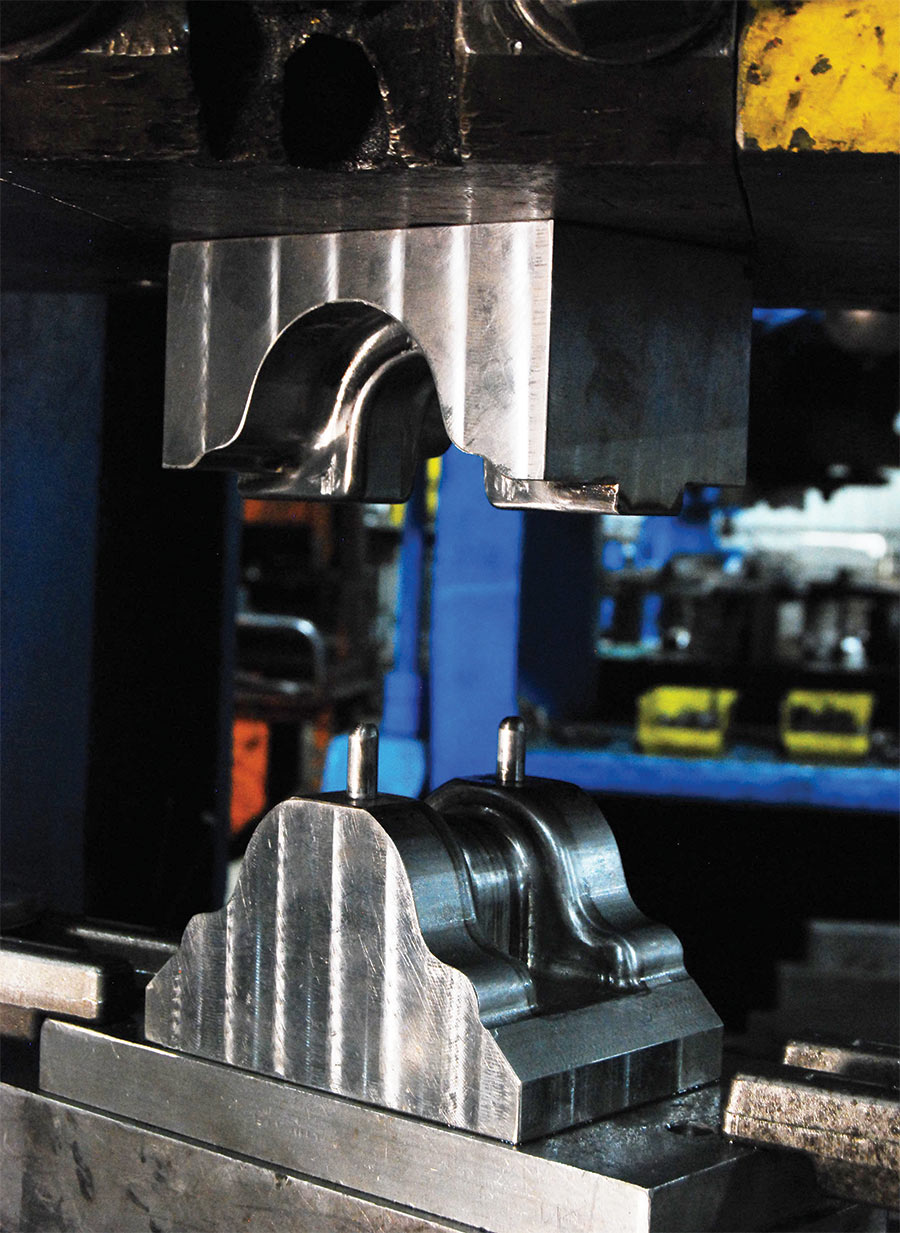

ith a collection of presses ranging from a 15-ton mechanical press to a 600-ton hydraulic press, Synergy Prototype Stamping LLC can take on an order for a single part or 100,000 units. For customers in search of sources for low-volume production, it can be difficult to find companies that won’t charge high prototype piece prices or huge tooling expenses seen for high-volume jobs.

A manufacturer of aftermarket off-road vehicle parts turned to Synergy to manage parts from start to finish. “We can buy turnkey with finished weldments, fully coated and inspected and ready for our final packaging. That saves us time and additional management on our end,” says an engineering product manager at an off-road aftermarket vehicle part manufacturer.

“Since Synergy is vertically integrated, they’re able to provide more production-oriented tooling setups and designs in order to optimize their process and get us a better price per piece as well,” he says.

Synergy produces parts that are durable and corrosion resistant. By stamping the customer’s aftermarket off-road vehicle parts, designers are able to improve strength, reduce weight, optimize fitment and provide desired aesthetics.

