he technology that moves us forward, affording people flexibility amid urgent situations, often makes its first inroads within the laboratory setting. Research continues to advance alloys to lighten the weight of vehicles as well as qualify more intricately printed parts. In metal fabrication, the military has installed its first metal printing solution to aid soldiers located far from the supply chain.

Where you really get the benefit of using additive manufacturing is you’re able to print crazy, organic designs that are both lightweight and structurally robust. You simply couldn’t create the part any other way.

Where you really get the benefit of using additive manufacturing is you’re able to print crazy, organic designs that are both lightweight and structurally robust. You simply couldn’t create the part any other way.

Where you really get the benefit of using additive manufacturing is you’re able to print crazy, organic designs that are both lightweight and structurally robust. You simply couldn’t create the part any other way.

Where you really get the benefit of using additive manufacturing is you’re able to print crazy, organic designs that are both lightweight and structurally robust. You simply couldn’t create the part any other way.

he technology that moves us forward, affording people flexibility amid urgent situations, often makes its first inroads within the laboratory setting. Research continues to advance alloys to lighten the weight of vehicles as well as qualify more intricately printed parts. In metal fabrication, the military has installed its first metal printing solution to aid soldiers located far from the supply chain.

“We develop and transition research to help move the process along and other departments can then focus on sustainment such as replacement parts, reducing long lead times, etc.,” McWilliams says. “We develop the recipe in our labs and hand it off.”

In 2019, McWilliams printed short-term-use empeller fans for M1 Abrams tanks. Since then, researchers are working to implement long-term metal printed solutions in the coming months. “The next group plugs and plays and goes into production mode,” he says.

“We’re figuring out how to achieve the complexity and design while working with new materials, including more affordable high-strength steel alloys,” he says.

Adjusting alloy composition is important for the next stages of additive manufacturing. In the lab and in the field, the Army is printing different compositions of parts, including those that call for greater hardness and toughness—“parts that can withstand the stresses of ballistics requirements,” McWilliams says. “If you look at any ground vehicle, the M1 Abrams, Bradley tanks—each are basically a box manufactured with flat plate. They were designed in the 1960s so we know we can [reduce] weight and increase performance as well as advance the overall vehicles’ designs.”

The printer lets us make anything from a complicated part to a standard screw. What would have taken weeks or months now takes on average a week to complete.

The printer lets us make anything from a complicated part to a standard screw. What would have taken weeks or months now takes on average a week to complete.

