DECODING DATA

5-axis metrology instantly unlocks intelligence on parts, processes, automates inspection and bridges labor gap

DECODING DATA

5-axis metrology instantly unlocks intelligence on parts, processes, automates inspection and bridges labor gap

Features

/customfabricator

/sawing

/laser

From the Editor

n March, Deloitte and The Manufacturing Institute released the results of two surveys gauging perceptions of U.S. manufacturing. The surveys targeted both executives and consumers. Attracting and retaining a quality workforce was at the top of the list for 83 percent of manufacturers surveyed. Almost 45 percent of executives said they turned down business opportunities due to a lack of workers.

A nationwide survey conducted by Leading2Lean found that 49 percent of millennials did not believe that manufacturing could offer fulfilling careers. The survey summarized the need to continue to reach young people through schools, universities, websites, scholarships and social media. But there is still work to do when it comes to exposing and educating individuals about modern fabrication shops and smart factories.

t can be easy to forget the importance of a strong domestic manufacturing base. These businesses, especially small to medium manufacturers that make up the bulk of local industry, rarely have a chance to be seen by the public in a positive light. When the public forgets the value of an industry, local and federal government focus their attention elsewhere.

he Harris Products Group, a Lincoln Electric company, designs, develops and manufactures cutting, brazing, welding and soldering equipment, consumables and gas distribution systems. Greg Doria, president, talks with FFJournal about the importance of providing customers with the expertise and support they need to stay safe and get the job done.

Green economy

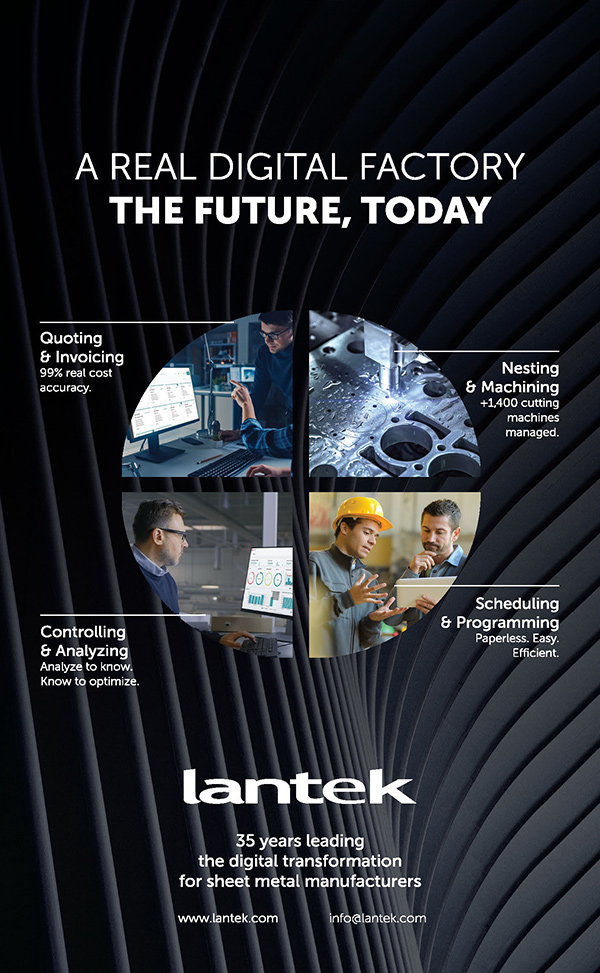

laus Schwab, founder and executive chairman of the World Economic Forum, coined the phrase the Fourth Industrial Revolution in 2015. That same year North American metalworkers and fabricators were introduced to Industry 4.0. Schwab said, “we are at the beginning of a revolution that is fundamentally changing the way we live, work and relate to one another.” He believed this fusion of physical, digital and biological spaces would impact all disciplines, economies and industries. And in many ways it has, from the rise of artificial intelligence, robotics and 3D printing to quantum computing.

Mining data from smart sensors, cloud computing and the interconnected Industrial Internet of Things (IIoT) platform have become the norm for many manufacturers. Statistics show that more than 70 percent of the world’s gross domestic product will go through some form of digitalization in 2022. By 2023, investment in Direct Digital Transformation (DXT) will total $6.8 trillion. Cloud data storage worldwide is expected to reach 200-plus zettabytes by 2025.

laus Schwab, founder and executive chairman of the World Economic Forum, coined the phrase the Fourth Industrial Revolution in 2015. That same year North American metalworkers and fabricators were introduced to Industry 4.0. Schwab said, “we are at the beginning of a revolution that is fundamentally changing the way we live, work and relate to one another.” He believed this fusion of physical, digital and biological spaces would impact all disciplines, economies and industries. And in many ways it has, from the rise of artificial intelligence, robotics and 3D printing to quantum computing.

