laus Schwab, founder and executive chairman of the World Economic Forum, coined the phrase the Fourth Industrial Revolution in 2015. That same year North American metalworkers and fabricators were introduced to Industry 4.0. Schwab said, “we are at the beginning of a revolution that is fundamentally changing the way we live, work and relate to one another.” He believed this fusion of physical, digital and biological spaces would impact all disciplines, economies and industries. And in many ways it has, from the rise of artificial intelligence, robotics and 3D printing to quantum computing.

Mining data from smart sensors, cloud computing and the interconnected Industrial Internet of Things (IIoT) platform have become the norm for many manufacturers. Statistics show that more than 70 percent of the world’s gross domestic product will go through some form of digitalization in 2022. By 2023, investment in Direct Digital Transformation (DXT) will total $6.8 trillion. Cloud data storage worldwide is expected to reach 200-plus zettabytes by 2025.

laus Schwab, founder and executive chairman of the World Economic Forum, coined the phrase the Fourth Industrial Revolution in 2015. That same year North American metalworkers and fabricators were introduced to Industry 4.0. Schwab said, “we are at the beginning of a revolution that is fundamentally changing the way we live, work and relate to one another.” He believed this fusion of physical, digital and biological spaces would impact all disciplines, economies and industries. And in many ways it has, from the rise of artificial intelligence, robotics and 3D printing to quantum computing.

Mining data from smart sensors, cloud computing and the interconnected Industrial Internet of Things (IIoT) platform have become the norm for many manufacturers. Statistics show that more than 70 percent of the world’s gross domestic product will go through some form of digitalization in 2022. By 2023, investment in Direct Digital Transformation (DXT) will total $6.8 trillion. Cloud data storage worldwide is expected to reach 200-plus zettabytes by 2025.

“A hard-bearing CMM that can be moved onto the shop floor and placed next to a machine can capture precise, usable intelligence at the point of use,” he continues. “Fundamentally, real time metrology is foundational to anything that is Industry 4.0 driven.”

In addition to the need to analyze and understand vast amounts of data collected from machine tools and production processes, fabricators are encountering new quality assurance challenges and increasing customer demand for 100 percent parts inspection. Coupled with the labor shortage and supply chain disruptions of the last two years, the need for a shop floor 5-axis CMM is now as central to parts production as a fiber laser, press brake or machining center.

Fundamentally, real-time metrology is foundational to anything that is Industry 4.0 driven.

Fundamentally, real-time metrology is foundational to anything that is Industry 4.0 driven.

“The personnel just aren’t there,” adds Mark Gearding, vice-president for AIMS. “We’re seeing more and more applications where a turnkey system from a support perspective is the best solution. How do you maintain competitiveness and still get parts out the door when you’ve lost 20 to 25 percent of your employees? That’s a huge disruption. By partnering up with companies like Renishaw and Verisurf, we’re helping job shops and fabricators implement an IIoT model where integrated measurement technology can effectively contribute to more efficient manufacturing processes through connectivity.”

In 2020, Honda Transmission Manufacturing of America Inc. approached AIMS about designing a stationary shop floor CMM that could accommodate large parts as well as a robot head and gripper for automated inspection. AIMS’ Summit 10.10.10 was developed with Renishaw’s 5-axis REVO-2 dynamic scanning probe for multi-sensor inspection.

“Renishaw’s core competency is sensor technology,” Skulan says. “We support OEMs like AIMS because they complete a deliverable package. They’ve done a great job with Honda and other companies by listening to [customer] feedback and building their machines around our technology.”

Renishaw introduced the first articulating probe head to the marketplace in 1979, and invented the industry’s first 5-axis probing system.

In 2021, AIMS selected Verisurf’s measurement and inspection software to expand its turnkey package. “What appealed to us was the fact that Verisurf developed and built its software on the CAD/CAM platform, one of the most widely used systems in the world,” says Gearding. “The company was started and grew from a shop floor focus—an objective we had in common.”

The CMM package comes complete and ready to operate for fabricators trying to find their footing with part changes. Electric vehicle sales, for example, soared in the first quarter of 2022 with Tesla and Polestar reporting sharp increases. Market demand for electric vehicles and hybrids is prompting a trend toward continued modification of parts. The integrated design of EV motors puts powertrain, drivetrain and electronics components into a single housing unit. This combined electric axle drive, also called the eAxle, reduces weight and axial installation space. eDrive housings and shaft and bearing quality for torque adaption and vectoring, are placing new demands on fabricators.

