ontext is important. Data by itself does not help resolve manufacturers’ problems like the bottlenecks or production process missteps that result in unnecessary waste. At Wintriss, ShopFloorConnect (SFC) software helps users efficiently access data that is easy to interpret to be used for increasing productivity.

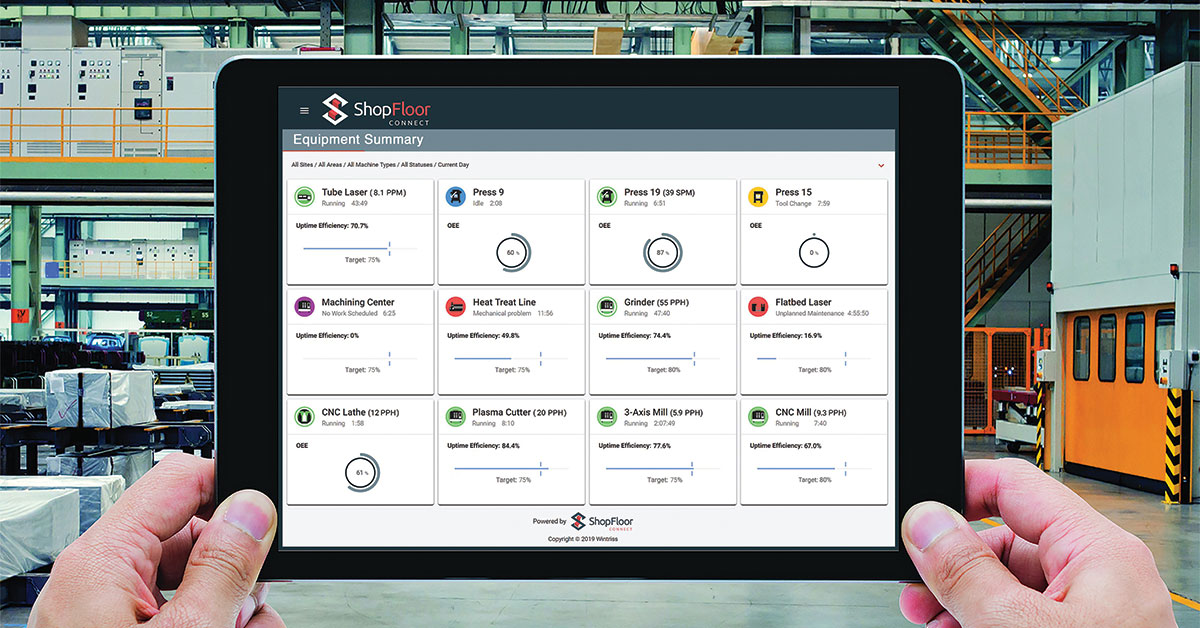

SFC overall equipment effectiveness (OEE) and data collection software identifies and quantifies excessive production losses. “The latest functionality in ShopFloorConnect gives manufacturing professionals efficient and easy-to-use software for increased efficiency and reduced downtime, including when remote monitoring is required,” says Jim Finnerty, product manager, Wintriss Controls Group, Acton, Massachusetts. “The data is displayed in real time and indispensable manufacturing reports are produced, including detailed OEE reports in a variety of formats.”

Users can use the browser-based reporting feature to configure and generate reports on demand, as well as set up schedules to automatically deliver preconfigured reports. “The ShopFloorConnect standard reports are templates that can be configured to include data from a specified time period as well as from specific machines, operators, part numbers or other important parameters depending on the machine type and/or shift,” Finnerty says. “The individual machine monitoring reports have a number of report-specific configurable parameters called filters that control the report content.”

