Features

/customfabricator

/deburring

/plateanglerolls

From the Editor

Fond Farewell

hen I first arrived at Trend Publishing’s Chicago office in 2010, I had just moved from Boston, where I worked as a reporter covering corporate governance. The financial crisis and ensuing recession was an interesting time to cover boardroom strategy but, simultaneously, it was time to move closer to home and try something new. I didn’t have any experience covering the metals and manufacturing sector, but I loved the idea of learning about an industry of movers and makers—and the opportunity to nerd out on some really incredible technology.

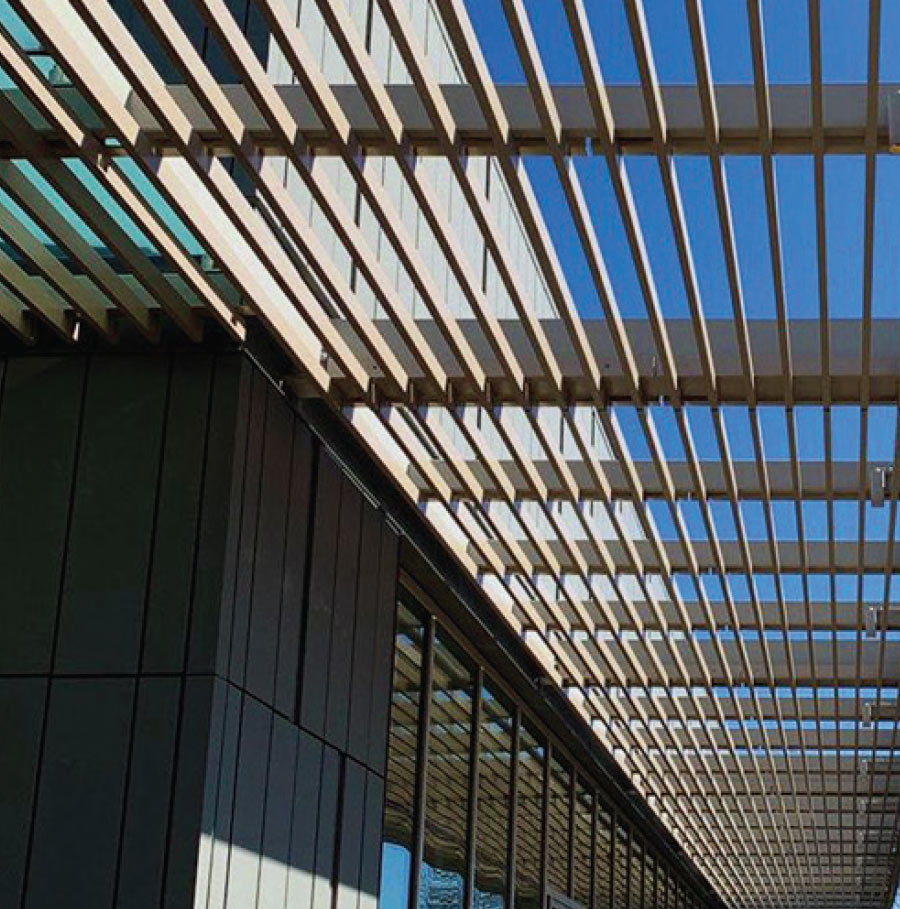

Sunshades play a big role in achieving higher standards and meeting building code compliance values.

to detail and a problem-solving mindset

here’s a big difference between a design on paper and a design that works. Collaborating with an experienced custom fabricator can help architects understand the capabilities and limitations of a design early in the process, eliminating waste later on.