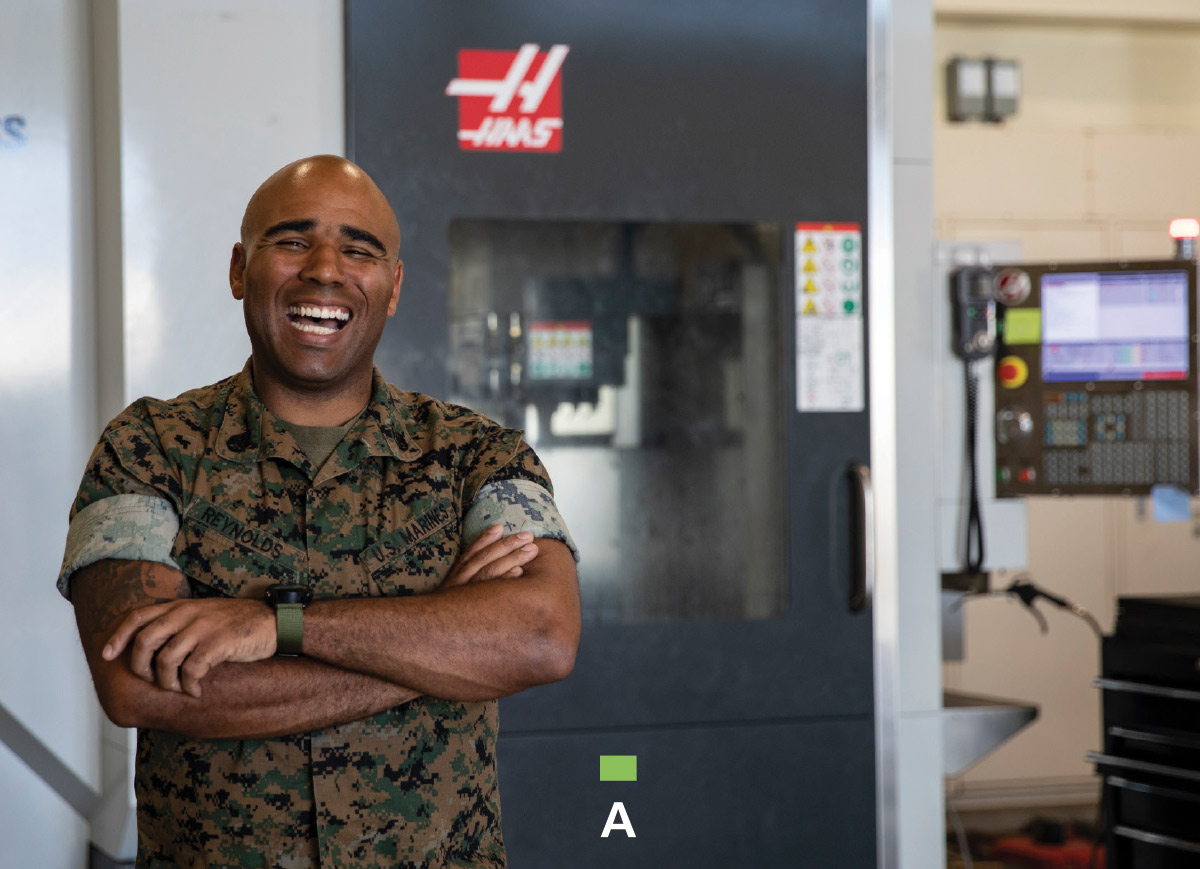

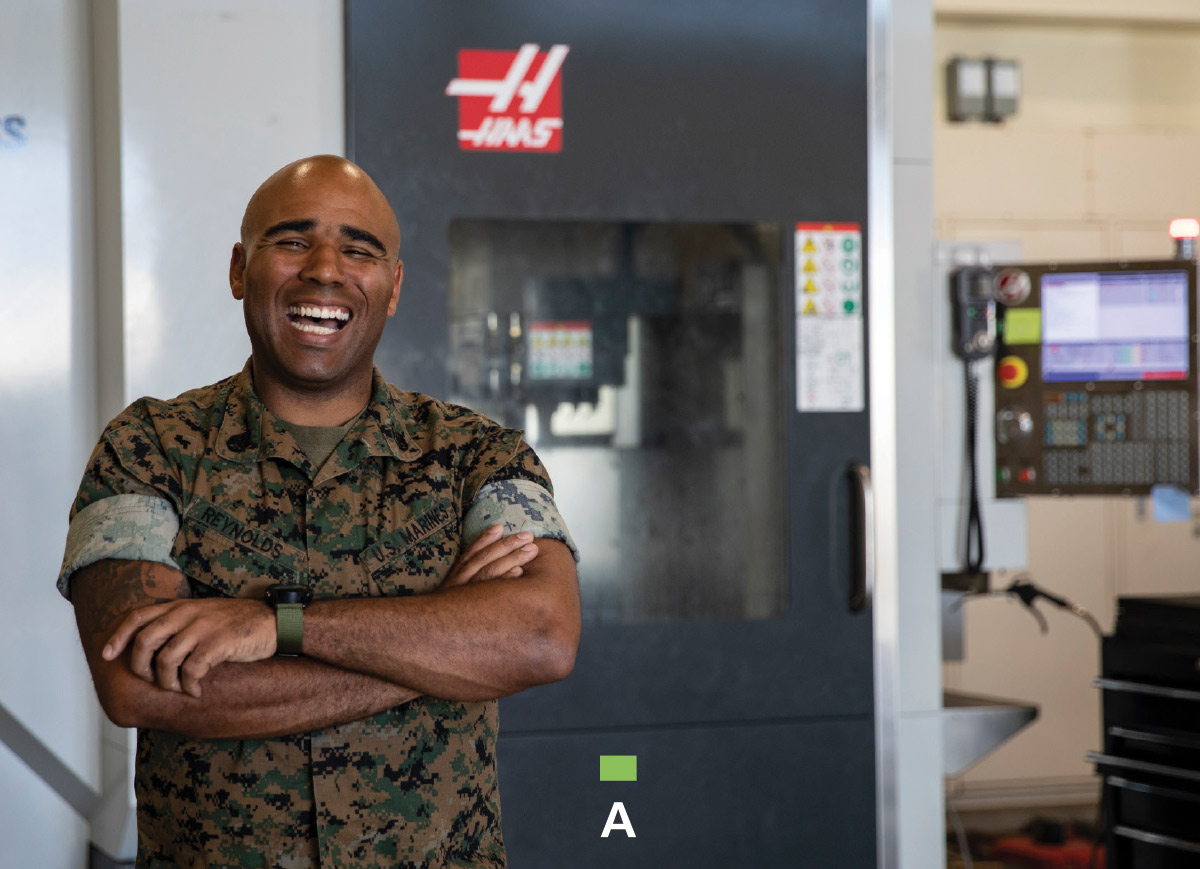

Sgt. Quincy Reynolds

B) Reynolds places a 3D-printed part onto a furnace plate to be transformed into its densest form.

C) A finished part is placed into a Markforged Wash-1, which is used to debind and dry 3D-printed parts.

D) Reynolds and Cpl. Chase Ramsby modify parts using SolidWorks before 3D printing.

