Abrasives

By Gretchen Salois, senior editor

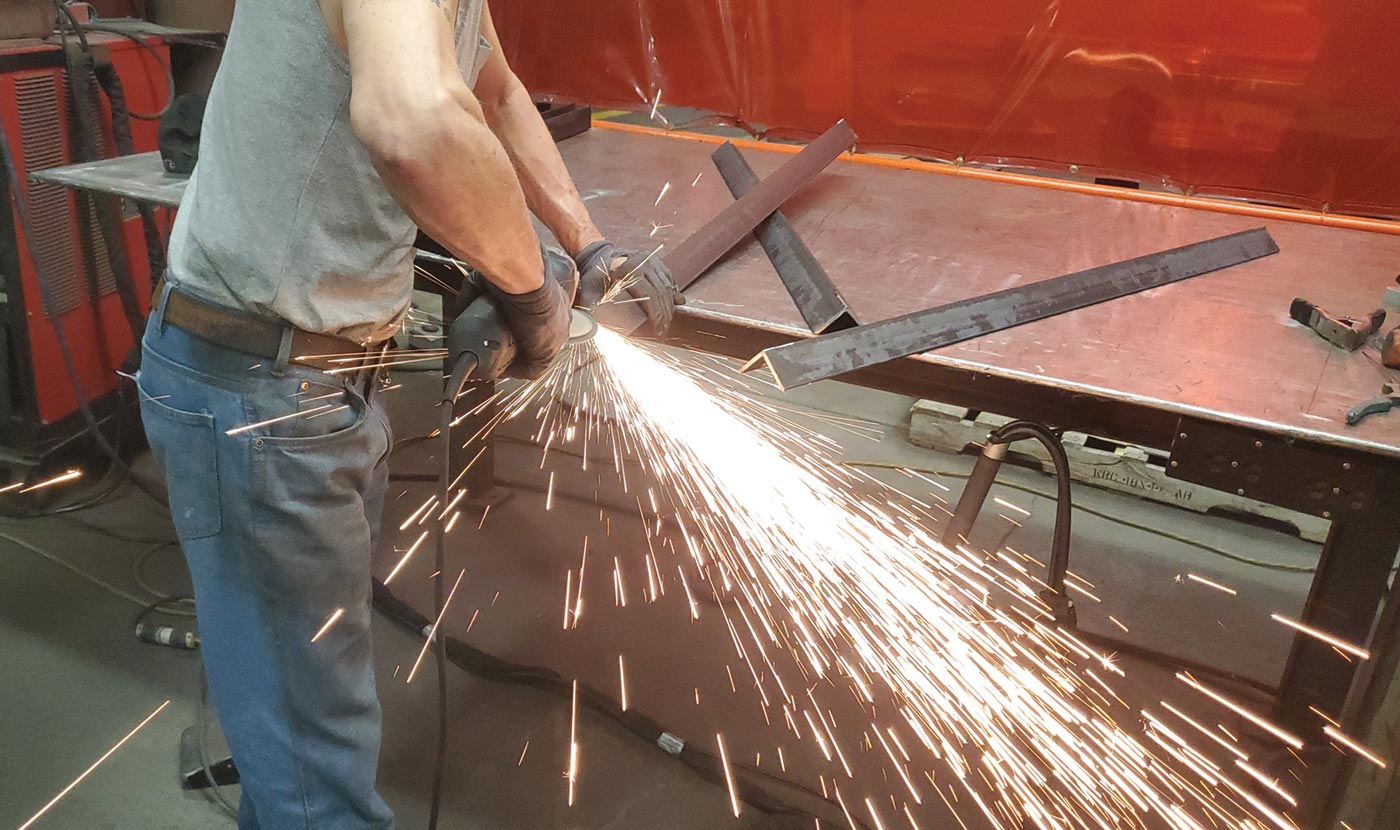

Specialty Welding and Fabricating of N.Y.’s fabricators can use upwards of 1,000 abrasive discs a week.