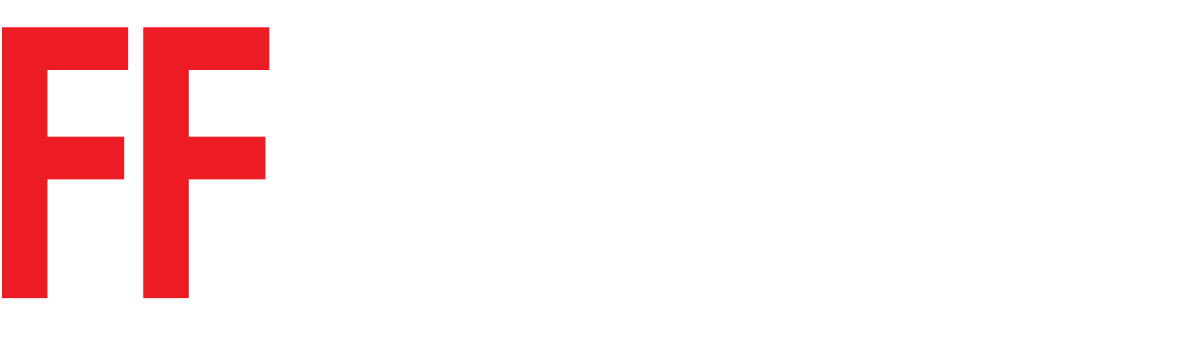

The team at Fabricated Products Group, Frankfort, Illinois, led by President Dan Shields, comprises experts in architectural systems and components, including sunshades and screening, grills and decorative louvers, and custom brackets. “We design and engineer our products, and we are custom fabricators,” Shields says. “We pride ourselves on working closely with the design intent from the architect in a collaborative environment and bringing it to reality.”

Positive Influence

an you add digital transformation to my quote? The term “digital transformation” keeps popping up over and over—in the media and webinars, in technology vendor presentations and other literature, but what does it really mean? And how does it impact materials supply shortages and staffing to support growing demand?

Digital transformation represents the aggregate of digital initiatives that take offline processes to create an online experience and take existing online processes and make them more efficient to deliver a differentiated, value-added experience. Buyers don’t ask their supply chain to add digital transformation to the list of product offerings—they ask them to access, deliver and support their businesses in a digital format that “works for them.”

Industry Solutions

TRUMPF team working on recovery efforts.

n Farmington, Connecticut, the factory floor in Building 2 hummed with activity. Production Manager Matthieu Prou was on his usual rounds, walking up and down the six aisles of TRUMPF Inc. as workers and machines processed sheet metal components for the manufacturer’s fabrication machinery. At approximately 10 a.m., he made his way down the last aisle and noticed a machine at the end of the aisle on fire. He smiled at a passing employee and thought, ‘What are my guys doing now?’ But before he could get any closer, a huge explosion knocked him and the employee to the ground. Now completely in the dark and with flames behind them, he pulled her away from the blast and they ran out of the building along with the rest of the nearly 100 employees in the facility.

TRUMPF team working on recovery efforts.

n Farmington, Connecticut, the factory floor in Building 2 hummed with activity. Production Manager Matthieu Prou was on his usual rounds, walking up and down the six aisles of TRUMPF Inc. as workers and machines processed sheet metal components for the manufacturer’s fabrication machinery. At approximately 10 a.m., he made his way down the last aisle and noticed a machine at the end of the aisle on fire. He smiled at a passing employee and thought, ‘What are my guys doing now?’ But before he could get any closer, a huge explosion knocked him and the employee to the ground. Now completely in the dark and with flames behind them, he pulled her away from the blast and they ran out of the building along with the rest of the nearly 100 employees in the facility.

This Greenerd straight-sided press, left, is gib-guided to counter the effects of off-center loading. Above, this custom 750-ton horizontal four-post gib-guided hydraulic press is integrated with two 6-axis robots that are programmed to prompt the press to perform multiple operations.

utomated technologies that can improve quality, reduce overhead and solve difficult problems have always been in demand,” says Mike Josefiak, mechanical engineer for Greenerd Press & Machine Co. “We are seeing a new class of small to mid-size manufacturers taking advantage of these technologies by relying on equipment OEMs to give them solutions that are tailored to their production requirements.”