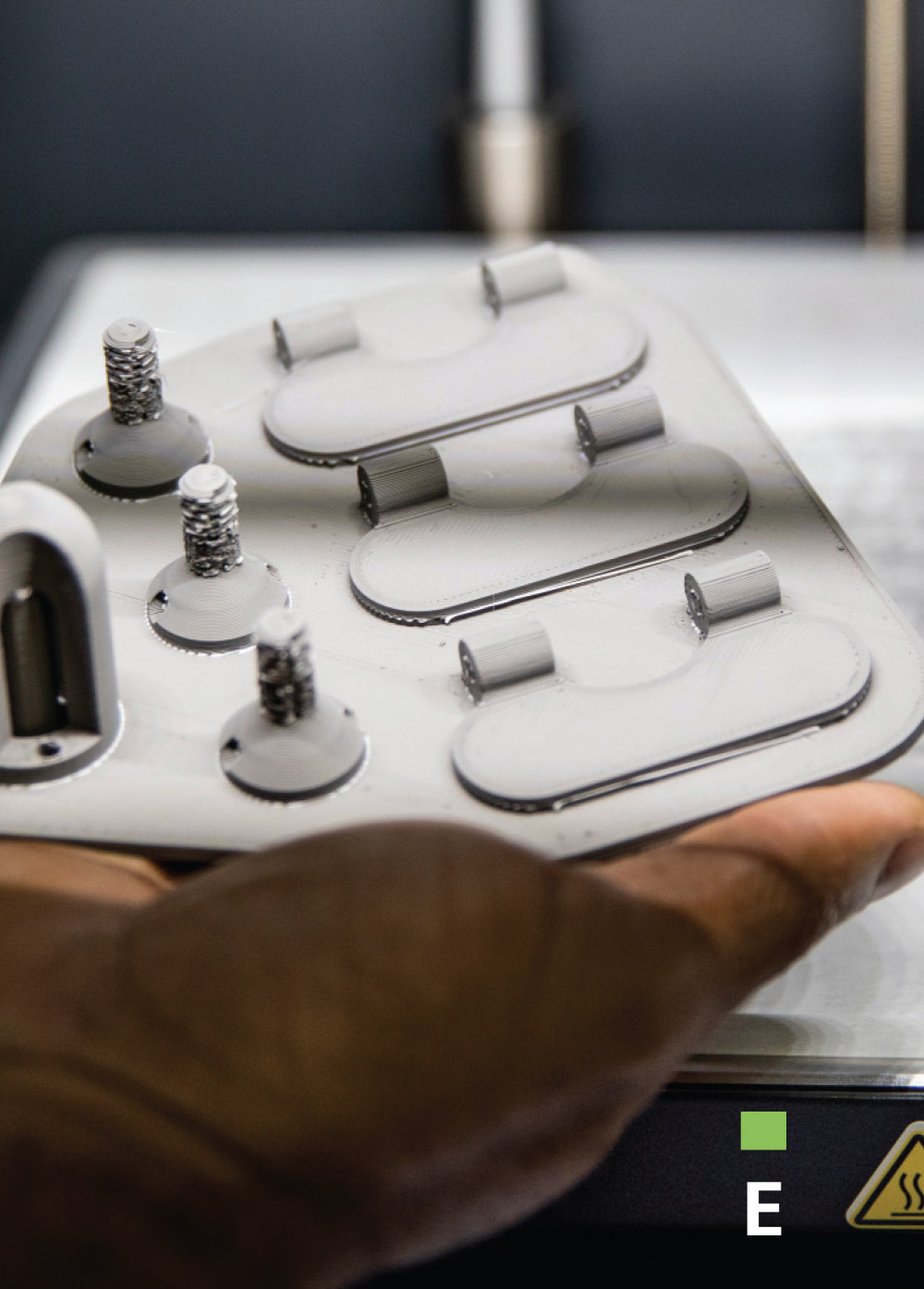

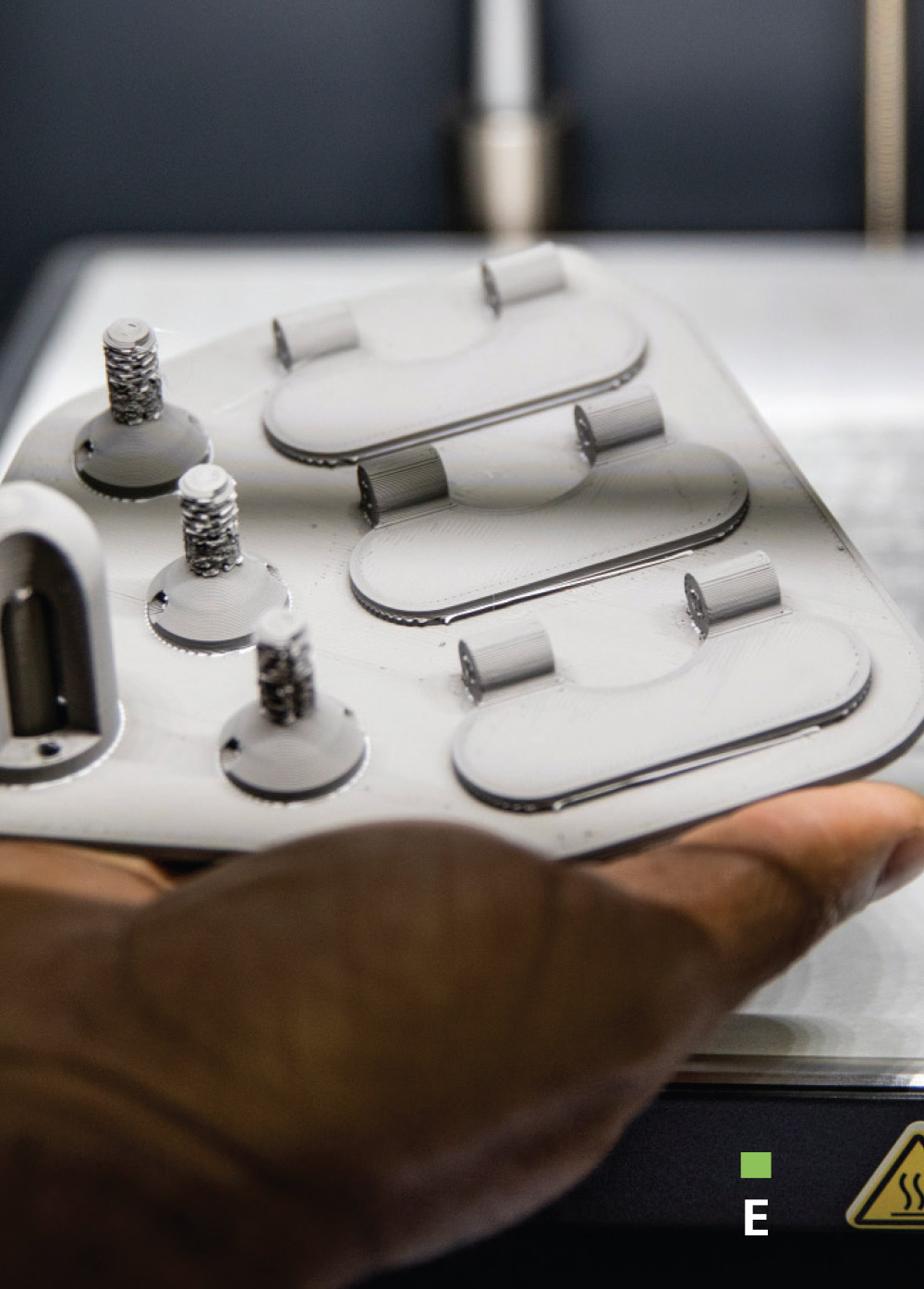

E) After the part has finished printing, it is ready to be washed and dried.

