Green economy

Vienna, Austria-based EasyJet Europe Airline GmbH, formed a partnership with U.S. startup Wright Electric Inc. in 2017. Successful production and early testing of a 2-megawatt electric powertrain motor led Wright to obtain certification of its zero-emissions single-aisle aircraft last year. The next phase of development will include creation of an in-house highly efficient inverter, high-altitude chamber testing and collection of test data for future aircraft certifications. The company plans ground tests this year and flight tests in 2023. Wright has plans for a two-electric engine flight in 2024, a four-electric engine flight in 2025 and the entry of the Wright Spirit into service in 2026.

The Albany, New York, company’s development efforts have been funded by NASA, the U.S. Department of Energy, the U.S. Army and the U.S. Air Force. Jeff Engler, CEO for Wright Electric, said, “We know transportation is the single largest contributor to carbon emissions and flying is a big part of that.” An estimated 200 global companies are pursuing electric aircraft projects.

We know transportation is the single largest contributor to carbon emissions right now. And flying is a big part of that.

We know transportation is the single largest contributor to carbon emissions right now. And flying is a big part of that.

Wright Electric

Besides Wright Electric and Wisk Aero, other manufacturers include Airflow, Beta Technologies, and Universal Hydrogen. The electric aircraft market is projected to see annual growth of more than 6 percent from 2022 to 2027. As airframe builders evaluate advantages such as improved fuel efficiency, reduced maintenance costs and enhanced reliability, technology advances could mean travelers could board a short-range electric aircraft by the end of this decade.

AWS Foundation launches YouTube series

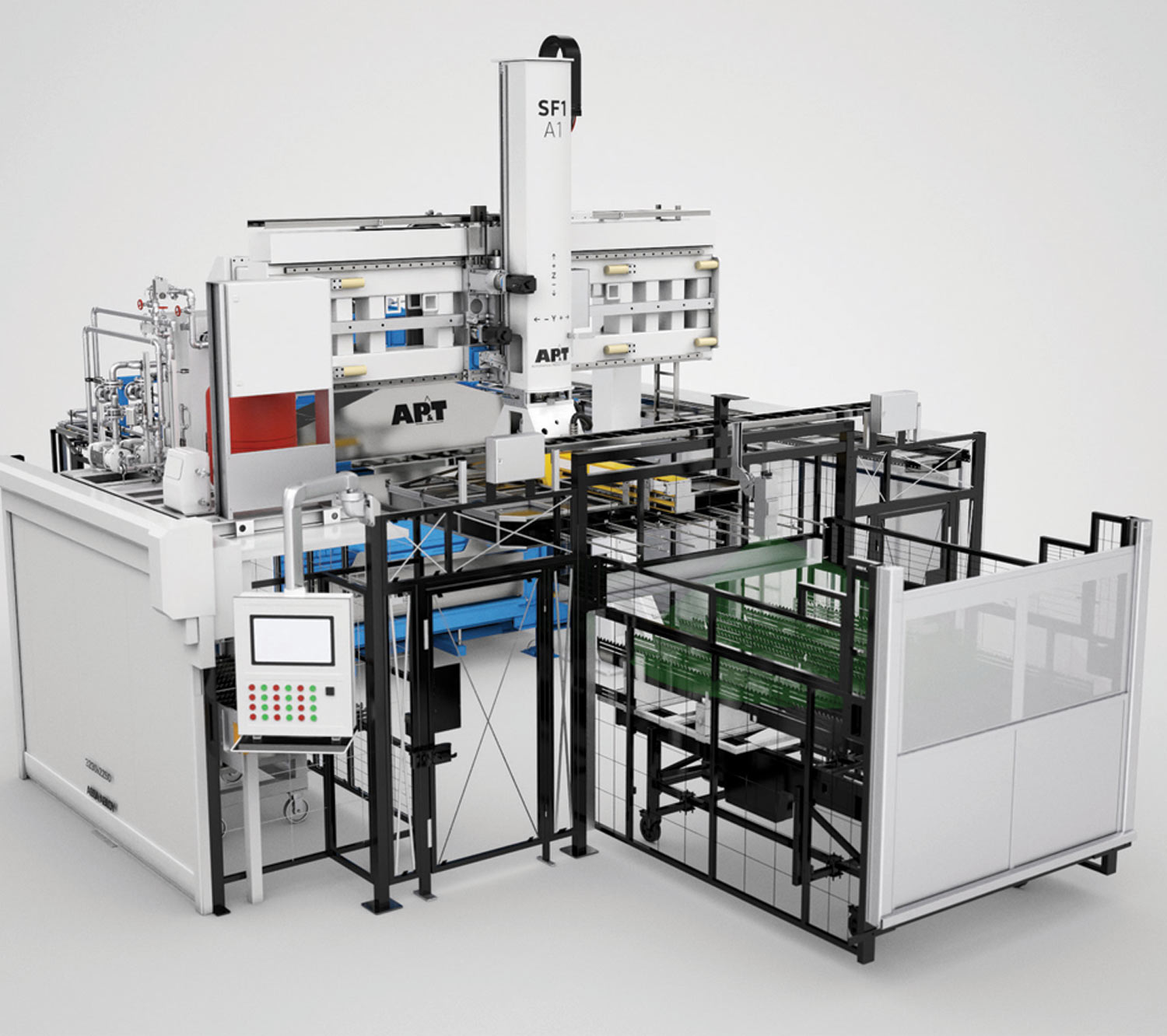

AP&T, Burbach, Germany, received an order from automaker Mercedes-Benz for its patented solution for advanced partial press hardening: TemperBox. The order includes AP&T’s Multi-Layer Furnace, automation equipment, control system and integration. The TemperBox will be used in test manufacturing a number of different parts, a process that demands flexibility.