AIMS’ mobile HB allows an operator to move 5-axis inspection anywhere on or near a production line for dimensional verification.

The right software is also a key tool. Verisurf is a 3D measurement platform that opens any CAD file or drawing, connects to any measuring device, and aligns to any part or assembly for live or offline measurement tasks.

“It’s about bringing the components together that will satisfy the customer,” says Nick Merrell, executive vice president for Verisurf. “One of our biggest value adds is our software’s capability to exchange and make practical use of information between devices made by different manufacturers. Easy to understand, useful, flexible software is why OEMs like AIMS choose us.”

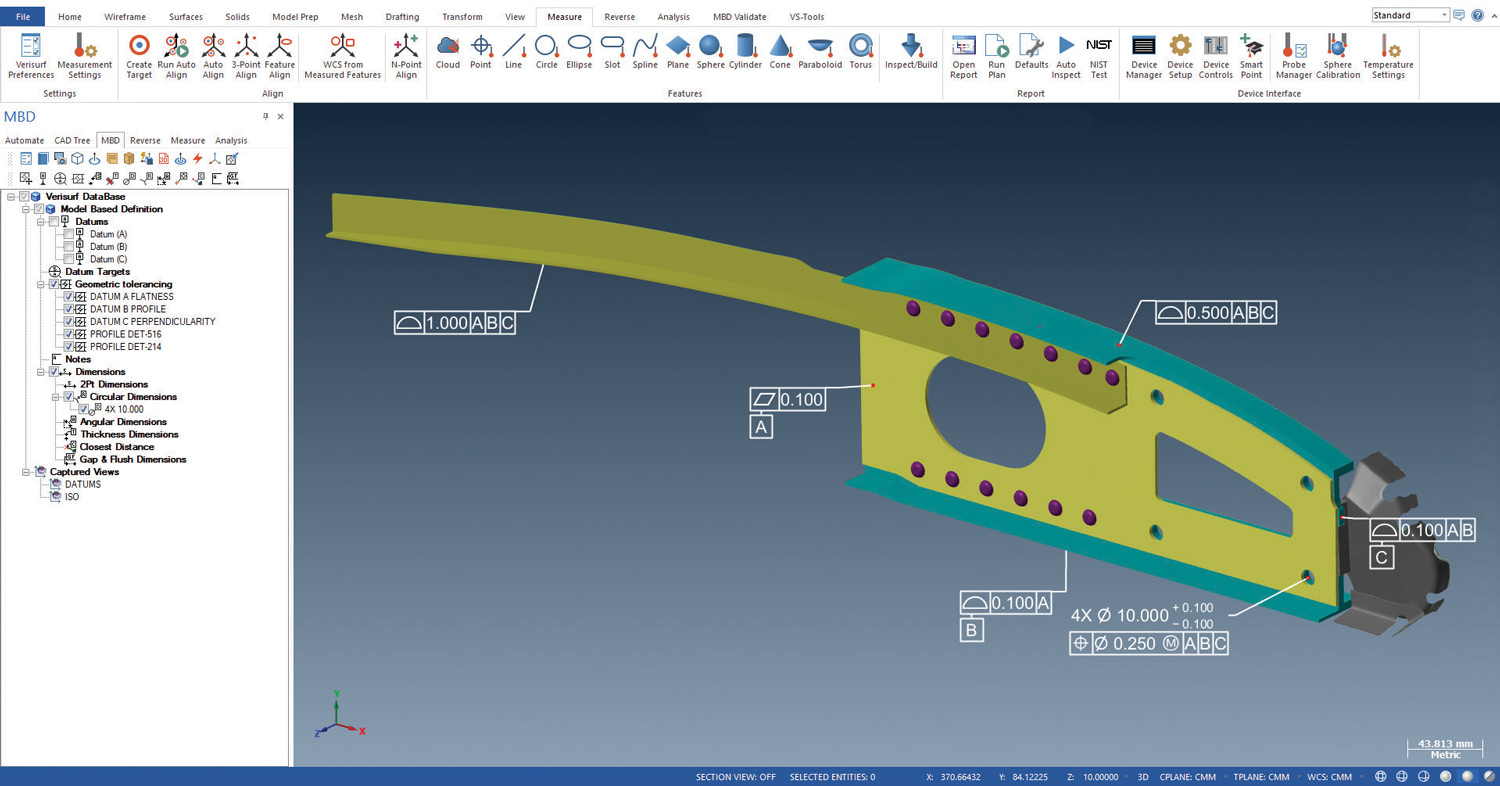

Verisurf uses Model-Based Definition (MBD) with CAD as the design authority to simplify and automate inspection planning for improved process control. MBD underpins Geometric Dimensioning and Tolerancing (GD&T). Engineers use the system to communicate design concepts using drawings and computer-generated 3D models. GD&T definitions are applied to part features and attributes. Quality, source and receiving inspectors can verify finished parts to design requirements in minutes.

“This process used to take hours,” says Merrell. “That’s just not practical [anymore], especially if 100 percent inspection is required. Adoption of automated quality inspection and reporting in job shops and contract manufacturers is growing. Our model-based platform with intelligent GD&T definitions also digitally connects inspection. There are considerable downstream advantages, including First Article Inspection and Statistical Process Control to proactively catch parts trending out of tolerance, before they become scrap,” he adds.

We’re seeing more and more applications where a turnkey system is the best solution.

We’re seeing more and more applications where a turnkey system is the best solution.

“We’re in a crisis,” says Skulan. “Fewer people are graduating and stepping into manufacturing jobs.Lack of human resources has helped accelerate a huge movement towards automation.”

“Automation is here to stay,” Gearding agrees. “More customers are looking at automating their measurement processes.”

The World Robotics 2021 Industrial Robots report revealed that there are approximately 310,700 industrial robots operating in U.S. factories. “Robots can replace manual tasks by providing the arms and hands for a process,” Skulan says. “What they can’t do is the thinking. They have to be taught. You do that with metrology. With a PH20 or REVO-2, a CMM like the HB or Summit acts as the brain for the robot. A robot can replicate mechanical motions. The eyes, ears and touch can’t be reproduced. That’s where a CMM with REVO-2 comes in.”

