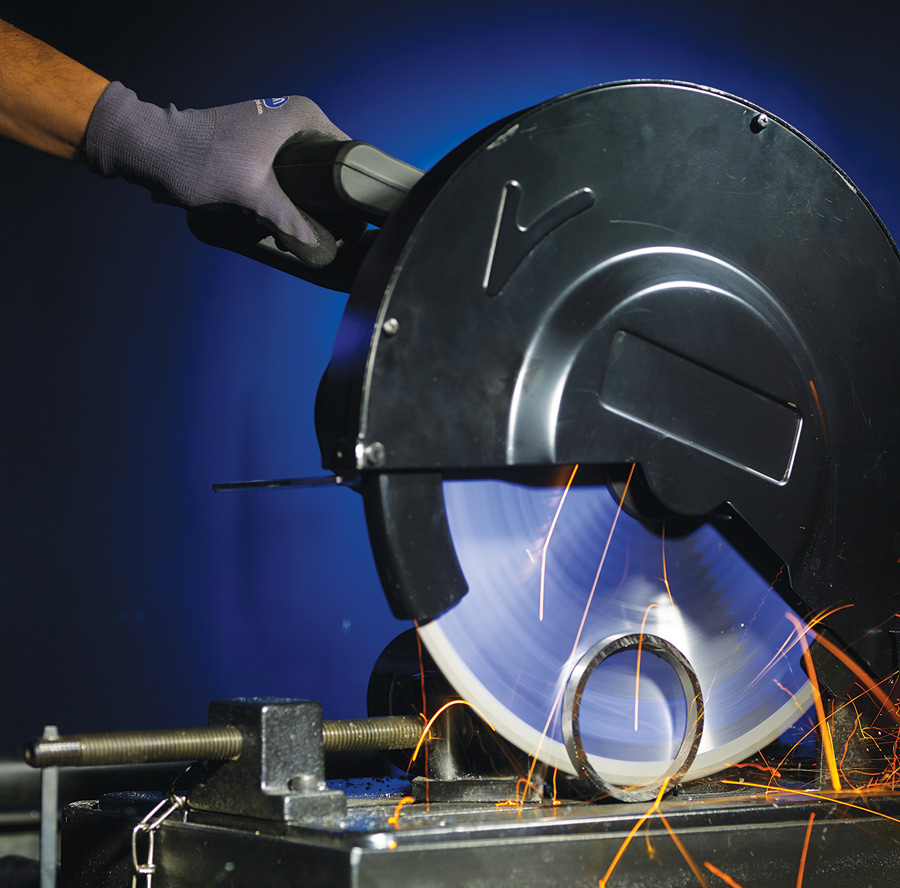

n Indianapolis, A.E.D. Motorsport Products is hard at work in the racing offseason. Pandemic or not, the hot rod and street performance business has been strong. “We process hundreds of suspension members for UPR Products (racing accessories),” says Al Lowe, owner.

A.E.D.’s workload varies from short-run cutting for packaging purposes, to high-volume orders. The company distributes finished metal products globally to the automotive performance, aviation and aerospace industries, performing cutting, profiling and end finishing. Its sister business, Boyce Industries, produces frame rails for companies such as Checkered Racing and Competition Engineering.

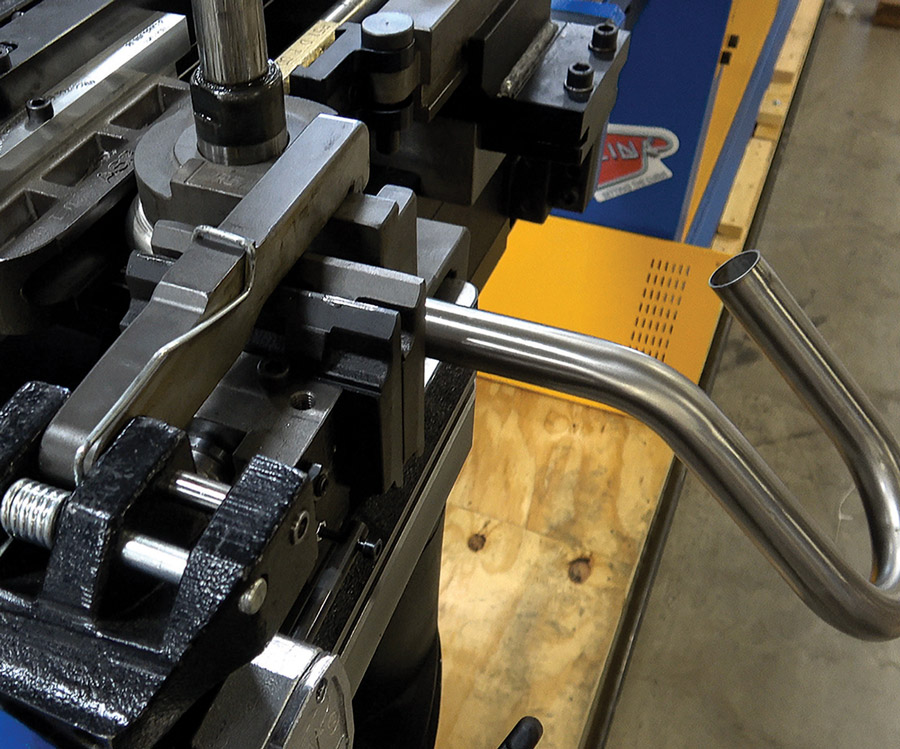

hen it comes to tube bending, the process is “still a bit of a mystery to a lot of fabricators,” CML USA Inc. General Manager Scott Tunis says. Bending tube is necessary for a broad range of applications from automotive, aerospace and shipbuilding to handrails, wheelchairs and amusement rides. Yet despite its expansive reach, Tunis says manufacturers tend to see the technology as a niche market.

“When people hear the phrase tube bender, they typically think in terms of round tubing,” Tunis adds. “But the uses for equipment like our Erco 65 CNC 3V1 Mandrel Bender are so diverse that we are still discovering new applications.”

Editor-in-Chief

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323, www.ffjournal.net

312/654-2309, Fax: 312/654-2323

mdalexander@ffjournal.net

Alaska, Arizona, Arkansas, California, Hawaii, Idaho, Montana, New Mexico, North Dakota, Oklahoma, Texas, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@ffjournal.net

Alabama, Colorado, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Pennsylvania, South Carolina, South Dakota, Tennessee

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@ffjournal.net

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@ffjournal.net

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@ffjournal.net

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJOURNAL® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJOURNAL® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.