Mining data from smart sensors, cloud computing and the interconnected Industrial Internet of Things (IIoT) platform have become the norm for many manufacturers. Statistics show that more than 70 percent of the world’s gross domestic product will go through some form of digitalization in 2022. By 2023, investment in Direct Digital Transformation (DXT) will total $6.8 trillion. Cloud data storage worldwide is expected to reach 200-plus zettabytes by 2025.

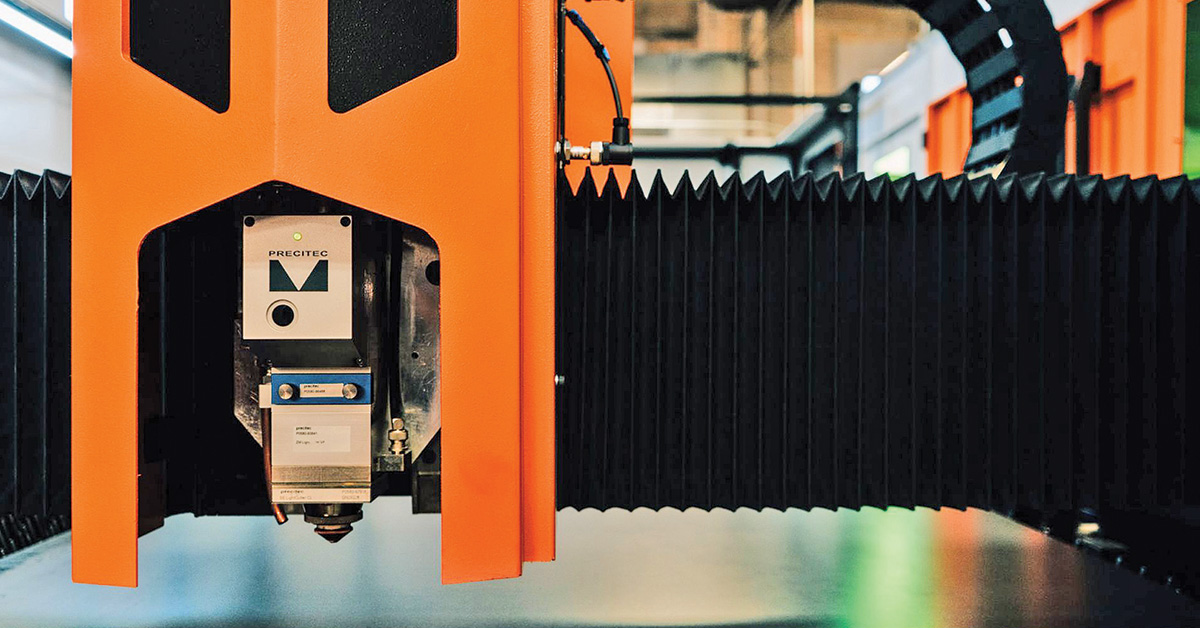

Laser Technology

By Lauren Duensing, contributing editor

Budget-friendly, high-performance laser encourages fabricator’s creativity

n 1992, author, inventor and futurist Raymond Kurzweil published “The Age of Intelligent Machines,” which discussed the roots of artificial intelligence and predicted 21st-century machines with superior intelligence and prodigious speed and memory. The same year, a laser-cutting machine was manufactured, a piece of equipment Enginaire Clean Air Systems would later acquire and use for 11 years.