LVD acquires robotics assets

LVD Co. N.V., Gullegem, Belgium, has acquired the solutions business unit of KUKA Automatisering + Robotics N.V. in Houthalen-Helchteren, Belgium, and will launch a new company, LVD Robotic Solutions B.V. The new entity will advance LVD’s expertise and market reach in robotics automation. The new entity will build on LVD’s experience with engineering robotic systems for sheet metalworking, centered on no robot teaching, high throughput, and fast “art to part.” LVD will leverage the proficiency and capabilities of KUKA to put robotized equipment within reach of manufacturers of all sizes and in a wide scope of industries beyond sheet metalworking.The new company will also allow LVD to serve as a single-source provider of automation solutions for their customers’ entire manufacturing business.

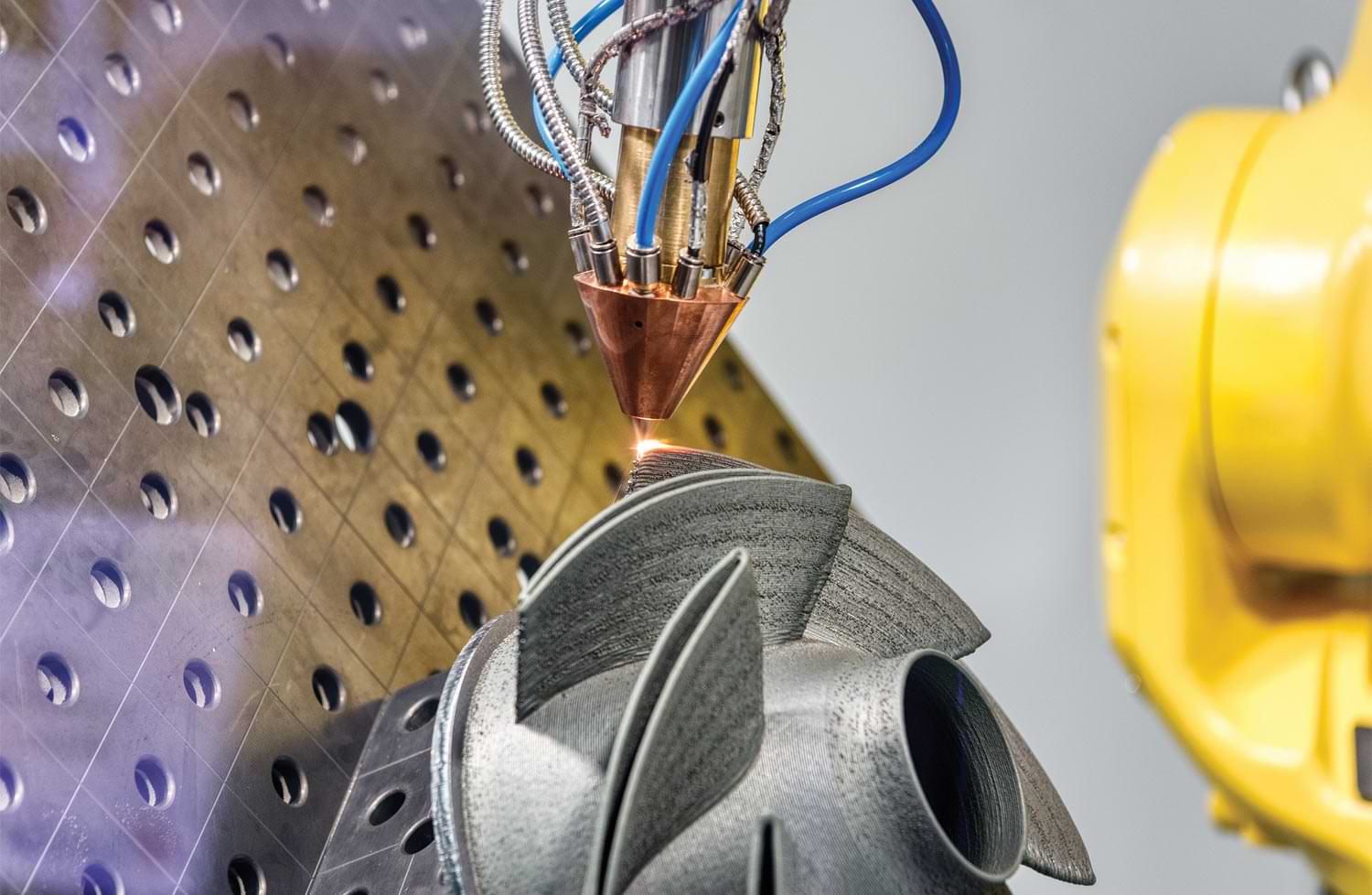

Lamprell Energy invests in PEMA machinery

Pemamek, Loimaa, Finland, won an order from Lamprell Energy Ltd., United Arab Emirates, which invests in welding production automation solutions as a response to the increasing demands on capacity in the renewables sector. Pemamek will supply PEMA heavy-duty welding, milling and material handling solutions so that Lamprell can upgrade its capabilities, including building a renewables production line, with jacket components, transition pieces, and monopiles.

Automation, standardization goal of partnership

HGG dedicates new service and support center

O’Neal Manufacturing Services receives safety award

Karl Weiler receives lifetime achievement award

Pennsylvania firm to open extrusion plant

at ffjournal.net