Delta Industrial works closely with machine manufacturers and customers to tailor press pits and machine foundations to specification.

Support Systems

Despite supply chain disruptions, press pit and machine foundation builder continues to complete projects on schedule

ike most companies that have weathered the events of the last 18 months, Delta Industrial has had to grapple with supply chain disruptions and worksite constraints, while continuing to meet customer demands. The Chesterfield, Michigan, company engineers and builds press pits and machine foundations, taking customers from design and construction to steel design and fabrication, concrete flatwork and contracting.

Following a brief shutdown in 2020, Delta Industrial was designated an essential business and tasked to ramp up operations and complete critical industrial infrastructure projects. The company adopted a strict set of safety guidelines to ensure the health of both employees and clients.

Delta Industrial had to balance material shipment delays, steadily increasing prices for steel and concrete, and the need to keep suppliers, staff and customers connected with meeting the demands of customers who still needed press pits, steel construction and machine foundation projects completed on schedule, with controlled costs, and a high enough level of productivity for success. Every delay put more strain on already strained budgets and schedules.

Voice of experience

“When you add in the pandemic to an already tough and harsh metal stamping, manufacturing and industrial environment, you face even greater challenges because the manufacturing process has already been disrupted,” Lytle says. “Our way of helping is to tighten down on the workflow and to communicate with the client even more. Communication is key.”

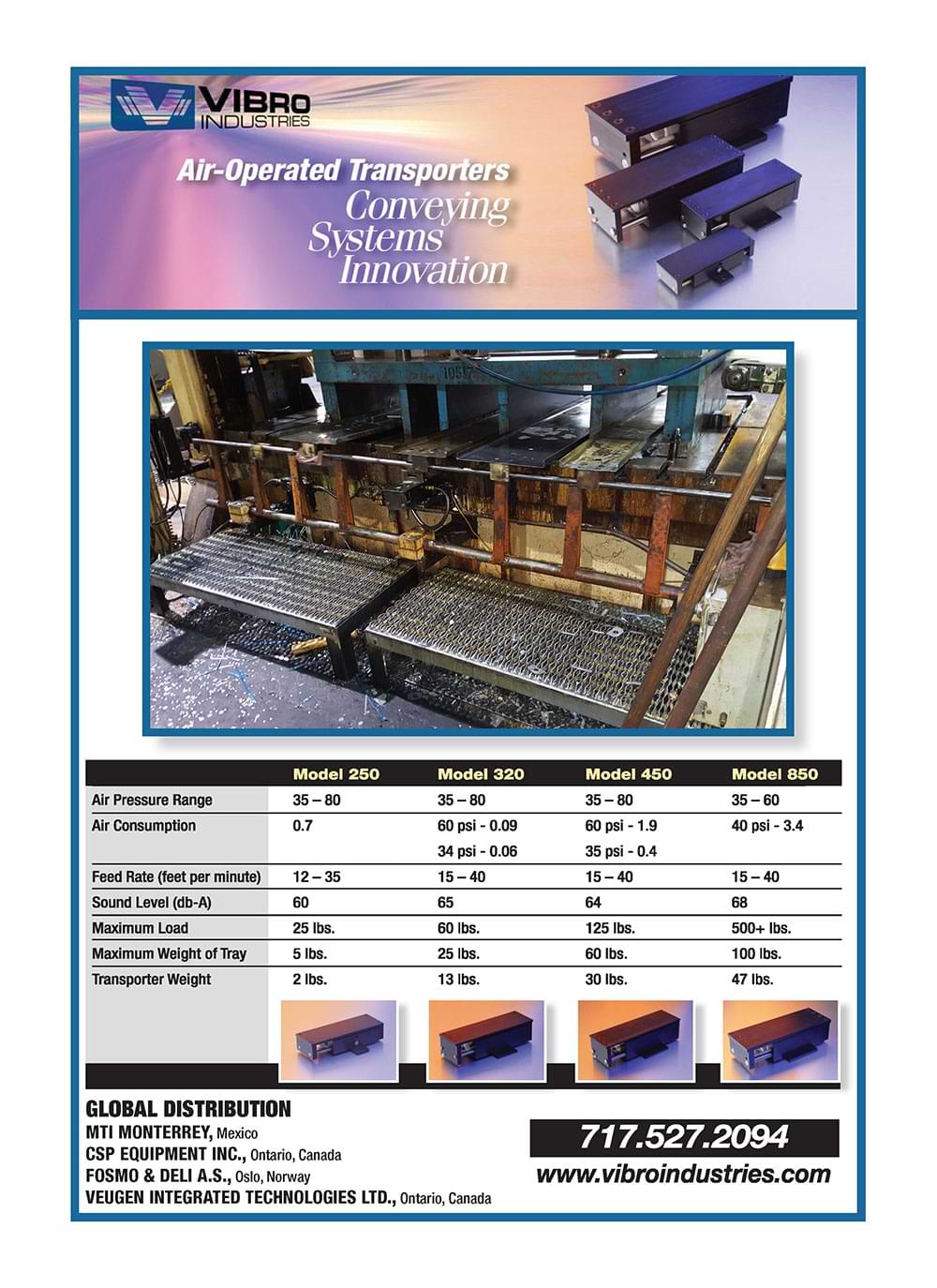

Delta’s turn-key installations include rigging, electrical/mechanical, floor plating, roof raises or building additions.

In the best of situations, a high level of engineering and design is required for building press pits, machine foundations and other types of industrial steel construction. Typical project profiles include building foundations 75,000 sq. ft. of slab on grade, loading docks and exterior paving, a 75,000 sq. ft. bay stamping expansion, a 3,000-ton press foundation, a 1,000-ton press foundation, scrap conveyor tunnels, building foundations, spotting press foundation, CNC foundation, bolster rail foundations, utility trenches and exterior paving.

When building a press pit, an experienced, well-trained staff makes all the difference.

When building a press pit, an experienced, well-trained staff makes all the difference.

Project profiles

In addition to the engineering and design work that goes into building press pits and machine foundations, Delta Industrial still had extensive bedrock demolition to perform so it could engineer additional structural modifications as well as add conveyor belts and customized deck plating. By paying close attention to cost and time restraints, the project was completed on time while allowing the supplier to operate at full capacity.

“Despite the unforeseen challenges we faced over these last two years, Delta Industrial has completed successes for leading manufacturers across the United States such as Tower Automotive, Midway and Titan Tire, just to name a few,” Lytle says. “Our skilled personnel have been our most important resource and given us the foundation we needed to support our customers.”

Delta Industrial,