A study released by the International Federation of Robotics estimates there will be more than 3.5 million operational industrial robots by the end of 2021. Deloitte’s Manufacturing Industry Outlook for 2021 stated a monthly average of 400,000 job openings are being posted by manufacturers. To balance workforce shortages with the need to maintain consistent output, a growing number of companies have accelerated adoption of automation and robotics.

Lack of skilled labor could also pose a challenge for manufacturers considering using robots to fill the gap. “The big promise that came with the introduction of collaborative robots was that they were simpler to program, anyone could learn to do it and they were safe enough to put anywhere on the shop floor,” says Zac Bogart, president of Productive Robotics. “But the truth is, you still needed an engineer to implement them.”

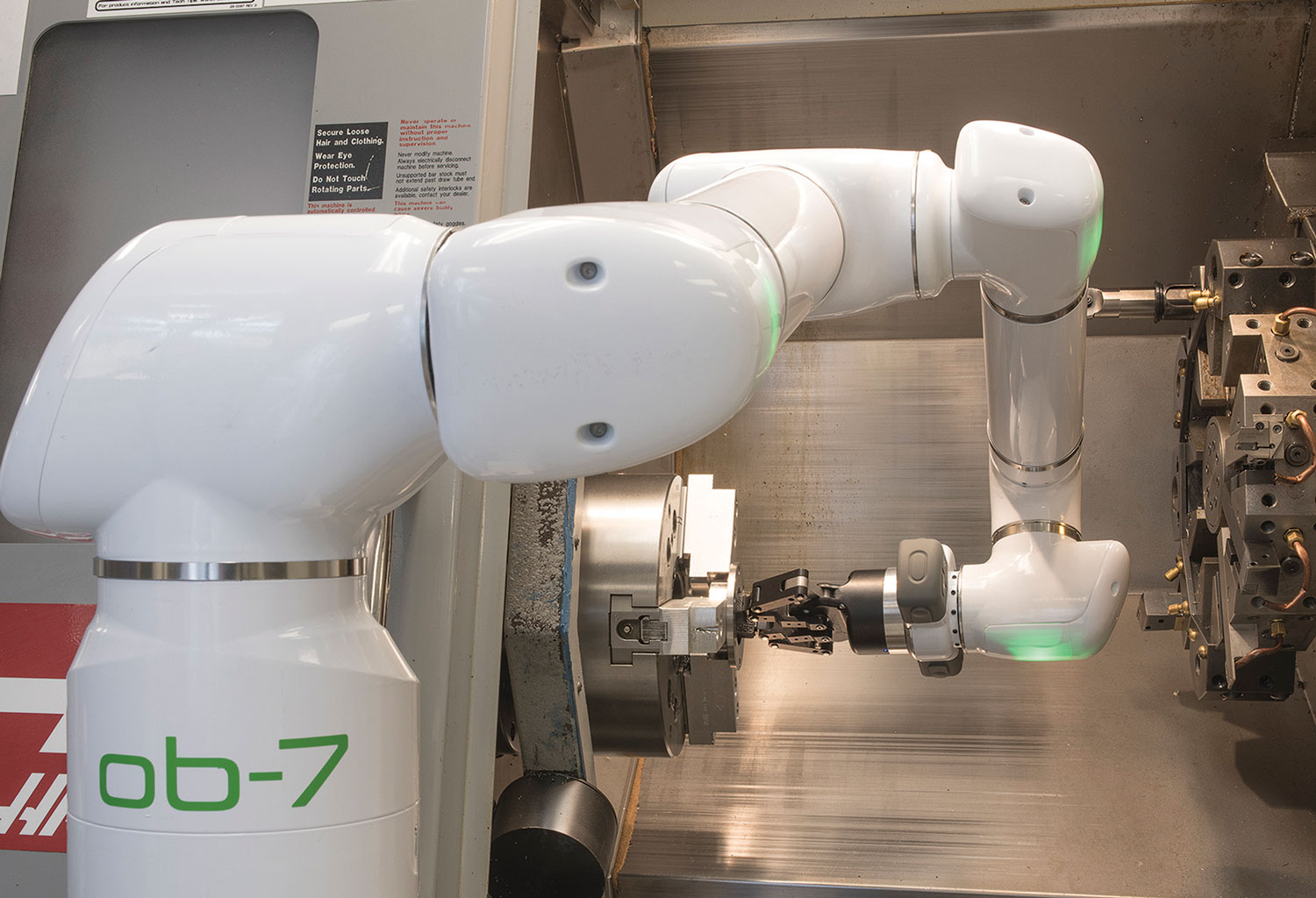

The Santa Barbara, California-based company manufactures 7-axis collaborative robotic arms. The proprietary, intuitive cobots can be used in myriad applications as augmented intelligent “co-workers,” yet require no programming.

“Our approach was to eliminate programming language,” says Bogart. An operator simply shows Productive Robotics’ OB7 what to do by “walking” it through a job’s required steps. Engineered with seven joints like a human arm, the OB7 has more freedom of movement than conventional cobots and can learn a job in a matter of minutes. It can work with new or legacy equipment from a CNC machine to a press brake, or take on a task such as material handling.

If you add a cobot like the OB7 you can get up to 24 hours of production and you don’t need a programmer or engineer to teach it or an operator to tend it.

If you add a cobot like the OB7 you can get up to 24 hours of production and you don’t need a programmer or engineer to teach it or an operator to tend it.

“Connectivity can be a complicated topic,” Bogart says. “The manufacturing industry is made up of more small- to medium-sized job shops than large companies. It’s harder for them to justify a large investment in data systems. And they typically don’t need complex data reporting. Our cloud analytics system provides full reporting on all of the cobot’s work. Our cobots are essentially plug and play. And they don’t mind taking on the boring, dirty jobs that don’t pay much.”

The dividends a cobot can generate for a job shop are significant. “A machine shop can keep its equipment running all night and triple its output with an OB7,” he says. “For example, if a job shop is running an 8-hour shift and a CNC machine finishes its cycle, there may not be an operator on hand to initiate another cycle, so the machine sits idle. Even if the jobs are timed perfectly, the most a company can expect to get is an 8-hour shift. But if you add a cobot like the OB7, you can get up to 24 hours of production and you don’t need a programmer or engineer to teach it or an operator to tend it.”

Productive Robotics’ cobots are kitted and come with instructions and tech support. Installation can take anywhere from an hour to a day. “Job shops and contractors are beginning to see the value, even the conservative ones,” he says.

Emuge-Franken USA, West Boylston, Massachusetts, and GROB Systems Inc., Bluffton, Ohio, have formed a strategic partnership. The alignment of Emuge-Franken, a high-performance cutting tools manufacturer, and GROB, a CNC machining centers manufacturer, provides advanced 5-axis machinery solutions, expertise and support.

Emuge-Franken USA President Bob Hellinger, left, and GROB Key Account Manager Kevin Gadde.

at ffjournal.net