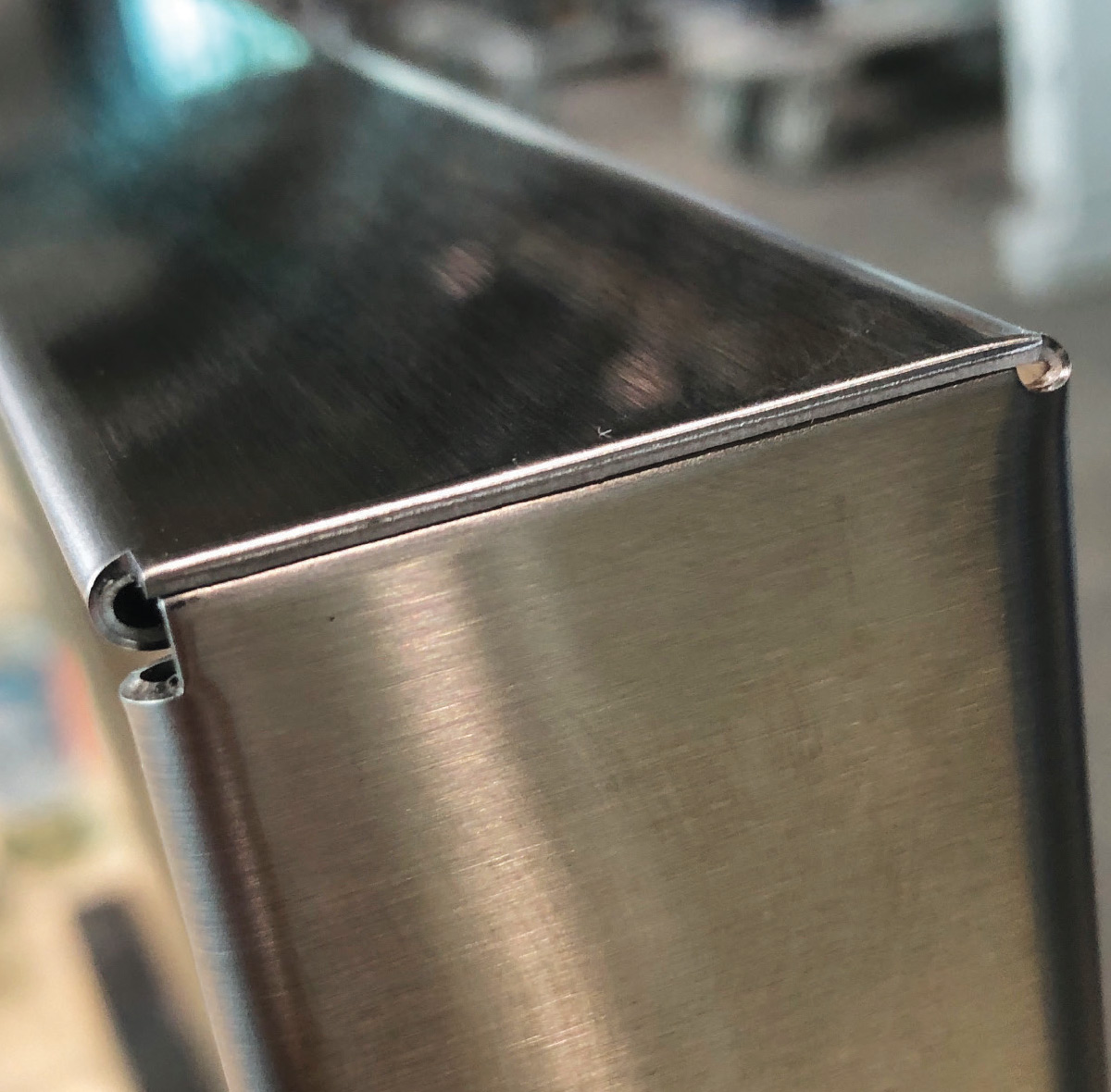

“Since 1972, we have been a manufacturer of proprietary air filtration products used in heavy-duty, extremely dusty applications,” says Enginaire President Bill Decker. “We are also a complete metal fabricator working in mild steel, aluminum and stainless steel. We make sanitary fabrications for the dairy and food processing industries.”

