The L.S. Starrett Co., Athol, Massachusetts, 888/674-7443, starrett.com.

SquareCut Technology doubles cut speed, improves edge quality and hole cylindricity in automated plasma applications. SquareCut Technology tilts the torch to compensate for the 1- to 3-degree edge angle inherent in high-precision plasma cutting to provide three distinct benefits: a High-Speed Mode cuts up to two times faster without increasing bevel angle; Quality Mode creates a cut surface with a 0 to 1 degree bevel; and improved enhanced hole technology cuts smaller holes with better cylindricity. SquareCut Technology works with ESAB’s Columbus CAD/CAM software, Vision T5 CNC, the DMX 5-axis beveller and iSeries high-precision power source. It works at cutting outputs from 100 to 400 amps when cutting mild steel plate from 0.25- to 1.5-in. thick. SquareCut integrates all bevel compensations into the CNC. The technology simplifies making square cuts and allows any fine tuning to be done quickly and easily at the machine.

ESAB Welding & Cutting Products, Annapolis Junction, Maryland, 800/372-2123, esab.com.

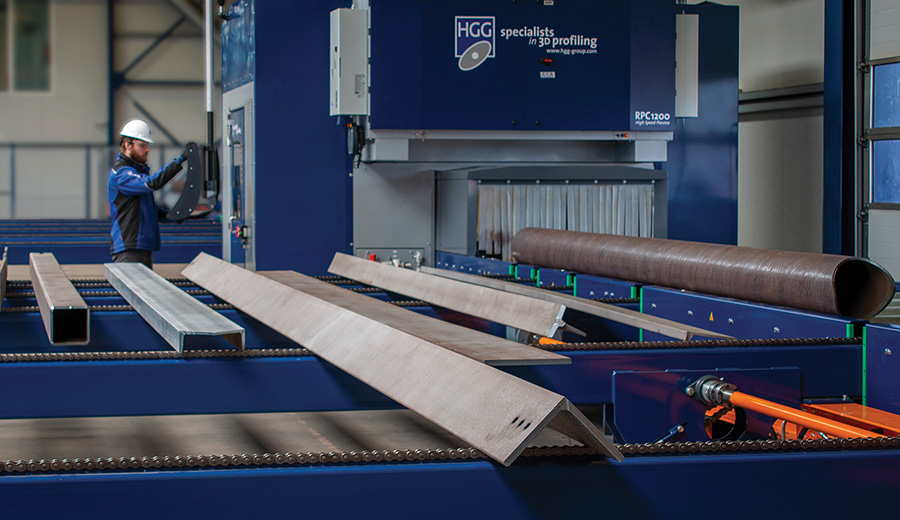

The RPC 1200 Mk3 is the first beam coping machine with the capability to profile structural beams, angle bars, channels, square tubes, plates, T-bars, and bulbs; and a versatile new capability to cut and profile pipes too. The RPC 1200 Mk3 provides fabricators an all-in-one 3D plasma-cutting robotic solution. Technological new feature innovations dramatically improve accuracy, quality, and overall productivity. The RPC 1200 Mk3 features HGG’s laser beam measurement vision system, automatically scanning profiles for common imperfections, including flanges that are not always perfectly straight and bodies that are off-center and/or twisted, resulting in superior accuracy and perfect hole technology.

HGG Profiling Equipment Inc., Houston, 833/444-4872, hgg-group.com.