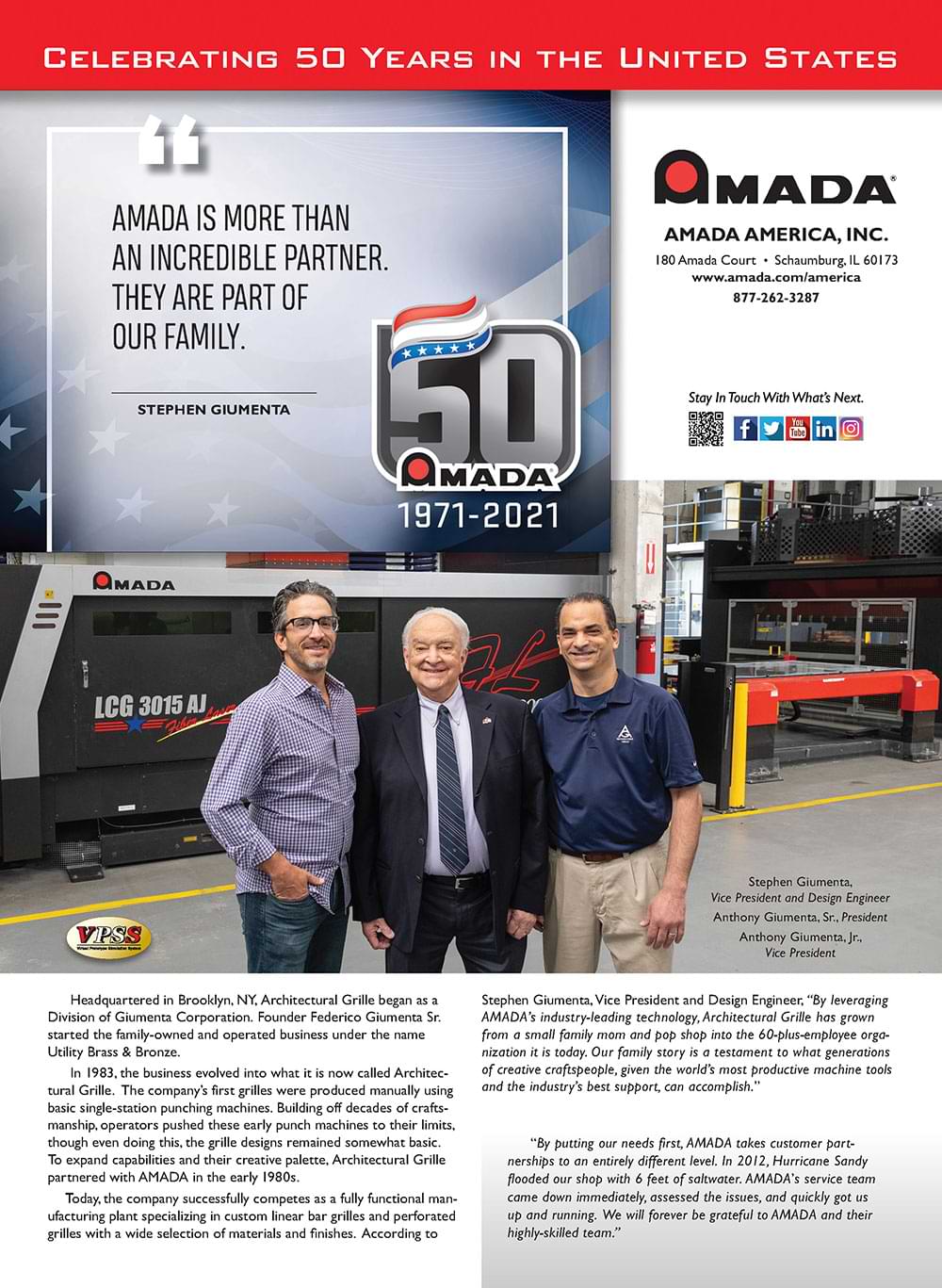

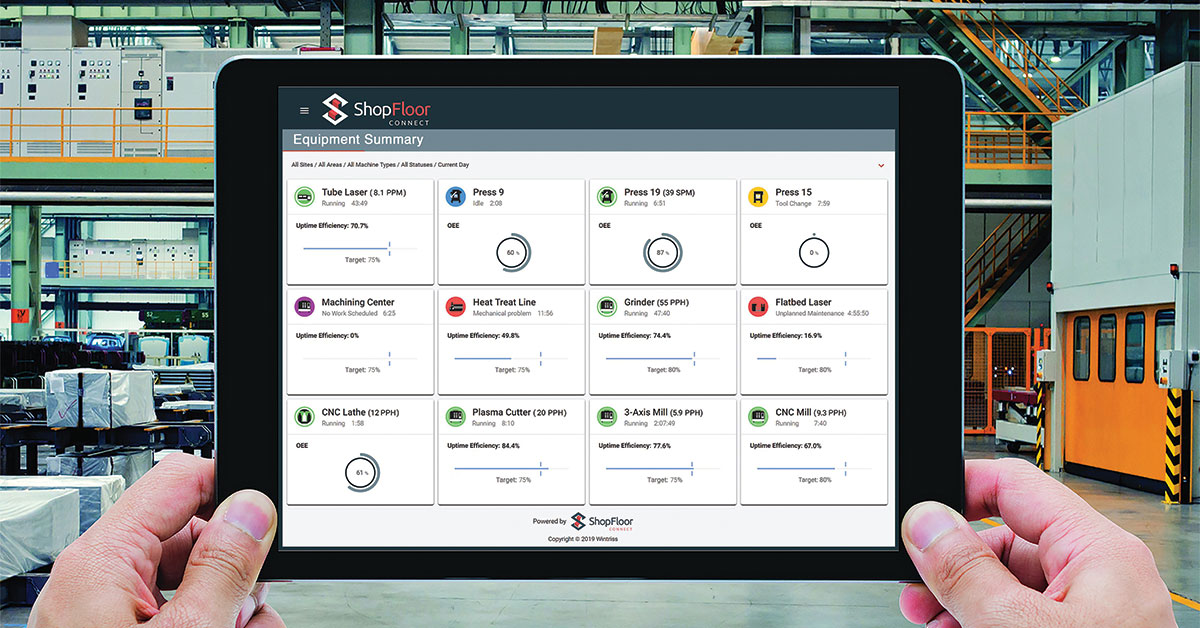

ontext is important. Data by itself does not help resolve manufacturers’ problems like the bottlenecks or production process missteps that result in unnecessary waste. At Wintriss, ShopFloorConnect (SFC) software helps users efficiently access data that is easy to interpret to be used for increasing productivity.