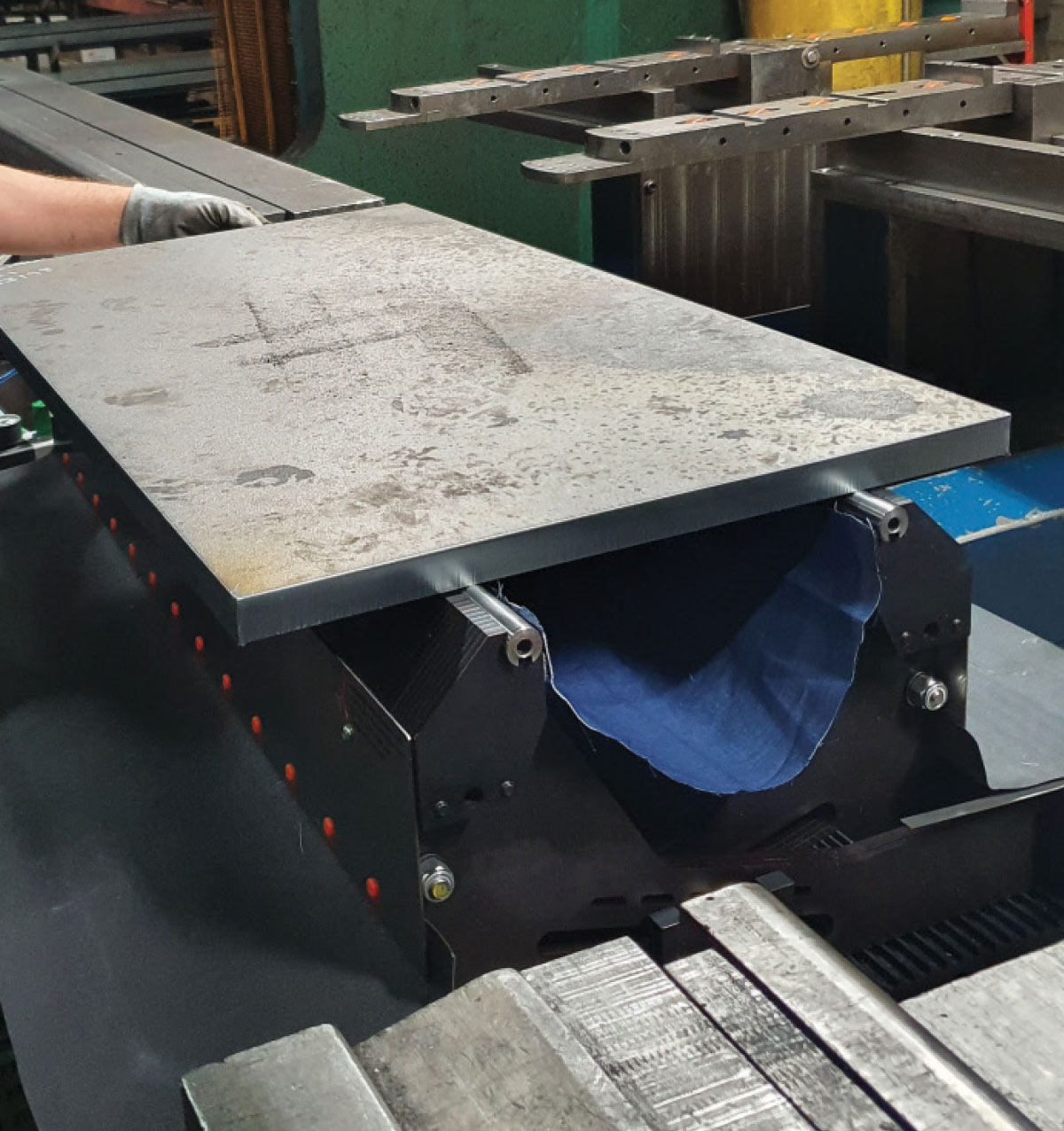

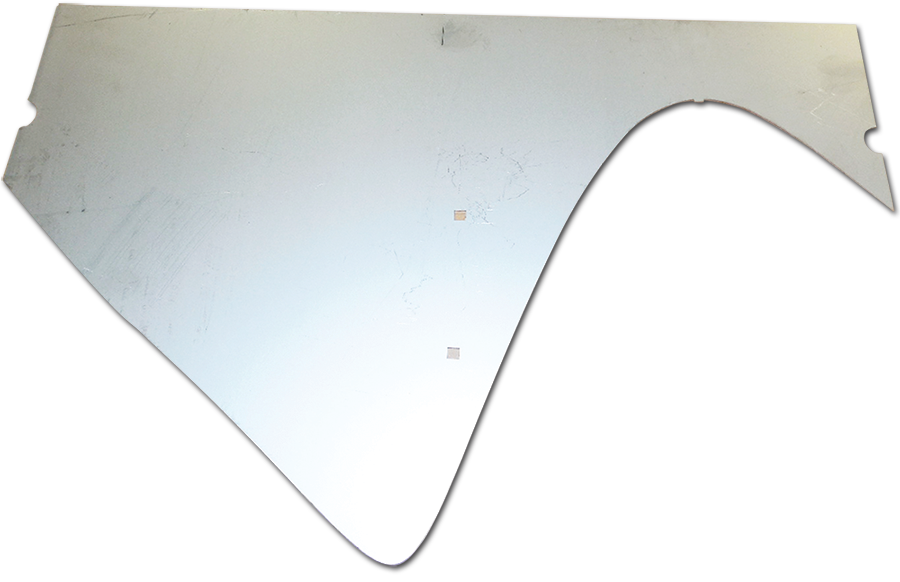

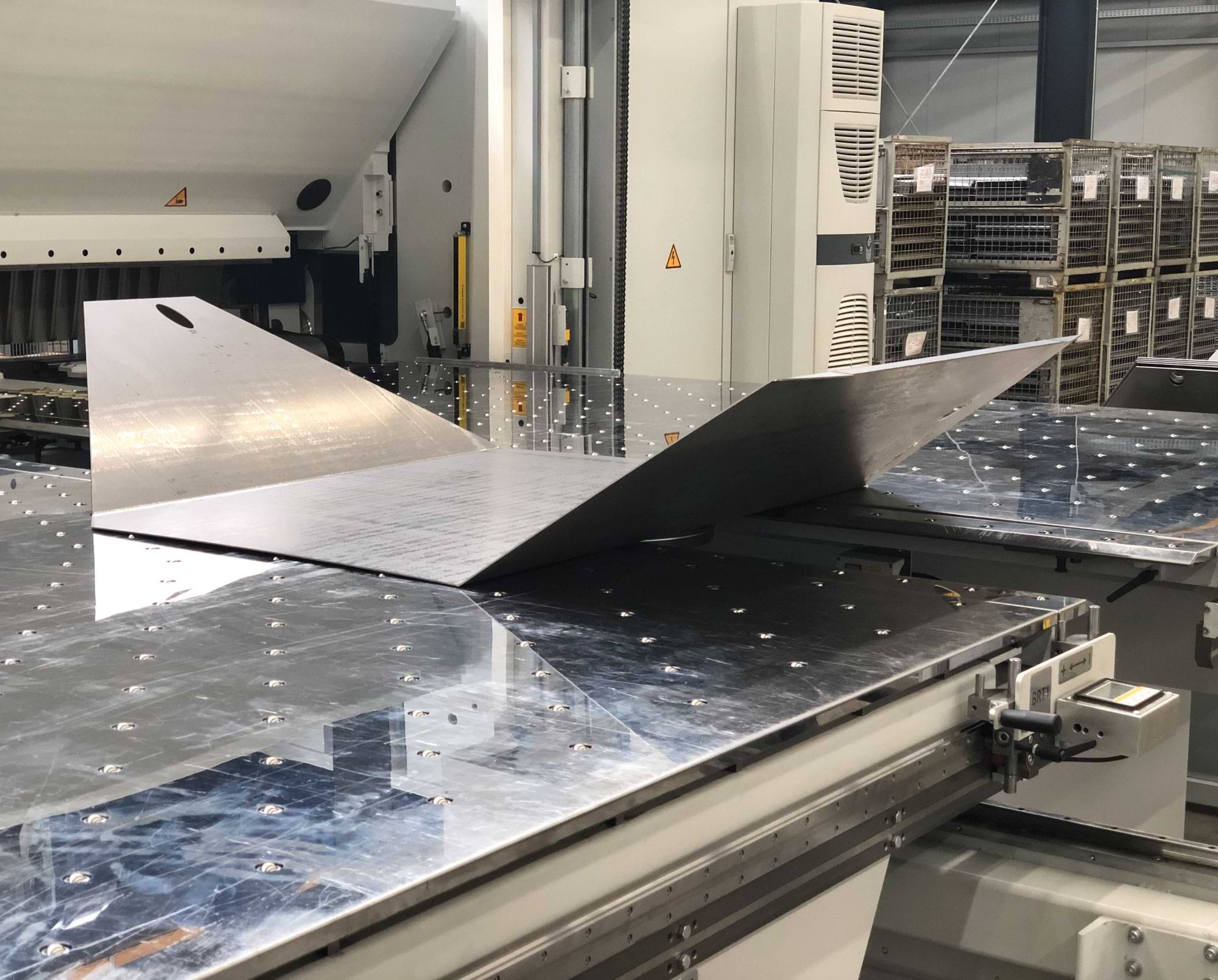

