A middle-ground option sparks customer interest in agile cutting capabilities

t’s no longer either/or for many fabricators when cutting thick or thin alloys. Fabricators want to be able to take on any job that comes through the door. “Versatility—a customer doesn’t always want to stick to thick or thin cuts, so we’ve introduced a plasma model that will let them do any combination quickly and reliably,” says Rashad Galloway, fabrication product manager at MultiCam Inc.

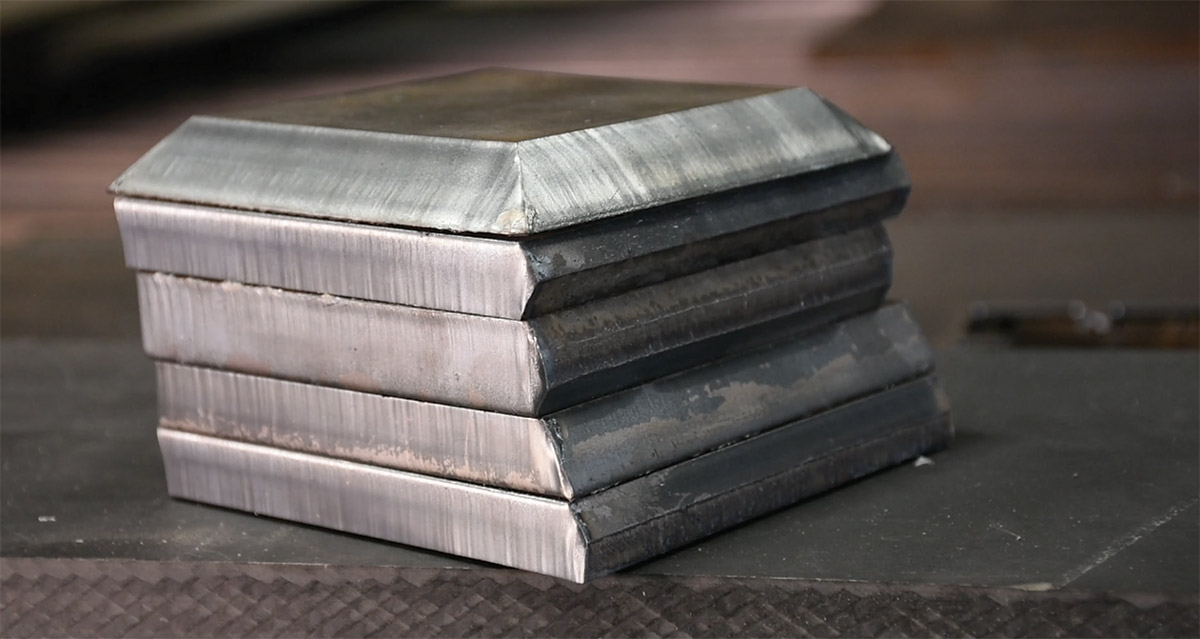

MultiCam debuted Arcos, its 5-axis plasma cutter, in September, giving customers an option that will provide a double edge for structural welding and a barcode platform to build upon current performance and capabilities. “We spent the last year doing extensive testing of the machine,” Galloway says. “We reached out to customers and asked them what they wanted to see, what kind of performance they needed. The answer was less post-processing.

“Customers want parts coming off the plasma in near-perfect condition so they’re ready for the next step of processing,” he continues. “That means less work to be done and any cleanup is quick and minimal.”

Arcos uses a 5-axis bevel system powered by ESAutomation that can cut up to a +/-50 degree bevel angle. The 5-axis bi-rotary head provides high accuracy and repeatability because of high-precision bearings and full digital ESAutomation.

Arcos’ bridge and rail design allows users to cut thin and thick parts quickly, powered by Hypertherm and an automatic oxyfuel system from IHT. Made from 1/2-in. tubular steel, the modular base rails on the Arcos are rigid, reducing vibration using modular sections that can be added for longer machine lengths.

“Customers have not only noted the risk as a result of COVID-19 but also what types of risks they are vulnerable to in the future,” he continues. “The question becomes, How do you get your business back to where it was and improve beyond that by planning for the future? And for a lot of our customers, that means investing in new, more versatile equipment.”

The question becomes, how do you get your business back to where it was and improve beyond that by planning for the future?

The question becomes, how do you get your business back to where it was and improve beyond that by planning for the future?