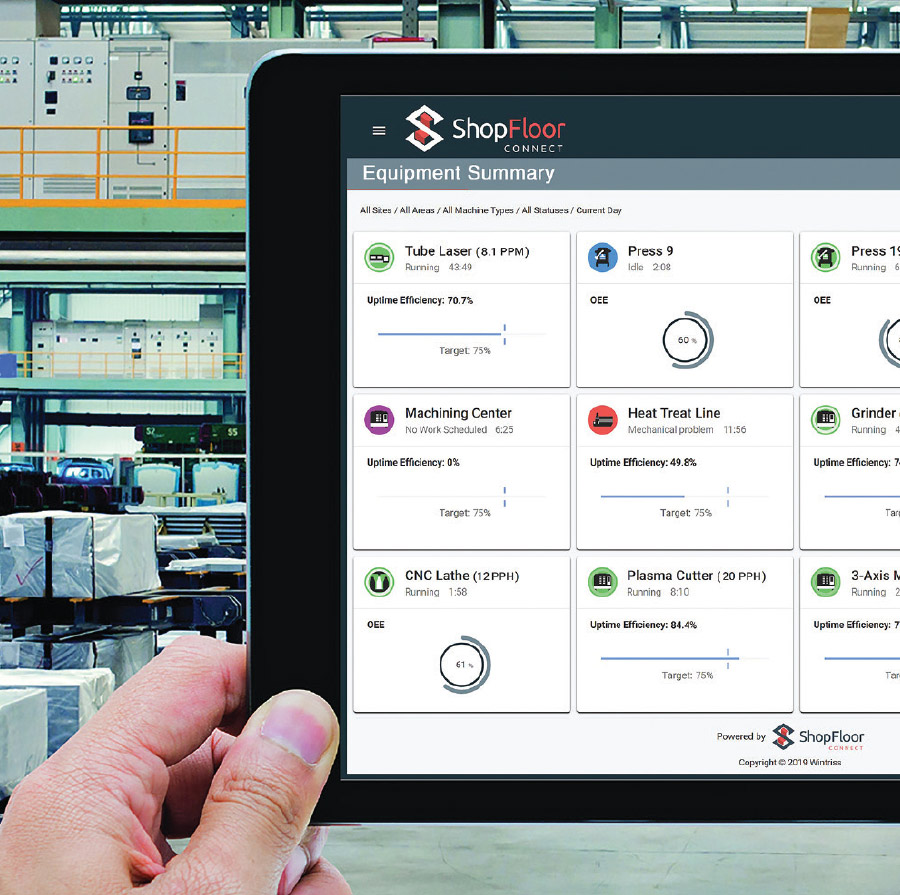

A middle-ground option sparks customer interest in agile cutting capabilities

t’s no longer either/or for many fabricators when cutting thick or thin alloys. Fabricators want to be able to take on any job that comes through the door. “Versatility—a customer doesn’t always want to stick to thick or thin cuts, so we’ve introduced a plasma model that will let them do any combination quickly and reliably,” says Rashad Galloway, fabrication product manager at MultiCam Inc.

glass recycler poses a unique air filtration challenge, says Rick Kreczmer, president of Sterling Heights, Michigan-based RoboVent, a designer and manufacturer of ventilation and filtration systems. “It is the stickiest, smelliest place ever.”

Many glass bottles, jars and other containers are coated in residue from the beverages and foods they once held—wine, beer, pickle relish—and they have to be crushed, which generates a lot of glass dust. “Think about employee retention,” Kreczmer says. “If you go into one of these facilities, your clothes smell so much that you don’t want to get into your car. And, at times, local municipalities can get involved instituting odor restrictions.”

he science of sintering first emerged in the 1940s. The technology has since matured. Today, the heat treatment is used to increase the strength and structural integrity of materials. Salem, Indiana-based GKN Sinter Metals—an expert in powder metallurgy—uses sintering to produce precision powder metal products for a broad range of markets that include automotive, industrial and consumer applications. To meet the evolving demands of customers like General Motors, Ford Motor Co., Toyota Motor Corp. and Honda Motor Co., GKN has married its sintered metal processing skills with IIoT practices in a digitized production environment. That included installing a fleet of almost 30 Yaskawa Motoman 6-axis robots.

Hobart, Tory, Ohio, 937/332-4000, hobartbrothers.com.