Any form of automation from a robot or conveyor system to an overhead gantry can be used with the HB and Summit. A robot tending a machine tool, for example, can place a part on a 5-axis CMM stationed next to it for inspection and measurement, then pick the part back up and send it to the next operation. While an HB fitted with a PH20 can be moved next to a machine or at any point in the manufacturing line, the Summit can also support an automated cell next to a stamping press or press brake with the proper isolation pads.

When it comes to automating inspection and measurement operations, Verisurf AUTOMATE creates and executes automated inspection plans and generates reports, among other tasks. The Verisurf Device Interface allows operators to connect and control virtually all metrology devices throughout a manufacturing facility.

“We have a huge presence in a lot of fabrication shops,” says Merrell. “When you buy a CMM like the HB or Summit and marry it with our software, you have a solution that is plug and play. You have a tool that does the job of many.”

Increasing part complexity and demand for 100 percent inspection make collecting actionable, accurate information crucial.

“MSI has more than 100 years of combined experience in the measurement and inspection industry,” says Gearding. “Adding that tribal knowledge to our in-house team allows us to ramp up customer support for our CMMs as well as Sheffield machines and other brands.”

“Unless a shop is brand new, they are going to have legacy equipment,” says Merrell. “Our software works with all CAD files and all CMMs.”

It’s about bringing the components together that will satisfy the customer.

It’s about bringing the components together that will satisfy the customer.

Renishaw takes a balanced approach to customer needs. “We make tactile probes and those that are non-contact,” says Skulan. “We advise customers to consider their application. If an operator needs a probe impervious to fluid on a part or light reflection, tactile is the right option. If a job demands a huge amount of data in a short amount of time, a non-contact probe is best. The REVO-2 has both so you aren’t held hostage by one or the other.”

Delph and Gearding attribute AIMS’ evolution to the partnerships it has formed with Renishaw, and Verisurf. “Multisensor inspection requirements will continue to grow in order to adapt to ongoing product changes,” says Gearding. “Because of these relationships, we are one of the few OEMs that can provide a true shop floor turnkey package along with the service and support.