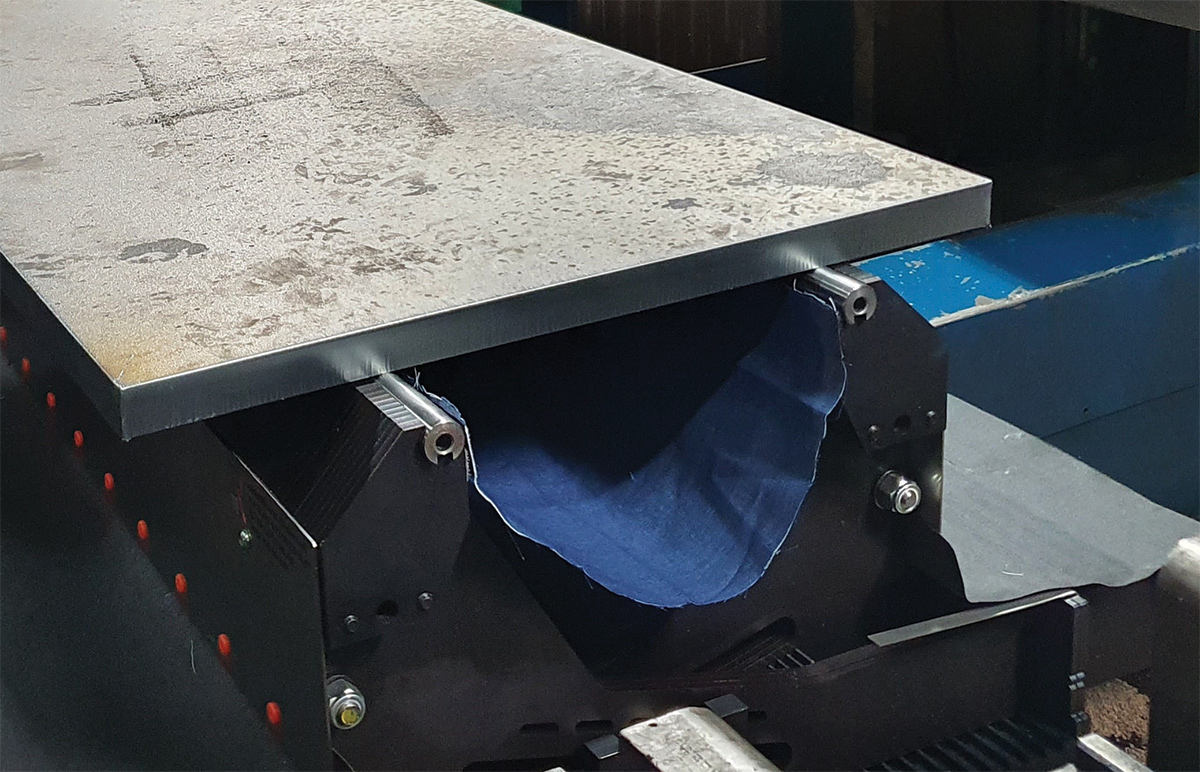

Once large volumes of blanks move downstream to forming operations, labor costs can become difficult to recoup.

