Laser Technology

By Lauren Duensing, contributing editor

Budget-friendly, high-performance laser encourages fabricator’s creativity

n 1992, author, inventor and futurist Raymond Kurzweil published “The Age of Intelligent Machines,” which discussed the roots of artificial intelligence and predicted 21st-century machines with superior intelligence and prodigious speed and memory. The same year, a laser-cutting machine was manufactured, a piece of equipment Enginaire Clean Air Systems would later acquire and use for 11 years.

“Since 1972, we have been a manufacturer of proprietary air filtration products used in heavy-duty, extremely dusty applications,” says Enginaire President Bill Decker. “We are also a complete metal fabricator working in mild steel, aluminum and stainless steel. We make sanitary fabrications for the dairy and food processing industries.”

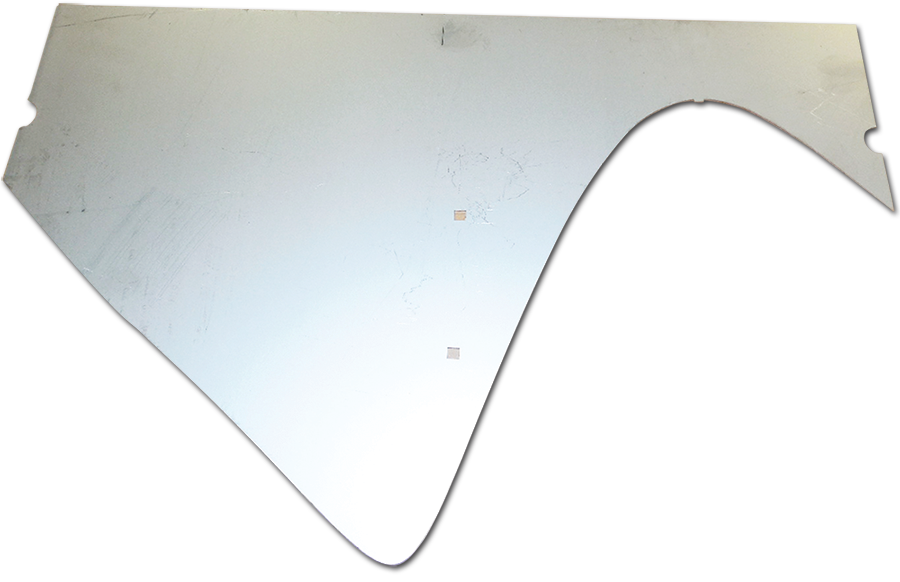

The Fibermak Hawk features manual clamps for the plate, manual adjustable focus lens and precise height control.

Lasers have allowed us to make difficult parts with great precision.

Lasers have allowed us to make difficult parts with great precision.

Comparing the Fibermak Hawk to Enginaire’s previous laser is similar to comparing an iPhone to a first-generation music player. “It has a large capacity and is much faster speed than our first laser that we purchased used from Mac-Tech in 2010,” says Decker, who was familiar with Ermaksan machines, having acquired a press brake in 2018. He says the Fibermak Hawk handles three times as much capacity and is about four times faster than the old laser.

According to Mac-Tech, “Fiber laser cutters are highly efficient. You may get more speed with a laser cutter above 2,000 watts, and a higher-powered machine can slice through thicker materials, but with higher wattage comes higher costs. Most shops can do well with 2,000 watts or less, depending on the materials worked on, saving money while still getting the performance required from the machine.”

“The Ermaksan laser has been operator friendly, and it has been easy for our operators to transition from the old laser to the new,” says Decker. “Mac-Tech did a good job of training our people.”

After installation, the Fibermak Hawk’s main job was to cut impellers for Enginaire’s air pre-cleaners. That’s still the bulk of its work, but the company has found that the laser’s capabilities allow it to design and manufacturer components that it couldn’t do before, such as double tangent filter body components.

“Our future looks bright,” Decker concludes. “We are continually growing our customer base largely due to our forward-looking ideas and state-of-the-art products.”