The printer lets us make anything from a complicated part to a standard screw. What would have taken weeks or months now takes on average a week to complete.

The printer lets us make anything from a complicated part to a standard screw. What would have taken weeks or months now takes on average a week to complete.

Sgt. Quincy Reynolds

B) Reynolds places a 3D-printed part onto a furnace plate to be transformed into its densest form.

C) A finished part is placed into a Markforged Wash-1, which is used to debind and dry 3D-printed parts.

D) Reynolds and Cpl. Chase Ramsby modify parts using SolidWorks before 3D printing.

E) After the part has finished printing, it is ready to be washed and dried.

Prior research tended to be more siloed into materials development, but additive “has made this more exciting. We’re tied to applications whereas before, we were more looking at one part of the process and not working together. The speed with which additive is advancing design and materials is amazing.”

Printing with titanium powder is nothing new but adjusting other alloy properties continues to aid in driving down printing costs.

“We’re working to tweak Inconels, high-strength steels, aluminum, magnesium as well as working on how we can adjust titanium to make working with that material more cost effective,” McWilliams says.

Where titanium would not typically be used for parts in a traditional setting due to cost, printing to create an exact part without waste does make sense.

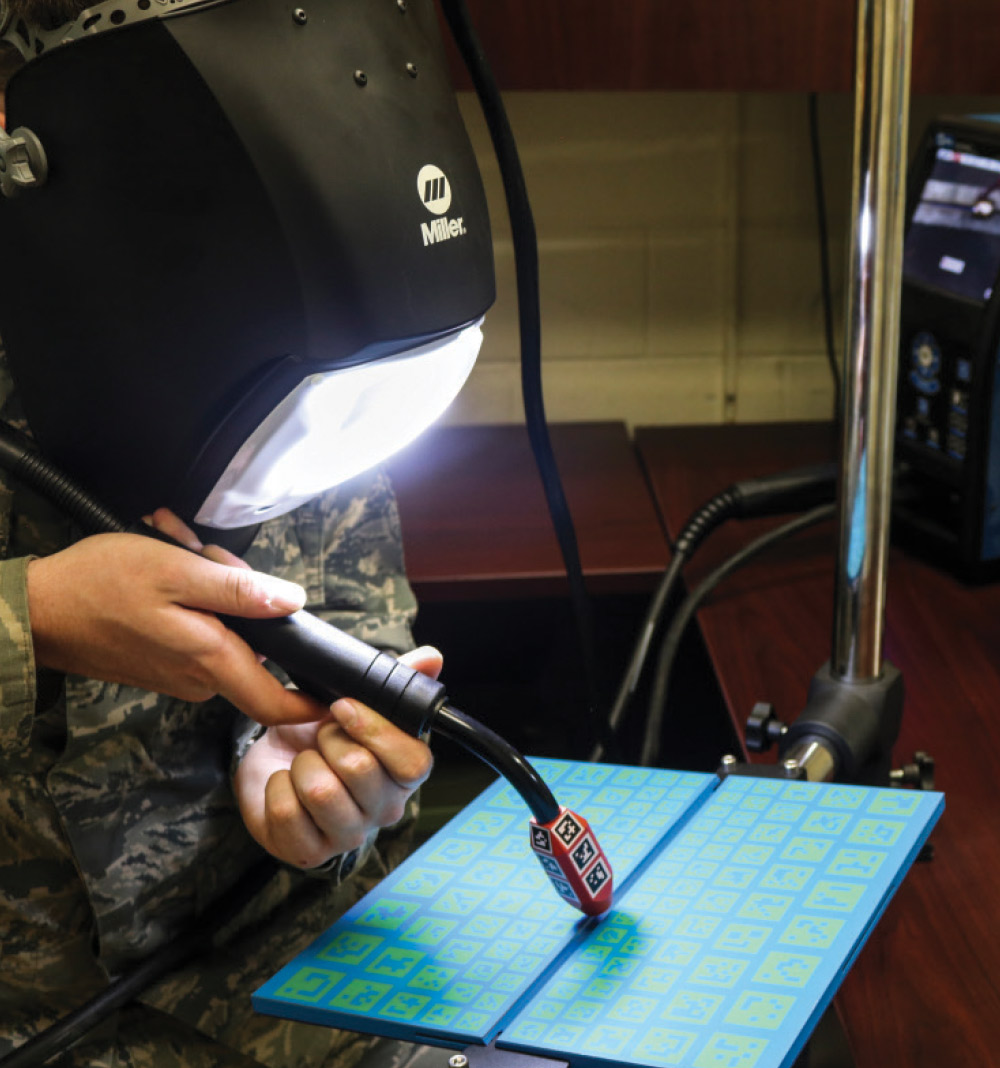

Airman 1st Class Taylor Dow uses augmented reality system to train on welding a groove well at Dyess Air Force Base, Texas. The augmented reality system is split into three training operations for welding: metal inert gas, tungsten inert gas and arc welding. Photos: Staff Sgt. David Owsianka

“It will typically take someone 200 to 300 welds to become proficient for aircraft quality welds so getting the basics down using this technology saves us a lot of resources,” Kirchner says.

Training experienced welders may prove more difficult than new recruits. “Welding is a very personal thing—you have your own technique so it takes us a little more time to get used to virtual guidance indicators,” he continues.

Welders are responsible for supportive equipment repairs using MIG welding. Inspection differs depending on where the part is used.

“For aircraft parts, we have to verify multiple components from structural criteria by using X-rays; and we are limited to one inclusion that is five times the thickness of one strand of human hair,” Kirchner says.

When aircraft parts are certified, “they have to be textbook perfect,” he says. “And because we’re always shooting for perfect, making mistakes via augmented reality is helpful because it tells you [where the mistake occurred] without going through thousands of physical pieces of steel sheet. We decreased the amount of steel used by 75 percent.”