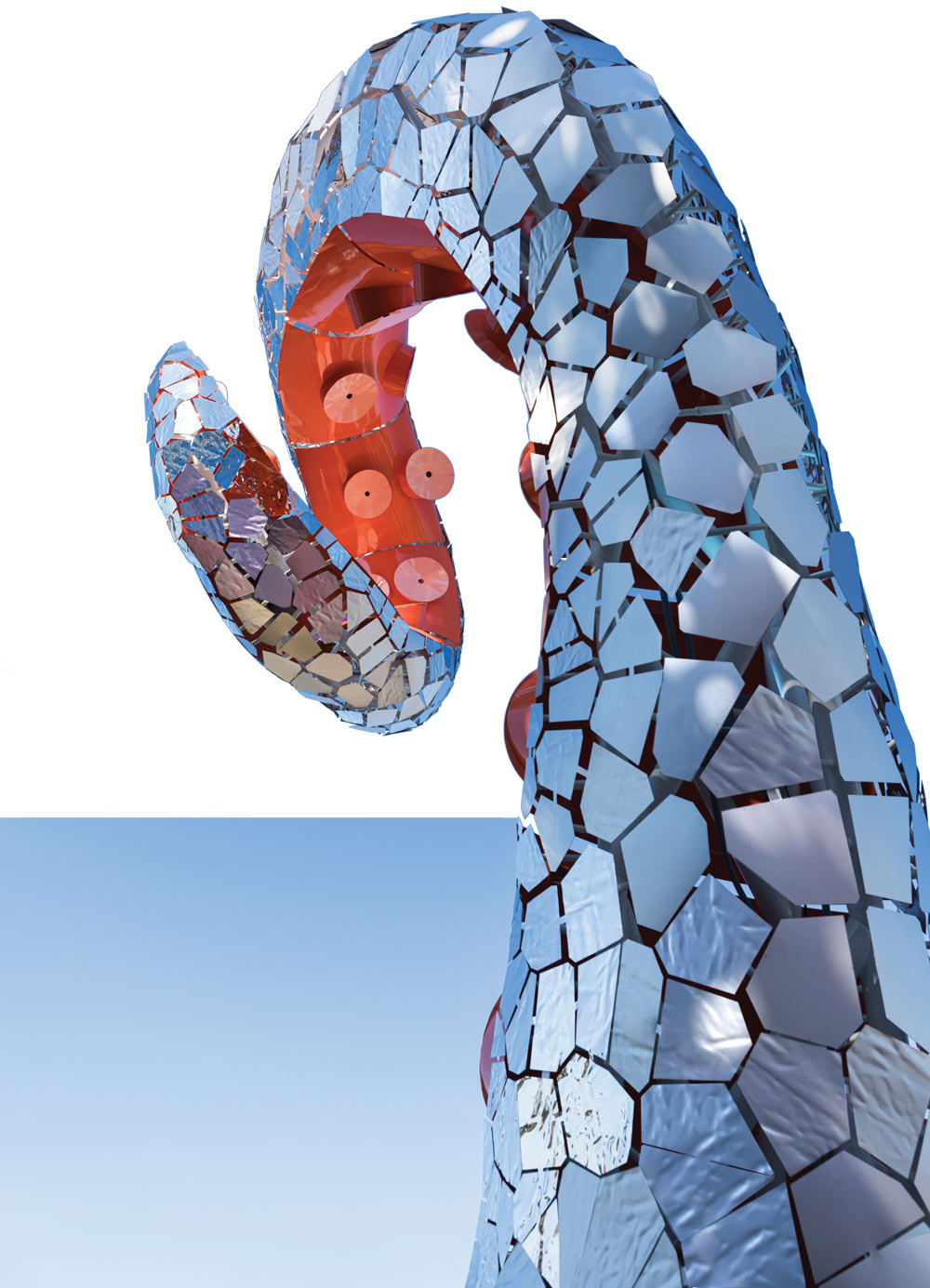

The octopus sculpture “Aquarius” that envelops the Aquarium at the Boardwalk in Branson, Missouri, is a collaboration between design studio Demiurge and aquarium developers Kuvera Partners. “Aquarius” was fabricated using stainless steel and painted carbon steel, weighs 34 tons and stands 55-ft. tall. Panels of polyhedral stainless steel with varying surface textures and finishes make up the skin components. An intricate internal structure of steel coils creates the organic form and provides connections for each of the panels. The aquarium opened to the public in November 2020 as the first phase in the Branson Boardwalk development.

Editor-in-Chief

Michael D’Alexander

Lynn Stanley

Gretchen Salois

J. Neiland Pennington

Lauren Duensing

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323

www.ffjournal.net

Carlotta Lacy

Matthew LaFleur

Mark Koenig

Michael D’Alexander

Jim D’Alexander

Wayne Krusen

Traci Fonville

Bill D’Alexander

312/654-2309, Fax: 312/654-2323

mdalexander@ffjournal.net

Alaska, Arizona, Arkansas, California, Colorado, Hawaii, Idaho, Montana, New Mexico, North Dakota, Oklahoma, Texas, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@ffjournal.net

Alabama, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Pennsylvania, South Carolina, South Dakota, Tennessee

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@ffjournal.net

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@ffjournal.net

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Valerie Treiber, National Sales Manager

203/894-5483

valerie@modernmetals.com

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@ffjournal.net

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJOURNAL® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to FFJOURNAL® c/o Creative Data Services, Inc., 440 Quadrangle Drive Suite E, Bolingbrook, IL 60440. Printed in the USA.