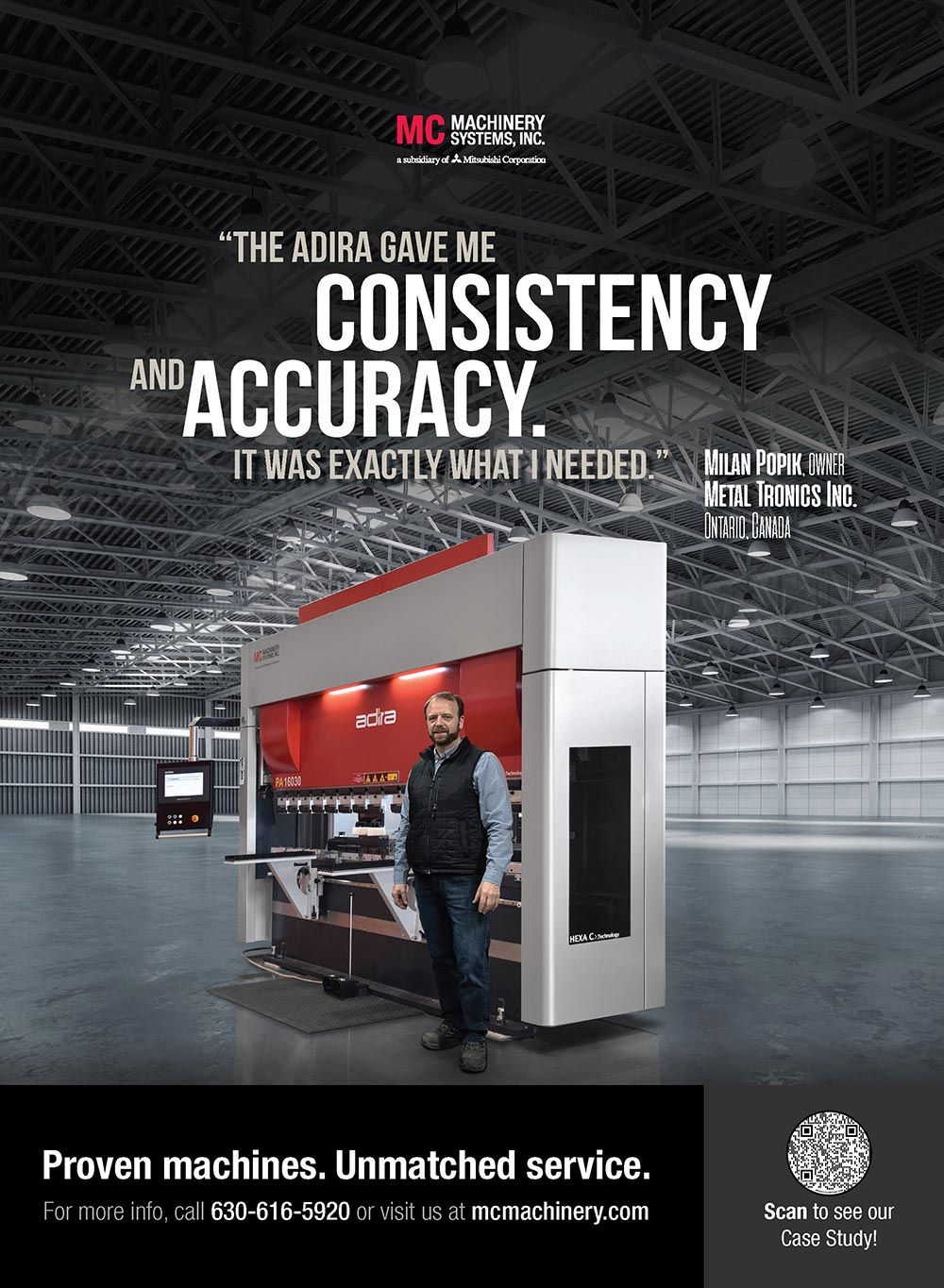

upply chain disruptions, soaring raw material prices, transportation bottlenecks and war in Ukraine continue to make headlines. Making matters worse for fabricators is the massive labor shortage while manufacturing booms. By 2030, an estimated 2.1 million manufacturing jobs will remain unfilled, costing the U.S. economy up to $1 trillion. Retirements are outpacing replacements. Entry-level positions remain unfilled, and mid-level positions are left vacant as required skills become harder to find.

brasion resistant (AR) steel plate is harder and tougher than high-strength structural plate and lasts four times longer. Tough yet formable, AR has primarily made its mark in mining and construction equipment. Growing demand to lightweight parts for mobile machinery-related applications has fabricators embracing the high-carbon alloy over more traditional choices such as other high-strength steels and aluminum.

An engineer uses SigmaNEST to nest CAD-drawn parts in groups for easy removal and drag and drop to the right cutting machine.

acrificing one thing to get more of something else is what economists call a trade-off. When it comes to nesting parts, job shops also struggle with trade-offs. Often, the advantage of nesting as many parts together as possible is outweighed by the need for organization. Operators find they must restrict nesting software in order to bundle and easily locate similar parts.