Welders typically weld stainless steel but are also using aluminum, titanium and exotic alloys.” This compares with the past, “when we used [carbon] steel and magnesium,” Kirchner says.

Technology goes beyond augmented reality as the Air Force prepares to use handheld scanners that will allow for 3D scanning.

“Any part brought in that we need to reverse engineer will be much easier because instead of manually drawing up calculations, the scanner will take a read,” Kirchner says. “For more advanced brackets, using this tool could eliminate 70 to 80 hours worth of programming.”

Actual alloy characteristics hold the key to accelerating materials development, says McWilliams. “We’re working with alloy grades that are 70 years old,” he says. Alloy development and design involve computational work. New design processes are limited as long as the alloys remain static. “As they currently exist, these alloys aren’t optimized for this process.” Researchers must use digital design tools to develop future additive applications and, eventually, “we’ll be light years ahead of where we started.”

Within the metal fabrication department, U.S. Marine Corps Staff Sgt. Quincy Reynolds at Camp Kinser uses the Marines’ first Metal X 3D printer to print parts otherwise difficult to procure. The flexibility to print on premise is invaluable as the 66-mile-long island relies on supplies from the mainland. About 26,000 U.S. military personnel inhabit the island, spread among 32 bases and 48 training sites.

“Here in Okinawa, there can be a logistics hassle when ordering certain parts with lead times up to six months,” Reynolds says. “The printer lets us make anything from a complicated part to a standard screw.”

Marines use SolidWorks software to design test parts in plastic before printing them using metal. “Once we’re sure the part is the right dimensions, we launch it into the Metal X printer so the Marine can then step away and work on something else,” Reynolds says. “Conventional ways would require having an operator or machinist present, working through each step, but with the printer you hit print, wait for the base layer, and that’s it. You don’t have to stand in front of it and watch it.”

Marines learn CAD/CAM SolidWorks software in order to reverse engineer parts. “With this basic understanding, there is very little learning curve because it’s similar to subtractive manufacturing,” Reynolds explains.

Eiger 3D printing software removes much of the manual calculating a fabricator would otherwise be required to perform. “Once we put the file into the Eiger slicing program, it converts the file to a thumb drive and the Marine puts the drive into the metal printer,” Reynolds explains.

Photo: Lance Cpl. Armando Elizalde, 3rd Marine Logistics Group

New filaments, including copper, continue to open up ways additive manufacturing can be used to print cooling fans for logistics tools, or “anything, really,” Reynolds adds. “The future using 3D printing is unlimited. We can go anywhere from here but we’re still figuring it out with every new request that comes in.”