Specialty Welding and Fabricating of N.Y.’s fabricators can use upwards of 1,000 abrasive discs a week.

Beyond Reproach

Discs enable fabricator to affordably provide clean, smooth surfaces

unctionality, clean lines and a mirror finish. Specialty Welding and Fabricating of N.Y. Inc. can produce the desired aesthetic whether a spiral staircase for Microsoft’s corporate office in Atlanta or heavy-duty racks for conveyors used on loading freighters and barges transporting grains along the Mississippi. “We’re a job shop. We’ll build anything anyone asks us to build,” says Robert Hayes, purchasing agent.

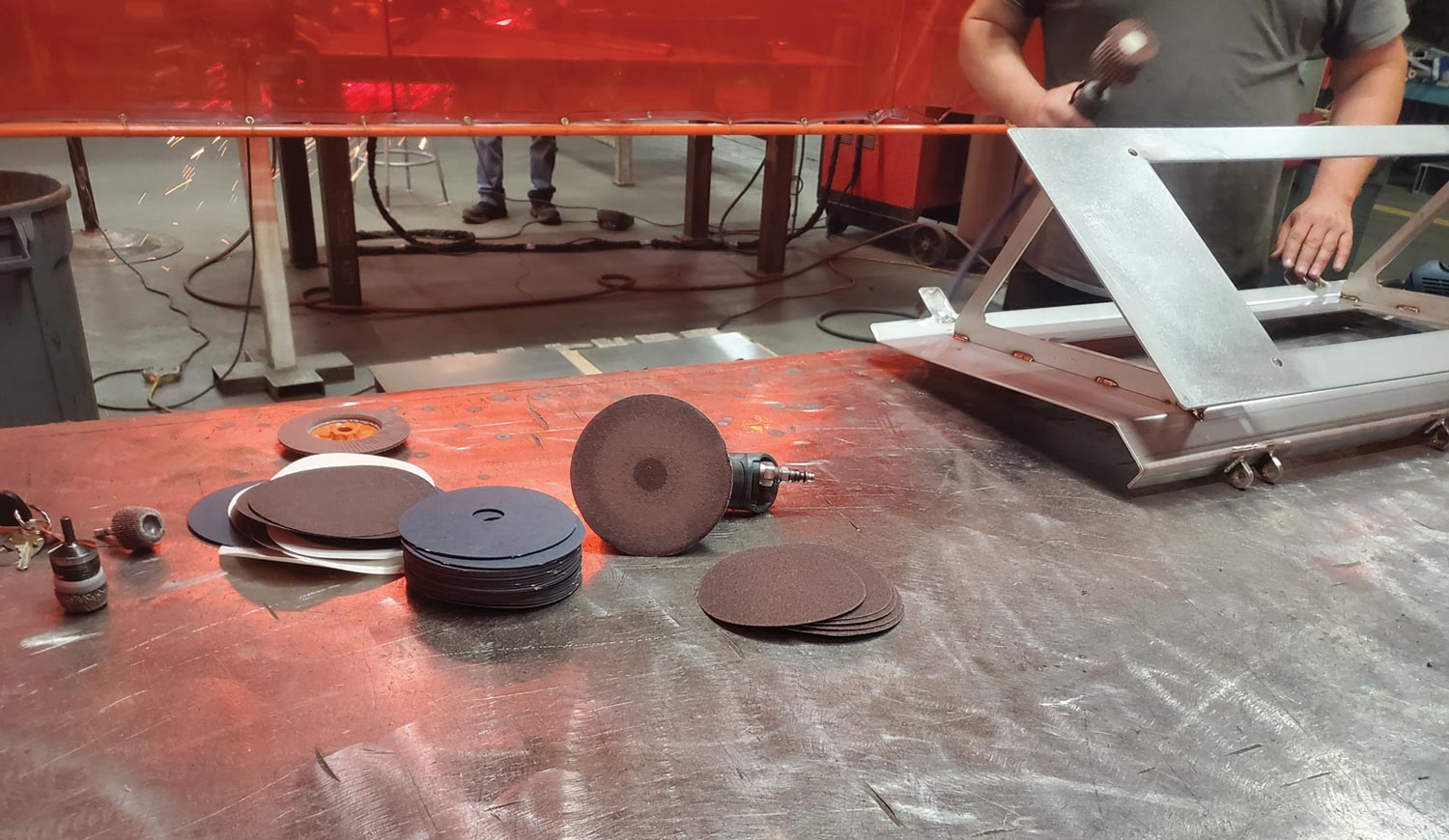

In order to keep up with demand, Hayes says Specialty’s fabricators go through as many as 1,000 abrasive discs a week. “Quality and cost add up when you’re buying as many discs as we need,” he says. “So, if I can maintain quality while reducing costs, I’m interested.”

Enter Joe Regal of Regal Associates, Mt. Morris, New York, a 45-year veteran distributor of abrasives spanning metals, wood, glass, plastic, fiberglass, granite and marble. “People call us when they want to know the best way to get the best finish,” says Regal, owner. The distributor supplies New York, Pennsylvania, Connecticut and Massachusetts, “and through word of mouth we’ve had people call us up in Mexico and Canada to ask for our help.”

Specialty Welding and Fabricating’s retail customers expect a mirror finish. Parts set to be powder coated must also be flawless as any weld seam or imperfection will be amplified when coated.

For customers powder coating parts after fabrication, finish is equally important because painting over a scratch or a bad weld amplifies the imperfection. “It looks awful,” Hayes says. “The metal surface has to look great before we can put any kind of coating on it.”

Customers come to Regal in need of a faster way of finishing without sacrificing quality. “We’ll suggest robotics equipment for some customers depending on the type of volume and finish they require,” Regal says. The distributor sells abrasives, waterjet consumables, robotics equipment, blasting media and other products. “Customers are increasingly interested in vibratory finishing/robotics,” he adds. “It depends on what the customer needs done.”

More options