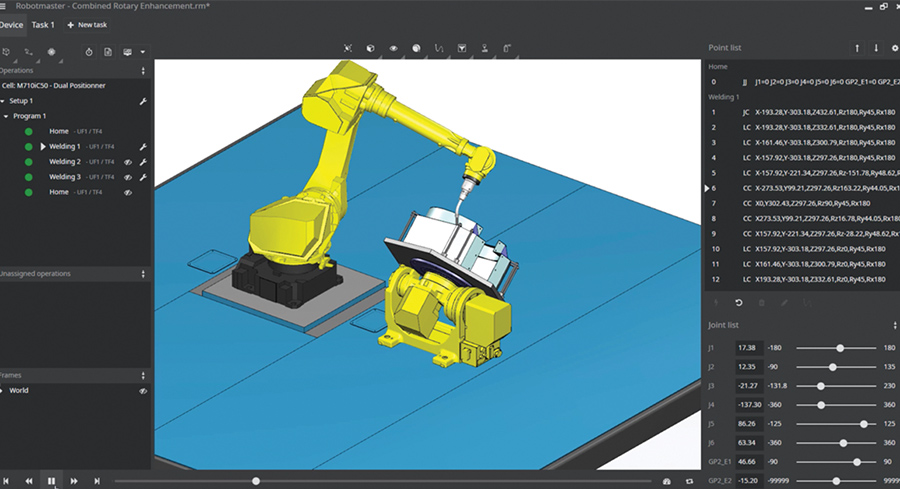

Newly released offline robot programming software Robotmaster Version 7.4 contains several enhancements designed to further simplify robotic programming, including: major enhancements to Remote Tool Center Point (RTCP) that allow for an improved end user experience and exploit the full capabilities of any robotic cell; additions to the surface paths with added strategies and advanced tools for applications such as polishing, grinding, deburring and more. The surface paths are designed to tie in with the enhancements to RTCP or traditional configurations for robotic finishing. Users also experience faster processing times when saving, loading, and calculating jobs, and improved real time feedback during simulation for faster part programming times. Enhancement to the Robotmaster Interactive Simulation Environment (RISE) delivers a more realistic simulation for external axes, along with tools to better control motion between the robot and external axes.

Hypertherm Inc., Hanover, New Hampshire, 603/643-3441, hypertherm.com.

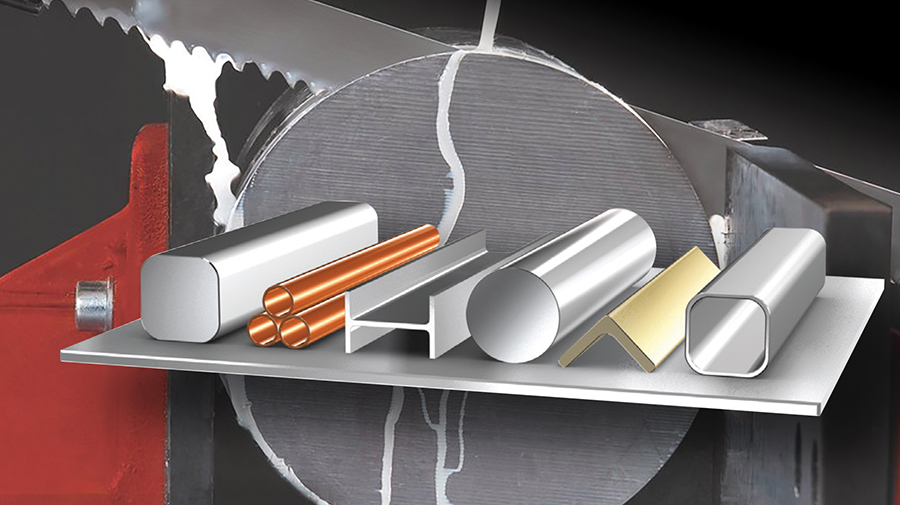

Developed to be a more affordable option for those in non-production settings, the V-1824 Vertical Tilt-Frame Band Saw is a manual design and allows for miter cuts ranging from 0 to 60 degrees, both left to right. The saw comes equipped with a 1 1/4 in. blade, a 5 hp blade motor, and comes standard with an adjustable 0 to 5 degree blade cant to help increase blade life and provide efficient cuts. Reaching blade speeds that range from 75 to 375 ft./min, and using both precision feed pressure and feed rate valve controls, the saw allows for quick adjustments depending on the material being cut.

Cosen Saws, Charlotte, North Carolina, 704/943-1030, cosensaws.com.