“Some of the parts Synergy produces for us are underbody suspension components exposed to high-stress, high-impact, weathering and general abuse that also require precise tolerances and dimensional consistency,” says the vehicle parts manufacturer. “Synergy has been able to meet those demands without issue.”

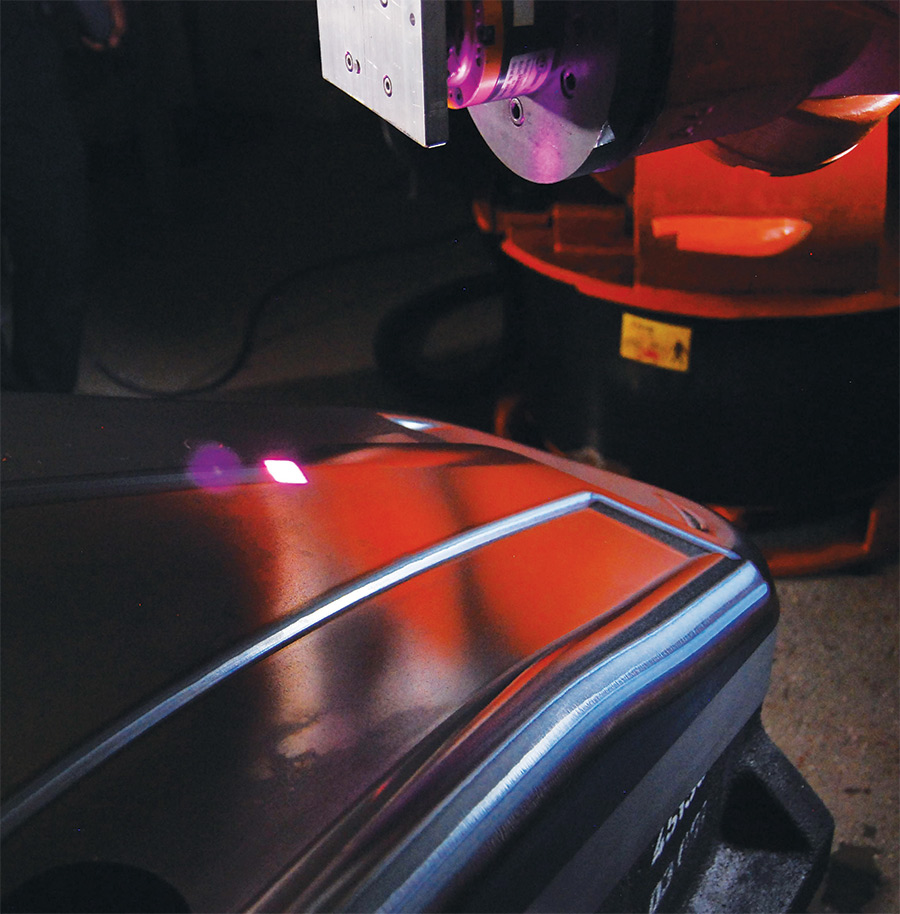

He cites in-house laser hardening as a way Synergy produces inexpensive tooling “that can still process higher strength steels and achieve the results and consistency we need.”

Fracturing of materials is a big concern when working with various types of high-strength metals. “Having experience and knowledge of how certain materials stretch is invaluable in guiding our customers toward which materials to use, the radii needed and which thicknesses would work best,” says Ryan Willette, sales/estimating manager at Synergy Prototype Stamping.

We know how certain materials stretch. We guide our customers toward the radii and thickness.

We know how certain materials stretch. We guide our customers toward the radii and thickness.

“We have found that we are most competitive on long-term production jobs up to 15,000 pieces per year,” Willette says. Turnaround times typically range from three to five weeks.

“We design our own tooling in-house and cut our own tooling using four CNC mills,” Willette says. Between Synergy Prototype Stamping and its sister company, Synergy Additive Manufacturing, Willette says the group offers in-house laser heat treating for hybrids between prototype and production tooling methods.

“This process is more cost competitive compared to conventional heat treating and allows good heat treat depths locally with no tool distortion,” Willette says. “Tool distortion, in many cases, creates the need for secondary machining after heat treating, which adds unnecessary costs.”

“Our established relationships with customers have allowed us to withstand the initial shortages experienced [early on during the pandemic],” Willette adds.

Synergy Additive Manufacturing LLC, also in Clinton Township, Michigan, has moved beyond older technologies and offers customers new heat treating solutions. “We have engineered advanced laser heat treating technology that results in minimal to no distortion on large dies, thereby eliminating the additional hard milling operations,” Willette says. “Synergy’s advance process algorithms keep the die surface temperature consistent within +/- 1 degree Celsius, resulting in superior hardness and consistency.”