Gemtex flap discs are a growing business for the abrasives manufacturer. “Customers want to see new and improved products that are different than what’s usually available,” says Frank Prenda, vice president of sales and marketing. While Gemtex offers a full catalog of expected options, there are a few models that customers find are making their lives a little easier.

“The alternatives to the typical discs are what help us stand out compared to other manufacturers,” Prenda says. In particular, four models solely manufactured by Gemtex offer an adjusted design: the Trim Kut, coated abrasive options in various minerals, grits and sizes including surface conditioning in all grades; Mini Grind R; Quicklock Spinner; and CZ45.

The Trim Kut allows the user to trim back the disc as it’s worn down. “Typically, when you wear out the outer diameter of a 3-in. disc, you throw it away,” Prenda explains. “The Trim Kut lets you trim it back. The 3 in. becomes 2 ¾ in., then the 2 ¾ in. becomes 2 ½ in., and so on, until you use the entire disc. You’re not throwing it out.

Paying for quality adds up when you’re buying as many discs as we need.

Paying for quality adds up when you’re buying as many discs as we need.

The Quicklock Spinner has the mounting located on the underside of the disc. “The metal clip screws right onto the ⅝ in.-11 grinder spindle so you don’t need a locking washer,” he says. “All other models from other manufacturers have a spin lock with a washer mounted on the face of the disc. When they grind, if they contact the metal at the wrong angle, that metal washer may contact the workpiece and mar the surface. The Quicklock Spinner eliminates that possibility.”

On the heels of the pandemic, pent-up demand is beginning to fill Specialty Welding and Fabricating’s pipeline. “A lot of project proposals sitting on people’s desks are starting to get approved and work is coming in. We’ve got our next few months of work already lined up,” Hayes says. “We do what we can to stay competitive so our work stands out—especially on larger projects.”

Hayes says the company recently finished one section of a multi-million dollar project along the Mississippi River. “We like hearing that the customer knows which section was completed by us because the quality [compared to sections completed by other companies] is that much better,” he says. “We put in the effort and need equipment that will allow us to put out quality work.”