earning through inquiry-based projects enables high school students at Science Leadership Academy (SLA) at City Center in Philadelphia to dig deep into the subject matter, says John Kamal, an engineering teacher at the school.

For example, instead of providing students the equation for how a pendulum moves, they create a pendulum, collect data, hypothesize about possible formulas that describe how a pendulum moves, debate the formulas and jointly reach a conclusion. “That’s how they learn the formula,” Kamal says. “That way, we believe students can understand the underlying principles of critical thinking and how science works.”

Fabricating projects in the engineering program’s shop helps prepare students for not only continuing their education after high school and, more importantly, for life. Kamal notes that students who are accepted into his program spend more than 1,000 hours studying engineering, including a lot of fabrication in class and as part of the after-school robotics club.

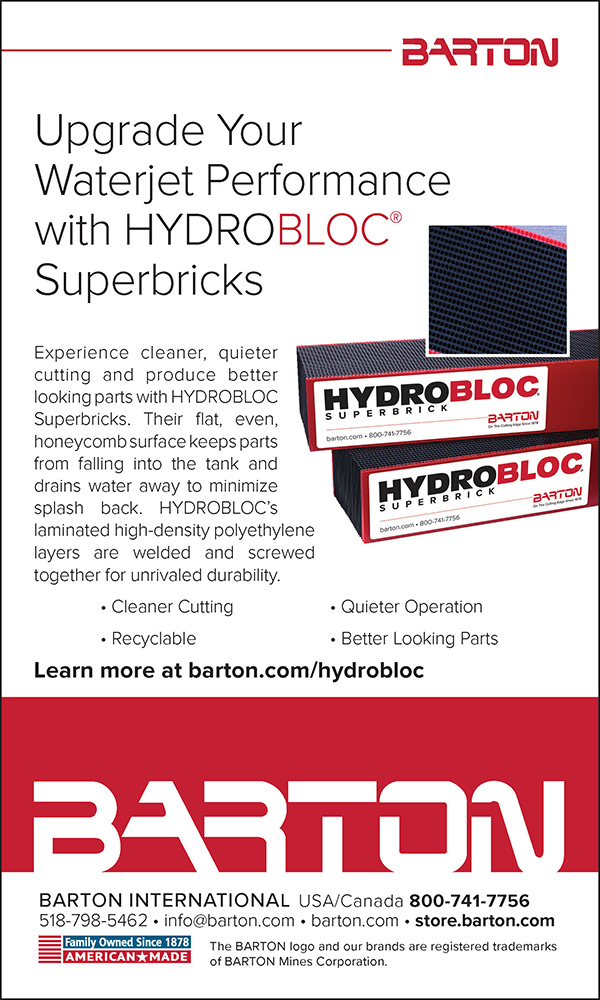

A capital grant presented the engineering program with the opportunity to add to the shop’s equipment list, so Kamal says the school decided to use the money to purchase an abrasive waterjet cutting machine. A waterjet’s capability would enable the shop to cut complex shapes in steel, such as for a protective plate for a robot, rather than outsourcing it to a machine shop with a waterjet.

