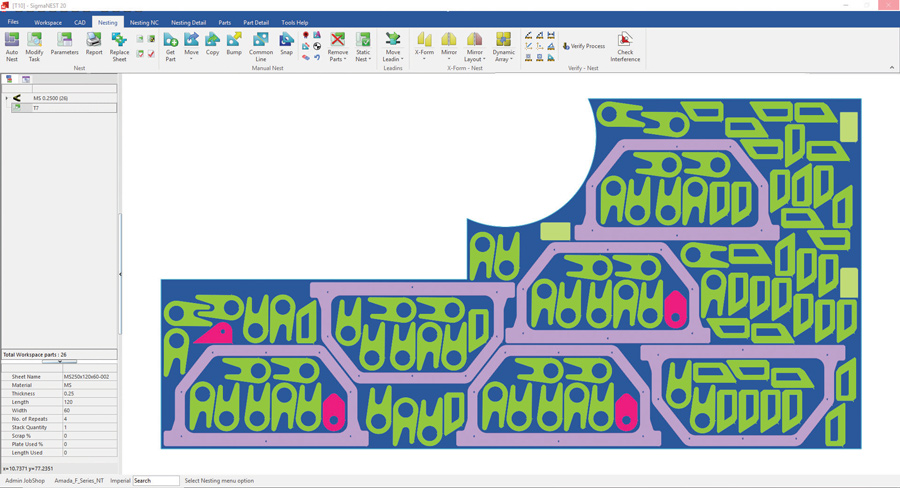

An engineer uses SigmaNEST to nest CAD-drawn parts in groups for easy removal and drag and drop to the right cutting machine.

acrificing one thing to get more of something else is what economists call a trade-off. When it comes to nesting parts, job shops also struggle with trade-offs. Often, the advantage of nesting as many parts together as possible is outweighed by the need for organization. Operators find they must restrict nesting software in order to bundle and easily locate similar parts.