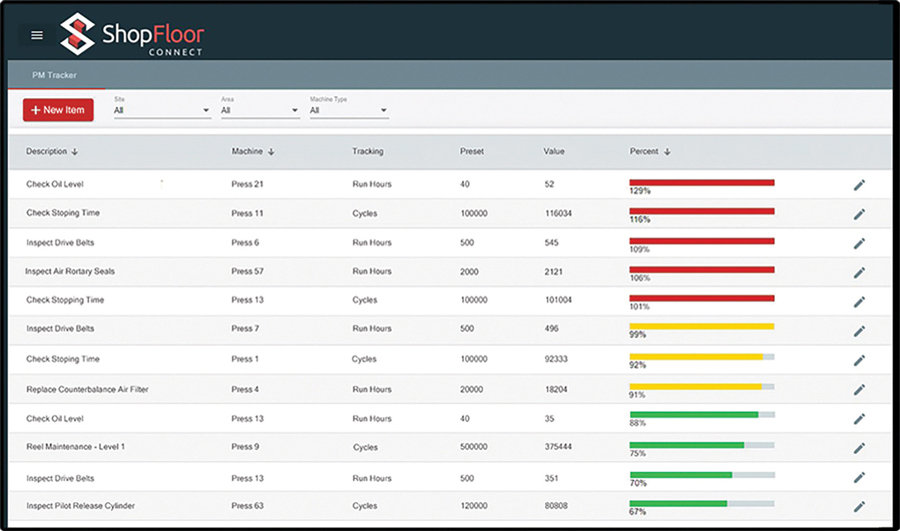

Software updates are ongoing. Scheduled updates keep users equipped with the latest security and user-requested features. “We schedule updates with the end user,” Finnerty says, adding that users have the option to opt in or out. Wintriss recently released the ShopFloorConnect PM Tracker feature, which allows users to track machine preventative maintenance (PM) items by run-hours or machine cycles. The software issues targeted alerts when an item requires PM, and it keeps track of maintenance work history for all machines.

Customizable dashboards allow users to show the information they want, the way they want to see it.

Customizable dashboards allow users to show the information they want, the way they want to see it.

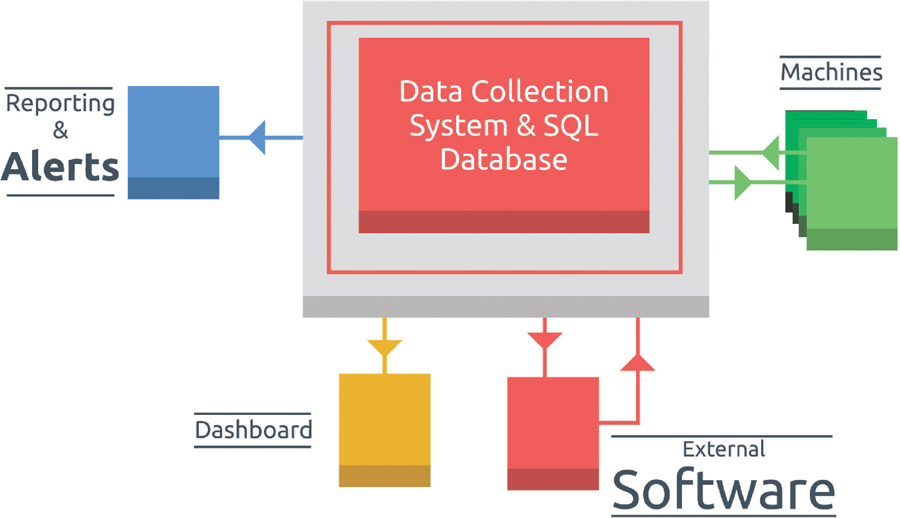

R&D is ongoing at Wintriss. The company recently released its latest Universal Interactive Application Program Interface (API) that enables users to quickly set up two-way data sharing with any ERP or MES software. “A streamlined interface with customizable dashboards allows each user to show the information they want, the way they want to see it,” Finnerty says.

The SMI 2 Machine Interface automatically collects uptime, downtime and production counts from any machine without operator input. “It also features user-configurable downtime reason menus for applications where you wish to require the operator to specify the reasons for downtime,” he says.

Users can create prioritized job queues for each machine. “Or by using the API, users can populate the production schedule from existing programs or files,” Finnerty says. “Estimated times/dates of completion are calculated for all jobs in the queue, and partially completed jobs can be automatically inserted back into the schedule. The SFC scheduler also gives users the ability to easily move scheduled jobs from machine to machine as conditions within the factory change.”

SFC allows users to compare machine OEE across several processes, and this can lead to interesting discoveries. One user noticed that when a certain group of machines had higher-than-normal OEE for short periods of time, downstream processes experienced a prolonged period of much lower OEE. After a brief investigation, they determined that the surge of parts from upstream overwhelmed a cleaning/drying operation, which resulted in wet parts being placed into the magazine-style feeds of the downstream machines. A combination of the wet parts sticking to each other and drying media being carried along with the parts resulted in excessive stoppages of the automatic machinery downstream. By limiting the output of the upstream machines to match the capacity of the cleaning/drying operation, this user was able to increase overall production by almost 50 percent from 350,000 units per day to 480,000 units per day using the same number of machines with fewer operators.