Below: ProtoMAX waterjet machines being produced at Omax’s facility in Kent, Washington.

Amada Machinery America Inc., Brea, California, 847/285-4800, amadamca.com.

The Iranian-American Farhang Foundation, which is nonreligious, nonpolitical and not for profit, chose British engineer and artist Cecil Balmond to create a sculpture that symbolizes religious freedom, cultural diversity and inclusiveness. The Freedom Sculpture he designed is a waterjet-cut, powder-coated stainless steel monument modeled on the Cyrus Cylinder of ancient Persia, an early declaration of human rights written on a clay vessel in 539 B.C. The shapes in Balmond’s sculpture appear to be moving lines of script. Balmond intended the work to be viewed by speeding traffic, so it gives an illusion of movement from all angles while also serving as a contemporary metaphor for the universal message of the Cyrus Cylinder traveling through time and space. During the day, the sculpture sparkles with natural sunlight, and at night, the gilt interior is artificially illuminated. The Freedom Sculpture was installed in 2017 in Century City, Los Angeles.

The Iranian-American Farhang Foundation, which is nonreligious, nonpolitical and not for profit, chose British engineer and artist Cecil Balmond to create a sculpture that symbolizes religious freedom, cultural diversity and inclusiveness. The Freedom Sculpture he designed is a waterjet-cut, powder-coated stainless steel monument modeled on the Cyrus Cylinder of ancient Persia, an early declaration of human rights written on a clay vessel in 539 B.C. The shapes in Balmond’s sculpture appear to be moving lines of script. Balmond intended the work to be viewed by speeding traffic, so it gives an illusion of movement from all angles while also serving as a contemporary metaphor for the universal message of the Cyrus Cylinder traveling through time and space. During the day, the sculpture sparkles with natural sunlight, and at night, the gilt interior is artificially illuminated. The Freedom Sculpture was installed in 2017 in Century City, Los Angeles.

Editor-in-Chief

Michael D’Alexander

Lynn Stanley

J. Neiland Pennington

Lauren Duensing

Alan Richter

123 W. Madison St., Suite 950, Chicago, IL 60602

312/654-2300, Fax: 312/654-2323

www.ffjournal.net

Carlotta Lacy

Matthew LaFleur

Mark Koenig

Michael D’Alexander

Jim D’Alexander

Wayne Krusen

Traci Fonville

Bill D’Alexander

312/654-2309, Fax: 312/654-2323

mdalexander@ffjournal.net

Alaska, Arizona, Arkansas, California, Colorado, Hawaii, Idaho, Montana, New Mexico, North Dakota, Oklahoma, Texas, Wyoming

Jim D’Alexander, Vice President

770/862-0815, Fax: 312/654-2323

jdalexander@ffjournal.net

Alabama, Florida, Georgia, Louisiana, Minnesota, Mississippi, W. New York, North Carolina, Pennsylvania, South Carolina,

South Dakota, Tennessee

Bill D’Alexander, Principal/Sales Manager

203/438-4174, Fax: 203/438-4948

bdalexander@ffjournal.net

Connecticut, Delaware, Kentucky, Maine, Maryland, Massachusetts, Missouri, Nevada, New Hampshire, New Jersey, E. New York, Ohio, Oregon, Rhode Island, Utah, Vermont, Virginia, Washington, West Virginia; International

Bob D’Alexander, Principal/Sales Manager

616/916-4348, Fax: 616/942-0798

rdalexander@ffjournal.net

Illinois, Indiana, Iowa, Kansas, Michigan, Nebraska, Wisconsin

Valerie Treiber, National Sales Manager

203/894-5483

valerie@modernmetals.com

Traci Fonville, Classifieds, Logos and Reprints

312/654-2325, Fax: 312/654-2323

tfon@ffjournal.net

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to: Omeda – FFJournal – 4 Overlook Pt., Ste. A25E, Lincolnshire, IL 60069. Printed in the USA.

Periodicals postage paid at Chicago and additional mailing offices. Postmaster: Send address changes to: Omeda – FFJournal – 4 Overlook Pt., Ste. A25E, Lincolnshire, IL 60069. Printed in the USA.