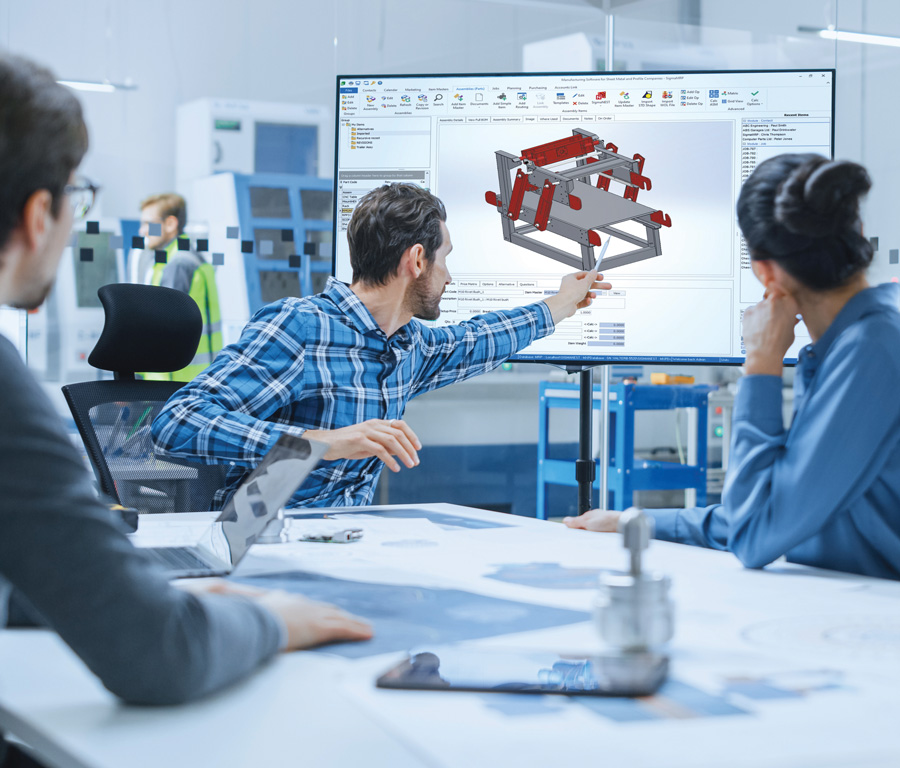

“Now job shops can have their cake and eat it too,” says Wayne Cathers, product owner—business systems for SigmaNEST. A developer of end-to-end CAD/CAM software solutions, SigmaNEST helps metalformers and fabricators optimize material use, machine motion, manpower and data management. It can also take a manufacturer from quoting to shipping and invoicing with linked business systems software programs.

SigmaNEST’s CAD/CAM nesting engine offers customizable modular features with the ability to drive nearly every type of cutting, routing or punching machine. It’s just one of the ways the software gives fabricators intelligent connections between machines and different operations.

He says customers increasingly “want integration to be less complex. The bigger shops get, the more complex their processes tend to become. They might have one software product to handle customer relations, one to process order entries and another for manufacturing.” In the past, says Cathers, shops would task their own IT people with integrating multiple software systems. “Now with labor shortages and the economy in general, fabricators either don’t have the finances to invest in in-house IT support or they can’t find people with these skills.”

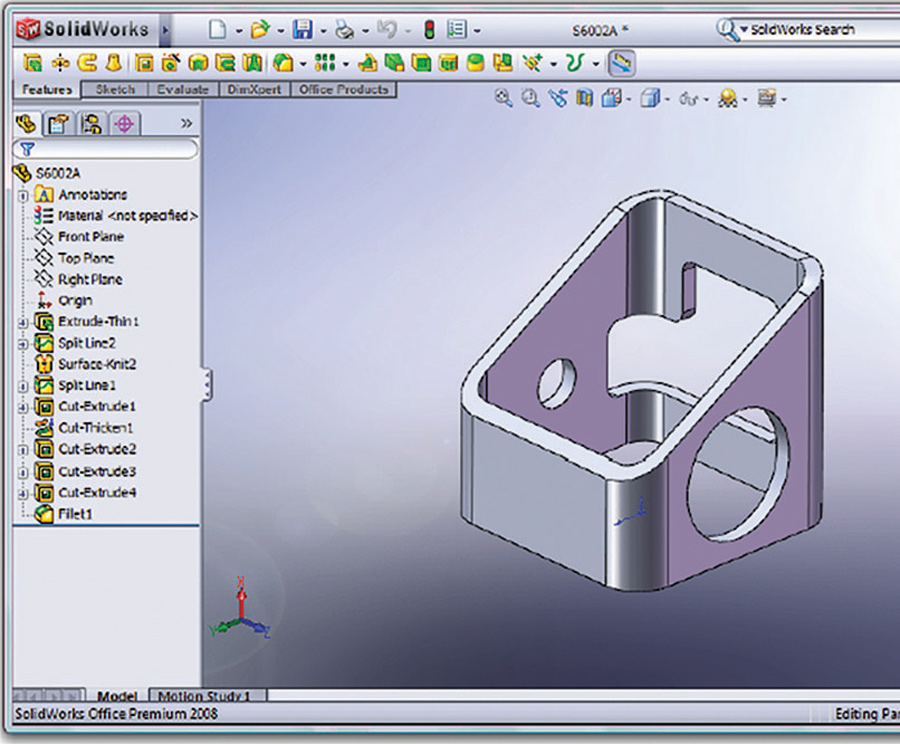

Engineers can import CAD-drawn assemblies, plus quote, nest and track parts through production down to the last bolt.

It’s more important than ever to have software that can do the work for you.

It’s more important than ever to have software that can do the work for you.

Each fall, SigmaNEST releases the next version of its platform. The software solution provider considers customer feedback in developing and testing new features. This year it will introduce easier ways to view data on the shop floor as well as functions to help users track quality, nonconformance reports and corrective action plans.